Duet 3 1XD low voltage issue

-

Hi,

I am connecting a stepper motor driver via the Duet 1XD module to the driver out outputs: +5V, step-, and dir-. When I click on the +50 or -50 shift on the panel, nothing happens.

After measuring the voltages with a multimeter on +5V and dir-, it shows 5V, and after changing the direction of movement, it shows 0V (which is correct).

When measuring the voltage between +5V and step-, it shows 0V, and when I click on the +50 or -50 shift on the panel, the voltage changes briefly to 0.05V (while it should change to 5V). What could be the cause?

-

@sebastianwac What driver and motor are you using? Please post the make and model number, and links to documentation. Also please post your config.g, and what firmware version you are using.

When I click on the +50 or -50 shift on the panel, nothing happens.

Have you wired enable to your driver? Most likely it is receiving the wrong signal, and the driver is not enabled. Often just disconnecting the enable signal will enable the driver, as most drivers are enabled by default.

When measuring the voltage between +5V and step-, it shows 0V, and when I click on the +50 or -50 shift on the panel, the voltage changes briefly to 0.05V (while it should change to 5V). What could be the cause?

The steps pulses are sent very fast, and most likely your multimeter can't react quick enough, so you just see the average voltage. However, the step pulses might be too short for the motor driver too. How have you set up the drive in config.g? Generally you need to set the stepper timings in the M569 command and T parameter that controls the motor. See https://docs.duet3d.com/Duet3D_hardware/Duet_3_family/Duet_3_Expansion_1XD#configuration-examples

Try something like:

M569 P40.0 S0 R1 T5:5:10:10Ian

-

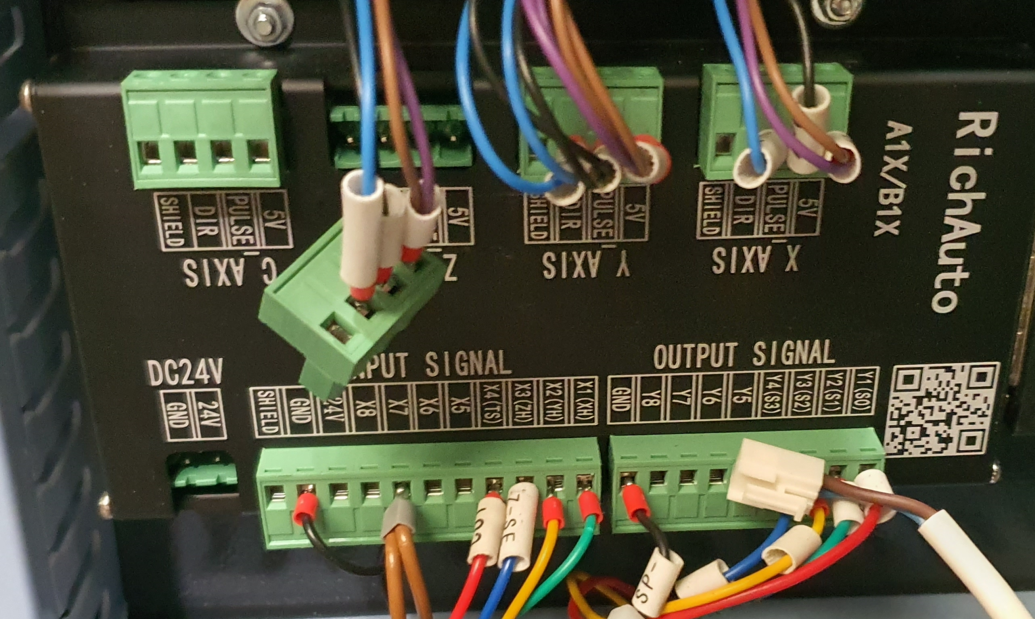

I am generally converting a CNC milling machine into a 3D printer. I want to replace the old motherboard (RichAuto A1X/B1X) with a Duet 6hc and 1xd modules.

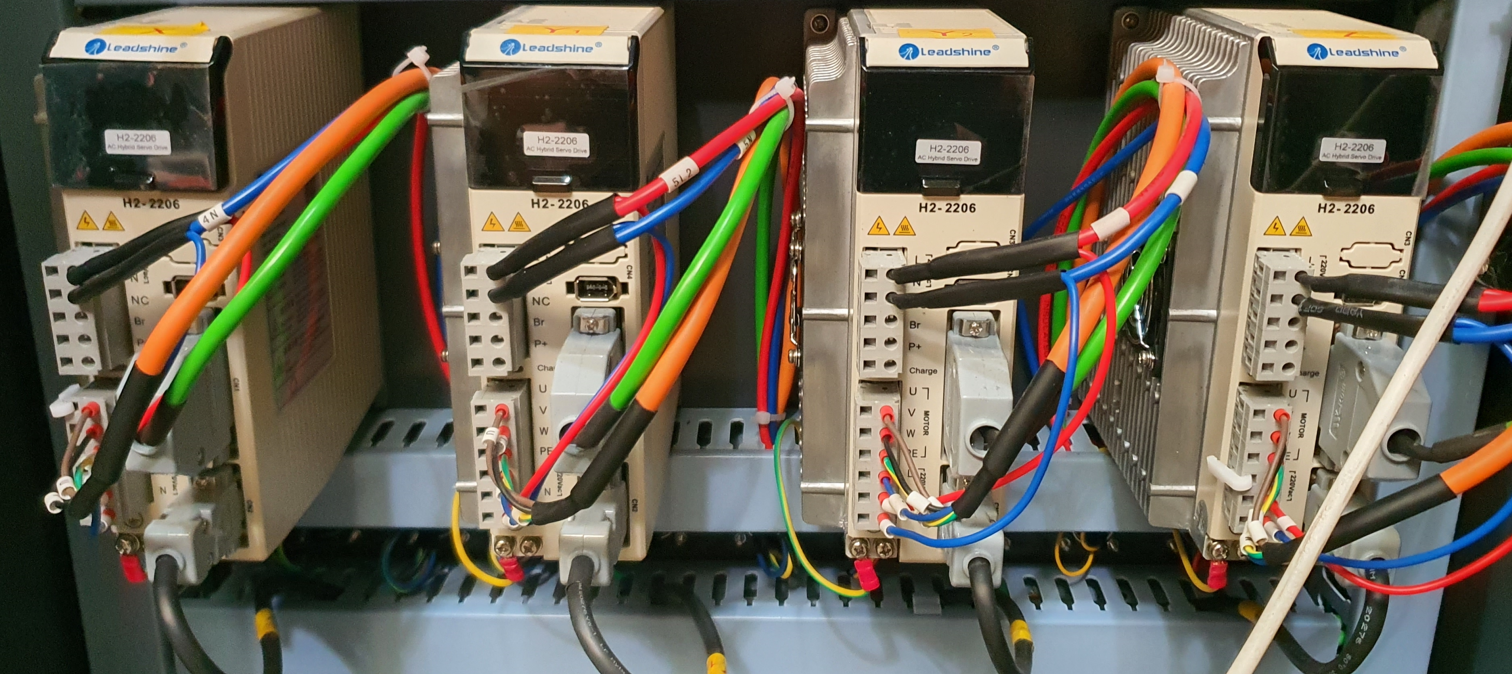

The motor drivers are H2-2206, and the servo motors are 863HSM100H. The documentation includes information about pulse times, and they are set in the firmware as follows:

M569 P41.0 S1 R1 T2.5:2.5:5:5Regarding the connections, +5V is connected to 5V, STEP- to PULSE-, and DIR- to DIR-. The drivers do not have EN inputs.

; Configuration file for Duet 3 (firmware version 3.5.1) ; executed by the firmware on start-up ; ; SBC Config M291 P"Applying persistent configuration options" R"Please wait" S1 T60 ; show that persistent settings are being configured while exists(sbc) && plugins.DuetPiManagementPlugin.pid < 0 && iterations < 30 G4 S2 ; wait for DuetPiManagementPlugin to become available G4 S2 ; wait another moment M929 S2 ; start logging events to the SD Card M550 P"MD" ; set persistent hostname for printer ;M551 P"mdrapid" ; set password M586 P0 S1 C"*" ; configure HTTP & enable CORS M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet M292 ; hide message box again upon completion ; General Preferences G21 ; Work in millimetres G90 ; absolute coordinates M83 ; relative extruder moves ; Drives M569 P41.0 S1 R1 T2.5:2.5:5:5 ; physical drive 0.0 goes forwards with active high enable config pulses intervals (x) M569 P42.0 S1 R1 T2.5:2.5:5:5 ; physical drive 0.0 goes forwards with active high enable config pulses intervals (y) M569 P43.0 S1 R1 T2.5:2.5:5:5 ; physical drive 0.0 goes forwards with active high enable config pulses intervals (z) M584 X41.0 Y42.0 Z43.0 ; set drive mapping M92 X83.50 Y83.50 Z320.00 ; set steps per mm M566 X600.00 Y600.00 Z60.00 ; set maximum instantaneous speed changes (mm/min) M203 X3000.00 Y3000.00 Z1800.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X2000 Y4000 Z320 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io2.in M574 Y1 S1 P"io3.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io3.in ; Z-Probe M558 P5 C"io5.in" H10 F900 T3000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z8 ; set Z probe trigger value, offset and trigger height M557 X0:1250 Y0:2400 S200 ; define mesh grid ; PE320 Extruder M569 P40.0 S1 R1 T0:0:0:0 ; external drive CAN address 40 goes forward, active high enable M584 E40.0 ; set drive mapping - map extruder to CAN address 40 M350 E1 I0 ; configure extruder with NO microstepping M92 E301.6485 ; set steps per mm - extruder E-steps/mm (resolution of 1:48) or 166.7 steps/rev M566 E3000 ; set maximum instantaneous speed changes (mm/min) M203 E3000 ; set maximum speeds (mm/min) M201 E20000 ; set accelerations (mm/s^2) ; Temp sensor parameters M308 S0 P"2.spi.cs0" Y"rtd-max31865" A"Top" M308 S1 P"2.spi.cs1" Y"rtd-max31865" A"Middle" M308 S2 P"2.spi.cs2" Y"rtd-max31865" A"Bottom" M308 S3 P"2.spi.cs3" Y"rtd-max31865" A"Nozzle" ; Create heaters M950 H0 C"out0" T0 ; create Top heater output on out0 and map it to sensor 0 M950 H1 C"out1" T1 ; create Middle heater output on out1 and map it to sensor 1 M950 H2 C"out2" T2 ; create Bottom heater output on out2 and map it to sensor 2 M950 H3 C"out3" T3 ; create Nozzle heater output on out3 and map it to sensor 3 ; Set PID heater parameters M307 H0 R1.319 K0.319:0.000 D25.28 E1.35 S1.00 B0 M307 H1 R0.650 K0.120:0.000 D35.30 E1.35 S1.00 B0 M307 H2 R0.636 K0.188:0.000 D41.46 E1.35 S1.00 B0 M307 H3 R0.500 K0.137:0.000 D21.29 E1.35 S1.00 B0 ; Maximum extruder heater temperature M143 H0 S400 ; set temperature limit for heater 0 to 400C M143 H1 S400 ; set temperature limit for heater 0 to 400C M143 H2 S400 ; set temperature limit for heater 0 to 400C M143 H3 S400 ; set temperature limit for heater 0 to 400C ; Extruder heater fault detection M570 H0 P60 T30 ; An anomaly on heaters 0 must persist for 60 seconds, and must be greater or less than 30C from the setpoint, to raise a heater fault. M570 H1 P60 T30 ; An anomaly on heaters 1 must persist for 60 seconds, and must be greater or less than 30C from the setpoint, to raise a heater fault. M570 H2 P60 T30 ; An anomaly on heaters 2 must persist for 60 seconds, and must be greater or less than 30C from the setpoint, to raise a heater fault. M570 H3 P60 T30 ; An anomaly on heaters 3 must persist for 60 seconds, and must be greater or less than 30C from the setpoint, to raise a heater fault. ; Define Heaters as Tools M563 P0 H0 S"Top" M563 P1 H1 S"Middle" M563 P2 H2 S"Bottom" M563 P3 D0 H3 S"Nozzle" ; Heater Cooling Fans M950 F0 C"2.out0+io1.in" Q100 A"Heat Break Fan" ; Heat Break Fan -- 4-wire PWM 12V fan so invert it, 100Hz PWM, NO tacho M950 F1 C"!2.out3+out3.tach" Q100 A"Top Fan" ; Top Fan -- 4-wire PWM 12V fan so invert it, 100Hz PWM, tacho connected M950 F2 C"!2.out4+out4.tach" Q100 A"Middle Fan" ; Middle Fan -- 4-wire 12V PWM fan so invert it, 100Hz PWM, tacho connected M950 F3 C"!2.out5+out5.tach" Q100 A"Bottom Fan" ; Bottom Fan -- 4-wire 12V PWM fan so invert it, 100Hz PWM, tacho connected M106 P0 S1 T40 H0:1:2:3 ; Turn on Heat Break Fans when heaters 0-3 are above 40 deg M106 P1 S0.5 ; Run at 20% speed at 2200rpm (max 11000rpm) M106 P2 S0.5 ; Run at 20% speed at 2200rpm (max 11000rpm) M106 P3 S0.5 ; Run at 20% speed at 2200rpm (max 11000rpm) ; Bed Heaters ;M308 S4 P"1.temp0" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed thermistor at 1.temp0 ;M308 S5 P"1.temp1" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed thermistor at 1.temp1 ;M308 S6 P"1.temp2" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed thermistor at 1.temp2 ;M308 S7 P"temp0" Y"thermistor" A"Bed" T100000 B4725 C7.06e-8 ; configure bed thermistor at temp0 ;M950 H4 C"1.out0" T4 Q10 ; create bed heater output on 1.out0 and map it to temp sensor 4 ;M950 H5 C"1.out1" T5 Q10 ; create bed heater output on 1.out1 and map it to temp sensor 5 ;M950 H6 C"1.out2" T6 Q10 ; create bed heater output on 1.out2 and map it to temp sensor 6 ;M950 H7 C"1.out3" T7 Q10 ; create bed heater output on 1.out3 and map it to temp sensor 7 ;M307 H4 R0.421 K0.321:0.000 D5.73 E1.35 S1.00 B0 ; Bed PID tuning parameters ;M140 P0 H4 ; map heater 4 to heated bed 0 ;M140 P1 H5 ; map heater 5 to heated bed 1 ;M140 P2 H6 ; map heater 6 to heated bed 2 ;M140 P3 H7 ; map heater 7 to heated bed 3 ;M143 H4 S120 ; max temp -- 120 deg C ;M143 H5 S120 ; max temp -- 120 deg C ;M143 H6 S120 ; max temp -- 120 deg C ;M143 H7 S120 ; max temp -- 120 deg C ;M570 H4 P60 T15 ; An anomaly on heaters 4 must persist for 60 seconds, and must be greater or less than 15C from the setpoint, to raise a heater fault. ;M570 H5 P60 T15 ; An anomaly on heaters 4 must persist for 60 seconds, and must be greater or less than 15C from the setpoint, to raise a heater fault. ;M570 H6 P60 T15 ; An anomaly on heaters 4 must persist for 60 seconds, and must be greater or less than 15C from the setpoint, to raise a heater fault. ;M570 H7 P60 T15 ; An anomaly on heaters 4 must persist for 60 seconds, and must be greater or less than 15C from the setpoint, to raise a heater fault. ; Define Bed Heaters as Tools ;M563 P4 H4 S"Bed 0" ;M563 P5 H5 S"Bed 1" ;M563 P6 H6 S"Bed 2" ;M563 P7 H7 S"Bed 3" ; Define Inputs M950 J0 C"io0.in" ; Relay 12 - Estop M950 J1 C"io1.in" ; Relay 13 - Reset ;M950 J2 C"io2.in" ; Relay 14 - X-Endstop ;M950 J3 C"io3.in" ; Relay 15 - Y-Endstop ;M950 J4 C"io4.in" ; Relay 16 - Z-Endstop ;M950 J5 C"io5.in" ; Relay 17 - Z-Probe M950 J6 C"io6.in" ; Relay 18 - FREE M950 J7 C"io7.in" ; Relay 19 - FREE M950 J8 C"io8.in" ; Relay 20 - FREE M950 J9 C"1.io0.in" ; Relay 21 - FREE M950 J10 C"1.io1.in" ; Relay 22 - FREE M950 J11 C"2.io0.in" ; Smart Wiring Loom - Material sensor LEFT M950 J12 C"2.io2.in" ; Smart Wiring Loom - Material sensor RIGHT M950 J13 C"40.io0.in" ; 1XD board - Servo Drive Fault ; Configure Input Triggers M581 P1 T2 S1 R0 ; Relay 13 - trigger 2 (Reset) activates on falling edge when Estop button is pressed M581 P13 T3 S1 R0 ; Trigger 3 (Servo Drive Fault) activates on falling edge when servo fault detected ; Define Ouputs M950 P0 C"out4" ; Relay 1 - Pellet Material Feed Solenoid M950 P1 C"out5" ; Relay 2 - Part Cooling Solenoid M950 P2 C"out6" ; Relay 3 - FREE M950 P3 C"out7" ; Relay 4 - FREE M950 P4 C"out8" ; Relay 5 - FREE M950 P5 C"out9" ; Relay 6 - FREE M950 P6 C"1.out1" ; Relay 7 - FREE M950 P7 C"1.out2" ; Relay 8 - FREE M950 P8 C"1.out3" ; Relay 9 - FREE M950 P9 C"1.out4" ; Relay 10 - FREE M950 P10 C"1.out5" ; Relay 11 - FREE M950 P11 C"40.io0.out" ; 1XD board - Clear Servo Drive Faults ; Set Outputs M42 P0 S0 ; Output OFF M42 P1 S0 ; Output OFF M42 P2 S0 ; Output OFF M42 P3 S0 ; Output OFF M42 P4 S0 ; Output OFF M42 P5 S0 ; Output OFF M42 P6 S0 ; Output OFF M42 P7 S0 ; Output OFF M42 P8 S0 ; Output OFF M42 P9 S0 ; Output OFF M42 P10 S0 ; Output OFF M42 P11 S0 ; Output OFF ; Select Tool T3 ; select nozzle heater with PE320 extruder M568 P3 A0 ; set nozzle heater to off ; Custom settingshttps://www.control-drive.com/Documents/Manuals/CN/H2-2206_manual_cn.pdf

https://www.scribd.com/document/717854727/H2-2206-manual-cn

https://forsuncnc.com/wp-content/uploads/2021/11/DSP-A11-User’s-Manual.pdfThis is the second milling machine I am converting into a 3D printer. The previous one was very similar, and it works correctly. The motor drivers there were H2-758. I also connected only 5V, Step-, and Dir- there. I used Duet 6xd there. When I measure the step signal during movement there, it shows 0.5V, which is more than on 1xd.

-

Never mind. I got it working. The issue was with the time delays.

Chinese documentation:

M569 P41.0 S1 R1 T2.5:2.5:5:5Reality:

M569 P41.0 S1 R1 T6:6:6:6 -

@sebastianwac Lol, Chinese documentation vs reality!

I was looking at the 1XD and 6XD outputs, wondering if you had wired it differently, as there is a difference between them; the 1XD can do single and differential signalling, while the 6XD only does single ended. However, glad it was something as simple as the timing, and you got it going.

Any reason you're using a 6HC rather than a 6XD for this conversion?

Ian

-

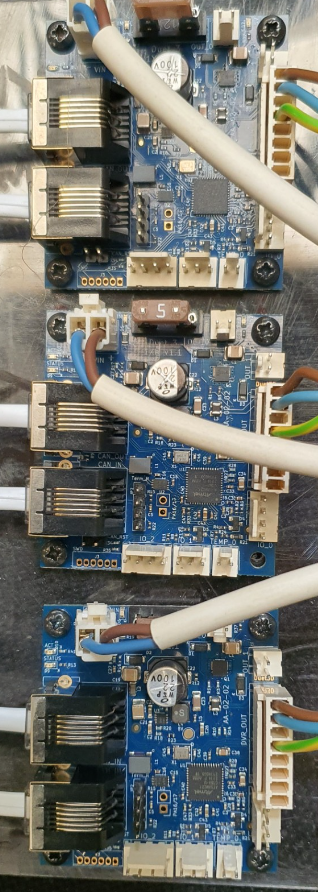

@droftarts At first, I intended to use the 6XD, but I received a pre-wired and configured 6HC bundled with an extruder, so I thought adding 3x 1XD would be faster and cheaper than switching to the 6XD.