Creality CR-10 upgrade

-

I have unbranded chinese psu which is loud and i am not comfortable leaving machine on with it. I was looking at meanwell psu's and thought, what will i need to swap if going 24V? Hotend heater? My bed is ac driven by ssr which is upto 36v.

I have 4 nema 17 and 1 nema 23 motors, would 150w be enough cause i dont need to drive the bed heater. -

To change from 12V to 24V you need to change any heater to 24V (in your case just the extruder heater cartridge(s)), also any fans if they are currently 12V fans. There are ways of using 12V fans, but it is usually simpler and costs very little to replace them with 24V fans.

A 150W PSU should be adequate if the bed heater is separately powered.

-

I will look into buck converters as noctua does not have 12v fans. I seen you mention somewhere how to wire it. Thank you

P.S. Here is what i found you wrote:Yes, that will work. Alternatively, if all your fans are 12V, then you can remove the V_FAN voltage selection jumper, connect the +12V output of the buck converter to the centre pin of the V_FAN voltage selection block, and connect the fans as normal.

So its a V_FAN jumper select. Then i connect step down converter to 24V PSU and 12V out to V_FAN pin with removed jumper. This is if converter is not isolated. Am i correct in this?

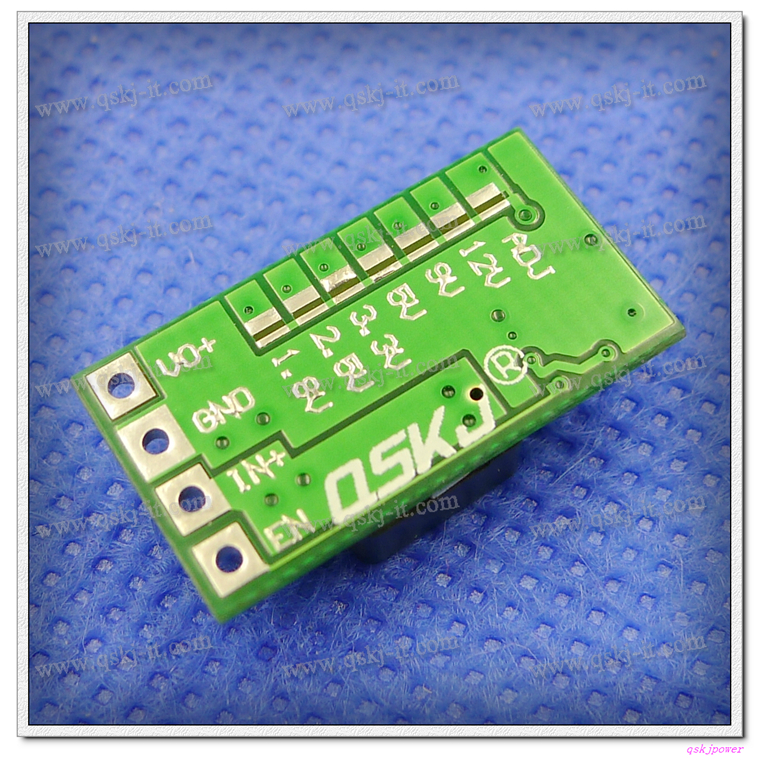

https://www.ebay.com/itm/2A-DC-DC-Buck-Step-down-Adjustable-Converter-Module-5-24V-to-1-8V-3-3V-5V-9V-12V/132109827948?hash=item1ec25bff6c:g:ODQAAOSwB-1YtB3B

I think this would be cheaper option and i will retain more common 12V fansBTW, i have set up printer with Prusa's induction probe and i have consistent Z where i can print without doing fine tuning each time. Probe sits too close to the bed for my liking but it works very good with consistent first layers. I just had 30h print and now running another production print which might take 90+h. Very happy all is running finally.

Would 24V will allow for power loss resume printing? Is it reliable or better not to bother?

-

Hi. Getting strange behavior on my filament runout. I have simple microswitch and i get random pause.

This is my filament runout:

M591 D0 P2 C4

I was wandering if anything else could cause pause on a print other than M591?

I tried M591 S0 while printing and while at pause then resuming a print but it still pauses after some time. -

A heater fault will also pause the print.

If you look in the GCode Console page of DWC, there should be a message giving the reason for the pause.

-

Having another issue.

When i log in to DWC from android phone, there is no button to upload gcode files. Tried multiple browsers (opera, chrome). -

@agniusm said in Creality CR-10 upgrade:

Having another issue.

When i log in to DWC from android phone, there is no button to upload gcode files. Tried multiple browsers (opera, chrome).That is correct but it is not really a bug - in fact there is just not enough space to display all the upload buttons in the same way as on on desktop PCs. I've never heard of anyone trying to upload G-code files on a cell phone so I haven't considered to add it back yet. How do you get the G-code file on your smartphone?

-

Well, was one of the reasons i bought wifi. My printer is off site doing 60h prints 24/7 and sometimes i need to update gcode files with improvements and that button is vital.

What do you mean how do i get it on the phone? That question would probably be relevant back in 2006 Here:

Here:

Via usb

Via flash drive and usb converter

Via micro sd

Via lan network sharing

Via remote desktop (team viewer)Now its a pain. I have to shutdown, pull out sdcard, pu it into my phone etc.

Another note is that it does not appear not only on mobile version of dwc but full one as well on smartphone. Weird -

DC42, is there a way to set duet port othe than 80? I see it was possible with older releases. Having no option on mobile device to upload gcode files i got couple router and ubiquiti is using 80 for web interface so i need something else on duet for port forwarfing

-

I would also strongly request adding upload option from modile devices.

-

@agniusm said in Creality CR-10 upgrade:

DC42, is there a way to set duet port othe than 80? I see it was possible with older releases. Having no option on mobile device to upload gcode files i got couple router and ubiquiti is using 80 for web interface so i need something else on duet for port forwarfing

See the description of the M586 command in the GCodes wiki page.

-

@agniusm said in Creality CR-10 upgrade:

I would also strongly request adding upload option from modile devices.

Please make that request in the DWC Wishlist section.

-

So my upgraded printer is working 24/7 great. Had a fan failure but that was to be expected with cheap chinese stuff. Got a small issue i was putting off for some time. i have mesh compensation in place and it works great but i have my front off the bed not completely working with this.

Here is 2 same run parts, one from the middle of the bed(rest are same good) and one from the front (on the right). The nozzle is a tad off when printing on the front of the bed:

I was wandering where i should look for the issue? I know my grid is set wrong as it misses some points(skips them). Would that cause an issue?

Otherwise i am very happy with Duet hardware and the way i can edit my configs on the fly, i can really appreciate that now since i am working on Marlin firmware for my budget cluster.

P.S. perhaps the tool to calculate mesh grid appeared for square build plates? That would be handy. or is there any plans on automatic calculation of the mesh? Say you enter how many grid points on x and y and it sets spacing? Would be even better. i think Marlin does that

-

@agniusm said in Creality CR-10 upgrade:

I know my grid is set wrong as it misses some points(skips them). Would that cause an issue?Any probe points that cannot be reached by the probe (taking into account the machine limits set by M208 and the Z probe offsets set by the G31 X and Y parameters) will be skipped.

P.S. perhaps the tool to calculate mesh grid appeared for square build plates? That would be handy. or is there any plans on automatic calculation of the mesh? Say you enter how many grid points on x and y and it sets spacing? Would be even better.

Good idea, I'll add it to the work list.

-

David, we were brainstorming a method for e3d toolchange and how we can automate tool offsets for different tools. Perhaps you have a solution but i got an idea i would like to test as it is relevant to me too.

I want to mount precision piezo disc on my frame where my extruder can reach and probe it to set the height of the nozzle then use inductive probe for mesh mapping. This way, each time i swap the nozzle, i dont have to readjust z offset as even quarter turn of the nozzle throws calibration away.

How can i implement this in duet settings? -

Have you looked at https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M585_Probe_Tool ?

-

Actually just yesterday was going through gcode wiki and saw this one. I will investigate.

-

@agniusm said in Creality CR-10 upgrade:

David, we were brainstorming a method for e3d toolchange and how we can automate tool offsets for different tools. Perhaps you have a solution but i got an idea i would like to test as it is relevant to me too.

I want to mount precision piezo disc on my frame where my extruder can reach and probe it to set the height of the nozzle then use inductive probe for mesh mapping. This way, each time i swap the nozzle, i dont have to readjust z offset as even quarter turn of the nozzle throws calibration away.

How can i implement this in duet settings?Are you using E3D hotends? The nozzle should tighten against the heat break so provided the nozzles are all the same length from end to tip, they should all tighten to the same distance.

-

@tjb1 Yes. Using e3d. Even if so printing different materials can have impact(thermal expansion) PLA vs PC can be 100C difference. This idea came thinking about e3d toolchanger. I was not specifically wanting to do this on my machine, but I had precision piezo kit and thought I will test the idea. Actually it will be handy if it works the way I think. Sometimes I need to change a fan and it is mounted with induction probe. Even if I do not touch induction probe out of the clamp it still needs recalibration.

@dc42 I want to place my probe slightly below my bed so it is out of the way. So my macro should look something like this:G28 ; home

G10 P0 Z0 ; clear Z offset

T0 ; select a tool

G1 X430 Y0 Z10 F3000 ; move above probe

M585 Z F400 E2(cant remember which is asignet to z stop(2?) and which to z probe) ; drive into probe

M500 ; save new offset

G1 Z20 ; lift the tool not to drive into bed edge

G28

M98 Pmeshbed.g

One thing I'm not sure about how to add extra distance if my probe is say 10mm below my bed. -

@agniusm said in Creality CR-10 upgrade:

One thing I'm not sure about how to add extra distance if my probe is say 10mm below my bed.

You could use G1 to move the nozzle to be above the switch at Z=5. Then send G92 Z15 to pretend it is at Z=15. Use the M585 command to probe the switch. Then do G1 Z15 followed by G92 Z5 to remove the 10mm Z offset.