Safety Relay for AC bed heater

-

I am using a thermal fuse connected to a relay that will disconnect AC power to the machine in the event of over-temp....

Some rtv silicone should do the job

-

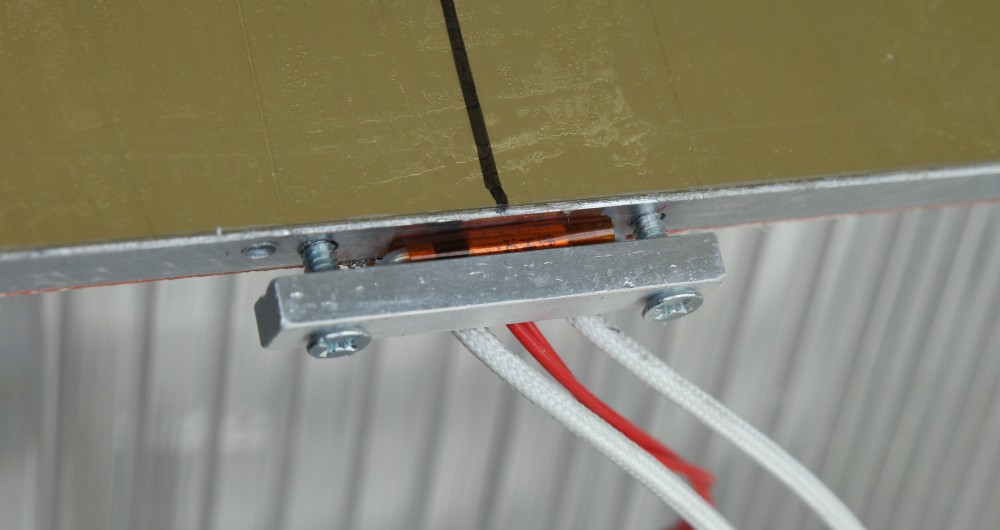

I don't know how your bed is made, but I attached a TCO to the edge of the 8mm tooling plate bed in my printer with a couple screws and a piece of scrap aluminum. It might be better to attach it to the heater itself using high temperature silicone. That way, if the adhesive holding the heater on the plate lets go, the TCO will stay with the heater and do its job.

I think that relying on active measures makes a lot of assumptions. If the controller loses its mind and leaves the bed heater switched on, will your relay system work? -

@mrehorstdmd I agree that I could use a thermal fuse and simply sticking it to the bottom of the silicone heater would work.

On the other hand I could feed a 24v relay directly off the power supply through an E-stop contact and then the thermal fuse, avoiding potentially exposed AC voltage in the event of adhesive or silicone breakdown. This would be preferable.

But, the idea of redundant, not active, disconnects is widely used and commonly accepted in industrial equipment. I may end up using both a relay driven from a fan output and a thermal fuse. I'm a bit concerned at the idea of the controller holding an output ON in the event of a fault. This should generally be one of the first potential problems addressed in development of a controller. If you're suggesting that this is remotely possible I may look at a different controller.

I did some failure testing on a few ramps 1.4 cheap clones and a MKS S-base and tried to lock up the processor and could never get any heater to fail on. Example: running from SD and removing the SD or running from USB and unplugging the cable mid heatup on both bed and extruder and during a print. Heaters all shutdown.

If this is actually a concern I hope to see some input from developers.

-

@betterhalf I would think the Duet is at least as good and very likely much better than Ramps in this regard.

https://duet3d.dozuki.com/Wiki/FireSafety

According to this you may be better off using the PS_on pin rather than a heater pin for your relay.

-

@betterhalf said in Safety Relay for AC bed heater:

I'm a bit concerned at the idea of the controller holding an output ON in the event of a fault. This should generally be one of the first potential problems addressed in development of a controller. If you're suggesting that this is remotely possible I may look at a different controller.

This is ALWAYS a possibility with anything controlled by a FET, other transistor, SCR, SSR, etc. If the component responsible for switching the current physically fails (usually burns), it may fail open or fail shorted. Every controller in the world is at the (approximate) same risk.*

If you are asking if the Duet controller has watchdogs, meaning checks for over temp and thermal runaway and unreasonable values from sensors, in its firmware code, then yes, Duet has tons. If you are asking if it has hardware timer watchdog to force a reset if the code is so locked up that the hardware watchdog expires, I actually don't know either way. Nor care. Because of the above issue, physical failure, there MUST be another layer of protection beyond any/all controller based things. Must for me, anyway.

Having an over-temp device, a physical device, either "one shot" or "self reset" on the bed is that layer, as far as I'm concerned. My mains supplied bed has an overtemp, installed by Keneevo when they built it. It is also very easy to install your own.

And, I have one more layer, that I sincerely hope never triggers: A fireball. These are fairly uncommon in the USA... they are a couple of kilos of the same powder found in a hand-operated fire extinguisher, wrapped around a very small black powder charge with fuses to the surface. If the surface is exposed to fire, within a few moments, the couple of kilos of power get blown over a meter or two circle. Extremely reliable self-triggering, no sensors or valves or pressure, the fire itself triggers it to spread the powder.

Here is one sitting on top of a large-ish delta.

* Some may debate that certain SSRs are known to fail closed, more than others. I'd offer that if the odds of a fail closed are non-zero, then another layer of protections is mandatory. Therefore, "approximately" the same...

-

@Danal the specified issue of "if the controller loses its mind" (@mrehorstdmd ) was interpreted as a software issue NOT a physical issue. I assumed that was fairly clear, my mistake.

But, yes I realize the any semiconductor switch can fail closed, that was the entire point of adding a mechanical relay. Also watchdog timers are pretty standard, I realize this. That is also why the idea of a duet failing ON in the event of a software fault was concerning. I understand the hardware basics, I realize electronic things fail, I'm trying to explore every possible safety option.

The fire extinguisher ball you use seems fairly similar to the charged nitrogen and bi-sodium carbonate fire suppression cannons used in industrial "dust collectors." I'm a controls engineer by trade and I have to look at remote possibilities for worst case scenario every day, so its become a bit of a habit.

The bed heater I ordered is from kenevo, I wasn't aware that they offered a self resetting overtemp device. All of the Thermal fuse style devices I have been able to locate are oneshot. If you have any suggestions on a supplier for self resetting thermal cutoffs that can be attached to a silicone heater such as digikey or mouser, I would appreciate your input (a link or partnumber).

I do appreciate everyone's input on using thermal cutoffs, but no one has answered the original question. I would still like to know if controlling a cutoff relay with bed heater enable is possible/feasible.

-

I was also unable to locate a self resetting. Keneevo stated they installed a self-resetting, but they did not specify which. I have not over-temped it to test that.

Were I to install myself, I'd just crimp a non-resetting one into each wire, and attach it to the bottom. If it ever over-temps, it would only take moments to replace. Maybe order 10 of them or similar.

-

The fire extinguisher ball does sound similar to the cannons you mention for dust collectors. Same basics.

One slight difference, and I I could easily be over-interpreting the words "charged nitrogen"... but one of the things I really like about the balls is that they contain nothing under pressure that could leak away. No gauge to be checked annually, etc. Just a small black powder charge that is ignited by the fire itself. Seems like a very reliable thing.

They are really designed for a person to toss or roll into a fire. I'm purely speculating... but I'm betting they were developed to help get past the fact that a regular extinguisher is most effective with a "base of flame" application from the operator. Unless a person has actually practiced this, it does not often happen in real fires. People almost always shoot at the most visible part, the upper part, of the flame.

The ball requires nothing from the person other than getting it into the fire.

Anyway... I like them as a final layer. I should also note, they are fairly pricey, at least the ones I've found available in the US, seem to run about $50.

-

@betterhalf said in Safety Relay for AC bed heater:

I do appreciate everyone's input on using thermal cutoffs, but no one has answered the original question. I would still like to know if controlling a cutoff relay with bed heater enable is possible/feasible.

I thought I had when I linked to the documentation which suggests using the ps_on pin instead.

-

@betterhalf said in Safety Relay for AC bed heater:

@Danal the specified issue of "if the controller loses its mind" (@mrehorstdmd ) was interpreted as a software issue NOT a physical issue. I assumed that was fairly clear, my mistake.

Actually, I was about 80 or 90 percent sure that's what you meant. I was just pointing out (in probably a too-long-winded fashion) that mains heated beds need a layer of protection totally separate from the controller/SSR... so adding a layer based on a different output of the controller doesn't really seem worthwhile.

Of course, it's hard to argue against layer after layer of protection... nonetheless, given the "sanity checks" that are already in the controller, physical over-temp cut out in the wiring to the bed*, and fire sense/suppress, having each layer be COMPLETELY separate from the prior, that seems to make more sense to me.

* It has been pointed out to me that a self-resetting physical over temp switch will just cause the bed to cycle around that max temp, and that the over-temp might eventually fail closed when cycling. So I am considering crimping a couple of "one shot" overtemp fuses into the wires. Maybe.

-

@betterhalf said in Safety Relay for AC bed heater:

I do appreciate everyone's input on using thermal cutoffs, but no one has answered the original question. I would still like to know if controlling a cutoff relay with bed heater enable is possible/feasible.

Yes, you could configure a fan output to be thermostatically controlled to trigger when the bed temperature exceeds a certain value, and set the I1 flag to invert the output.

-

@Phaedrux I did read the fire safety section on the wiki before my original post. That was part of my justification for using a relay cutoff. I wanted to keep the option of shutting down the dc power supply and I was looking at using a 24v relay (which I already have several) vs a 5v relay. The 24v relays I have available can be mounted in a relay base and have screw terminals. I am mainly looking at ease of use and parts on hand.

@dc42 Thank you for the confirmation. Setting a limit and disabling the output above that limit seems like a simpler approach to the same goal.

@Danal I did find some additional options for thermal cutoffs. I was initially only searching "thermal fuse" which gave me only oneshot devices. After searching for "thermal cutoff" or "thermal switch" I found some self resetting options, but most of them seem to go from 90-100c to 200c with very little in between. If I find something in the 110-120c I'll definitely add one.

Thanks again to everyone who gave input, I'll take it all into consideration during the build.

-

"the idea of redundant, not active, disconnects is widely used and commonly accepted in industrial equipment."

The other thing that's even more common is to have fail-safe cutoffs like TCOs and fuses (and is probably required for every type of safety certification there is). If you use a relay, whatever drives it has to be guaranteed to be working when the temperature control mechanism fails. The controller that drives the relay is also the brains of the temperature control mechanism. If the temperature control portion of the controller fails, what makes you think that the part that controls the relay will still be working? Can you guarantee that the controller will work if there's a bug in the code, one of its components fails, if there a lightning strike on the power line, or someone spills a soda on the machine?

I wouldn't use a self resetting TCO as a safety device, either. If there's a dangerous condition that causes the bed temperature to get out of control, you want power to the bed to be cut until the source of the problem is discovered and repaired. Automatically reconnecting the power to a failed system is not safe. The one-shot TCO I used cost about $1 and takes about 10 minutes to replace. That's the cheapest insurance I'll ever buy.

I'm not saying don't use a relay. I'm just saying if you're going to use a relay, use a TCO and a relay. If you're choosing one or the other, choose the TCO because there are fewer and more unlikely scenarios in which it will fail to do its job. If you use both, set the temperature threshold in the relay driver lower than the TCO operating temperature so that the relay kills power first (if it is still working when the temperature control is lost). If that system fails and the temperature keeps rising, the TCO will open before a fire is started.

When you select a TCO, be sure it is rated for the current your bed requires and choose the operating temperature per the instructions on the data sheet or manufacturer's ap note. These devices self-heat, and the nature of their construction requires that the operating temperature be set higher than the highest anticipated use temperature. In my case, I wanted the bed to be usable up to 160C, and ended up with a TCO operating temperature of 184C to avoid premature failure.

-

@mrehorstdmd I agree completely, everything should be in a fail safe condition. And after seeing how strongly everyone feels about adding a thermal cutoff, I see no reason not to add one in addition to the relay.

There will be at least 3 layers of independent protection.

- If the SSR fails closed the controller should open the relay and cut power above 120C it may cycle on and off in slow intervals at worst case scenario not exceeding 120C by much.

- If the controller fails in an ON state due to hardware or software the thermal cutoff can disconnect power, regardless of self reset or one-shot worst case result means power cycles in slow cool down and heat up intervals at ~140C (depending on the thermal cutoff)

- input power to the heater will be fused close to 115% as feasible (probably 8 amp fast blow) as its a 750w heater. In the event of a short circuit any electrical failure power should be cut. And the main plug will be fused at 10amps

- Kenevo stated the heater will only reach ~200C in open ambient air at full power. I may test this to confirm, but that would only be enough to deform some surrounding support brackets (PETG) and not cause a fire.

I'm still debating on what thermal cutoff to use. If I use a standard thermal fuse similar to the one in the picture Danal posted, I should just use high temp RTV and stick it to the bottom of the heater? I'm also considering insulating the space between the bottom of the bed heater and the frame using a glass wool blanket material used in industrial heaters rated for 1200F. Could this cause any issues?

-

I'd just trust Keenovo when they say it gets to 200C. That's probably a destructive test.

I think using high temperature silicone- like the stuff used to make gaskets for engines and available at any auto parts store, would be the best way to attach it to the heater.

Are you planning to attach the insulation to the bed or to the bottom of the printer's frame? A long time ago I attached some 1" thick PIR foam insulation to the bottom side of the bed and found that I had to keep reattaching it because the hot parts against the bed expanded and the other side stayed cool and didn't expand, forcing the whole thing to dish. In the end I just ditched the insulation completely because the heater had enough power to get the bed up to temperature in just a few minutes, and there wasn't anything under the bed that needed to be protected from the heat.

You won't need any insulation to help the bed get up to temperature with a 750W heater. My current printer's bed is 300x300x8mm cast aluminum and the same Keenovo 750W heater gets it up to 100C in 4.5 minutes.

-

@mrehorstdmd As I have mentioned before, most self resetting fuses do work this way, power is cut but a small amount of leakage current prevents the fuse from self resetting until the issue is remedied. By all means run multiple fuses, but you can save yourself effort by having the initial cut out be a self resetting fuse, that way if the SSR fails the heatbed stops heating and you replace the SSR without needing to do any actual wiring work to the heatbed.

-

@dino The devices you linked are fuses that protect against excessive current, not excessive temperature. They are intended to be mounted on a PCB (like the ones on the Chinese RAMPS board that often fail) to monitor the current in a heater, etc., to protect the connectors, traces, and MOSFET on the circuit board.