thanks for the reply.

what you you mean by:

@dc42 said in problem mesh bed. Delta printer:

most likely the tilt of your effector is varying with position

I got the printer mostly square and plum.

thanks in advance!

thanks for the reply.

what you you mean by:

@dc42 said in problem mesh bed. Delta printer:

most likely the tilt of your effector is varying with position

I got the printer mostly square and plum.

thanks in advance!

Hey,

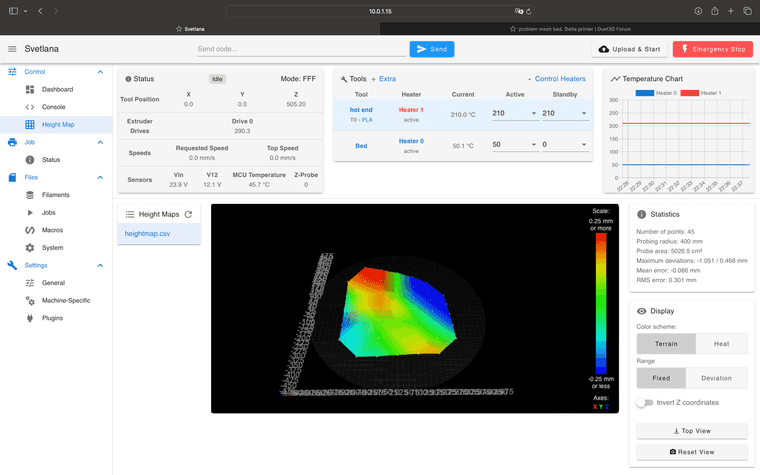

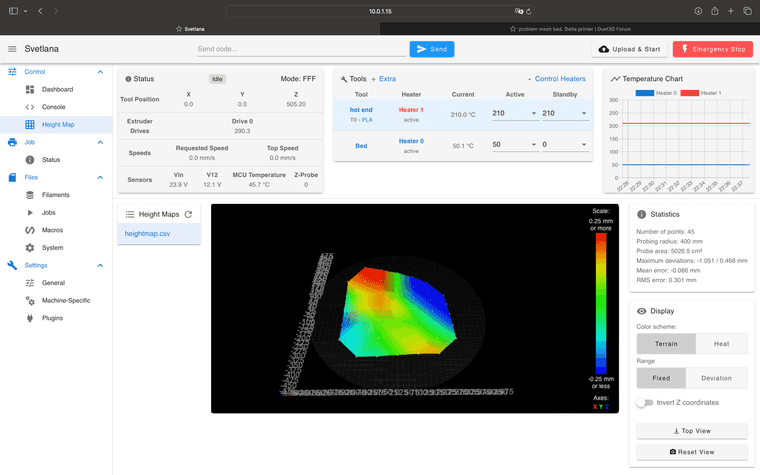

I got a really big delta printer with a Duet 6HC board, only thing I can't get working is the mesh bed level(See picture)

the probing works and also te hight map looks fine (I think).

can someone take a look at the files/pictures and help.

Thanks in advance!!!!

config file:

; Configuration file for Duet 3 MB 6HC (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.4.1 on Sun May 05 2024 12:41:38 GMT+0200 (Central European Summer Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Svetlana" ; set printer name

M665 R500 L1060 B483 H1468 ;B483 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them

; Wait a moment for the CAN expansion boards to start

G4 S2

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P20.0 S0 ; physical drive 0.3 goes forwards

M584 X0.0 Y0.1 Z0.2 E20.0 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E409.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X2000 Y2000 Z2000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

;M208 Z1500 S1 ; set minimum Z

; Endstops

M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in

M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in

M574 Z2 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin io2.in

; Z-Probe

M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"20.io0.in" H10 F1000 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X36 Y24 Z4.1 ; set Z probe trigger value, offset and trigger height

M557 R483 S200 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 R0.199 K0.344:0.000 D6.06 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S60 ; set temperature limit for heater 0 to 120C

M308 S1 P"20.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0

M950 H1 C"20.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1

M307 H1 R1.528 K0.177:0.000 D9.18 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S300 ; set temperature limit for heater 1 to 300C

;RUNOUT SENSOR

M591 D0 P2 C"20.io1.in" S1 ;RUNOUT SENSOR

; Fans

M950 F0 C"20.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency

M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"20.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off

; Tools

M563 P0 S"hot end" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

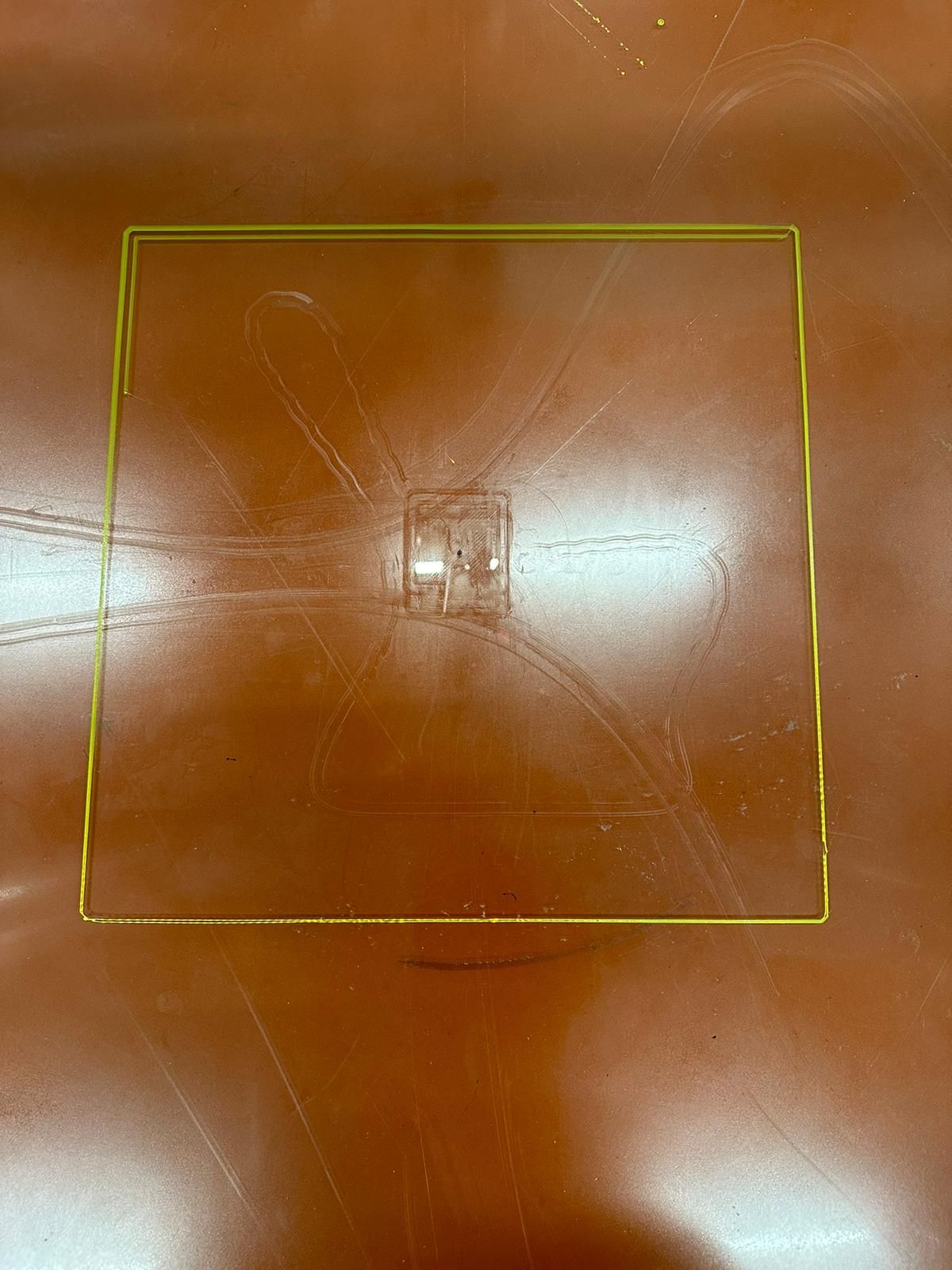

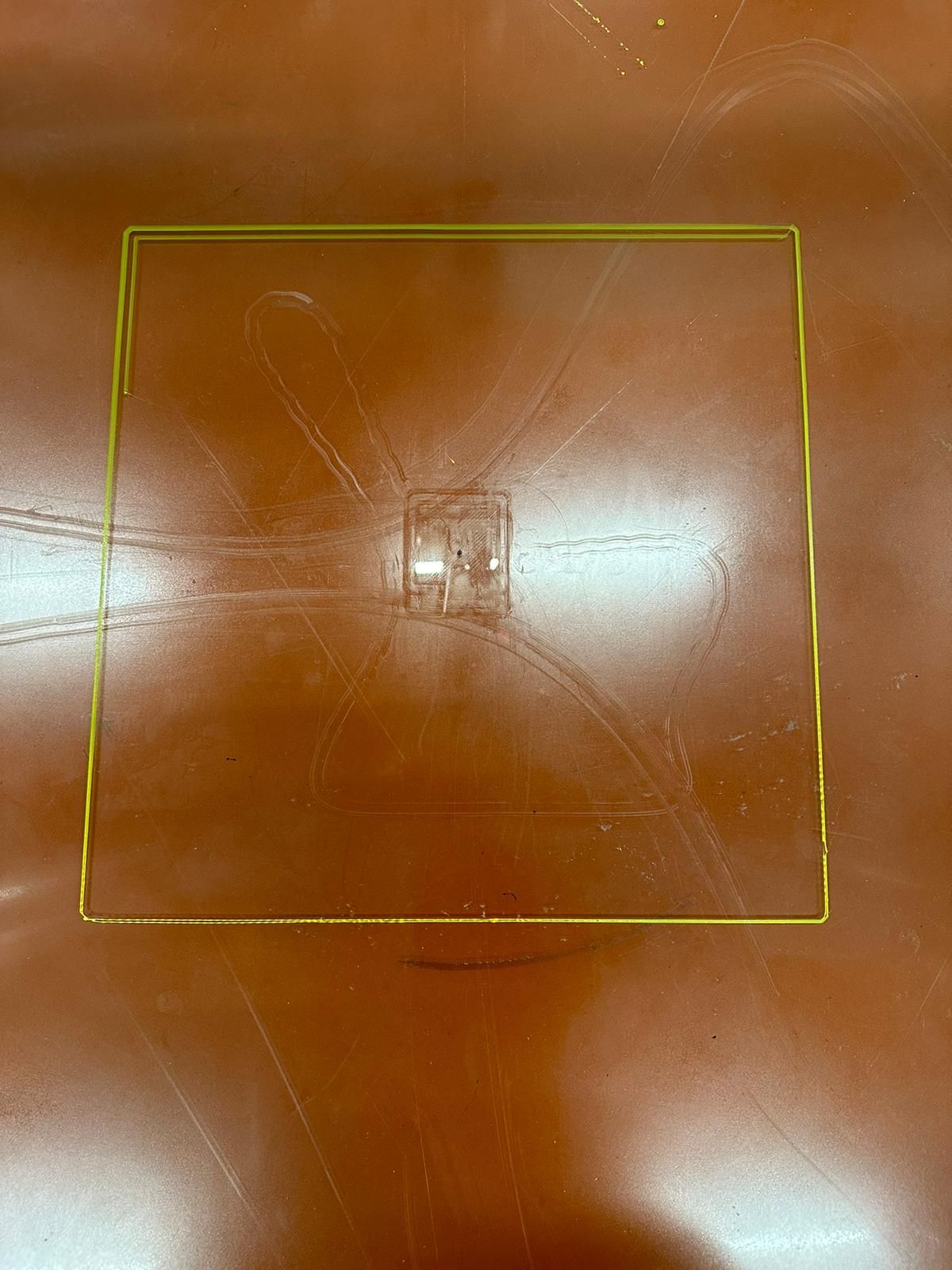

this is a picture of the first layer:

when I start the machine ill do a home all and then this macro to set the delta calibration and the mesh bed leveling:

G28 ;homedelta

G0 X0 Y0 Z40 f10000

M557 X-380:380 Y-380:380 S200

M557 R400 S100

G30 ;set 0

G32 ;delta cal

G29 ;heighthmap

G0 X0 Y0 Z40 f10000

this is a example code from the picture (Just the setup part)

; G-Code generated by Simplify3D(R) Version 5.1.2

; Jun 11, 2024 at 10:22:32 PM

; Settings Summary

; processName,Process 1

; autoConfigureMaterial,PLA

; autoConfigureQuality,Medium

; targetModels,xyzCalibration_cube(2)(2)

; profileName,Svetlana

; profileVersion,2024-06-11 19:34:08

; app,S3D-Software 5.1.2

; technology,fff

; baseProfile,

; extruder,Extruder 1

; toolheadNumber,0

; nozzleDiameter,0.80000

; extrusionMultiplier,1.00000

; extrusionWidthMode,automatic

; extrusionWidth,0.40000

; useRetraction,1

; retractDistance,1.00000

; extraRestartDistance,0.00000

; retractVerticalLift,0.00000

; retractSpeed,1800.00000

; useCoasting,0

; coastingDistance,0.20000

; useWiping,0

; wipingDistance,5.00000

; speedMaxFlowRate,900.00000

; toolheadOffsetX,0.00000

; toolheadOffsetY,0.00000

; filamentDiameter,1.75000

; filamentPricePerKilogram,25.00000

; filamentDensity,1.25000

; primaryExtruder,Extruder 1

; layerHeight,0.20000

; topSolidLayers,3

; bottomSolidLayers,3

; outlinePerimeters,2

; useVaseMode,0

; useAdaptiveLayerHeights,0

; minAdaptiveLayerHeight,0.10000

; maxAdaptiveLayerHeight,0.30000

; adaptiveSmoothingLevel,5

; horizontalOuterCompensation,0.00000

; horizontalInnerCompensation,0.00000

; firstLayerUnits,percentage

; firstLayerHeightPercentage,100

; firstLayerWidthPercentage,100

; firstLayerSpeedPercentage,50

; firstLayerHeightAbsolute,0.30000

; firstLayerWidthAbsolute,0.40000

; firstLayerSpeedAbsolute,900.00000

; startPointStrategy,closest

; alignStartPointsX,0.00000

; alignStartPointsY,0.00000

; restrictStartPoints,1

; perimeterPrintingOrder,inside_out

; islandPrintingOrder,closest

; printInfillBeforePerimeters,0

; useSkirt,1

; skirtExtruder,Extruder 1

; skirtLayers,1

; skirtOffset,4.00000

; skirtOutlines,2

; useRaft,0

; raftExtruder,Extruder 1

; raftBaseLayers,2

; raftTopLayers,3

; raftOffset,3.00000

; raftSeparationDistance,0.14000

; raftSpeedUnits,percentage

; raftSpeedPercentage,30

; raftSpeedAbsolute,600.00000

; usePrimePillar,0

; primePillarExtruder,Extruder 1

; primePillarWidth,12.00000

; primePillarLocation,north_west

; primePillarSpeedPercentage,100

; primePillarInfillPercentage,100

; autoStopPrimePillar,1

; primePillarLayersAfterAutoStop,0

; useOozeShield,0

; oozeShieldExtruder,Extruder 1

; oozeShieldOffset,2.00000

; oozeShieldOutlines,1

; oozeShieldSidewallShape,waterfall

; oozeShieldSidewallAngle,30

; oozeShieldSpeedPercentage,100

; autoStopOozeShield,1

; oozeShieldLayersAfterAutoStop,0

; sparseInfillExtruder,Extruder 1

; sparseInfillPattern,rectilinear

; sparseInfillRotation,0

; sparseInfillPercentage,20

; sparseInfillExtrusionWidthPercentage,100

; sparseInfillCombinedLayers,1

; denseInfillLayers,0

; denseInfillPercentage,50

; infillOutlineOverlapPercentage,15

; minInfillLength,5.00000

; externalInfillPattern,rectilinear

; externalInfillRotation,0

; solidInfillThresholdArea,25.00000

; solidInfillExtraExpansion,0.00000

; useMonotonic,0

; useDiaphragm,0

; diaphragmSolidLayers,3

; diaphragmSpacingLayers,20

; topLayerExtraExpansion,1.00000

; topLayerExtrusionModifier,100

; overrideFanSpeedForTopLayer,0

; topLayerFanSpeedPercentage,100

; useIroning,0

; ironingOutlineOffsetPercentage,50

; ironingExtrusionWidthPercentage,25

; ironingExtrusionModifier,15

; ironingSpeedModifier,30

; sparseSupportExtruder,Extruder 1

; sparseSupportInfillPattern,aligned

; sparseSupportInfillRotation,0

; sparseSupportInfillPercentage,30

; sparseSupportOutlines,0

; sparseSupportCombinedLayers,1

; upperDenseSupportLayers,0

; lowerDenseSupportLayers,0

; denseSupportExtruder,Extruder 1

; denseSupportInfillPercentage,70

; denseSupportExtraExpansion,0.00000

; baseSupportLayers,0

; supportInflationDistance,0.00000

; supportHorizontalPartOffset,0.30000

; supportUpperSeparationLayers,1

; supportLowerSeparationLayers,1

; temperatureController,Extruder 1

; enableTemperatureController,1

; temperatureNumber,0

; temperatureType,extruder

; stabilizeAtStartup,1

; temperatureSetpoints,1|210

; useIdleCooldown,0

; cooldownTemperature,150

; cooldownRequiredIdleTime,180

; cooldownReheatTime,60

; temperatureController,bed

; enableTemperatureController,1

; temperatureNumber,0

; temperatureType,platform

; stabilizeAtStartup,1

; temperatureSetpoints,1|50

; useIdleCooldown,0

; cooldownTemperature,150

; cooldownRequiredIdleTime,180

; cooldownReheatTime,60

; fan,Cooling Fan

; fanNumber,0

; fanType,extruder

; blipFanToFullPower,0

; fanSetpoints,1|0,2|100

; increaseFanForQuickLayers,1

; fanMaxQuickLayerTime,45.00000

; fanMinQuickLayerTime,15.00000

; maxQuickLayerFanSpeedPercentage,100

; defaultPrintSpeed,1800.00000

; outerPerimeterSpeedPercentage,60

; innerPerimeterSpeedPercentage,80

; topLayerSpeedPercentage,50

; solidInfillSpeedPercentage,80

; sparseSupportSpeedPercentage,80

; denseSupportSpeedPercentage,70

; travelSpeedXY,3600.00000

; travelSpeedZ,2400.00000

; reduceSpeedForQuickLayers,1

; speedMaxQuickLayerTime,20.00000

; minQuickLayerSpeedPercentage,30

; reduceSpeedForShortPerimeters,1

; speedMaxShortPerimeterLength,80.00000

; minShortPerimeterSpeedPercentage,50

; reduceSpeedForMaxFlowRate,0

; accelXY,1000.00000

; accelZ,150.00000

; accelE,3000.00000

; jerkXY,600.00000

; jerkZ,24.00000

; jerkE,300.00000

; exportFileFormat,gcode

; useStickyCommands,1

; use5D,1

; relativeExtrusionDistances,0

; allowExtruderAxisZeroing,1

; independentExtruderAxes,0

; includeM10123,0

; includeThumbnailImages,0

; thumbnailImageEncoding,standard

; thumbnailImageSizes,300|300

; x3gMachineProfile,r2

; overrideStepsPerMillimeter,0

; stepsPerMillimeterX,88.57319

; stepsPerMillimeterY,88.57319

; stepsPerMillimeterZ,400.00000

; stepsPerMillimeterA,96.27520

; stepsPerMillimeterB,96.27520

; xyzFileFormatVersion,1

; makerBotMachineProfile,replicator_5

; makerBotModelExtruder,mk13

; makerBotSupportExtruder,mk14_s

; makerBotModelMaterial,pla

; makerBotSupportMaterial,pva

; globalOffsetX,0.00000

; globalOffsetY,0.00000

; globalOffsetZ,0.00000

; applyToolheadOffsets,0

; buildVolumeShape,cylindrical

; buildVolumeX,200.00000

; buildVolumeY,200.00000

; buildVolumeZ,1300.00000

; buildVolumeDiameter,1000.00000

; originOffsetX,500.00000

; originOffsetY,500.00000

; originOffsetZ,0.00000

; homingDirectionX,center

; homingDirectionY,center

; homingDirectionZ,max

; mirrorVisualX,0

; mirrorVisualY,1

; mirrorVisualZ,0

; machineBackgroundModel,

; startingScript,G0 x0 y0 Z40 F6000|G30|

; preLayerChangeScript,

; postLayerChangeScript,

; preRetractionScript,

; postRetractionScript,

; preToolChangeScript,

; postToolChangeScript,

; processChangeScript,

; endingScript,M104 S0 ; turn off extruder|M84 ; disable motors

; postProcessingScript,

; useBridging,1

; bridgingThresholdArea,50.00000

; bridgingInfillExtraExpansion,0.00000

; bridgingExtrusionModifier,100

; bridgingSpeedModifier,100

; overrideFanSpeedForBridging,0

; bridgingFanSpeedPercentage,100

; useFixedBridgingAngle,0

; fixedBridgingAngle,0

; applyBridgingToPerimeters,0

; bridgingPerimeterExtraOverlap,0.00000

; minBridgingPerimeterLength,10.00000

; useToolChangeRetraction,1

; toolChangeRetractDistance,12.00000

; toolChangeExtraRestartDistance,-0.50000

; toolChangeRetractSpeed,600.00000

; toolChangePrimeOnFirstUse,0

; toolChangeRetractAtEnd,0

; externalThinWallType,perimeters_only

; internalThinWallType,gap_fill

; thinWallAllowedOverlapPercentage,10

; singleExtrusionMinLength,1.00000

; singleExtrusionMinWidthPercentage,50

; singleExtrusionMaxWidthPercentage,200

; singleExtrusionEndpointExtensionDistance,0.20000

; onlyRetractWhenCrossingOutlines,1

; retractBetweenLayers,1

; retractOnTopLayers,0

; useRetractionMinTravel,0

; retractionMinTravel,5.00000

; useRetractionMinExtrusion,0

; retractionMinExtrusion,3.00000

; onlyVerticalLiftOnTopLayers,0

; retractWhileWiping,0

; wipingMode,outer_perimeter

; avoidCrossingOutlines,0

; maxMovementDetourFactor,3.00000

; openLoopSlicingBehavior,heal

; openLoopThickenWidth,0.50000

; slicingRegionRepairMode,positive

G90

M82

M106 S0 P0

M140 S50

M190 S50

M104 S210 T0

M109 S210 T0

G0 x0 y0 Z40 F6000

G30

; process Process 1

; layer 1, Z = 0.2000

T0

G92 E0.00000

G1 E-1.00000 F1800

; feature skirt

; tool H0.2000 W0.960

G1 Z0.2000 F2400

G1 X201.778 Y200.186 F3600

G92 E0.00000

G1 E1.00000 F1800

G92 E0.00000

G1 X-202.729 Y200.186 E32.28947 F900

G1 X-205.915 Y196.999 E32.64921

G1 X-205.915 Y-207.507 E64.93868

G1 X-202.729 Y-210.694 E65.29842

thank you in advance!!

@droftarts said in problem mesh bed. Delta printer:

I notice you are using a BLTouch, but there's no X or Y offset in the G31 command. Is it permanently mounted next to the nozzle? If so, it should have an offset.

I see, changed the offset but kept the same problem.

new config file:

; Configuration file for Duet 3 MB 6HC (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.4.1 on Sun May 05 2024 12:41:38 GMT+0200 (Central European Summer Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Svetlana" ; set printer name

M665 R500 L1060 B483 H1468 ;B483 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them

; Wait a moment for the CAN expansion boards to start

G4 S2

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P20.0 S0 ; physical drive 0.3 goes forwards

M584 X0.0 Y0.1 Z0.2 E20.0 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E409.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X2000 Y2000 Z2000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

;M208 Z1500 S1 ; set minimum Z

; Endstops

M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in

M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in

M574 Z2 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin io2.in

; Z-Probe

M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"20.io0.in" H10 F1000 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X36 Y24 Z4.1 ; set Z probe trigger value, offset and trigger height

M557 R483 S200 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 R0.199 K0.344:0.000 D6.06 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S60 ; set temperature limit for heater 0 to 120C

M308 S1 P"20.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0

M950 H1 C"20.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1

M307 H1 R1.528 K0.177:0.000 D9.18 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S300 ; set temperature limit for heater 1 to 300C

;RUNOUT SENSOR

M591 D0 P2 C"20.io1.in" S1 ;RUNOUT SENSOR

; Fans

M950 F0 C"20.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency

M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"20.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off

; Tools

M563 P0 S"hot end" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

@droftarts said in problem mesh bed. Delta printer:

Can you post an image of the bed mesh that is produced?

there you go

this is a picture of the first layer:

when I start the machine ill do a home all and then this macro to set the delta calibration and the mesh bed leveling:

G28 ;homedelta

G0 X0 Y0 Z40 f10000

M557 X-380:380 Y-380:380 S200

M557 R400 S100

G30 ;set 0

G32 ;delta cal

G29 ;heighthmap

G0 X0 Y0 Z40 f10000

this is a example code from the picture (Just the setup part)

; G-Code generated by Simplify3D(R) Version 5.1.2

; Jun 11, 2024 at 10:22:32 PM

; Settings Summary

; processName,Process 1

; autoConfigureMaterial,PLA

; autoConfigureQuality,Medium

; targetModels,xyzCalibration_cube(2)(2)

; profileName,Svetlana

; profileVersion,2024-06-11 19:34:08

; app,S3D-Software 5.1.2

; technology,fff

; baseProfile,

; extruder,Extruder 1

; toolheadNumber,0

; nozzleDiameter,0.80000

; extrusionMultiplier,1.00000

; extrusionWidthMode,automatic

; extrusionWidth,0.40000

; useRetraction,1

; retractDistance,1.00000

; extraRestartDistance,0.00000

; retractVerticalLift,0.00000

; retractSpeed,1800.00000

; useCoasting,0

; coastingDistance,0.20000

; useWiping,0

; wipingDistance,5.00000

; speedMaxFlowRate,900.00000

; toolheadOffsetX,0.00000

; toolheadOffsetY,0.00000

; filamentDiameter,1.75000

; filamentPricePerKilogram,25.00000

; filamentDensity,1.25000

; primaryExtruder,Extruder 1

; layerHeight,0.20000

; topSolidLayers,3

; bottomSolidLayers,3

; outlinePerimeters,2

; useVaseMode,0

; useAdaptiveLayerHeights,0

; minAdaptiveLayerHeight,0.10000

; maxAdaptiveLayerHeight,0.30000

; adaptiveSmoothingLevel,5

; horizontalOuterCompensation,0.00000

; horizontalInnerCompensation,0.00000

; firstLayerUnits,percentage

; firstLayerHeightPercentage,100

; firstLayerWidthPercentage,100

; firstLayerSpeedPercentage,50

; firstLayerHeightAbsolute,0.30000

; firstLayerWidthAbsolute,0.40000

; firstLayerSpeedAbsolute,900.00000

; startPointStrategy,closest

; alignStartPointsX,0.00000

; alignStartPointsY,0.00000

; restrictStartPoints,1

; perimeterPrintingOrder,inside_out

; islandPrintingOrder,closest

; printInfillBeforePerimeters,0

; useSkirt,1

; skirtExtruder,Extruder 1

; skirtLayers,1

; skirtOffset,4.00000

; skirtOutlines,2

; useRaft,0

; raftExtruder,Extruder 1

; raftBaseLayers,2

; raftTopLayers,3

; raftOffset,3.00000

; raftSeparationDistance,0.14000

; raftSpeedUnits,percentage

; raftSpeedPercentage,30

; raftSpeedAbsolute,600.00000

; usePrimePillar,0

; primePillarExtruder,Extruder 1

; primePillarWidth,12.00000

; primePillarLocation,north_west

; primePillarSpeedPercentage,100

; primePillarInfillPercentage,100

; autoStopPrimePillar,1

; primePillarLayersAfterAutoStop,0

; useOozeShield,0

; oozeShieldExtruder,Extruder 1

; oozeShieldOffset,2.00000

; oozeShieldOutlines,1

; oozeShieldSidewallShape,waterfall

; oozeShieldSidewallAngle,30

; oozeShieldSpeedPercentage,100

; autoStopOozeShield,1

; oozeShieldLayersAfterAutoStop,0

; sparseInfillExtruder,Extruder 1

; sparseInfillPattern,rectilinear

; sparseInfillRotation,0

; sparseInfillPercentage,20

; sparseInfillExtrusionWidthPercentage,100

; sparseInfillCombinedLayers,1

; denseInfillLayers,0

; denseInfillPercentage,50

; infillOutlineOverlapPercentage,15

; minInfillLength,5.00000

; externalInfillPattern,rectilinear

; externalInfillRotation,0

; solidInfillThresholdArea,25.00000

; solidInfillExtraExpansion,0.00000

; useMonotonic,0

; useDiaphragm,0

; diaphragmSolidLayers,3

; diaphragmSpacingLayers,20

; topLayerExtraExpansion,1.00000

; topLayerExtrusionModifier,100

; overrideFanSpeedForTopLayer,0

; topLayerFanSpeedPercentage,100

; useIroning,0

; ironingOutlineOffsetPercentage,50

; ironingExtrusionWidthPercentage,25

; ironingExtrusionModifier,15

; ironingSpeedModifier,30

; sparseSupportExtruder,Extruder 1

; sparseSupportInfillPattern,aligned

; sparseSupportInfillRotation,0

; sparseSupportInfillPercentage,30

; sparseSupportOutlines,0

; sparseSupportCombinedLayers,1

; upperDenseSupportLayers,0

; lowerDenseSupportLayers,0

; denseSupportExtruder,Extruder 1

; denseSupportInfillPercentage,70

; denseSupportExtraExpansion,0.00000

; baseSupportLayers,0

; supportInflationDistance,0.00000

; supportHorizontalPartOffset,0.30000

; supportUpperSeparationLayers,1

; supportLowerSeparationLayers,1

; temperatureController,Extruder 1

; enableTemperatureController,1

; temperatureNumber,0

; temperatureType,extruder

; stabilizeAtStartup,1

; temperatureSetpoints,1|210

; useIdleCooldown,0

; cooldownTemperature,150

; cooldownRequiredIdleTime,180

; cooldownReheatTime,60

; temperatureController,bed

; enableTemperatureController,1

; temperatureNumber,0

; temperatureType,platform

; stabilizeAtStartup,1

; temperatureSetpoints,1|50

; useIdleCooldown,0

; cooldownTemperature,150

; cooldownRequiredIdleTime,180

; cooldownReheatTime,60

; fan,Cooling Fan

; fanNumber,0

; fanType,extruder

; blipFanToFullPower,0

; fanSetpoints,1|0,2|100

; increaseFanForQuickLayers,1

; fanMaxQuickLayerTime,45.00000

; fanMinQuickLayerTime,15.00000

; maxQuickLayerFanSpeedPercentage,100

; defaultPrintSpeed,1800.00000

; outerPerimeterSpeedPercentage,60

; innerPerimeterSpeedPercentage,80

; topLayerSpeedPercentage,50

; solidInfillSpeedPercentage,80

; sparseSupportSpeedPercentage,80

; denseSupportSpeedPercentage,70

; travelSpeedXY,3600.00000

; travelSpeedZ,2400.00000

; reduceSpeedForQuickLayers,1

; speedMaxQuickLayerTime,20.00000

; minQuickLayerSpeedPercentage,30

; reduceSpeedForShortPerimeters,1

; speedMaxShortPerimeterLength,80.00000

; minShortPerimeterSpeedPercentage,50

; reduceSpeedForMaxFlowRate,0

; accelXY,1000.00000

; accelZ,150.00000

; accelE,3000.00000

; jerkXY,600.00000

; jerkZ,24.00000

; jerkE,300.00000

; exportFileFormat,gcode

; useStickyCommands,1

; use5D,1

; relativeExtrusionDistances,0

; allowExtruderAxisZeroing,1

; independentExtruderAxes,0

; includeM10123,0

; includeThumbnailImages,0

; thumbnailImageEncoding,standard

; thumbnailImageSizes,300|300

; x3gMachineProfile,r2

; overrideStepsPerMillimeter,0

; stepsPerMillimeterX,88.57319

; stepsPerMillimeterY,88.57319

; stepsPerMillimeterZ,400.00000

; stepsPerMillimeterA,96.27520

; stepsPerMillimeterB,96.27520

; xyzFileFormatVersion,1

; makerBotMachineProfile,replicator_5

; makerBotModelExtruder,mk13

; makerBotSupportExtruder,mk14_s

; makerBotModelMaterial,pla

; makerBotSupportMaterial,pva

; globalOffsetX,0.00000

; globalOffsetY,0.00000

; globalOffsetZ,0.00000

; applyToolheadOffsets,0

; buildVolumeShape,cylindrical

; buildVolumeX,200.00000

; buildVolumeY,200.00000

; buildVolumeZ,1300.00000

; buildVolumeDiameter,1000.00000

; originOffsetX,500.00000

; originOffsetY,500.00000

; originOffsetZ,0.00000

; homingDirectionX,center

; homingDirectionY,center

; homingDirectionZ,max

; mirrorVisualX,0

; mirrorVisualY,1

; mirrorVisualZ,0

; machineBackgroundModel,

; startingScript,G0 x0 y0 Z40 F6000|G30|

; preLayerChangeScript,

; postLayerChangeScript,

; preRetractionScript,

; postRetractionScript,

; preToolChangeScript,

; postToolChangeScript,

; processChangeScript,

; endingScript,M104 S0 ; turn off extruder|M84 ; disable motors

; postProcessingScript,

; useBridging,1

; bridgingThresholdArea,50.00000

; bridgingInfillExtraExpansion,0.00000

; bridgingExtrusionModifier,100

; bridgingSpeedModifier,100

; overrideFanSpeedForBridging,0

; bridgingFanSpeedPercentage,100

; useFixedBridgingAngle,0

; fixedBridgingAngle,0

; applyBridgingToPerimeters,0

; bridgingPerimeterExtraOverlap,0.00000

; minBridgingPerimeterLength,10.00000

; useToolChangeRetraction,1

; toolChangeRetractDistance,12.00000

; toolChangeExtraRestartDistance,-0.50000

; toolChangeRetractSpeed,600.00000

; toolChangePrimeOnFirstUse,0

; toolChangeRetractAtEnd,0

; externalThinWallType,perimeters_only

; internalThinWallType,gap_fill

; thinWallAllowedOverlapPercentage,10

; singleExtrusionMinLength,1.00000

; singleExtrusionMinWidthPercentage,50

; singleExtrusionMaxWidthPercentage,200

; singleExtrusionEndpointExtensionDistance,0.20000

; onlyRetractWhenCrossingOutlines,1

; retractBetweenLayers,1

; retractOnTopLayers,0

; useRetractionMinTravel,0

; retractionMinTravel,5.00000

; useRetractionMinExtrusion,0

; retractionMinExtrusion,3.00000

; onlyVerticalLiftOnTopLayers,0

; retractWhileWiping,0

; wipingMode,outer_perimeter

; avoidCrossingOutlines,0

; maxMovementDetourFactor,3.00000

; openLoopSlicingBehavior,heal

; openLoopThickenWidth,0.50000

; slicingRegionRepairMode,positive

G90

M82

M106 S0 P0

M140 S50

M190 S50

M104 S210 T0

M109 S210 T0

G0 x0 y0 Z40 F6000

G30

; process Process 1

; layer 1, Z = 0.2000

T0

G92 E0.00000

G1 E-1.00000 F1800

; feature skirt

; tool H0.2000 W0.960

G1 Z0.2000 F2400

G1 X201.778 Y200.186 F3600

G92 E0.00000

G1 E1.00000 F1800

G92 E0.00000

G1 X-202.729 Y200.186 E32.28947 F900

G1 X-205.915 Y196.999 E32.64921

G1 X-205.915 Y-207.507 E64.93868

G1 X-202.729 Y-210.694 E65.29842

thank you in advance!!

I got a really big delta printer up and running with a duet 6HC and toolbar 1LC.

everything works fine apart from the mesh bed.

can't get a solid first layer, the Y direction is most of the problem. (See attached pictures)

can someone help me?

I'll share the following;

-Config.G

-Bed.G

-Simplify start Gcode and End Gcode

Config.G

; Configuration file for Duet 3 MB 6HC (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.4.1 on Sun May 05 2024 12:41:38 GMT+0200 (Central European Summer Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Svetlana" ; set printer name

M665 R483 L1060 B483 H1468 ;B483 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them

; Wait a moment for the CAN expansion boards to start

G4 S2

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P20.0 S0 ; physical drive 0.3 goes forwards

M584 X0.0 Y0.1 Z0.2 E20.0 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E409.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X2000 Y2000 Z2000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

;M208 Z1500 S1 ; set minimum Z

; Endstops

M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in

M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in

M574 Z2 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin io2.in

; Z-Probe

M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"20.io0.in" H10 F1000 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z3.5 ; set Z probe trigger value, offset and trigger height

M557 R483 S200 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 R0.199 K0.344:0.000 D6.06 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S60 ; set temperature limit for heater 0 to 120C

M308 S1 P"20.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0

M950 H1 C"20.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1

M307 H1 R1.528 K0.177:0.000 D9.18 E1.35 S1.00 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S300 ; set temperature limit for heater 1 to 300C

;RUNOUT SENSOR

M591 D0 P2 C"20.io1.in" S1 ;RUNOUT SENSOR

; Fans

M950 F0 C"20.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency

M106 P0 S0 H1 T45 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"20.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off

; Tools

M563 P0 S"hot end" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

Bed.G

; bed.g

; called to perform automatic delta calibration via G32

;

; generated by RepRapFirmware Configuration Tool v3.4.1 on Thu May 16 2024 15:48:45 GMT+0200 (Central European Summer Time)

M561 ; clear any bed transform

; Probe the bed at 3 peripheral and 3 halfway points, and perform 6-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.

G30 P0 X0 Y439.9 H0 Z-99999

G30 P1 X380.96 Y-219.95 H0 Z-99999

G30 P2 X-380.96 Y-219.95 H0 Z-99999

G30 P3 X0 Y219.9 H0 Z-99999

G30 P4 X190.44 Y-109.95 H0 Z-99999

G30 P5 X-190.44 Y-109.95 H0 Z-99999

G30 P6 X0 Y0 H0 Z-99999 S6

; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors

; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)

Start Gcode

G28 ; home all axes

G0 Z30 f4000 ;move down to buildplate

G30 ;Set z0

G32 ; delta calibratie

G29 ;make map bed

G29 S1 ; load map

G1 X0 X0 Y0 Z10 ;go centre

End Gcode

M104 S0 ; turn off extruder

M84 ; disable motors

Thank You! I updated both the toolboard and the mainboard and all problems disappeared.

03/05/2024, 10:09:03 M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.3 (2021-06-15 21:45:47) running on Duet 3 MB6HC v1.01 or later (standalone mode)

Board ID: 08DJM-9P63L-DJMSS-6J1FL-3S86L-18DM9

Used output buffers: 1 of 40 (12 max)

=== RTOS ===

Static ram: 150904

Dynamic ram: 89720 of which 572 recycled

Never used RAM 112996, free system stack 200 words

Tasks: NETWORK(ready,28.2%,230) ETHERNET(notifyWait,0.1%,117) HEAT(delaying,0.0%,405) Move(notifyWait,0.0%,352) CanReceiv(notifyWait,0.0%,799) CanSender(notifyWait,0.0%,374) CanClock(delaying,0.0%,339) TMC(notifyWait,7.5%,93) MAIN(running,59.5%,1114) IDLE(ready,4.7%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:01:02 ago, cause: software

Last software reset at 2024-05-03 10:07, reason: User, GCodes spinning, available RAM 112996, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Step timer max interval 127

MCU temperature: min 30.5, current 32.2, max 32.3

Supply voltage: min 23.7, current 23.7, max 23.8, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 192685, standstill, reads 20881, writes 14 timeouts 0, SG min/max 0/0

Driver 1: position 192685, standstill, reads 20881, writes 14 timeouts 0, SG min/max 0/0

Driver 2: position 192685, standstill, reads 20881, writes 14 timeouts 0, SG min/max 0/0

Driver 3: position 0, standstill, reads 20884, writes 11 timeouts 0, SG min/max 0/0

Driver 4: position 0, standstill, reads 20884, writes 11 timeouts 0, SG min/max 0/0

Driver 5: position 0, standstill, reads 20885, writes 11 timeouts 0, SG min/max 0/0

Date/time: 2024-05-03 10:09:03

Slowest loop: 3.94ms; fastest: 0.05ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 0.9ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== CAN ===

Messages queued 328, received 994, lost 0, longest wait 3ms for reply type 6013, peak Tx sync delay 6, free buffers 49 (min 48), ts 313/312/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 7.02ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions

HTTP sessions: 1 of 8

; Configuration file for Duet 3 MB 6HC (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.4.1 on Thu May 02 2024 17:50:51 GMT+0200 (Central European Summer Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Svetlana" ; set printer name

M665 R483 L1060 B483 H1465 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them

; Wait a moment for the CAN expansion boards to start

G4 S2

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P20.0 S1 ; physical drive 121.0 goes forwards

M584 X0.0 Y0.1 Z0.2 E20.0 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E397.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 Z1465 S1 ; set minimum Z

; Endstops

M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in

M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in

M574 Z1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin io2.in

; Z-Probe

M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"20.io0.in" H10 F2500 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M143 H1 S250

M557 R483 S200 ; define mesh grid

; HotEnd Heaters and Thermistor HotEnd

M308 S1 P"20.temp0" Y"20.thermistor" T100000 ;B4138 ; Set thermistor + ADC parameters for heater 1 HotEnd

M950 H1 C"20.out0" T1 ; Create HotEnd Heater

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M950 F0 C"121.out1" Q500 ; create fan 0 on pin 121.out1 and set its frequency

M106 P0 C"Hot end fan" S0 H0 T45 ; set fan 0 name and value. Thermostatic control is turned on

M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 S1 H-1

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

Hey!

I’m building a delta printer with the Toolboard 1LC as hot end. The BL touch en thermostat work perfectly via the toolboard. Only issue I got is the heater. Got it defined in the config.g but it stays off when I click the heater it should turn on and start heating but I can’t get it to show active.

When I put the normal out0 from the duet 3 6H it wil work.

Has anyone an idea? Thanks in advance