Overloading the Duet 3 Mini 5+ with commands, causing stuttering

-

@droftarts Hi, yeah so the printer is a Zortrax M200 I've converted, I added a Duet 3 Mini 5+. I think its got Nema 16s and mechanically runs very smoothly. I took the diagnostics this morning after printing some parts that have a few stutter artefacts overnight:

=== Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.2 (2024-06-11 17:14:16) running on Duet 3 Mini5plus Ethernet (standalone mode) Board ID: BM90W-YV8LU-F65J0-409NL-1903Z-HKBR7 Used output buffers: 1 of 40 (40 max) === RTOS === Static ram: 103368 Dynamic ram: 117356 of which 392 recycled Never used RAM 16300, free system stack 112 words Tasks: NETWORK(1,ready,23.0%,155) ETHERNET(5,nWait 7,0.1%,560) HEAT(3,nWait 1,0.1%,325) Move(4,nWait 6,3.7%,253) CanReceiv(6,nWait 1,0.0%,939) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,334) TMC(4,nWait 6,0.8%,100) MAIN(1,running,71.5%,623) IDLE(0,ready,0.0%,29) AIN(4,delaying,0.9%,255), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 47:03:23 ago, cause: software Last software reset at 2024-09-12 10:32, reason: User, Gcodes spinning, available RAM 17836, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00487000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x04 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 169425619, completed 169425617, timed out 0, errs 0 MCU temperature: min 21.9, current 30.8, max 32.1 Supply voltage: min 23.5, current 23.8, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/668/668, gc cycles 310 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, read errors 0, write errors 0, ifcnt 125, reads 53047, writes 4, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 53, reads 53051, writes 0, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 143, reads 53044, writes 6, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 0, ifcnt 137, reads 53045, writes 6, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 0, ifcnt 138, reads 53045, writes 6, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2024-09-14 09:36:11 Cache data hit count 4294967295 Slowest loop: 1550.99ms; fastest: 0.10ms === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 5.3ms, write time 215.4ms, max retries 0 === Move === DMs created 84, segments created 44, maxWait 5940785ms, bed compensation in use: mesh, height map offset 0.000, max steps late 1, min interval 0, bad calcs 0, ebfmin -0.00, ebfmax 1.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 2526188, completed 2526188, hiccups 0, stepErrors 0, LaErrors 0, Underruns [302, 1, 1064], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.4 Heater 1 is on, I-accum = 0.3 === GCodes === Movement locks held by null, null HTTP is ready with "m122 b0" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000807 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 487148590 clear 138923008 Extruder 0: pos 13756.29, errs: frame 2619 parity 10 ovrun 14317 pol 338 ovdue 0 === CAN === Messages queued 458274, received 0, lost 0, errs 241814300, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 26 (min 26), ts 254597/0/0 Tx timeouts 0,0,254597,0,0,203677 last cancelled message type 30 dest 127 === Network === Slowest loop: 1549.47ms; fastest: 0.04ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = Ethernet = Interface state: active Error counts: 0 0 0 0 0 0 Socket states: 2 2 2 2 2 0 0 0; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Mon May 23 2022 00:42:46 GMT+0100 (BST) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Zortrax M200" ; set printer name ; Network M551 P"reprap" ; set password M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.4 S0 D3 V0 ; physical drive 0.3 goes backwards M569 P0.3 S1 D3 V0 ; physical drive 0.2 goes backwards M569 P0.2 S0 D3 V0 ; physical drive 0.1 goes forwards M569 P0.0 S1 D3 V0 ; physical drive 0.0 goes forwards M584 X0.4 Y0.3 Z0.2 E0.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E120 ; set steps per mm M566 X600.00 Y600.00 Z120 E10000 P1 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z900.00 E10000 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z400.00 E20000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E450 I10 ; set motor currents (mA) M84 S3 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X200 Y188 Z180 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io6.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io6.in M574 Y1 S1 P"io5.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io5.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F200 A02 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y-20 z0.37 ; set Z probe trigger value, offset and trigger height - decrease to raise nozzel M557 X0:200 Y0:188 P20:20 ; define mesh grid M671 X40:100:160 Y213:-13:213 P0.5 ; define adjusting screw positions ; Filament Monitor M591 D0 P3 C"io2.in" L25.87 S1 ; filament monitor connected to io2.in calibrated with 25.87 ;M591 D0 ; display filament sensor parameters for extruder drive 0 ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"pt1000" ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin !out4 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"out5" Q500 ; create fan 2 on pin out5 and set its frequency M106 P2 S0.5 H1:0 T45 ; set fan 2 value. Thermostatic control is turned on M950 F3 C"out6" Q500 ; create fan 3 on pin out6 and set its frequency M106 P3 S0.5 H1:0 T45 ; set fan 3 value. Thermostatic control is turned on ; Tools M563 P0 S"Extruder1" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;M572 D0 S0.1 ; set pressure advance to 0.1s ; Custom settings are not defined ; Miscellaneous M950 E0 C"led" ; LED strip settings M912 P0 S-6.7 M501 ; load saved parameters from non-volatile memory M911 S0 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; LED control if {state.status} == "paused" M150 R255 U150 B070 P255 S21 F1 ; white M150 R255 U160 B000 P255 S21 ; yellow M300 S4000 P50 G4 P300 M300 S4000 P50 ; double beep elif {state.status} == "processing" || {state.status} == "busy" M150 R255 U150 B070 P255 S42 ; white elif {heat.heaters[0].current} > 32 || {heat.heaters[1].current} > 32 M150 R255 U000 B000 P255 S04 F1 ; red M150 R255 U150 B070 P255 S13 F1 ; white M150 R255 U000 B000 P255 S08 F1 ; red M150 R255 U150 B070 P255 S13 F1 ; white M150 R255 U000 B000 P255 S04 F1 ; red M150 R255 U150 B070 P255 S03 ; white elif {state.status} == "idle" M150 R000 U255 B000 P255 S04 F1 ; green M150 R255 U150 B070 P255 S13 F1 ; white M150 R000 U255 B000 P255 S08 F1 ; green M150 R255 U150 B070 P255 S13 F1 ; white M150 R000 U255 B000 P255 S04 F1 ; green M150 R255 U150 B070 P255 S03 ; white else M150 R255 U150 B070 P255 S21 F1 ; white M150 R150 U0 B150 P255 S21 ; purple -

Have you tried running a print without the daemon.g code?

Is it always on curves?

-

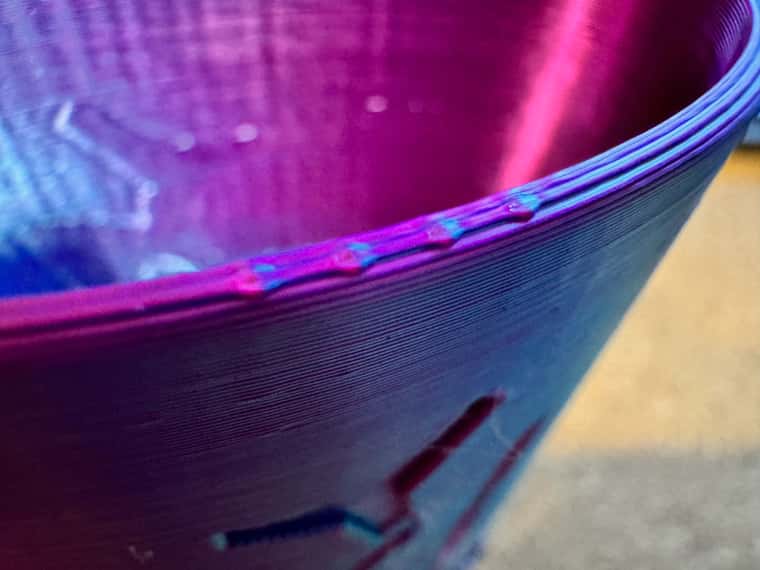

@Phaedrux Yes always on curves, and only with many parts on the bed and later in the print, like there's a cashe of memory that's getting filled.

Its difficult to replicate as it requires the need to print quite a few curved parts (ovals or cylinders are the main culprits)...

I can try with the deamon off, or is there a way to decrease the frequency which it runs?

-

The default time for daemon.g to run is 10 seconds. To make it longer you can add a G4 delay at the end for longer than 10 seconds. Ex: G4 S20

-

@VirtualBrown It may be worth checking your SD card; it may be a slow read speed on Gcode with particularly short movements (ie curves with fine slicer resolution) is causing queue starvation. Check what class your current SD card is, how full it is, and what the read speeds are by seeing this page: https://docs.duet3d.com/en/User_manual/RepRapFirmware/SD_card#troubleshooting-sd-card-issues

We recommend SD cards of the following specification: https://docs.duet3d.com/en/User_manual/RepRapFirmware/SD_card#specificationIan

-

@droftarts Interesting, so the SD card is the original that came with the board and the interface speed looks as expected: 22.5 MB/s

But the read write test is very slow:

SD write speed for 10.0MByte file was 0.43MBytes/sec

Testing SD card read speed...Doesn't seem to ever finish the read test.

Not much free space either:

SD card in slot 0: capacity 7.95GB, partition size 0.26GB, free space 0.06GB, speed 22.50MBytes/sec, cluster size 512 bytesI'm not sure where its all gone, I regularly delete all the jobs.

Could be a nice fix as I have another 32 GB SD card, once I format it as FAT 32 do I just copy all the files over? Can I reformat it using Mac OS?

-

Your original card likely has a double partition arrangement. One for use with an SBC, and another smaller for use in standalone.

I'd suggest using a new, larger, faster card.

I would suggest using the official SD card association formatter tool. https://www.sdcard.org/downloads/formatter/

You can then copy the existing files from the SD card across. Keep it as a backup.

-

@VirtualBrown said in Overloading the Duet 3 Mini 5+ with commands, causing stuttering:

once I format it as FAT 32 do I just copy all the files over? Can I reformat it using Mac OS?

Sure - works fine

-

@VirtualBrown Also see my post here about SD cards bigger than 32GB: https://forum.duet3d.com/topic/36414/using-sd-cards-with-capacity-32gb

Ian

-

Thanks everyone for your help, it looks like a new SD card has fixed the problem, which is great!

-

@VirtualBrown Looking back at the M122 report you posted, I see:

=== DDARing 0 === Scheduled moves 2526188, completed 2526188, hiccups 0, stepErrors 0, LaErrors 0, Underruns [302, 1, 1064], CDDA state -1It's the

Underruns [302, 1, 1064]that will have been causing pauses.The first underrun number is the number of 'lookahead' underruns, i.e. there were not enough spaces available in the move queue to do full lookahead. This type of underrun causes movement to be slower when there are very many short decelerating segments in succession. This should not cause a pause/stutter.

The second figure is the number of 'prepare' underruns. This indicates that the step interrupt service routine wanted another move, but although there was one it had not been prepared for execution. If the SD card was struggling to supply the next move, the processor may not have had time to prepare it for when it was needed. This may cause a stutter.

The third figure is the number of "no move" underruns. This indicates that the step interrupt routine wanted another move but none was available. If the SD card couldn't supply the next move in time to even be prepared, this will cause a stutter.

To check everything is okay now, start a print job, send M122. This will clear any existing errors. At the end of the job, send M122 again and see if it reports any of the above errors.

Probably just reformatting your original card would have cured it; I expect it was just running out of space, and causing files to be fragmented and taking longer to read.

Ian