Spirograph emulator with Duet2

-

I've generated a testfile with Sandify for a polar machine. But the file looks like classic cartesian coordinates with 0,0 at the bottom/left end instead of center.

Is RRF able to digest that on a polar bed?<edit> according to the Wiki XY-offset is not supported yet

Is it possible to use a G1.1 macro instead which does the post processing on the fly?; ; File name: 'PolarSandify' ; File type: gcode ; G1 X117.776 Y111.451 G1 X87.768 Y122.172 G1 X67.855 Y95.324 G1 X88.664 Y67.022 G1 X123.451 Y78.957 G1 X122.412 Y117.191 G1 X84.209 Y127.838 G1 X62.033 Y93.102 G1 X89.794 Y60.376 G1 X130.841 Y77.746 G1 X126.383 Y123.577 G1 X79.901 Y133.128 G1 X56.414 Y90.128 G1 X91.762 Y53.782 G1 X138.485 Y77.431 G1 X129.625 Y130.544 G1 X74.879 Y137.970 G1 X51.070 Y86.420 G1 X94.566 Y47.321 G1 X146.295 Y78.037 G1 X132.081 Y138.024 G1 X69.184 Y142.294 G1 X46.072 Y82.003 G1 X98.194 Y41.072 G1 X154.184 Y79.584 G1 X133.701 Y145.943 G1 X62.864 Y146.034 G1 X41.488 Y76.908 G1 X102.629 Y35.115 G1 X162.063 Y82.081 G1 X134.440 Y154.223 G1 X55.972 Y149.130 G1 X37.386 Y71.172 G1 X107.846 Y29.527 G1 X169.842 Y85.534 G1 X134.258 Y162.782 G1 X48.566 Y151.522 G1 X33.828 Y64.837 G1 X113.815 Y24.386 G1 X177.429 Y89.936 G1 X133.125 Y171.536 G1 X40.709 Y153.160 G1 X30.874 Y57.950 G1 X120.498 Y19.763 G1 X184.735 Y95.276 G1 X131.016 Y180.395 G1 X32.470 Y153.995 G1 X28.579 Y50.565 G1 X127.851 Y15.730 G1 X191.671 Y101.533 -

@o_lampe said in Spirograph emulator with Duet2:

according to the Wiki XY-offset is not supported yet

For polar kinematics, that is correct. However, you can use workplace coordinate offsets to adjust the position. See the G10 command with the L2 or L20 parameter.

-

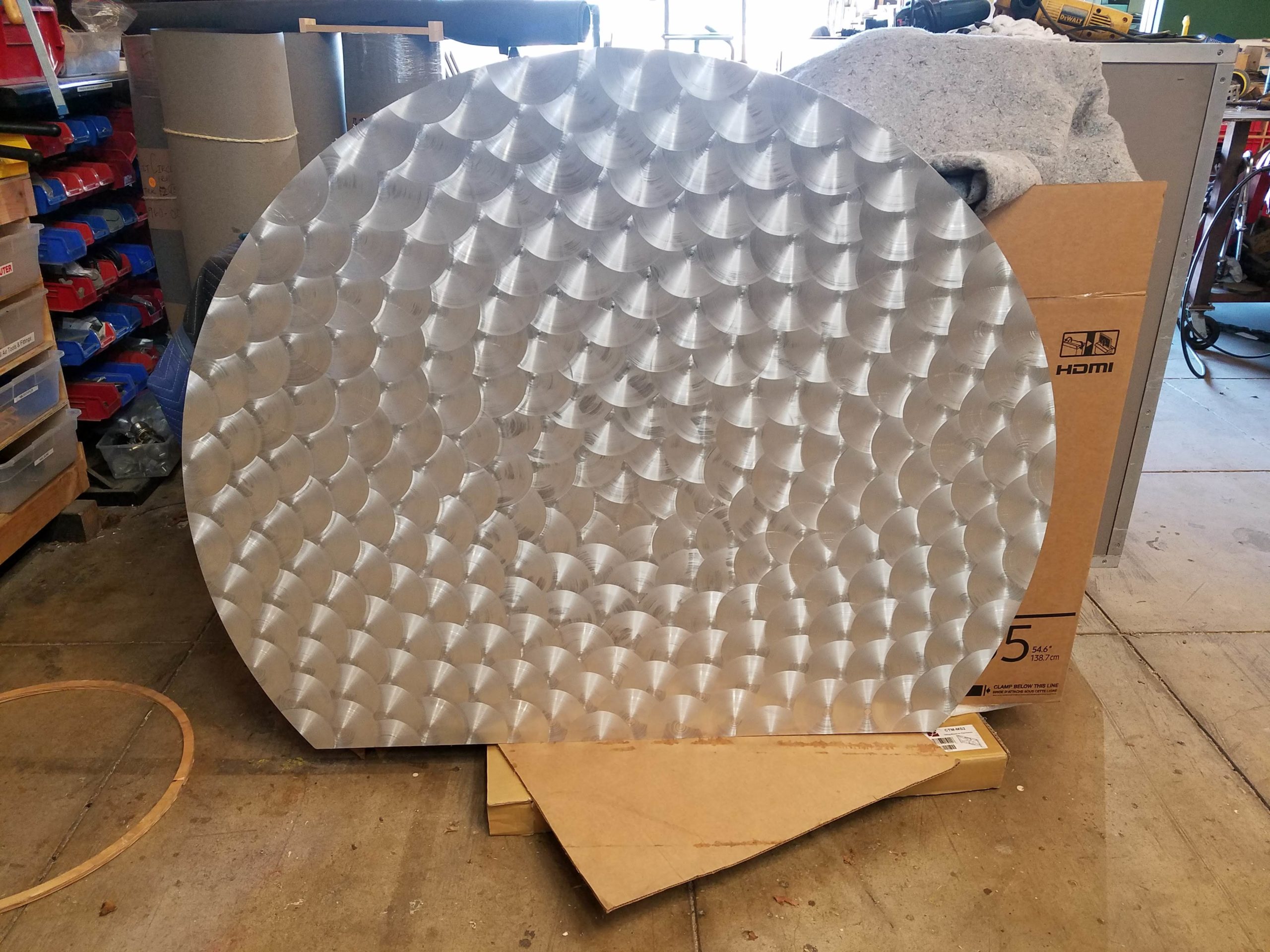

@o_lampe I've been thinking about building a machine that uses the sandify generated patterns to move a spinning abrasive head to do fancy engine-turning on metals.

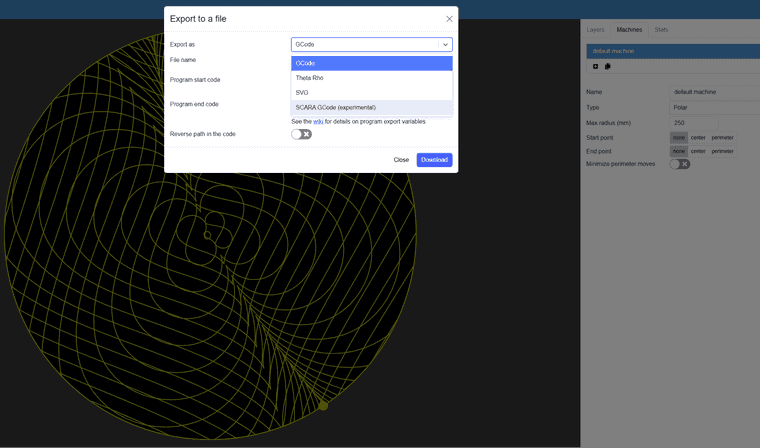

You can export the sandify patterns in different formats:

-

@mrehorstdmd My understanding is, when using polar printer kinematics, RRF internally converts regular gcode (XY based moves) into theta/rho values.

Brushed metal always looks great, but wouldn't it kill the brush, when it moves sideways while pressed on the sheet?

Guess what?!

My Boss has seen your Arrakis videos and now I have to build a sand table first

-

@o_lampe I would build the machine and alter the sandify patterns using a post processor, to press the spinning abrasive down and lift it up again at specified or calculated distances as it follows the pattern. But, it might also be create an interesting finish to drag it around while it is spinning against the metal.

There are abrasive "sticks" made for engine turning operations that wear away as they are used. They provide a consistent scratch size by controlling the diameter of the diamonds or other abrasive stones embedded in the stick. See: https://www.cratex.com/engine-turning-sticks

Are you going to use servomotors or steppers?

-

@mrehorstdmd said in Spirograph emulator with Duet2:

Are you going to use servomotors or steppers?

For the sand table my Boss donored a 60x40 window panel. It's the double walled/vacuum type.

I drilled a hole between the glass sheets and could fit a10mm steelball.

With a size like that, I guess steppers will do.

Fitting LED strips will be like building a bottle-ship, but without illumination it'll look dull.When I build an engraving polar machine later, it'll need strong motors. I think I use my favoured hoverboard BLDC motor with simpleFOCs step/dir interface.

-

@mrehorstdmd

I got 1kg of baking soda, but before I fill it in I want to know if I have to take any precautions.

What about air humidity?

Is static charge a problem?TIA

Olaf -

Maestro with M150 LED strips?

Another issue, I couldn't find answers yet. I want to use a Maestro board for the sand table, but couldn't find any info.

Is it the same NeoPixel/WS2812 pin as Duet2?

How many LEDs can I address? -

@o_lampe please be aware that we have stopped developing firmware for the Maestro, and there has never been official support for WS1812 or similar LEDs on the Maestro.

-

@dc42 Too bad, but understandable.

If I had more knowledge of the whole compiling stuff, I'd probably build a FW-version with only CoreXY support. No extruders, fans or z-probe stuff to free as much RAM as possible.I guess, I have to digg deeper in my HW-grave. IIRC I still have a FLY super8 with burnt bed heater FET.

-

@o_lampe Are you planning to put the sand and ball between the two glass sheets? That's going to be a problem for spreading the sand. Also with narrow spacing, you can expect some of the sand to stick to the top glass from static charges. You really want to be able to clean the top glass, by lifting it up or removing it completely. Also, if you put LED strips in a narrow space at the level of the ball/sand, the sand will end up blocking the light. I think you really want to have 50 mm or so between the two sheets of glass, and the LED strips should sit about 10-20 mm above the level of the bottom glass.

A steel ball rolling on glass is surprisingly noisy. I used a fake leather white vinyl cloth to cover the bottom of the table to reduce the noise, and to always leave the bottom of the grooves drawn in the sand white. I also use an air gap between the magnet and the bottom glass to prevent noise from the magnet dragging on the glass.

I use RGB LED strips that allow color changes, and typically operate with two different colors because I like the contrast, but white all around also looks pretty good and long as the illumination angle is low so the ridges in the sand cast shadows. A lot of people use addressable LEDs and create all sorts of light shows, but I find I want to watch the ball drawing in the sand and flashing lights quickly become hard to look at.

Humidity isn't usually a problem with baking soda. I find that if I don't run the table for a couple weeks, small lumps will start to form, but they crumble to dust the instant the ball runs again.

I'm probably going to end up building a new coffee table because I don't think my brother is going to give me the old one back. I will buy a glass top table at a thrift store, and then either modify the table or throw the table away and use the top for the top glass on the sand table. I'm going to try using dibond material for the bottom of the table- it's a lot lighter and cheaper than glass (custom sized glass), it's rigid, and I can cut it to the size I need. I'm not sure if it will create drag because of eddy currents generated in the aluminum by the moving magnet- it shouldn't matter at low speeds, but high speeds?