Extruder skips mid print randomly/Infill pattern problem

-

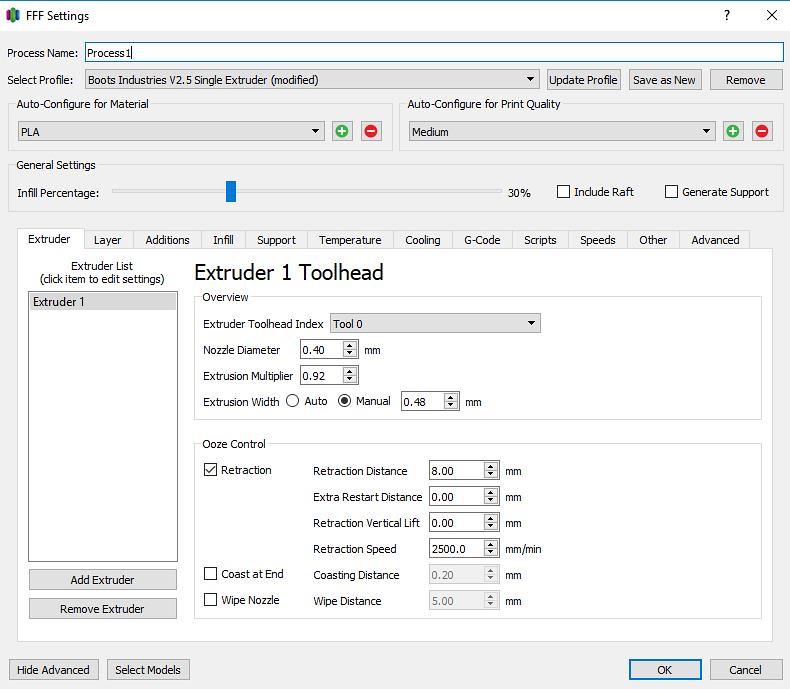

0.40mm nozzle, extrusion multiplier is at 0.88mm, extrusion width is at 0.48mm, layer is at 0.20mm

-

Have you calibrated your extruder steps? Maybe you're extruding more than expected, or maybe the current is not enough.

Are you sure mechanics is OK? I had that kind of extruder problems in the past due to several causes:

- Extruder not perfectly aligned with the extruder support (causes friction, so is harder to push)

- Bowden tube dirty (Not sure if you use bowden)

- Bad quality filament (bigger than expected, more friction inside Bowden tube… I've struggled a lot with this... spending a lot of time trying to print something, and then, change to another filament and printing it first try without issues...)

- Bad bed calibration (if the nozzle is closer to the bed than it should, motor struggle to push, it jumps, and there you have the several lines failure)

- E3d fan not working (yup, it happened to me... I need to disable it for bed levelling to avoid noise, and I've forgot to enable it again... now I'm using a macro to avoid those silly mistakes xD), this causes clogs in the hotend due to excessive heat in the heatbreak

- Clogged or partially clogged nozzle

I know how frustrating this can be... I had tons of weird issues =_=...

Cheers!

-

Have you calibrated your extruder steps? Maybe you're extruding more than expected, or maybe the current is not enough.

Are you sure mechanics is OK? I had that kind of extruder problems in the past due to several causes:

- Extruder not perfectly aligned with the extruder support (causes friction, so is harder to push)

- Bowden tube dirty (Not sure if you use bowden)

- Bad quality filament (bigger than expected, more friction inside Bowden tube… I've struggled a lot with this... spending a lot of time trying to print something, and then, change to another filament and printing it first try without issues...)

- Bad bed calibration (if the nozzle is closer to the bed than it should, motor struggle to push, it jumps, and there you have the several lines failure)

- E3d fan not working (yup, it happened to me... I need to disable it for bed levelling to avoid noise, and I've forgot to enable it again... now I'm using a macro to avoid those silly mistakes xD), this causes clogs in the hotend due to excessive heat in the heatbreak

- Clogged or partially clogged nozzle

I know how frustrating this can be... I had tons of weird issues =_=...

Cheers!

-Yes extruder has been calibrated, is pushing exactly 100mm when i push 100mm through.

-Bowden tube is brand new.

-It's brand new Hatchbox PLA 1.75mm (measuring at an average between 10 at 1.71mm

-Bed is completely level, as far as the middle part where i'm printing. getting a solid 0.20 first layer.

-The E3D fan is definitely working

-The 0.25mm nozzle I was using was brand new, and swapped it out for another brand new 0.25mm nozzle, then just recently swithed to a brand new 0.4mm nozzle.

-Extrusion multiplier is 100% correct. I calibrated 3 times in a row this morningYea I mean this isn't my first printer or first Delta printer. I know quite a bit, but i'm far from an expert. And i've literally changed everything that I know how to that would have something to do with it. I'm just stumped.

-

Does the problem occur at the same point each time you print the same GCode file, or at different points?

How have you connected to the printer: via networking, USB, or both?

What type of extruder are you using?

-

The problem occurs at random times, more frequently during the first and/or second solid layer and infill.

I have connected both ways, but never at the same time. Mainly through the network.

I am using the SeeMeCNC EZ Struder.

-

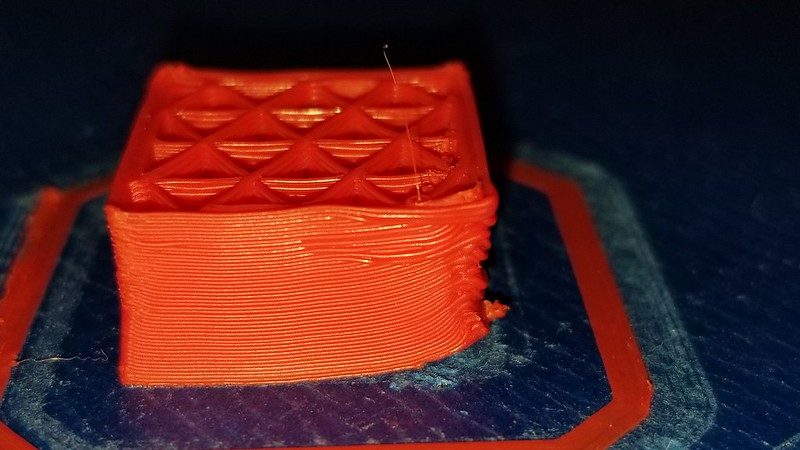

Here's a print I just did, it's all kinds of crazy

Test Cube3 by Sammy Saltalamacchia, on Flickr

Test Cube3 by Sammy Saltalamacchia, on Flickr -

Extruder tab by Sammy Saltalamacchia, on Flickr

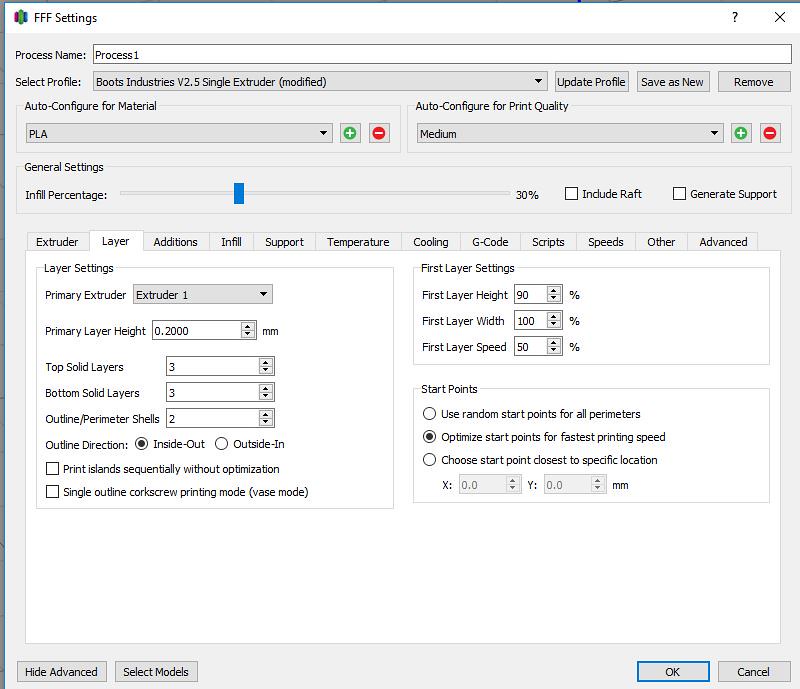

Extruder tab by Sammy Saltalamacchia, on Flickr Layer tab by Sammy Saltalamacchia, on Flickr

Layer tab by Sammy Saltalamacchia, on Flickr Infill tab by Sammy Saltalamacchia, on Flickr

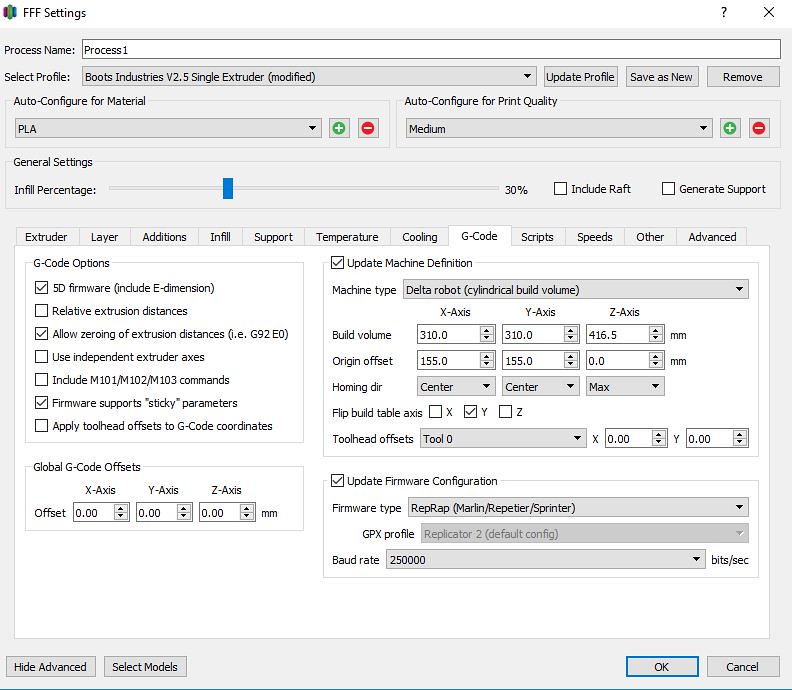

Infill tab by Sammy Saltalamacchia, on Flickr G-code tab by Sammy Saltalamacchia, on Flickr

G-code tab by Sammy Saltalamacchia, on Flickrconfig.g:

; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Mon Jan 01 2018 09:06:20 GMT-0500 (Eastern Standard Time); General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates…

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare

; Automatic saving after power loss is not enabled

M665 R252.412 L450 B145 H416.55 ; Set delta radius, diagonal rod length, printable radius and homed height ;was R252.412 L450 B145 H416.55

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them ;was X0 Y0 Z0

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops

M558 P4 X0 Y0 Z0 F2400 I0 T6000 ; Set Z probe type to switch and the dive height + speeds; removed H15

G31 P200 Z-0.811 ; Set Z probe trigger value, offset and trigger height

M557 R150 S20 ; Define mesh grid; Drives

M569 P0 S0 ; Drive 0 goes backwards

M569 P1 S0 ; Drive 1 goes backwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S1 ; Drive 3 goes backwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E92.5 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min)

M201 X5000 Y5000 Z5000 E1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Heaters

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Network

M550 PMy Guys v1.0 ; Set machine name

M552 S1 ; Enable network

M587 S"The Salt's-2G" P"TheGoodLife!0716!" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Custom settings are not configured

M501 ;Use config-override.g -

It's probably not related to your problem, but for RRF we recommend you check "Relative extrusion distances", un-check "Allow zeroing of extrusion distances", and include M83 in your slicer start GCode script.

-

It's probably not related to your problem, but for RRF we recommend you check "Relative extrusion distances", un-check "Allow zeroing of extrusion distances", and include M83 in your slicer start GCode script.

As you said it doesn't seem to be related to the issue, but I did make the suggested changes. Thanks.

-

Another print.

Test Cube4 by Sammy Saltalamacchia, on Flickr

Test Cube4 by Sammy Saltalamacchia, on Flickr -

I managed to get the print better, but the skipping that is happening is still ruining the prints. Any ideas?

-

I managed to get the print better, but the skipping that is happening is still ruining the prints. Any ideas?

Check your extruder stepper wires. It is possible you're only running on one coil because one wire is off , broken or otherwise disconnected. Also check you've got your current for that motor high enough.

-

I just had a look at the video and it looks a bit to me like the extruder does a retract but it's not followed by an unretract. Very odd behaviour…...

Check through the gcode file and see if you can spot any negative extruder moves that are not immediately followed by a positive extruder move. It looks like you are using 8mm retraction (which is a bit high) so you'll be looking for something like G1 E-8 followed by G1 E8.

Thinking about it a bit more, another possibility is that you are suffering from heat creep, causing the filament to swell in the area of the heat break. So when you do a (8mm) retract, it pulls some of the molten filament up beyond the heat break where it partially solidifies, binds, and prevents the extruder from pushing the filament back down during what should be the unretract move. A quick test would be to set retraction to zero (ooze control), slice it like that and see if things improve.

HTH

-

Ian's post alerted me to the fact that you posted a video, which I hadn't noticed before. I'm fairly sure that your extruder drive is skipping steps because it isn't producing enough drive force. That's why it doesn't skip on the outlines, because they are printed more slowly so less force is needed.

You are using an ungeared extruder, so this is not unusual. What model of stepper motor are you using to drive it? I see that you have the extruder motor current set to 800mA. If that's less than 85% of the stepper motor rated current, try increasing it.

-

Good catch David. I hadn't spotted the extruder steps per mm set to 92 which would indicate an ungeared extruder. Heat creep may also be playing a part which would be exacerbated by using an ungeared extruder. As you say, increasing the motor current if possible will help, as would changing to 24V if the OP is using 12V (couldn't see anything to indicate what the PSU is).

-

Changing to 24V won't help unless the motor is a low current high voltage one, because extruder motor speed isn't the problem.

-

That's true. I'd forgotten that we are talking about low speeds.

-

1. All of the stepper wires have good connections.

2. These are the exact motors I have. https://www.aliexpress.com/item/New-Arrival-5PCS-Wantai-Nema17-Stepper-Motor-42BYGHW609P1-Single-Flat-4000g-cm-40mm-1-7A-4/2047689916.html

3. 850 was my current, but someone had suggested to bring it down a little bit to see if there was a difference (brought it to 800, no difference)

4. It is all 12v. I am planning to upgrade at some point in the near future. Just wanted to get all the kinks worked out first.

5. At 92 steps it pushes out the correct amount of filament every time.

UPDATES:

1. I decided to hook up the FSRs and give it one more try ( i couldn't get it working right so went back to springs) and somehow am getting a GREAT skirt and first layer, but that jerk is not happening anymore, but it's still skipping but in a different way now.2. It's acting like the extruder is trying to give the hotend too much filament and it is forcing the filament to start popping out of the gear threads, which is taking pressure off of the filament and the filament stops coming out for those little periods then it catches back up and starts laying filament down again. It usually only stops for like 4-10 lines.

3. I turned retraction off. issue didn't change.

4. I brought the current back to 850. issue didn't change.

I appreciate you guys trying to help out. I'm at a concrete wall right now, and beginning to lose hope lol

-

What happens when you jack the current up to like 1.2 or 1.4A ?

Going from 800 to 850 is like nothing…50mA is nothing to these motors.

-

Check through the gcode file and see if you can spot any negative extruder moves that are not immediately followed by a positive extruder move. It looks like you are using 8mm retraction (which is a bit high) so you'll be looking for something like G1 E-8 followed by G1 E8.

HTHI looked through the code and I do see the "G1 E-8.0000 F2500"

the "G1 E8.0000 F2500" is a couple lines down.G1 E-8.0000 F2500

; layer 12, Z = 2.380

; inner perimeter

G1 X9.280 Y-9.280 F4800

G1 Z2.380 F1000

G1 E8.0000 F2500