I think I have Bowden problems

-

it obviously varies with filament type but ive found theres and upper limit to retraction speed vs quality, well at least on my machine anyway.

abs i retract at 25-35mm/s and pla 50mm/s. its plenty fast enough, i also run very high extruder accel and jerk too -

what are your accel/jerk numbers?

If you see this and reply quick enough, I can try it with a print overnight.Thanks

-

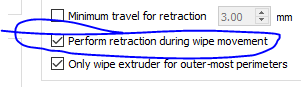

Per picture below, that option is supposed to mean that the hotend keeps moving and stops stationary retractions. But the hotend keeps stopping leaving a rock (blob) to later run over and shake the whole printer.

Is there something I could be setting up wrong?

Thanks!

-

Have you tried any other slicers? I find it handy to be familiar with Cura and slic3r PE to help identify issues. If it happens in one slicer but not the other with similar settings it might give you a clue where to look.

There's also the option of using firmware retraction which may behave in a more simple and straightforward manor compared to simplify 3d.

-

My experience, based almost entirely on printing PLA:

- Zits that occur just before travel moves indicate insufficient retraction.

- Stringing indicates that the print temperature is too high.

- I retract as fast as my extruder can. Typically the retraction speed is acceleration-limited. For a Titan I use M201 E1000 and M203 E3600. I specify 60mm/sec retraction in the slicer.

- Bowden systems need a retraction distance of around

8%0.8% of the Bowden tube length plus 1mm. A little less using Capricorn tubing; a little more if you don't have clips under the collets. Tune the retraction by increasing it until the zits disappear. - On a delta I use a little Z lift during retraction, on other printers I don't because it is slow and wears the Z leadscrew.

- I don't use wipe while retraction, or coast to end.

- Pressure advance helps, but tune retraction first. When using large amounts of pressure advance you must reduce retraction distance.

HTH David

-

@dc42 said in I think I have Bowden problems:

8% of the Bowden tube length

That seems really high, do you mean 0.8%?

-

Yes I meant 0.8%.

-

@dc42

I have to measure out my Capricorn to get that .8 +1mm number, but I changed the rest of the settings to match yours. And yes it's much improved. Still have issues, but they are not the same blobs I was getting. They are more so shapped then a blob and now also some scarring.

If I tighten down my titan extruder it eats away and or flattens out the filament making it unable to go through the Capricorn tube. Usually it stops right after it pushes out a few mm of plastic out the nozzle. If I losen it, it stops shortly after the filament hits the nozzle and chews up whats in the titan. If its in the middle, it seems to click randomly (takes bites out if the filament each time) and over time causes the filament to cause too much drag again in the tube.

What do I do when it's clicking? Tighten the screw in the Titan, or losen it more? I didn't have this problem when I used the standard white bowden tube but had a lot of thick thin extrusion layers in prints and had to print faster to keep the pressure up to reduce the effect...

My other printer is a wade and don't have the experience troubleshooting these issues

Thanks for the help!

-

@phaedrux

@phaedrux

I started using S3d 20 minutes after opening Cura. Haven't tried to use the others yet. For being super new at 3d printing, Cura was way over my head. I didn't know what to look for let alone make any changes. I printed a benchy with both Cura and S3d when I didn't know anything about either. I liked the S3d one better and it was easier to learn, I kept using it.

As that was almost 10 months ago now, I should look over and learn other slicers. It's nit a bad idea. May do that after I get this printer working.How or where do I make retraction settings on the Duet2?

Thanks!

-

Still playing around with this...

When I enable Pressure Advance at .1, my extruder is noisy and sounds like its ticking, as it looks like the stepper is fighting with itself, and the gears doesn't know which direction to go. Is this normal? or at least expected? It just sounds like the its going to have an early death.

I backed it off to .6, and its a lot quieter, but still playing with this.Thanks!

-

@bluedust I'm curious what current you are using for the extruder. If you increase it to 85% of max rated does the behaviour improve at all?

-

I bought e3d steppers. 1.68A Phase.

I had it at 1.2a and now just at 1a. can easily up to 1.4 -

@bluedust said in I think I have Bowden problems:

Still playing around with this...

When I enable Pressure Advance at .1, my extruder is noisy and sounds like its ticking, as it looks like the stepper is fighting with itself, and the gears doesn't know which direction to go. Is this normal? or at least expected? It just sounds like the its going to have an early death.

I backed it off to .6, and its a lot quieter, but still playing with this.It's normal for the extruder drive to move backwards a little at the end of a move when using pressure advance. Whether the extruder is noisy when it does this depends on how well the gears mesh.

-

I think all this trouble was caused by a bad stepper motor. Going to find out how the warranty works on it.

-

I had a bad bearing in my titan extruder. E3d and Filastruder were very helpful in troubleshooting and I received a new bearing + spares. I have heard how awesome their support was, and now can say its true first hand. Very happy. Well worth spending the extra money and getting brand name parts.

And yes, I also appreciate all the help I have received on this forum with my DuetEth board. Calling out @dc42 for helping me many times in the short amount of time I have had my Duet board.I have also met Filament Friday and have been talking to the 3d Printing Professor for a few weeks now. Both very awesome people.

A few more people/groups to call out.

Roy and his V-King builders group.

RatRig's builders group.

CoreXY Facebook group.A mention to the Professors Low Poly Dinos! Very cool. Alot of work. Did I say very cool!? https://www.kickstarter.com/projects/3dpprofessor/low-poly-dinos-dinosaur-3d-models-by-3d-printing-p

The 3d printing community has some pretty awesome people. I am happy to be apart of this community and hope to contribute in someway once I lose my noob status. I really do appreciate all the help I have received here and on other forums I have been apart of.

You guys are awesome!

-

A free opinion and worth every penny:

I am not a big fan of Titan extruders. I've slowly gotten rid of all my Titans in favor of Bondtech BMG.

I do agree that E3D has fantastic service. That makes it doubly weird that they ignore the fundamental design flaw in the Titan (misalignment). It has been posted to their forums many times, and they always suggest the same fix (that doesn't actually fix it) and refuse to consider changing the design.

See how the filament is not "in the valley" of the hob? Despite the metal piece being forced to the left of the plastic gear to the point you can see splines sticking out? That "move the metal in relation to the gear" is the suggested fix that doesn't really work. The misalignment was much worse prior to the suggested fix... but it is still not right.

Also, if the filament DOES "move into the sweet spot", the diameter of the drive effectively changes, and extruder calibration goes out the window... unless it stays there while you calibrate... which it doesn't.

.

Anyway, enough of that... Try a Bondtech BMG.

P.S. The BMG handles flex filaments just fine (the Titan doesn't claim to handle flex, and definitely doesn't in actual use). So even if you don't care about any of the stuff in my rant above...

consider the BMG for future, uh, "flex"-ability!

consider the BMG for future, uh, "flex"-ability! -

@dc42 said in I think I have Bowden problems:

- Bowden systems need a retraction distance of around

8%0.8% of the Bowden tube length plus 1mm. A little less using Capricorn tubing; a little more if you don't have clips under the collets. Tune the retraction by increasing it until the zits disappear.

Fantastic! I'd been using "more retract on longer bowden" but it never occurred to me to figure out a percentage factor... I'm going to cross check with my "gut feel" settings.

FANTASTIC. Thank you.

- On a delta I use a little Z lift during retraction, on other printers I don't because it is slow and wears the Z leadscrew.

Me too.

- Bowden systems need a retraction distance of around

-

@danal The Titan gear alignment can certainly be fixed, but it is a pain, but once done it stays fixed.

Before:

After:

The black gear needs to be forceably slid down the drive shaft about a milimeter or so. Then the drive gear needs to be slid down the motor shaft correspondingly so that the black gear and drive gear are aligned again. The idler arm rides against the drive gear, and the filament path is inside the idler arm, so it will then line up with the center groove of the drive teeth. In addition to this, I've added three 1mm spacers onto the motor shaft on the heat sink side of the idler arm to keep it in alignment.

It's an unfortunate amount of work to have to do to get decent performance out of such a pricey extruder, but when it works it does work well.

It has other issues as well though. The bolt that goes through the black drive gear is way too easy to over tighten, which completely damages the bearings. Tighten it by finger tip only.

I've bought a bag of replacement MR95ZZ bearings just in case.

-

My titan extruder is currently mounted in a way that makes it hard to get a really good picture. Saying that, it doesn't appear I have the same problem you guys do.

-

@bluedust said in I think I have Bowden problems:

My titan extruder is currently mounted in a way that makes it hard to get a really good picture. Saying that, it doesn't appear I have the same problem you guys do.!

Yes, that looks pretty good!

If a Titan self-aligned like that, I'd be happy enough with them to use them in most places. In fact, I've found that some of the Titan clones actually work fine, because they don't suffer the alignment problem. Very nice that that one is aligned and works fine.

If aligned, the only difference then would be Bondtech BMGs vastly superior ability to feed flex filaments.