Homeall.g fails when homing all axes

-

For X-axis i have 2 endstops, one at 0(min) and other at 340 (max) ) but both are connected together to act as 1 single endstop

That's a problem: Endstops are a means to determine a physical location for an axis. If you can "home" the axis to two opposite locations, having both endstops wired together (i.e. in parallel), you are lost. Best is to just keep one endstop per axis.

-

according to Duet3 Documentation :

RepRapFirmware only supports one endstop per motor per axis. If your axis only has one motor, you can only have one endstop . is this still the case ?

On X-axis & Y-axis

To try and remedy this: i am thinking of doing this

(1) For X-axis , only have 1 physical endstop at min or max

(2) For Y-axis, only have 2 physical endstops (connected in parallel) each per Y-axis rail both at min or max

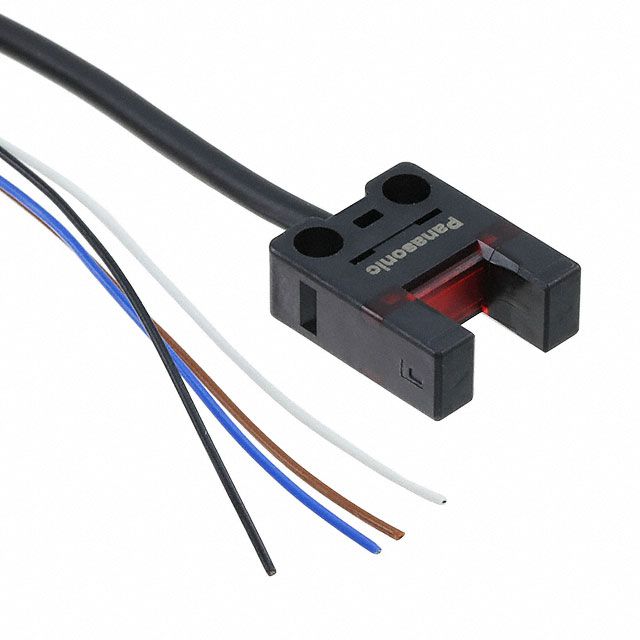

NOTE: i have the 4-wire Panasonic Optical Endstops PM-U25-N ( NPN type) (Black, Blue, Brown, white ) connected to Duet3D 6XD & 3HC board IO ports as follows:

Panasonic pm-254565_e_cata.pdf

Black Wire ==> IOx.in

Blue Wire ==> GND

Brown Wire ==> 5V_EXTQuick Question: Normally what is the best location for an endstop for Duet3D 6XD boards is at Min or Max locations of the Axis ?

My triggers seem to be acting in reverse.

Trigger OFF means ON (Green on Dashboard) and Trigger ON means OFF for all axes

-

@developeralgo222 yes, that's still the case of 1 per axis.

It makes normal difference whether they are at min or max -

@developeralgo222 said in Homeall.g fails when homing all axes:

Trigger OFF means ON (Green on Dashboard) and Trigger ON means OFF for all axes

This is because the endstops are defined with the signal inverted, due to the "!", e.g.:

M574 X1 S1 P"!0.io1.in"see:

https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m574-set-endstop-configurationTry

M574 X1 S1 P"0.io1.in"Its really worth following the documentation for setting up endstops:

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Sensors_endstopsOnly have the endstop at one end of the axis.

Regarding this:

@developeralgo222 said in Homeall.g fails when homing all axes:

(2) For Y-axis, only have 2 physical endstops (connected in parallel) each per Y-axis rail both at min or max

However in your config.g you only have 1 motor on Y so you can only have 1 endstop:

M584 X0.0 Y0.1 Z1.0 U1.1 V1.2 W2.0 A2.1 B2.2 C3.0 D3.1 'k3.2 R0 S0 -

(1) For X-axis , only have 1 physical endstop at min or max

That's fine.

(2) For Y-axis, only have 2 physical endstops (connected in parallel) each per Y-axis rail both at min or max

Why? For each axis, you want to have one known position from where you then establish a coordinate system.

There are reasons to become confused:

- in case you have multiple steppers per axis (think of 3 motors for Z), you may want to level or tram the printbed or maybe the X plane (2 steppers). These cases are supported by RRF, but the rule: "one endtop per motor" stays valid. If your idea is to "tram" the Y axis, you need to wire one endstop per motor. In your arrangement, one or both of the endstops act as a combo, i.e. they don't provide one signal per stepper.

- as a safety measure, endstops on each end of an axis can be helpful (well, sometimes). If triggered, they can stop any motion beyond their respective positions. Technically, you can invoke a trigger (e.g. macro) to take appropriate action. That's a use case where an arrangement of endstops such as yours makes perfect sense.

- to initiate a coordinate system, you need to know one single spot per axis. This can be at any location on an axis, so the term "endstop" is somehow misleading. Many users have the idea of their "endstops" representing the origin of the printable area, but RRF allows you to define the origin to be somewhere else - for example, my X(Y origin is in the bed's center.

-

@infiniteloop said in Homeall.g fails when homing all axes:

(2) For Y-axis, only have 2 physical endstops (connected in parallel) each per Y-axis rail both at min or max

Why? For each axis, you want to have one known position from where you then establish a coordinate system.

I have 2 linear rails on Y-axis ( it moves on Dual Rail ) but only 1 Stepper Motor for controlling the Y-axis . So to comply with 1 Endstop/Motor/Axis on Duet and to remedy the Y-axis i am removing 2 endstops at the Max of the Y-axis. Just leaving 2 endstops at the Min of each rail . The 2 endstops are connected as a 1 single Endstop at the Min only. Will this work for Y-axis?

-

What is your thinking on having those two endstops?

You are aware that endstops serve no purpose except during G1 H1 or G1 H3 or G1 H4 moves?

Frederick

-

@fcwilt

wasn't aware of that . So really, what's the value-added in having endstops anyway in duet ? since they seem to be integral part in some Duet's movement process. I am confused about your statement -

@fcwilt said in Homeall.g fails when homing all axes:

What is your thinking on having those two endstops?

You are aware that endstops serve no purpose except during G1 H1 or G1 H3 or G1 H4 moves?

Just having a single endstop at the min Y-axis. Since only 1 Single Endstop is allowed , by connecting the 2 physical endstops (at minimum) together to act as only a single endpoint at minimum

-

@developeralgo222 if you really want to use 2 Y endstops even though you have just 1 Y motor, then my interpretation of the datasheet you linked to is that you need to use the white wire as the output connected to the iox_in pin (not the black wire), connect both sensors in parallel, and use the ! character at the start of the pin name.

You can activate the endstops manually (i.e. place a piece pf card in the slot) and use the Object Model Browser in DWC to check that activating either endstop changes the state of the endstop in the object mode to triggered.

-

@developeralgo222 said in Homeall.g fails when homing all axes:

@fcwilt

wasn't aware of that . So really, what's the value-added in having endstops anyway in duet ? since they seem to be integral part in some Duet's movement process. I am confused about your statementWhen you first power on a machine (or after any reset) the physical position of each axis is unknown.

The homing processes use G1 H1 moves and the action of the axis endstops to determine the actual physical position and thus sync the logical position with the physical position.

The position of the endstop must be near one end of the axis and must work in such away that it is not possible to obtain a physical position past the endstop where the endstop is not activated.

The G1 H1 moves allow stopping motion when the endstop is triggered. Since the location of the endstop is known (indeed it must be known) once the G1 H1 move is stopped the physical position of the axis is known and the the logical position of the axis (the value you see on the DWC) can be synced with the actual physical position.

Once the logical and physical are in sync normal G90 G1 moves can move to any point on the axis (within the min/max range) with a good deal of accuracy.

IF the endstop triggered at exactly the min or max of the axis (depending on where the endstop was) the G1 H1 move would establish BOTH the axis physical and logical position simultaneously.

However, I have never had a printer where that was true and it has always required a bit of additional code in the homing routine to sync the physical and logical positions.

Frederick

-

-

You can install two Y endstop sensors but you are not going to derive any benefit from doing so, when you only have one Y stepper motor.

Frederick

-

@developeralgo222 for Y axis and white wires use !iox.in

-

Just leaving 2 endstops at the Min of each rail . The 2 endstops are connected as a 1 single Endstop at the Min only. Will this work for Y-axis?

Yes - because, as you rightly say, the two endstops are wired to act as a single switch.

-

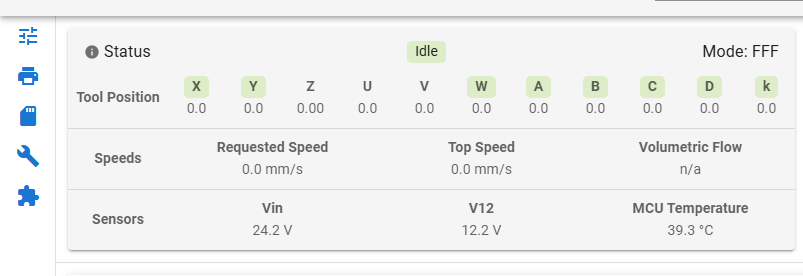

Ok i have made the modifications on Endstops

X-Axis ---- Endstop works fine now and triggers correctly

Y-Axis ---- Endstop works fine now and triggers correctly

W, A, B, C, D, k ---- Endstop works fine now and triggers correctly

Test:

Working on Z, U , V Axes:

Not sure how this need to be configured ( This are shared Z-CAM based axis ) for 6 Nozzles

Z , U , V ( Z-Axis = (Z1, Z2), U-Axis = (Z3, Z4), V-Axis= (Z5, Z6) ) only Z2 , Z4, Z6 triggers Z , U , V respectively but not Z1, Z3, Z5

; Endstops ; For X and Y Axis M574 X1 S1 P"0.io1.in" ; configure active high endstop switch for low end on X via pin io1.in M574 Y1 S1 P"0.io2.in" ; configure active high endstop switch for low end on Y via pin io2.in ; For Z-Axis (Shared Z,U,V) - Up/down) -- CAM Driven Dual Nozzles ( 1 Motor rotates up/down to drive 2 Nozzles ) M574 Z1 S1 P"1.io0.in" ; configure active high endstop switch for low end on Z via pin 1.io0.in M574 Z2 S1 P"1.io1.in" ; configure active high endstop switch for High end on Z via pin 1.io1.in M574 U1 S1 P"1.io2.in" ; configure active high endstop switch for low end on U via pin 1.io2.in M574 U2 S1 P"1.io3.in" ; configure active high endstop switch for High end on U via pin 1.io3.in M574 V1 S1 P"1.io4.in" ; configure active high endstop switch for low end on V via pin 1.io4.in M574 V2 S1 P"1.io5.in" ; configure active high endstop switch for High end on V via pin 1.io5.in ; For Rotational Axes only (W, A, B, C, D, 'k(k)) M574 W1 S1 P"2.io3.in" ; configure active high endstop switch for low end on W via pin 2.io3.in M574 A1 S1 P"2.io4.in" ; configure active high endstop switch for low end on A via pin 2.io4.in M574 B1 S1 P"2.io5.in" ; configure active high endstop switch for low end on B via pin 2.io5.in M574 C1 S1 P"3.io3.in" ; configure active high endstop switch for low end on C via pin 3.io3.in M574 D1 S1 P"3.io4.in" ; configure active high endstop switch for low end on D via pin 3.io4.in M574 'k1 S1 P"3.io5.in" ; configure active high endstop switch for low end on 'k via pin 3.io5.inHere is a photo of the 6-Nozzles with a little grainy photo to show some of the 6 endstops under each Z-based axis ( Z, U, V )

-

@developeralgo222

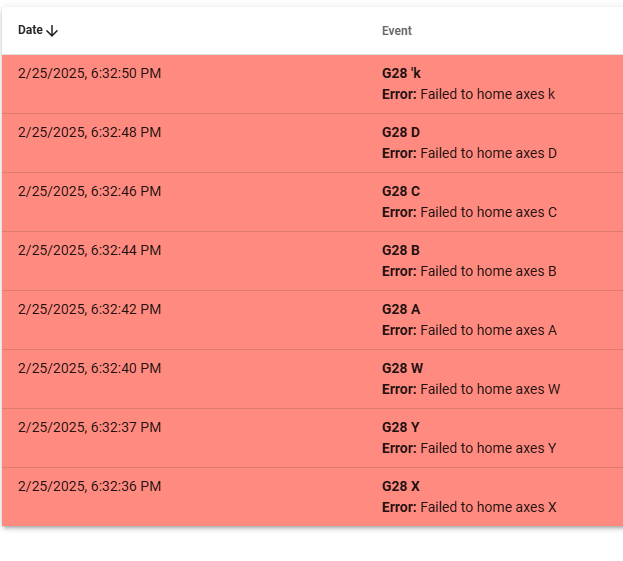

i went back to try and individually home all Axes that have their end stops corrected i.eX-Axis ---- End stop works fine now and triggers correctly

Y-Axis ---- End stop works fine now and triggers correctly

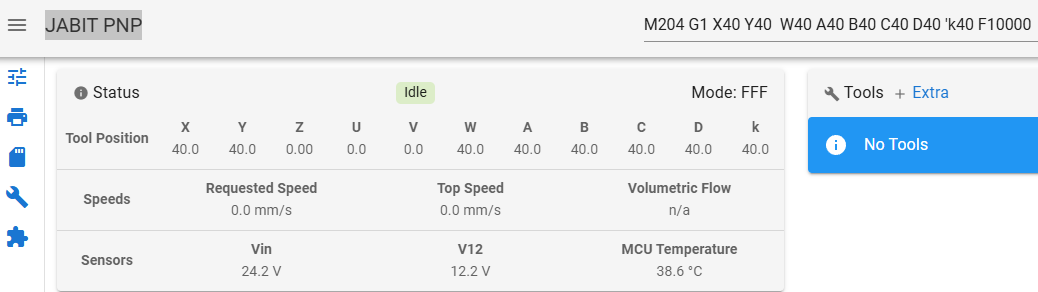

W, A, B, C, D, k ---- End stop works fine now and triggers correctlyHoming fails on all of them. e.g. homing X-axis, this is what i have in the file ( very simple, nothing complicated ). It completes the movements in homing X-axis fine with no issues but DWC reports that Homing X failed e.g

; Home X-Axis G91 ; relative positioning G1 H2 X0 ; set axes position explicitly to Zero i.e move X and Y-axis Minimum Homing endstop and stop there G1 H2 X40 F10000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-40 F10000 ; go back a few mm G1 H2 X0 ; move X and Y-axis Minimum Homing endstop and stop there (first pass) G90 ; absolute positioning

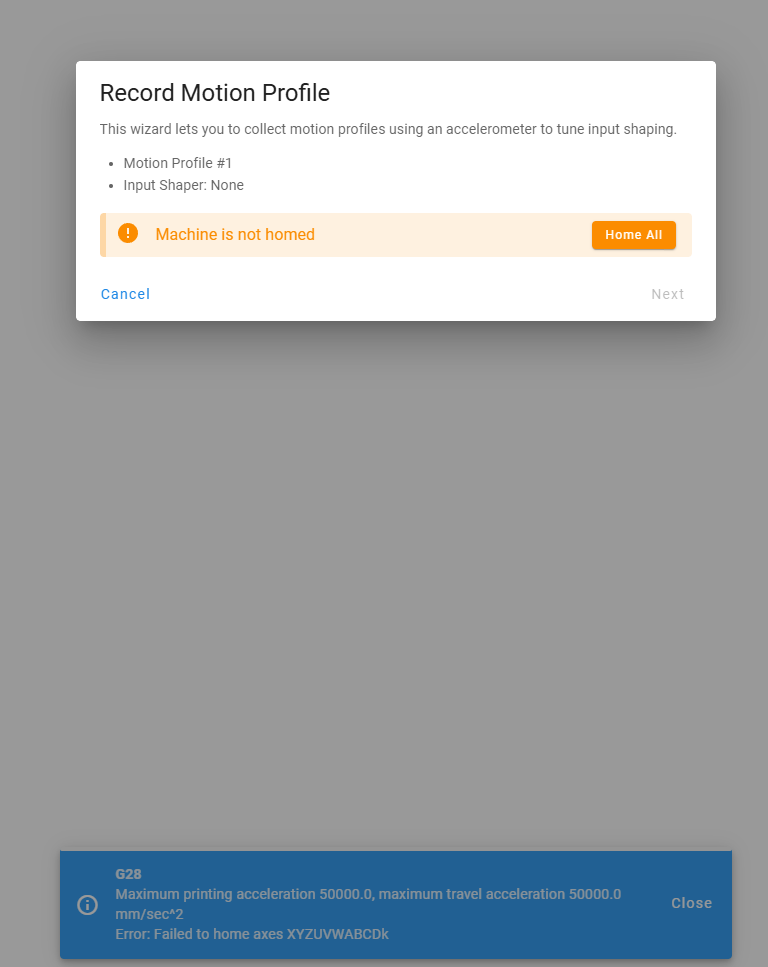

It affects me in that i can't use Input Shaping with Accelerometer from the DWC to help tune and optimize my PNP machine Speed and acceleration . Input Shaping from DWC is using HomeAll button . Not sure if its failing bacause of Z, U, V that have endstop issues

-

; Home X-Axis G91 ; relative positioning G1 H2 X0 ; set axes position explicitly to Zero i.e move X and Y-axis Minimum Homing endstop and stop there G1 H2 X40 F10000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-40 F10000 ; go back a few mm G1 H2 X0 ; move X and Y-axis Minimum Homing endstop and stop there (first pass) G90 ; absolute positioningG1 H2 doesn't do what you think it does here.

G1 H2 X0 means to do a zero movement move regardless if the axis is homed or not. G1 H2 moves are meant to leat you move the axis away from an endstop slightly before a homing move, or to raise the z axis before making an X Y move to prevent scraping.

An actual homing move is done with a G1 H1 movement which needs to be long enough to strike the endstop even from the farthest opposing position. It also must be in the direction of the endstop.

-

You are using H2 instead of H1.

You posted that the X endstop is at the low end.

I don't know how long the X axis is but you need something like...

G91 G1 H1 X-999 F5000 ; use a value large enough to move the entire length of the X axis G1 X10 G1 H1 X-15 F500...then based on what the physical position is when stopped by the endstop being triggered

G1 Xnnn ; move to some known position on the axis - note this is a relative move still G92 Xppp ; set the X axis logical position to match the physical positionFrederick

-

@fcwilt

X-axis = 340 mm and Y-axis = 447mm.I think i only have extra additional of -2.0516mm on X-axis on the low end and -4.0244mm on Y-axis