End Stop for high temperature coreXY - suggestion/advise

-

Hellooooooo ! Dear beauty of a community

...

...

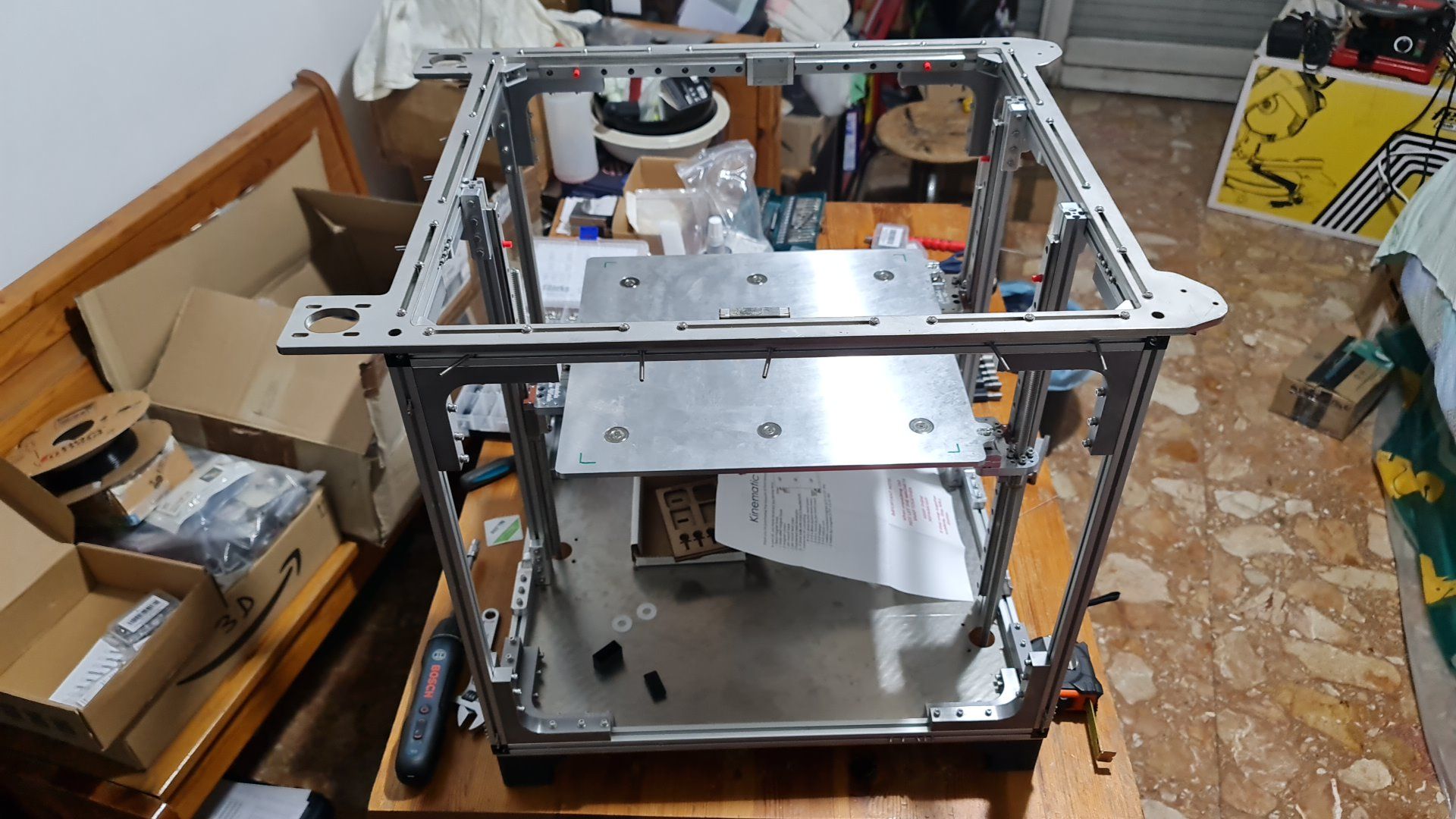

Im building (as reported lots of time ago) this "fine" piece of printer.

I'll open the proper 3D in the right section with all the spec , mods , developments etc etc.

The electronic are all Duet . With some structural customization , but the project is this one https://railcore.dozuki.com/c/RailCore_II

Now:

This thing would be designed for high temp material . The rails are Misumi for high temp (rated 140deg) . Rest is metal.

The problem I realized , the end stop ! Rest intended that I have to build their support but , which ones ?

The ones I found may resist and stay operational till 85 degree . But If I'll print policarbonate or peek this will be not enough (maybe) or too close the rated temp.

Do you have any suggestion on the right model suited for the task ? And maybe also where to buy them.

I'll need 7 of them. 2 for X , 2 for Y and 3 for Z .

Thanksss ! -

@giostark if you go to https://www.digikey.co.uk/en/products/filter/limit-switches/198 (or the Digikey site for your own country) you will find that you can select microswitches with a high maximum working temperature, up to 260C.

What is your planned maximum working temperature? If it's really as high as 140C then you might experience creep in your aluminium alloy extrusions. I recall that Concorde was limited to Mach 2.0 (reduced from the original target of Mach 2.2) because the maximum working temperature of the aluminium alloy used was (AFAIR) 120C.

-

@dc42

Thanks David!

The idea would be stay at max 100d in the enclosure. This should be enough for the material I'll go to print . But to have some margin can be useful , for safety and maybe upgrade. The link is very appreciate !

For peek I read that the enclosure should stay from 70 to 150d . I cannot effort the 150 target (because all the hardware limitation) but maybe a compromise is achievable and enough at the end.

I'm not in hurry to finish the printer so I would like build something that have sense and is coherent with all its parts.

I'll keep you informed on the progression of the selection and installation !

Cheer !!!