Core XY Judder & Slowdown on Circle

-

Hi All,

I'm getting a slow down and judder at the four sections of a circle that are close to parallel to the axis, ie the 12, 3, 6, and 9 O'clock positions. Seems to only happen at one of the speeds used in my print which I think is the first two contours of the three perimeters. I've currently got this set to 80. Is this simply to high to print without the judder? The external contour is printed with smooth head motion at 40.

I think these are the critical bits of the config file:

M92 X200 Y200 Z400 E830 ; Steps/mm

M566 X450 Y450 Z30 E1500 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000 Y12000 Z600 E3600 ; Set maximum speeds (mm/min)

M201 X3000 Y3000 Z250 E3000 ; Set accelerations (mm/s^2)

M906 X1400 Y1400 Z900 E1400 I30 ; Set motor currents (mA) and motor idle factor in per centOn top of this Slic3r is set to reduce the acceleration on the following geometries:

Perimeters 1000

Infill 1500

Bridge 1000

Default 1000...so in other words it's only the jumps/travel moves that are making use of the full 3000 acceleration.

Edit: Here is the motor https://e3d-online.com/high-torque-axes-motor

-

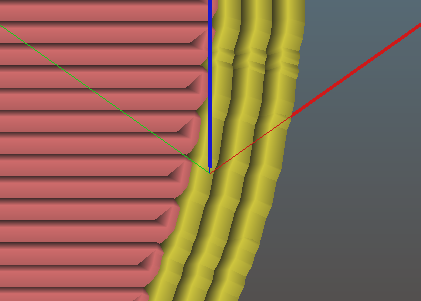

The raw stl file doesn't help matters. The circular edge looks very voxelated for lack of a better way of putting it and this does place the juddery sections parrallel to the axis. I'ts interesting that the judder causes slowdown with the 80 mm/sec speed, but not 40. Presume this is my jerk settings becoming the limiting factor? Do the settings look about par for the course?

This is the works machine which started out as the thingverse spauda d-bot but has had an additional screw for the z, extra z-axis wheel guides, and direct extrusion head with a Bondtech BMG.

-

I believe the M566 jerk setting would need to be increased to get smoother motion on small circles.

-

Wes,

Not by any chance using pressure advance are you? If so try turning it off and see if that helps.

-

@timcurtis67 We could do with a staw pole on these values. I thought I was running close to the upper advisable limits?

Edit: This circle is about 60mm diameter.

-

@deckingman Hi. Will try a couple of layers with it off next time I'm in work thanks.

-

@doctrucker said in Core XY Judder & Slowdown on Circle:

@timcurtis67 We could do with a staw pole on these values. I thought I was running close to the upper advisable limits?

Edit: This circle is about 60mm diameter.

60mm circle is pretty big. I'll bet it's what Ian (@deckingman) said, It's probably a pressure advance issue.

-

In a way, I do hope it's a pressure advance thing - it'd be good to know that I'm not the only one who has problems with it (starting to get paranoid

).

). -

@deckingman said in Core XY Judder & Slowdown on Circle:

In a way, I do hope it's a pressure advance thing - it'd be good to know that I'm not the only one who has problems with it (starting to get paranoid

).

).Ian, I have abandon pressure advance for now myself. I just never got it working as good as I would like on all area's of my prints.

Disclaimer, I'm not saying pressure advance is bad, just saying it's not for me in my setup.

-

@timcurtis67 said in Core XY Judder & Slowdown on Circle:

@deckingman said in Core XY Judder & Slowdown on Circle:

In a way, I do hope it's a pressure advance thing - it'd be good to know that I'm not the only one who has problems with it (starting to get paranoid

).

).Ian, I have abandon pressure advance for now myself. I just never got it working as good as I would like on all area's of my prints.

Disclaimer, I'm not saying pressure advance is bad, just saying it's not for me in my setup.

Likewise. For anything other than slow prints (less than 60mm/sec) , it really helps cleaning up the over/under extrusion that I get at the start and end of each (longish) move. But for whatever reason, my Diamond hot ends need a lot of it - like 0.4 to 0.5. However, this causes havoc for me when doing circles or arcs. It used to be just with multiple extruders but since about Jan of this year, it's been causing havoc using just a single extruder. So I've had to turn it off (and print slow). But this is all the subject of a different (and very long) thread.

-

I've created a simplified gcode file to demonstrate the problem. Be aware that this does set non-linear extrusion & pressure advance in this file. It also uses volumetric extrusion and firmware advance & retract.

Interesting dive through the gcode there and noticed a few things. It's using the support settings for the outer skirt and the jumps between perimeters are done at travel speed which explains the stutter between the contours but not the judder on the faster perimeters. I'm guessing (/hoping) there is a setting somewhere to avoid attempting a travel speed jump between perimeters. Ideally I'd like it to set a maximum speed for the move which is attainable for a proportion of the move rather than flat out accelerate and decelerate with no steady state...

-

...and here's a video from the original build:

-

Did you try it without pressure advance? Also without volumetric extrusion?

I would try it without either one (one at a time) to see which has the biggest effect.

I don't believe Acceleration or jerk settings will make much difference here. I never tried volumetric extrusion so I'm not sure how that would/wound not factor in but I'll bet Ian (@deckingman) was right with it having to do with pressure advance at the higher speeds.

-

@timcurtis67 Not tried either yet. The last couple of posts were sharing a cut down version of the problem file and a video of the problem. I'm working from home today & tomorrow, but will be in to check it out further early next week. I've got a gut feeling that it's a poor slice file issue that's colliding with the something like the pressure advance/jerk/speed settings/etc.

-

@doctrucker said in Core XY Judder & Slowdown on Circle:

@timcurtis67 Not tried either yet. The last couple of posts were sharing a cut down version of the problem file and a video of the problem. I'm working from home today & tomorrow, but will be in to check it out further early next week. I've got a gut feeling that it's a poor slice file issue that's colliding with the something like the pressure advance/jerk/speed settings/etc.

What I get with Slic3r is that it seemingly randomly generates differing segment lengths for circles and arcs. What I also get is that seemingly randomly, pressure advance triggers multiple times during circles and arcs, causing the print head to jerk, stutter, and generally misbehave. I can't help thinking that two are related (I hate coincidences).

-

@deckingman That certainly makes sense yes.

I've potentially added a poor STL file to this pile of challenging situations. As you follow the anti-clockwise perimeter where there should be all left hand turns there's a few rights with sharper lefts after them rattling the head about a bit creating the situation where pressure advance becomes active, and potentially exacerbates my problem.

-

@deckingman said in Core XY Judder & Slowdown on Circle:

@doctrucker said in Core XY Judder & Slowdown on Circle:

@timcurtis67 Not tried either yet. The last couple of posts were sharing a cut down version of the problem file and a video of the problem. I'm working from home today & tomorrow, but will be in to check it out further early next week. I've got a gut feeling that it's a poor slice file issue that's colliding with the something like the pressure advance/jerk/speed settings/etc.

What I get with Slic3r is that it seemingly randomly generates differing segment lengths for circles and arcs.

Ian, do you think that slicing with a different slicer would produce different results? It may be worth testing.

-

@timcurtis67 said in Core XY Judder & Slowdown on Circle:

@deckingman said in Core XY Judder & Slowdown on Circle:

@doctrucker said in Core XY Judder & Slowdown on Circle:

@timcurtis67 Not tried either yet. The last couple of posts were sharing a cut down version of the problem file and a video of the problem. I'm working from home today & tomorrow, but will be in to check it out further early next week. I've got a gut feeling that it's a poor slice file issue that's colliding with the something like the pressure advance/jerk/speed settings/etc.

What I get with Slic3r is that it seemingly randomly generates differing segment lengths for circles and arcs.

Ian, do you think that slicing with a different slicer would produce different results? It may be worth testing.

Let's just not go down that road Tim. It might well be a solution but I've tried them all and none would be any good to me. I need support for 5 extruders minimum. I need to be able to easily switch between different machine profiles (3 extruders, 5 extruders, a single extruder) any or all of which could have different nozzle sizes, and I need to be able to switch between those machine profiles without having to set up filament parameters and print settings (speeds and so forth) for each machine profile. I also need firmware retraction. I need to easily be able to assign different extruders (tools) to different parts of a model (to print in multiple colours). Slic3r is the only one that'll give me that. So although another slicer might help with the pressure advance issue, I won't be able to print the things that I want to print for a number of reasons.

Plus I don't think anyone wants the situation where the firmware only works with certain slicers. Slic3R has it's faults but so does every other slicer.

-

@deckingman Agreed.

-

I had another crack at this today. I changed my jerk speed from 450 to 900 in x and y amd things improved a lot. Tried with and without pressure advance and with old and new jerk settings. In this instance increasing the jerk smoothened things out a lot. I can't say if with or without pressure advance had much of an effect, but certainly not as much as increasing jerk.

In summary I think the rough path from the poor stl file caused the angle to increase between some of the bectors to the point where the head needed todo a full stop rather than applying jerk.