Are Z Motors slipping or are motors worthless?

-

I have two motors for my Z axis using the RRF Configurator for my X and Y motors the steps per mm is 160

for Z using the calculate steps per mm tool I get 4266.667 steps for Z I have a M8 lead screw with a 1.5mm pitch.If I try to do a +10 on the Z axis they start to move then stop turning making a noise like they are slipping. Well the shafts are not turning.

Is the problem with the step 4266.667 or is the accelaration maybe to fast?

I used, just to test, a 160 for Z and even if i do a +100 there is no problem.Or are motors worthless?

-

Maybe you are trying to move them too fast?

David provided a spreadsheet to work out the speed at which torque starts to drop off:

https://www.dropbox.com/s/5z66rgjc8gptn5o/StepperMotor.ods?dl=1EDIT: It was found here: https://duet3d.com/wiki/Choosing_stepper_motors

-

Yes, you probably have the acceleration or max speed set too high. My Ormerod has 4000 Z steps/mm and I have these settings:

M201 X1200 Y1200 Z20 E1000 ; set accelerations

M203 X12000 Y12000 Z250 E3600 ; set XYZ and extruder speeds

M566 X1800 Y1800 Z40 E300 ; Maximum instantaneous speed changes mm/minute -

Are your lead screws single start? The pitch is meaningless, it's the lead that is important. It just happens that with single start threads the lead happens to be the same as the pitch so many people use the term pitch for lead. So for example if the screws were two start 1.5mm pitch, then the lead would be 3mm, for 4 start it's 6mm etc.

Assuming they are single start screws, with 1.5mm lead then for a 1.8 degree motor (200 steps per rev) the steps per mm at 16X micro stepping would be 200/1.5*16 = 2133.333. As you are using 4266.667 then that would indicate that you are using 0.9 degree motors (400 steps per mm) and 16X micro stepping and that your screws are single start 1.5mm lead. Is that correct?

-

Thanks for the info will check as soon as I get home from work.

Ian will let you know specifics for the lead screws. I got them on motedis and yes I 'm using 0.9 degree motors.

If i rememer correctly the screws are 8 mm and the pitch is 1.5 mm.If if can get thinks all set and my last piece arrives I will do a test print this weekend.

-

It's a bit unusual to find multi start screws in 8mm diameter so they are most likely to be single start and in that case 1.5mm lead. Generally, if a only a pitch is specified but no "lead" then it's usually a sign that they are single start and the lead is the same as the pitch (although it remains a pet hate of mine that "pitch" is used when referring to lead screws). The important thing to know is how far a nut would travel along the screw in one revolution - that is the lead. The pitch is merely the distance from one thread peak to another.

-

If you are using 0.9deg motors on the Z axis then the speed may be voltage-limited, especially if you are using 12V power. See the link that Martin_S posted earlier.

-

Hi and thanks to all for your help,

the settings were way out of tune slowed down using david's setting and now it does not slip or lose torque

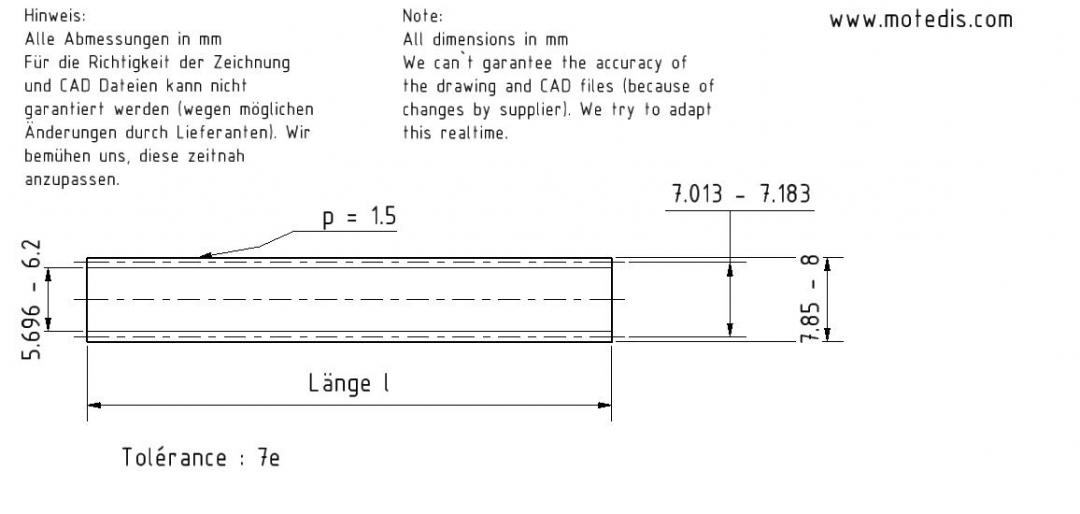

I also put back in the 4266.667 setting for the Z motors.here is the lead screw I am using right now

Ian from your calculations does that mean the setting is correct? So if i set movi 1 mm its moves one mm.

Will do some test to see.

Motors are

rated current 2.4

phase resistance 1

phase inductance 1.8

holding torque gcm 4200

lead wires 4

rotoe inertia 68

detent torque 220usings Martin_S's link i get this

Motor characteristics NotesMotor full step angle (degrees) 0,9 Normally 1.8 or 0.9

Phase inductance (mH) 1,8

Phase resistance (ohms) 1

Rated current (A) 2,4

Holding torque at rated current (N.cm) 42 To convert Kg.cm to N.cm, multiply by 9.8How you are using them

Steps/mm @ 16x microstepping 160 Specify this at x16 microstepping even if you are using a different microstepping

Factor for printer geometry 1,7 1 for Cartesian, 1.414 for CoreXY, approx. 1.7 for delta

Actual current (peak per phase) 1 Usually 60% to 85% of rated current

Number of motors connected in series 1

Driver supply voltage 12 Usually 12 or 24

Driver voltage drop 1 Usually about 1VResults

Speed at which torque starts to drop (mm/sec), low slip angle 143.2 These are for the worst case moves (diagonal move for CoreXY, radial move opposite a tower for a delta)

Step pulse frequency at this speed and x16 microstepping 39,0

Speed at which torque starts to drop (mm/sec), high slip angle 189.7

Step pulse frequency at this speed and x16 microstepping 51,6 -

….............I also put back in the 4266.667 setting for the Z motors.

'''''''''''''''Ian from your calculations does that mean the setting is correct? So if i set movi 1 mm its moves one mm.

Short answer - Yes.

Long answer - the drawing is a bit naff but as there is no information as to the number of thread starts (1,2 or 4 being the most common in that order) then it's probably safe to assume that it's single start. If it was 2 start, then you'd get twice the amount of movement for the steps per mm that you have, but it would also require twice the torque, which in a long rambling way, brings me back to the reason I asked in the first place. i.e. a course lead screw requires more torque to move it than a fine lead screw.

BTW. With that lead, and those motors 400 full steps gives you 1.5 mm of movement. So 1mm would take 266.666 recurring full steps and 0.1 mm would take 26.666 recurring full steps. It's generally not a good idea to rely on micro-stepping for positional accuracy so I suggest you use layer heights that can be achieved using full steps. Use multiple of 0.03 mm because 0.03 mm would use 8 full steps. So 0.09 is good as it uses 24 full steps, but 0.1 is not so good as it uses 26.666 recurring. 0.2mm layer height uses 53.3333 full steps but 0.18 or 0.21 are both good as they use even multiples, and what is probably the most common layer height of 0.3mm is also good.

HTH -

Great thanks for all the help, just tell me when you say use layer heights like 0.3mm are you talking about the slicer?

also what is the best all around slicer? -

Great thanks for all the help, just tell me when you say use layer heights like 0.3mm are you talking about the slicer?

also what is the best all around slicer?Not 0.3.

0.03

-

It's a bit unusual to find multi start screws in 8mm diameter so they are most likely to be single start and in that case 1.5mm lead. Generally, if a only a pitch is specified but no "lead" then it's usually a sign that they are single start and the lead is the same as the pitch (although it remains a pet hate of mine that "pitch" is used when referring to lead screws). The important thing to know is how far a nut would travel along the screw in one revolution - that is the lead. The pitch is merely the distance from one thread peak to another.

8mm 4 start leadscrews are pretty much the defacto standard for Prusa and it's clones.

https://www.google.com/search?q=t8+lead+screw+8mm&ie=utf-8&oe=utf-8&client=firefox-b-1 -

Sorry my bad, 0.03 it is.

-

Sorry my bad, 0.03 it is.

Multiples of 0.03 for your lead screws.

You wouldn't want to print with a layer height of 0.03 mm as it is much too small unless you have a really tiny nozzle diameter like 0.1mm. As a rule of thumb, selecting a layer height that is about 70% of the nozzle diameter will give the best compromise between quality and speed. As the most common nozzle sizes are 0.4mm and 0.5mm, then most people choose a layer height of 0.3mm which will work fine for you. However, for more detailed parts people often reduce the layer height to 0.2 or even 0.1 mm. These values wouldn't be ideal for you, as you would then be relying on micro stepping for positional accuracy. So instead of 0.1mm choose either 0.09 or 0.12 and instead of 0.2m choose either 0.18 or 0.21mm.

HTH -

8mm 4 start leadscrews are pretty much the defacto standard for Prusa and it's clones.

https://www.google.com/search?q=t8+lead+screw+8mm&ie=utf-8&oe=utf-8&client=firefox-b-1Really? Sorry my bad - I didn't know that. I'd have thought that Prusa would have had more sense. (for the reasons set out in my blog here https://somei3deas.wordpress.com/2017/01/31/z-axis-lead-screws/))

-

Thanks Ian for the additional info, also read your blog. Well written asnd I liked it.