Motor current idle factor not working over canbus?

-

This post is deleted! -

@droftarts said in Motor current idle factor not working over canbus?:

Sorry, senior moment,

LOL, no worries, I know the feeling!

Could you test without stallguard and with the drivers in spreadCycle?

Just tried it, unfortunately no luck, problem still persists.

Otherwise I'll try and test early next week

Thank you! And please do let me know if there is anything I can do on my end to help with the debugging.

-

Hey @droftarts - just noticed this issue has been closed in github. Was this by mistake? Or has there been some resolution I'm not aware of?

-

@mike_b I was able to replicate your issue in old firmware, but not with the updated versions, so as far as we can tell it's fixed. However, it doesn't explain why it's still an issue for you. Unfortunately, I haven't had time to rebuild the test set up to test with your config.g. I will try to early next week.

Ian

-

@droftarts Ok, thanks! I'll repeat here what I posted on github, because I think it's important: I really don't want to come across as overly demanding - I fully appreciate how challenging it is to allocate resources in an open-source project. That said, the safety implicating of this particular issue are significant. I do have brakes on my z-stage motors but brakes clearly don't help in this situation. Although I guess you could argue a belted z-stage is a terrible idea in the first place

anyway, again, I deeply respect the effort it takes to maintain an open-source project, so please don't take this as an entitled complaint - just a genuine concern I felt was worth sharing.

anyway, again, I deeply respect the effort it takes to maintain an open-source project, so please don't take this as an entitled complaint - just a genuine concern I felt was worth sharing.All that siad, I’m more than happy to take a more active role in debugging this issue, whether it involves hardware (I have multimeters, oscilloscopes, etc.) or software troubleshooting.

-

@mike_b lets see if @droftarts can replicate it with your config.g and take it from there.

-

@droftarts please can you confirm if the issue can be replicated using @mike_b 's config.

-

@mike_b Sorry it's taken a while to get a test set back up, but the Christmas holidays are long in this house!

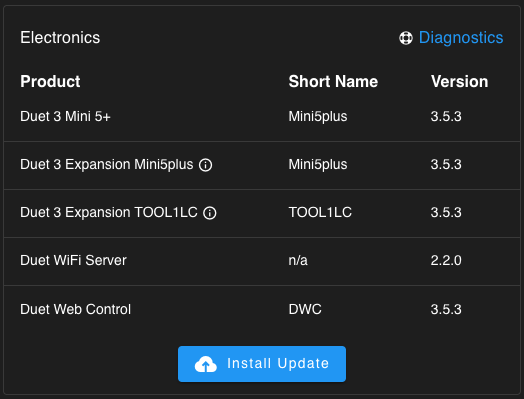

I managed to set up a test machine as closely as I could to yours, with Mini 5+ WiFi v0.5 mainboard, Mini 5+ Ethernet v1.02a as expansion, and 1LC v1.2a, all running on 3.5.3 in standalone:

I'm using a lightly modified version of your config.g (added network and PanelDue support, edited out missing global parameters, changed temperature sensors to match mine, disabled Z probe dock as it conflicts with PanelDue):

; Network M550 P"MinIan" ; set printer name M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; disable FTP M586 P2 S0 ; disable Telnet ; Display M575 P1 S1 B57600 ; enable support for PanelDue ; get variables ;M98 P"/sys/constants.g" ; General G90 ; absolute coordinates M83 ; relative extruder moves ; Wait a moment for the CAN expansion boards to become available G4 S2 ; Kinematics; Cartesian M669 K0 ; Drivers M569 P0.0 S1 D3 V9 ; x0 M915 P0.0 S10 ; x0, stallguard threshold M569 P0.1 S0 D3 V9 ; x1 M915 P0.1 S10 ; x1, stallguard threshold M569 P0.2 S0 D3 V9 ; y0 M915 P0.2 S10 ; y0, stallguard threshold M569 P0.3 S1 D3 V9 ; y1 M915 P0.3 S10 ; y1, stallguard threshold M569 P40.0 S1 D3 V9 ; z0 M569 P40.1 S1 D3 V9 ; z1 M569 P40.2 S1 D3 V9 ; z2 M569 P40.3 S1 D3 V9 ; z3 M569 P121.0 S1 D3 V2 ; e ; ---- axes M584 X0.0:0.1 Y0.2:0.3 Z40.0:40.1:40.2:40.3 E121.0 ; axis mapping M350 X16 Y16 Z16 E16 I1 ; microstepping with interpolation M906 X1200 Y1200 Z1200 E500 ; axis driver currents M917 X100 Y100 Z100 E70 ; set motor standstill M92 X79.87 Y79.80 Z160.31 E722.76 ; steps per mm M208 X-10:270 Y-15:270 Z0:295 ; minimum and maximum axis limits ; ---- motor idle M84 S600 ; idle timeout, 10min M906 I95 ; idle current, 95% ; ---- accelerations and jerks M203 X15000 Y15000 Z6000 E2000 ; maximum speeds (mm/min) E max: 8.3mm/sec, 20mm^3/sec M201 X6000 Y6000 Z1000 E1000 ; accelerations (mm/s^2) individual axes M204 P6000 T3000 ; accelerations (mm/s^2) total motion, (P)rinting and (T)ravel M566 X1200 Y1200 Z200 E400 P1 ; maximum instantaneous speed changes (mm/min) ; ---- temp Sensors M308 S0 P"0.temp0" Y"thermistor" A"Heated Bed" T100000 B3988 ; bed M308 S1 P"121.temp0" Y"thermistor" A"Nozzle" T100000 B4388 C7.06e-8 ; nozzle M308 S2 P"40.temp0" Y"thermistor" A"Filament Dryer" T10000 B3892 ; filament dryer ; Fans ; --- air pump; brushed DC motors should operate nicely with a PWM freq of 50 to 100 M950 F0 C"0.out2" Q250 M106 P0 C"Tool fan" S0 B0.0 H-1 L0 X0.5 ; --- turn on auto when heatbreak is 45C M950 F1 C"121.out2" M106 P1 C"heatbreak fan" S0 B0.1 H1 T45 L0 X1 ; --- BAG enclosure fan 1 M950 F3 C"!0.out3" M106 P3 C"BAG fan 1 (weak)" S0 B0.1 H-1 L0 X1 M950 F4 C"!0.out4" M106 P4 C"BAG fan 2 (strong)" S0 B0.1 H-1 L0 X1 ; Heater, bed M950 H0 C"0.out5" T0 Q500 ; create heater #0 M140 P0 H0 ; configure heated bed #0 M143 H0 P0 T0 C0 S140 A0 ; heater monitor #0 for heater #0 M307 H0 R0.645 K0.227:0.000 D11.51 E1.35 S1.00 B0 ; PID tune ; Heater, extruder M950 H1 C"121.out0" T1 ; create heater #1 M143 H1 P1 T1 C0 S310 A0 ; configure heater monitor #0 for heater #1 M570 H1 P15 T20 ; fault only after 15sec and 20C excursion ;if global.hotend == "magnum" ; M307 H1 R2.510 K0.449:0.000 D5.91 E1.35 S1.00 B0 V23.7 ;elif global.hotend == "mosquito" M307 H1 R3.039 K0.404:0.000 D5.22 E1.35 S1.00 B0 V23.4 ;else ; M307 H1 B1 ; Endstops M574 X1 S4 M574 Y1 S4 M574 Z0 ; Tools M563 P0 S"T0" D0 H1 F0 ; create tool #0 M568 P0 R0 S0 ; initial tool #0 active and standby temperatures to 0C ;if global.nozzle_diameter < 0.6 ; heater feedforward for tool 0 M309 P0 S0.08 ;if global.nozzle_diameter >= 0.6 ; M309 P0 S0.3 ; z-probe dock ;M950 S0 C"out6" Q50 ; servo, assign GPIO port 1 to out9 (Servo header), servo mode ;M950 J0 C"!0.io0.in" ; sensor ; z brake M569.7 P40.3 C"out1" S100 ; accelerometer; I is the orientation M955 P121.0 I24 ; sensorless homing M915 X Y R0 F0 ; extra sensors M308 S10 Y"mcu-temp" P"0.dummy" A"0.MCU" M308 S11 Y"mcu-temp" P"40.dummy" A"40.MCU" M308 S12 Y"mcu-temp" P"121.dummy" A"121.MCU" ; electronics bag fan M950 F5 C"40.out6" M106 P5 C"electronics fan" B0.1 H11 T45 L0 X0.7Mini 5+ as expansion config.g, note M906 is commented out:

; M906 I90 M954 A40This config.g runs without errors, though some components are not connected (filament temperature, 'BAG' fans). Unless I'm missing something, you don't seem to have a Z-probe or Z endstop configured? Or perhaps it is configured in the homing macros?

Testing:

- turn on, connect via DWC

- Send G92 X0 Y0 Z0 to home axes

- Jog Z axis (I have 4 motors connected to the 5+ as expansion), check timeout and motor current is work, again by turning motor shaft and feeling resistance

- Adjust M906 I#. The change in resistance should be felt immediately while the motor is on 'hold'

The result for me was that M906 I# works, and changes the motor current of the motors on the Mini5+ as-expansion. Sending M906 I1, the motors were easy to turn, sending M906 I100, they were hard to turn. Sending M906 I0 caused the motors to turn off, and the axes to become unhomed. This shows that the 5+ as expansion does pick up the change.

Can you do the above test and make sure you can feel a change in the motor current on hold? I struggled to tell if the motor current was different when set anywhere between 10% and 70%, but that may be down to my choice of motor. Rather than risk you bed crashing, maybe disconnect the Z motors and block the bed from dropping, and connect a motor that is not physically connected to the machine, especially if you are setting 0 or 1% currents.

However, I think I have found another issue, at least in RRF 3.5.3. If you do change the motor idle current with M906 I#, it seems that the motor current is not restored correctly when the axis is asked to move again, for axes connected to the mainboard-as-expansion board (axes connected to the mainboard work correctly), it stays at the idle current. For example, if M906 I1 (ie 1%) is set in config.g, turn on machine, G92 all axes, move Z, hold time and idle current are correct (same for X). If I then send M906 I100, followed by M906 I1, then move the Z axis, the motor current does not increase for the move or for the hold time. I need to test this with 3.5.4 and the latest 3.6 beta.

Ian

-

@mike_b I've reopened the issue on Github, and added the results of my testing, and @dc42 will be looking at it. This also seems to affect expansion boards. https://github.com/Duet3D/RepRapFirmware/issues/1019

Ian

-

@mike_b please note, the issue that has been reproduced is not the original one that you reported. I fixed the original one some time ago. The bug that has recently been reproduced (and I have just fixed) is that if a M906 command with the I parameter is issued when the motors have moved or been enabled, but they have subsequently become idle, then on expansion boards (including main boards used as expansion boards) the regular motor current was incorrectly sent to the idle current. The consequence was that when you commanded them to move again, they didn't receive the full current.

-

@dc42 thank you for the update and the heads up! Very much appreciate it.

-

@droftarts thanks for this very detailed write up, and thanks again for putting so much effort into this! I realy appreciate it. Unfortunately I'm dealing with some health issues at the moment but should be able to test in a week or two. Thanks again!