Need help, willing to pay, I'm completely stuck.

-

Merged into one post

-

Merged into one post

-

For the clicking and temperature, are you sure you have the right heater parameters set for your thermistor? Do you have a multimeter with a thermocouple to verify the actual temperature of the heat block? Your temp readings could be reporting that it's hotter than it actually is. Once you're sure you have the thermistor values right you can run a PID tuning. But that is a problem for another day.

Your z axis is moving very slowly in the video and it looks like it's causing the bltouch pin to hit again before the head raises causing it to go into error.

Try using these for Z speeds. Slightly faster than what latexcupcake posted, but not crazy. Should be doable for the printer. If they seem to cause bad behaviour, reduce the speed a bit. But it should hopefully allow the pin to stop hitting the bed.

M566 Z30

M203 Z300

M201 Z30Your gcode start script looks fine.

Your heightmap has a big problem with that huge dip in the corner. I think that is the most likely cause for smashing into the bed. It thinks the bed surface is way lower than it is and is trying to move the nozzle down to compensate.

You have a couple options.

-

your bed looks to be fairly flat as it is, so you could try disabling mesh compensation entirely in the DWC. Remove G32 and G29 from your startup script and just use G28 to home the printer. Even if the first layer doesn't stick perfectly, I think it will stop it from driving into the bed.

-

If that solves the problem you can try running G29 again with those increased z speeds to see if that will let the bltouch provide a better height map and remove that big dip. Or you can manually edit the heightmap.csv file to change that huge dip to be more in line with the other values. The heightmap.csv is in the system folder. You can right click and edit.

M851 in marlin is equivalent to G31 Z in reprapfirmware and you find the right value using this procedure: https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe?revisionid=HEAD#Section_Calibrate_the_Z_probe_trigger_height

-

-

I changed the M556, M203 and M201 as suggested and set the printer to Home All in preparation to re do the Z Probe calibration.

Unfortunately, the nozzle crashed into the bed again and this time I didn't catch it time, it's now damaged the mounts which hold the z axis nut on the left side.

I have replacements which I'll fit, then I'll re-attempt to Home All again.

This whole printer seems like 2 steps forward 1 step back!

I'll update when I replace the mounts.

Could me setting in the G31 Z value to 0 (As per the calibration instruction) have anything to do with it?

-

@jameswstubbs Well it should only be set to 0 when doing the measurement, but even then it should be able to stop the bed in time it just won't know exactly where your nozzle is.

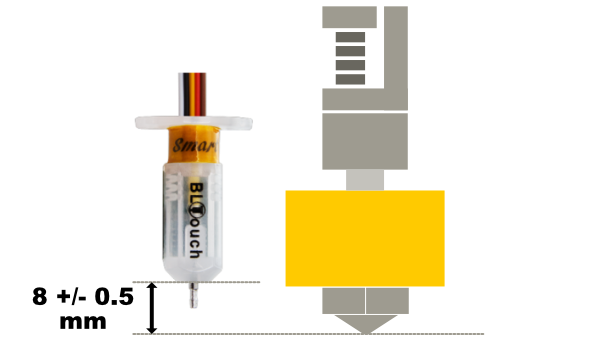

This leads me to wonder if you have the BLTouch mounted too high or too low.

The body of the BLTouch should be 8mm above the nozzle tip. Are you close to that?

-

Crashing: LONG before the nozzle gets to the bed, trigger the BLTouch probe with your finger. Everything should stop moving down.

Do this with your other hand on the power switch, ready to power down INSTANTLY if things do not stop.

That's how you avoid crashes, with any probe, while figuring out the physical and configuration offsets.

-

Hi, apologies I've been away a few days and had to collect the spare z nut holders (literally the other end of the country!!)

I've now repaired what became damaged.

I measured the BlTouch as suggested, to my surprise it was about 10mm higher than the nozzle, this was surprising as the whole carriage design is based around having this sensor and it's a genuine item!

I've now placed two washers between the BlTouch and the mount, this should bring it within the roughly 8mm.

This is the result of my mesh compensation now:

I'm using a genuine E3D V6 and having done a search of the forums, I have found this:

https://forum.duet3d.com/topic/2501/e3d-v6-thermistor-settings/7

Am I right in saying that I need to use?:

M305 P1 T100000 B4725 C7.06e-8 R4700 ; Set thermistor + ADC parameters for heater 1

-

https://wiki.e3d-online.com/E3D-v6_Assembly#Configure_Firmware_.28Easy.21.29

Here's E3D s docs on setting it up for reprap.

-

Your height map looks much better. Are you still having issues or is it resolved now?

-

Just changed some settings with the e3D and have ran a M303 to autotune and have set a M307 command in the config file.

I was having issues with adhesion earlier that I didn't used to have using Marlin.

I'm trying another print now with the new thermistor/PID settings.

Otherwise, it may be the Z offset that is off. -

Did you receive measure the z trigger height after adding the washers?

You may also want to remeasure your e steps per mm since your temperature may have been off before.

-

We're printing!!

I can already tell it's not a good print, but the fact it's printing is a massive step!

I'm using the recommended e steps for the titan extruder at the moment, but I'll measure this myself properly tomorrow morning.

I recalibrated the z offset and it came out at 0.995 three times in a row, where as beforehand it varied between 0.2 and 0.5.

I think the BlTouch was too high to work properly as you suggested.

-

Glad to hear it's working now

-

I'm genuinely surprised at how quiet it is! Do you have a donate link on thingiverse or a paypal account? I wasn't kidding when I said I'd be willing to pay and I do insist.

-

https://ibb.co/cCaNcK

https://ibb.co/iss2cK

https://ibb.co/cFfYjz

https://ibb.co/jEj4reNow it's the long process of trying to tune the prints and improve my bed adhesion.

At the moment I the bed is probed in 5 places when printing, how would I convert to mesh bed compensation?

-

@jameswstubbs said in Need help, willing to pay, I'm completely stuck.:

At the moment I the bed is probed in 5 places when printing, how would I convert to mesh bed compensation?

-

@jameswstubbs Well if you insist. I think I have a tip option on thingiverse. I've never got a tip before. https://www.thingiverse.com/Phaedrux/about

You can find out more about mesh compensation here: https://duet3d.dozuki.com/Wiki/Using_mesh_bed_compensation

It may help you out a bit because it can give a much higher resolution heightmap.

Your print looks like a decent starting point. Tuning the e steps and extrusion multiplier will help get your slight over extrusion under control. It also looks like it might be printed a little hot and a little too fast, but it's hard to tell on such a small test print.