Ideamaker with Idex

-

Hello everyone, I have a problem with dual printing with Ideamaker. When I print with both extruders, it doesn’t return to my 3mm safety distance after the first tool change, and prints in the air. With Simplify 3d it works perfectly. Does anyone have an idea?

; tpost0.g ; called after tool 0 has been selected ; ; generated by RepRapFirmware Configuration Tool v3.3.14 on Wed Nov 16 2022 15:37:20 GMT+0100 (Mitteleuropäische Normalzeit) ; Wait for set temperatures to be reached M703 M116 P0 M106 R2 ; restore print cooling fan speed M116 P0 ; wait for tool 0 heaters to reach operating temperature M83 G1 E0.8 F3600 ; extrude 2mm; tpost1.g ; called after tool 1 has been selected ; ; generated by RepRapFirmware Configuration Tool v3.3.14 on Wed Nov 16 2022 15:37:20 GMT+0100 (Mitteleuropäische Normalzeit) ; Wait for set temperatures to be reached M703 M116 P1 M106 R2 ; restore print cooling fan speed M116 P1 ; wait for tool 1 heaters to reach operating temperature M83 G1 E0.8 F3600 ; extrude 2mm; tfree0.g ; called when tool 0 is freed ; ; generated by RepRapFirmware Configuration Tool v3.3.14 on Wed Nov 16 2022 15:37:20 GMT+0100 (Mitteleuropäische Normalzeit) M83 ; relative extruder movement G1 E-0.5 F3600 ; retract 2mm M106 S0 ; turn off our print cooling fan G91 ; relative axis movement G1 Z3 F500 ; up 3mm G90 ; absolute axis movement G1 X-400 F3600 ; park the X carriage at -48mm; tfree1.g ; called when tool 1 is freed ; ; generated by RepRapFirmware Configuration Tool v3.3.14 on Wed Nov 16 2022 15:37:20 GMT+0100 (Mitteleuropäische Normalzeit) M83 ; relative extruder movement G1 E-0.5 F3600 ; retract 2mm M106 S0 ; turn off our print cooling fan G91 ; relative axis movement G1 Z3 F500 ; up 3mm G90 ; absolute axis movement G1 U400 F6000 ; park the U carriage at +355mm -

@Proschi78 Can you post an example print file for both slicers?

I'm thinking you may need to restore the Z position after each tool change. See the notes for "G1" on the "R" parameter https://docs.duet3d.com/User_manual/Reference/Gcodes#g1-controlled-linear-move

Also, though you shouldn't need to call it out, read through "R2" for G60 https://docs.duet3d.com/User_manual/Reference/Gcodes#g60-save-current-position-to-slot These details are also described in the tool change section of the Gcode dictionary https://docs.duet3d.com/User_manual/Reference/Gcodes#t-select-tool

If another tool is already selected, the current coordinates are saved to memory slot 2 automatically (see G60), run macro tfree#.g where # is the number of that tool.The fix for you would likely to to include

G1 R2 Z0in your t*post files. This will restore the Z position to the location from stored position slot "2" (R2), which is created when your tool change process starts. -

-

@sebkritikel That was indeed the solution. The print has been running without errors so far

-

@Proschi78 Awesome! Let me know if anything else crops up.

-

@Proschi78 To summarize my line of thinking - I've seen other users have this issue, and often in the print files what happens is the new tool is called, but no Z position is specified in the successive moves, until the next layer or next tool change. With no restore point callout in the tool change files, you end up maintaining that 3mm safety move from your tfree file. The "G1 R2 Z0" solves this by restoring to the Z position stored from the start of the tool change.

I just opened your print files, and am a tad bit confused as (at least in the first layer) it appears as both Ideamaker and S3D are handling it correctly. At least in the files your provided, both Ideamaker and S3D provide a Z height a few lines after the tool change, this should move the tool to the correct printing height.

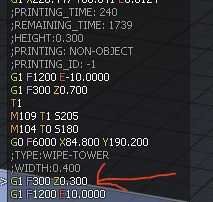

Ideamaker:

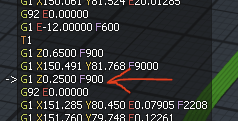

S3D

-

@sebkritikel Thanks for the explanation. S3D seems to be doing it right.