problem mesh bed. Delta printer

-

I got a really big delta printer up and running with a duet 6HC and toolbar 1LC.

everything works fine apart from the mesh bed.

can't get a solid first layer, the Y direction is most of the problem. (See attached pictures)can someone help me?

I'll share the following;

-Config.G

-Bed.G

-Simplify start Gcode and End GcodeConfig.G

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.4.1 on Sun May 05 2024 12:41:38 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Svetlana" ; set printer name M665 R483 L1060 B483 H1468 ;B483 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P20.0 S0 ; physical drive 0.3 goes forwards M584 X0.0 Y0.1 Z0.2 E20.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E409.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X2000 Y2000 Z2000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits ;M208 Z1500 S1 ; set minimum Z ; Endstops M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in M574 Z2 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin io2.in ; Z-Probe M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"20.io0.in" H10 F1000 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z3.5 ; set Z probe trigger value, offset and trigger height M557 R483 S200 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.199 K0.344:0.000 D6.06 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S60 ; set temperature limit for heater 0 to 120C M308 S1 P"20.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"20.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 R1.528 K0.177:0.000 D9.18 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ;RUNOUT SENSOR M591 D0 P2 C"20.io1.in" S1 ;RUNOUT SENSOR ; Fans M950 F0 C"20.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"20.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"hot end" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not definedBed.G

; bed.g ; called to perform automatic delta calibration via G32 ; ; generated by RepRapFirmware Configuration Tool v3.4.1 on Thu May 16 2024 15:48:45 GMT+0200 (Central European Summer Time) M561 ; clear any bed transform ; Probe the bed at 3 peripheral and 3 halfway points, and perform 6-factor auto compensation ; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g. G30 P0 X0 Y439.9 H0 Z-99999 G30 P1 X380.96 Y-219.95 H0 Z-99999 G30 P2 X-380.96 Y-219.95 H0 Z-99999 G30 P3 X0 Y219.9 H0 Z-99999 G30 P4 X190.44 Y-109.95 H0 Z-99999 G30 P5 X-190.44 Y-109.95 H0 Z-99999 G30 P6 X0 Y0 H0 Z-99999 S6 ; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors ; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)Start Gcode

G28 ; home all axes G0 Z30 f4000 ;move down to buildplate G30 ;Set z0 G32 ; delta calibratie G29 ;make map bed G29 S1 ; load map G1 X0 X0 Y0 Z10 ;go centreEnd Gcode

M104 S0 ; turn off extruder M84 ; disable motors -

undefined 2000thy marked this topic as a question

undefined 2000thy marked this topic as a question

-

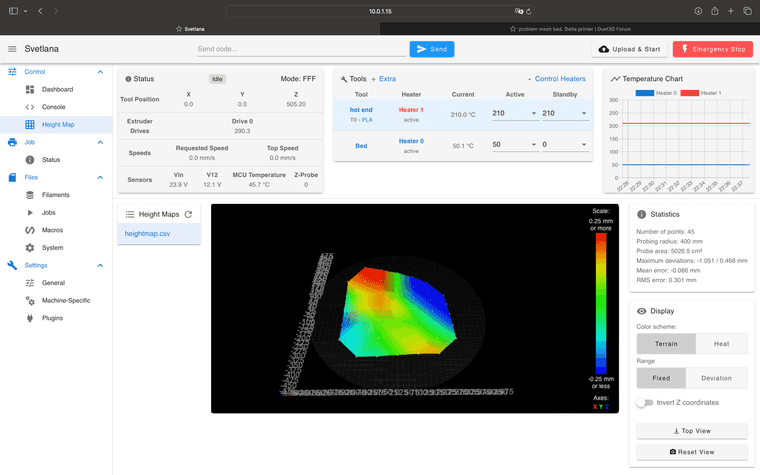

@2000thy Can you post an image of the bed mesh that is produced? I notice you are using a BLTouch, but there's no X or Y offset in the G31 command. Is it permanently mounted next to the nozzle? If so, it should have an offset.

If you're running the calibration in bed.g, it will be using the calibration until you reset. Usually you run M500 after calibration, to save the settings to config-override.g, then this is loaded when config.g is run, if you have M501 in it, which you don't appear to.

Ian

-

@2000thy I don't think it affects your problem, but it seems a notable coincidence that your bed radius (M665 B parameter) is exactly the same as your delta radius (M665 R parameter). Is that correct?

I don't think you need a bare

G29and aG29 S1. A bareG29if there is no mesh.g does aG29 S0which probes saves the heightmap and activates compensation, I believe. Again, though, I don't think it affects your problem. -

@droftarts said in problem mesh bed. Delta printer:

I notice you are using a BLTouch, but there's no X or Y offset in the G31 command. Is it permanently mounted next to the nozzle? If so, it should have an offset.

I see, changed the offset but kept the same problem.

new config file:

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.4.1 on Sun May 05 2024 12:41:38 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Svetlana" ; set printer name M665 R500 L1060 B483 H1468 ;B483 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P20.0 S0 ; physical drive 0.3 goes forwards M584 X0.0 Y0.1 Z0.2 E20.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E409.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X2000 Y2000 Z2000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits ;M208 Z1500 S1 ; set minimum Z ; Endstops M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in M574 Z2 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin io2.in ; Z-Probe M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"20.io0.in" H10 F1000 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X36 Y24 Z4.1 ; set Z probe trigger value, offset and trigger height M557 R483 S200 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.199 K0.344:0.000 D6.06 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S60 ; set temperature limit for heater 0 to 120C M308 S1 P"20.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"20.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 R1.528 K0.177:0.000 D9.18 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ;RUNOUT SENSOR M591 D0 P2 C"20.io1.in" S1 ;RUNOUT SENSOR ; Fans M950 F0 C"20.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"20.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"hot end" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined@droftarts said in problem mesh bed. Delta printer:

Can you post an image of the bed mesh that is produced?

there you go

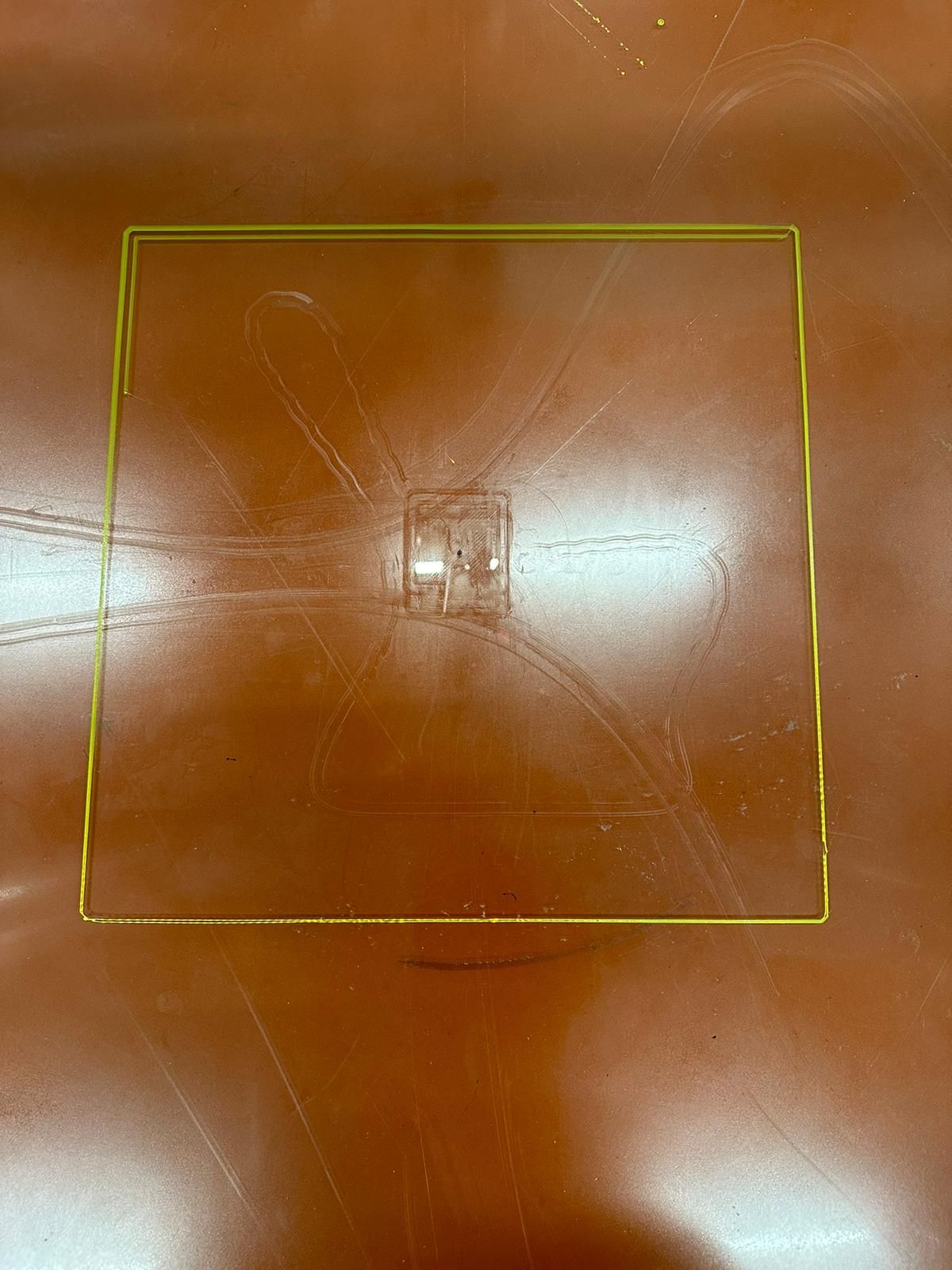

this is a picture of the first layer:

when I start the machine ill do a home all and then this macro to set the delta calibration and the mesh bed leveling:

G28 ;homedelta G0 X0 Y0 Z40 f10000 M557 X-380:380 Y-380:380 S200 M557 R400 S100 G30 ;set 0 G32 ;delta cal G29 ;heighthmap G0 X0 Y0 Z40 f10000this is a example code from the picture (Just the setup part)

; G-Code generated by Simplify3D(R) Version 5.1.2 ; Jun 11, 2024 at 10:22:32 PM ; Settings Summary ; processName,Process 1 ; autoConfigureMaterial,PLA ; autoConfigureQuality,Medium ; targetModels,xyzCalibration_cube(2)(2) ; profileName,Svetlana ; profileVersion,2024-06-11 19:34:08 ; app,S3D-Software 5.1.2 ; technology,fff ; baseProfile, ; extruder,Extruder 1 ; toolheadNumber,0 ; nozzleDiameter,0.80000 ; extrusionMultiplier,1.00000 ; extrusionWidthMode,automatic ; extrusionWidth,0.40000 ; useRetraction,1 ; retractDistance,1.00000 ; extraRestartDistance,0.00000 ; retractVerticalLift,0.00000 ; retractSpeed,1800.00000 ; useCoasting,0 ; coastingDistance,0.20000 ; useWiping,0 ; wipingDistance,5.00000 ; speedMaxFlowRate,900.00000 ; toolheadOffsetX,0.00000 ; toolheadOffsetY,0.00000 ; filamentDiameter,1.75000 ; filamentPricePerKilogram,25.00000 ; filamentDensity,1.25000 ; primaryExtruder,Extruder 1 ; layerHeight,0.20000 ; topSolidLayers,3 ; bottomSolidLayers,3 ; outlinePerimeters,2 ; useVaseMode,0 ; useAdaptiveLayerHeights,0 ; minAdaptiveLayerHeight,0.10000 ; maxAdaptiveLayerHeight,0.30000 ; adaptiveSmoothingLevel,5 ; horizontalOuterCompensation,0.00000 ; horizontalInnerCompensation,0.00000 ; firstLayerUnits,percentage ; firstLayerHeightPercentage,100 ; firstLayerWidthPercentage,100 ; firstLayerSpeedPercentage,50 ; firstLayerHeightAbsolute,0.30000 ; firstLayerWidthAbsolute,0.40000 ; firstLayerSpeedAbsolute,900.00000 ; startPointStrategy,closest ; alignStartPointsX,0.00000 ; alignStartPointsY,0.00000 ; restrictStartPoints,1 ; perimeterPrintingOrder,inside_out ; islandPrintingOrder,closest ; printInfillBeforePerimeters,0 ; useSkirt,1 ; skirtExtruder,Extruder 1 ; skirtLayers,1 ; skirtOffset,4.00000 ; skirtOutlines,2 ; useRaft,0 ; raftExtruder,Extruder 1 ; raftBaseLayers,2 ; raftTopLayers,3 ; raftOffset,3.00000 ; raftSeparationDistance,0.14000 ; raftSpeedUnits,percentage ; raftSpeedPercentage,30 ; raftSpeedAbsolute,600.00000 ; usePrimePillar,0 ; primePillarExtruder,Extruder 1 ; primePillarWidth,12.00000 ; primePillarLocation,north_west ; primePillarSpeedPercentage,100 ; primePillarInfillPercentage,100 ; autoStopPrimePillar,1 ; primePillarLayersAfterAutoStop,0 ; useOozeShield,0 ; oozeShieldExtruder,Extruder 1 ; oozeShieldOffset,2.00000 ; oozeShieldOutlines,1 ; oozeShieldSidewallShape,waterfall ; oozeShieldSidewallAngle,30 ; oozeShieldSpeedPercentage,100 ; autoStopOozeShield,1 ; oozeShieldLayersAfterAutoStop,0 ; sparseInfillExtruder,Extruder 1 ; sparseInfillPattern,rectilinear ; sparseInfillRotation,0 ; sparseInfillPercentage,20 ; sparseInfillExtrusionWidthPercentage,100 ; sparseInfillCombinedLayers,1 ; denseInfillLayers,0 ; denseInfillPercentage,50 ; infillOutlineOverlapPercentage,15 ; minInfillLength,5.00000 ; externalInfillPattern,rectilinear ; externalInfillRotation,0 ; solidInfillThresholdArea,25.00000 ; solidInfillExtraExpansion,0.00000 ; useMonotonic,0 ; useDiaphragm,0 ; diaphragmSolidLayers,3 ; diaphragmSpacingLayers,20 ; topLayerExtraExpansion,1.00000 ; topLayerExtrusionModifier,100 ; overrideFanSpeedForTopLayer,0 ; topLayerFanSpeedPercentage,100 ; useIroning,0 ; ironingOutlineOffsetPercentage,50 ; ironingExtrusionWidthPercentage,25 ; ironingExtrusionModifier,15 ; ironingSpeedModifier,30 ; sparseSupportExtruder,Extruder 1 ; sparseSupportInfillPattern,aligned ; sparseSupportInfillRotation,0 ; sparseSupportInfillPercentage,30 ; sparseSupportOutlines,0 ; sparseSupportCombinedLayers,1 ; upperDenseSupportLayers,0 ; lowerDenseSupportLayers,0 ; denseSupportExtruder,Extruder 1 ; denseSupportInfillPercentage,70 ; denseSupportExtraExpansion,0.00000 ; baseSupportLayers,0 ; supportInflationDistance,0.00000 ; supportHorizontalPartOffset,0.30000 ; supportUpperSeparationLayers,1 ; supportLowerSeparationLayers,1 ; temperatureController,Extruder 1 ; enableTemperatureController,1 ; temperatureNumber,0 ; temperatureType,extruder ; stabilizeAtStartup,1 ; temperatureSetpoints,1|210 ; useIdleCooldown,0 ; cooldownTemperature,150 ; cooldownRequiredIdleTime,180 ; cooldownReheatTime,60 ; temperatureController,bed ; enableTemperatureController,1 ; temperatureNumber,0 ; temperatureType,platform ; stabilizeAtStartup,1 ; temperatureSetpoints,1|50 ; useIdleCooldown,0 ; cooldownTemperature,150 ; cooldownRequiredIdleTime,180 ; cooldownReheatTime,60 ; fan,Cooling Fan ; fanNumber,0 ; fanType,extruder ; blipFanToFullPower,0 ; fanSetpoints,1|0,2|100 ; increaseFanForQuickLayers,1 ; fanMaxQuickLayerTime,45.00000 ; fanMinQuickLayerTime,15.00000 ; maxQuickLayerFanSpeedPercentage,100 ; defaultPrintSpeed,1800.00000 ; outerPerimeterSpeedPercentage,60 ; innerPerimeterSpeedPercentage,80 ; topLayerSpeedPercentage,50 ; solidInfillSpeedPercentage,80 ; sparseSupportSpeedPercentage,80 ; denseSupportSpeedPercentage,70 ; travelSpeedXY,3600.00000 ; travelSpeedZ,2400.00000 ; reduceSpeedForQuickLayers,1 ; speedMaxQuickLayerTime,20.00000 ; minQuickLayerSpeedPercentage,30 ; reduceSpeedForShortPerimeters,1 ; speedMaxShortPerimeterLength,80.00000 ; minShortPerimeterSpeedPercentage,50 ; reduceSpeedForMaxFlowRate,0 ; accelXY,1000.00000 ; accelZ,150.00000 ; accelE,3000.00000 ; jerkXY,600.00000 ; jerkZ,24.00000 ; jerkE,300.00000 ; exportFileFormat,gcode ; useStickyCommands,1 ; use5D,1 ; relativeExtrusionDistances,0 ; allowExtruderAxisZeroing,1 ; independentExtruderAxes,0 ; includeM10123,0 ; includeThumbnailImages,0 ; thumbnailImageEncoding,standard ; thumbnailImageSizes,300|300 ; x3gMachineProfile,r2 ; overrideStepsPerMillimeter,0 ; stepsPerMillimeterX,88.57319 ; stepsPerMillimeterY,88.57319 ; stepsPerMillimeterZ,400.00000 ; stepsPerMillimeterA,96.27520 ; stepsPerMillimeterB,96.27520 ; xyzFileFormatVersion,1 ; makerBotMachineProfile,replicator_5 ; makerBotModelExtruder,mk13 ; makerBotSupportExtruder,mk14_s ; makerBotModelMaterial,pla ; makerBotSupportMaterial,pva ; globalOffsetX,0.00000 ; globalOffsetY,0.00000 ; globalOffsetZ,0.00000 ; applyToolheadOffsets,0 ; buildVolumeShape,cylindrical ; buildVolumeX,200.00000 ; buildVolumeY,200.00000 ; buildVolumeZ,1300.00000 ; buildVolumeDiameter,1000.00000 ; originOffsetX,500.00000 ; originOffsetY,500.00000 ; originOffsetZ,0.00000 ; homingDirectionX,center ; homingDirectionY,center ; homingDirectionZ,max ; mirrorVisualX,0 ; mirrorVisualY,1 ; mirrorVisualZ,0 ; machineBackgroundModel, ; startingScript,G0 x0 y0 Z40 F6000|G30| ; preLayerChangeScript, ; postLayerChangeScript, ; preRetractionScript, ; postRetractionScript, ; preToolChangeScript, ; postToolChangeScript, ; processChangeScript, ; endingScript,M104 S0 ; turn off extruder|M84 ; disable motors ; postProcessingScript, ; useBridging,1 ; bridgingThresholdArea,50.00000 ; bridgingInfillExtraExpansion,0.00000 ; bridgingExtrusionModifier,100 ; bridgingSpeedModifier,100 ; overrideFanSpeedForBridging,0 ; bridgingFanSpeedPercentage,100 ; useFixedBridgingAngle,0 ; fixedBridgingAngle,0 ; applyBridgingToPerimeters,0 ; bridgingPerimeterExtraOverlap,0.00000 ; minBridgingPerimeterLength,10.00000 ; useToolChangeRetraction,1 ; toolChangeRetractDistance,12.00000 ; toolChangeExtraRestartDistance,-0.50000 ; toolChangeRetractSpeed,600.00000 ; toolChangePrimeOnFirstUse,0 ; toolChangeRetractAtEnd,0 ; externalThinWallType,perimeters_only ; internalThinWallType,gap_fill ; thinWallAllowedOverlapPercentage,10 ; singleExtrusionMinLength,1.00000 ; singleExtrusionMinWidthPercentage,50 ; singleExtrusionMaxWidthPercentage,200 ; singleExtrusionEndpointExtensionDistance,0.20000 ; onlyRetractWhenCrossingOutlines,1 ; retractBetweenLayers,1 ; retractOnTopLayers,0 ; useRetractionMinTravel,0 ; retractionMinTravel,5.00000 ; useRetractionMinExtrusion,0 ; retractionMinExtrusion,3.00000 ; onlyVerticalLiftOnTopLayers,0 ; retractWhileWiping,0 ; wipingMode,outer_perimeter ; avoidCrossingOutlines,0 ; maxMovementDetourFactor,3.00000 ; openLoopSlicingBehavior,heal ; openLoopThickenWidth,0.50000 ; slicingRegionRepairMode,positive G90 M82 M106 S0 P0 M140 S50 M190 S50 M104 S210 T0 M109 S210 T0 G0 x0 y0 Z40 F6000 G30 ; process Process 1 ; layer 1, Z = 0.2000 T0 G92 E0.00000 G1 E-1.00000 F1800 ; feature skirt ; tool H0.2000 W0.960 G1 Z0.2000 F2400 G1 X201.778 Y200.186 F3600 G92 E0.00000 G1 E1.00000 F1800 G92 E0.00000 G1 X-202.729 Y200.186 E32.28947 F900 G1 X-205.915 Y196.999 E32.64921 G1 X-205.915 Y-207.507 E64.93868 G1 X-202.729 Y-210.694 E65.29842thank you in advance!!

-

undefined droftarts referenced this topic

undefined droftarts referenced this topic

-

@2000thy most likely the tilt of your effector is varying with position. Read https://docs.duet3d.com/en/User_manual/Tuning/Delta_calibration and mount a bulls eye spirit level on the effector to make the tilt visible.

For delta printers it's much better to use a nozzle contact probe rather than an offset probe such as BLTouch.

-

thanks for the reply.

what you you mean by:

@dc42 said in problem mesh bed. Delta printer:most likely the tilt of your effector is varying with position

I got the printer mostly square and plum.

thanks in advance!

-

@2000thy said in problem mesh bed. Delta printer:

M558 P9 C"20.io0.in" H10 F1000 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z3.5What probe are you using? If it's a bltouch, than it has an offset from the nozzle. If the effector has a varying amount of tilt based on XY position, than the distance between the nozzle and probe will change as well, meaning your trigger height will be incorrect at certain positions.

This is why using nozzle contact probes for delta printers is strongly recommended.