Duet 2 v1.02 not responding

-

@dc42 still this even I plugged it to spi.cs2 and changed the code M308 S1 P"spi.cs2" Y"rtd-max31865"

Heater 1 fault: failed to read sensor: hardwareError

-

-

@thomasvanderwal You have assembled the hot end incorrectly. The nozzle shouldn't be sticking out this far, and the heater block should not be touching the heatsink:

This looks like an E3D V6 hot end. See https://e3d-online.zendesk.com/hc/en-us/articles/360017013257-V6-Assembly-Guide-Edition-2

When you replaced the hot end, did you replace the temperature sensor as well? Remove it from the heater block to be sure it's not shorting there (there's a grub screw holding it in, see the instructions above), disconnect it from the Duet, then measure the resistance of the temperature sensor with a multimeter. The reading at room temperature should indicate what kind of temperature sensor it is.

Ian

-

@droftarts aha oke the wires are lose from the temperature sensor. Is this fixable?

-

@thomasvanderwal Is this the original temperature sensor? Either crimping or soldering may repair it.

Ian

-

@droftarts do you know how? When the two wires Connect I get as circuit error.

The sensor itself is a resistor? So soldering without touching eachother? -

@thomasvanderwal I'll ask a third time; is this the original temperature sensor, or a different one? Maybe post a picture of the temperature sensor, removed from the heater block. Yes, the wires should be soldered without touching each other, and be insulated from the heater block. Replacement PT100 temperature sensors (as well as PT1000 and thermistors) are available from E3D: https://e3d-online.com/products/pt100-temperature-sensor

The temperature sensor is a type of resistor, but the resistance changes with temperature. PT100, PT1000 and thermistors are different, and need to be setup differently in config.g.

A PT100 has a resistance of 100 ohms at 0C, see the resistance table here https://www.sterlingsensors.co.uk/pt100-resistance-table

A PT1000 has a resistance of 1000 ohms at 0C, see the resistance table here https://www.sterlingsensors.co.uk/pt1000-resistance-table

A 100k thermistor has a resistance of 100000 Ohms at 25C, for example see the resistance table here https://www.bapihvac.com/wp-content/uploads/2010/11/Thermistor_100K.pdfNote how the PT100 and PT1000 resistance increases with increasing temperature, while the thermistor resistance decreases with increasing temperature. This is why it's important to correctly identify what temperature sensor you are using. Please measure the resistance of the temperature sensor with a multimeter at room temperature.

Ian

-

The sensor itself is a resistor? So soldering without touching each other?

Solder joints iin the immediate vicinity of a hotend which can easily reach the temperature of a soldering iron? Perhaps not the best idea. Better replace the temp sensor with a new one. There’s a reason why these come with heat resistant connection cables.

-

@droftarts oh sorry, it is a spare. So I think it is a original. An thank you for your patience. Due to lack of time I'm on and off with this printer conquest.

-

@thomasvanderwal So it may not be a PT100. PT1000 and thermistors connect directly to the Duet, not through the temperature daughterboard. The only way to know is to measure the resistance.

If you can refit the original temperature sensor, that's probably the easiest thing to do. If you look at the hot end assembly guide I posted earlier, you'll see how the temperature sensor is secured in the heater block by a grub screw. Loosen that, replace the temperature sensor with the original one.

Ian

-

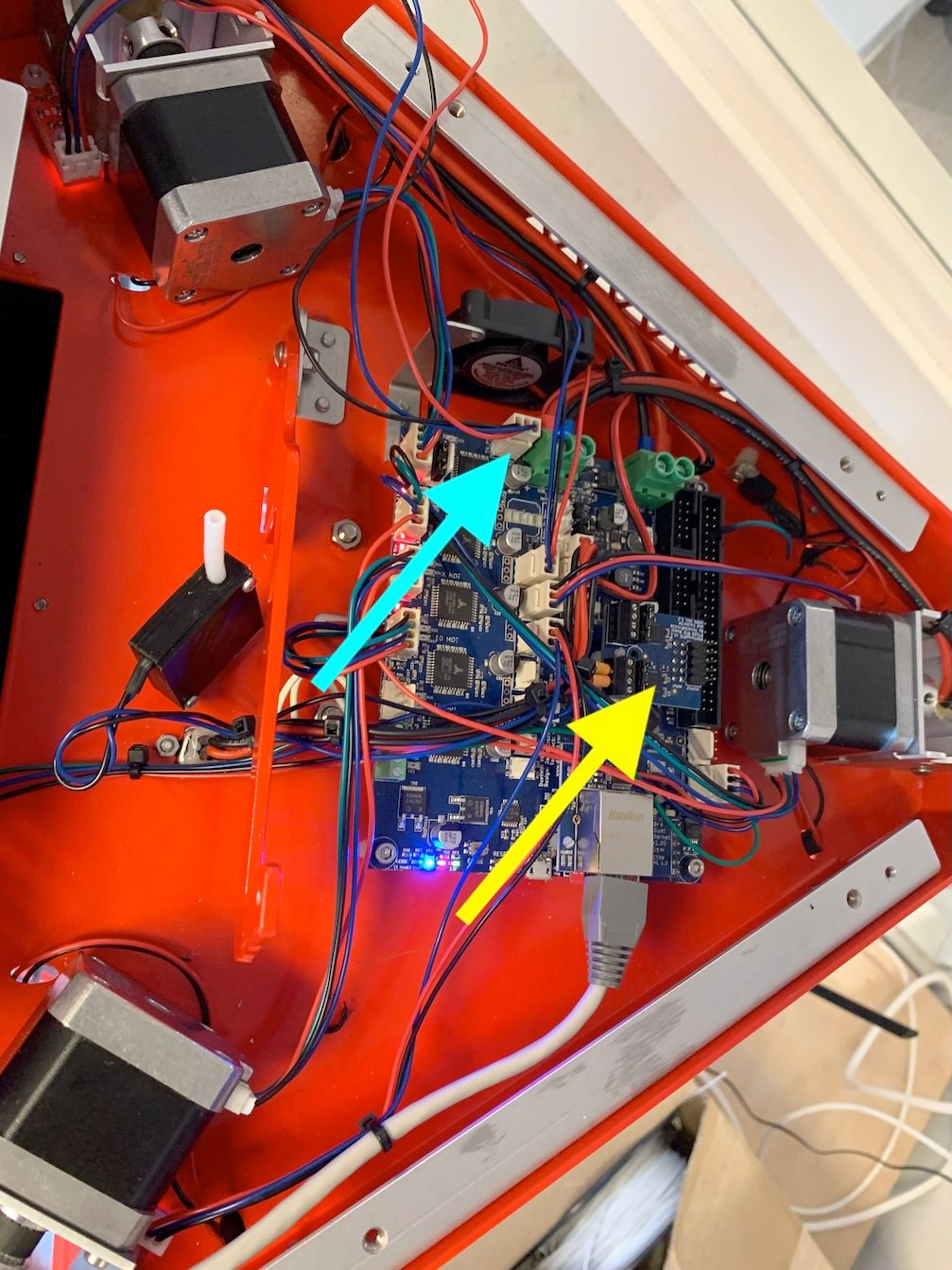

You can see my daughterboard (yellow arrow). I ordered a PT100 for a e3D.

-

undefined droftarts referenced this topic

undefined droftarts referenced this topic

-

@thomasvanderwal as RRF is reporting "Hardware error" I suggest you test the PT100 daughter board. The simplest way is to connect a 100 ohm resistor between the middle pair of terminals in the connector block (in place of the sensor wires that are currently connected there). That should give a reading close to 0C.

-

@dc42 My replacement for the thermistor is arrived. That solved the problem.

Calibration is now the problem. After setting the trigger height and z0 I wanted to Run Delta calibration. This is going well. But the mesh compansation is not going well : Error: G29: Probe was not triggered during probing move

The nozzle even goes besides the bed? I have in config.g : M557 R95 S10. The bed is 20cm in diameter,Z probing works fine. If I touch/push bed it gets a z-probe 1000 in stead of 0.

When I test a print it first touches the bed. Then it goes up a bit during moving. Than it touches the bed and then up again. It prints in the air. So the calibration is very wrong.

-

@thomasvanderwal said in Duet 2 v1.02 not responding:

Calibration is now the problem. After setting the trigger height and z0 I wanted to Run Delta calibration. This is going well. But the mesh compansation is not going well : Error: G29: Probe was not triggered during probing move

The nozzle even goes besides the bed? I have in config.g : M557 R95 S10. The bed is 20cm in diameter,As this thread is now well over 100 posts and does not match the description and initial issue, I think you'd have better luck starting a new thread for your delta calibration issue. You're more likely to get some helpful delta users to lend a hand with calibration.