Nema17 heat, how to deal with it?

-

@dc42 Thnx. I changed them to 1200mA they skip a bit faster now but still have quite a bit of force. Running a long term test now to see if they get hot. I am still somewhat affraid of the motor skipping steps during prints though on 1200mA. (On 1500mA there's little that'll stop them

)

)I also tested a run with a passive CPU heatsink and a bit of thermal paste and that makes quite a bit of difference as well.

The real culprit wasn't the heat though. My motor coupling was slipping...

-

Ok. I changed it to 1200mA and they get less hot but within an hour still 35 to 40 degrees. Which is still to warm for my taste.

I have now changed the Y back to 1500mA and mounted a heatsink and fan to it and have running for test purposes.

-

https://somei3deas.wordpress.com/2017/04/18/stepper-motor-and-electronics-cooling/

You can pick up NEMA17 sized heatsinks very cheaply on ebay or aliexpress. Even without a fan they work rather well.

-

do your axis move freely with out the motors attached? i run my corexy at 850 with no skipped steps. the motors stay cool to the touch. you may just have too much mechanical resistance. that will heat up the motors along with the need of high current.

-

@phaedrux Thnx. I used these just as a test case to check the difference. Also I can put a stikker on it with Intel Inside now

After christmas I'll probably order those.

-

@antlestxp Yes they move freely. The problem with one of the axis looking like it skips steps is actually a bad motor coupling.

Do you run 1.8 degree or 0.9 degree motors. For my taste when I run a test and stop the axes by hand on 1200mA it's fairly easy to make the motor mis steps. On 1500mA it's still possible but far more difficult.

The question is what is needed though.

-

@nemesis i use 1.9deg motors all around. i also run 24v. i did notice i had to use more amps when i was on 12v. at 850 with a bit of pressure i can cause a skip, tho it seems like something else wants to give before the motor. at 1000 the whole printer will move to keep the stepper in motion.

-

@antlestxp 1.9degree? I'll assume 0.9.

Then you have a setup similar to mine (motor and voltage wise). I'm not happy with the current XY arrangement. The frition is not to bad but still higher then I would like it to be.

Yeah agreed if I do not hold onto the printer when stopping the movement the whole printer indeed moves. But for me that is from 1100mA upward.

The XY arrangement has quite a few contact points with printed linear bearing so probably quite a bit more friction then your setup. (On a single axes I have 5 bearings) also 2 of the rods on a axes turn as well as provide linear motion.

The coolers are keeping the steppers super cool at 1500mA.

I learned a lot from the current build! Even though it has some design flaws it prints WAY better then my upgraded Anet A6.

-

Does a heatsink on one end of the motor cool anything but that end of the motor?

I have aluminum motor mounts bolted to aluminum plates in my printer.

I'll see if I can get a thermal image of one of the motors after it's been running for a while. I'm guessing the end that isn't bolted to the mount will be quite a bit warmer than the other. Steel isn't a very good thermal conductor, and motors are mostly steel.

Operating a stepper at 35-40C is absolutely no problem for the motor, and isn't hot enough to burn someone who touches it.

-

@mrehorstdmd From my tests yeah. It makes quite a lot of difference. Quite a bit of heat bleeds out through the heat sinks.

The motors are cold to the touch now. The motors never got hot enough to burn yourself. However the 35-40 degrees was after a 1,5 hour print. So a longer print might produce more heat. The heat accumulation is quite slow.

Edit: Been thinking about this, For the next build I'll be using Alu mounting brackets. Using the frame as a heat sink might actually work.

-

Since my original post I've reduced the friction on the axes quite a bit and that seems to really help in the heat department.

Also took the motors off and it seems I have a faulty motor for the Y axes. If I connect a motor clamp to it and hold the clamp with a tool I can easily make it skip on 1500mA. The motor on the X axes on the other hand is extremely difficult to make skip.

-

@nemesis said in Nema17 heat, how to deal with it?:

Also took the motors off and it seems I have a faulty motor for the Y axes. If I connect a motor clamp to it and hold the clamp with a tool I can easily make it skip on 1500mA. The motor on the X axes on the other hand is extremely difficult to make skip.

With the belt removed, does the Y motor shaft spin freely?

-

@dc42 said in Nema17 heat, how to deal with it?:

With the belt removed, does the Y motor shaft spin freely?

Not sure what you mean exactly so I'll give multiple answers:

- The motor shaft turns freely if there is nothing connected.

- The motor shaft gives resistance when it's in IDLE 1500mA 30% idle percentage. If nothing is connected to the motor. However it's fairly easy to push through compared to any other motor of the same type.

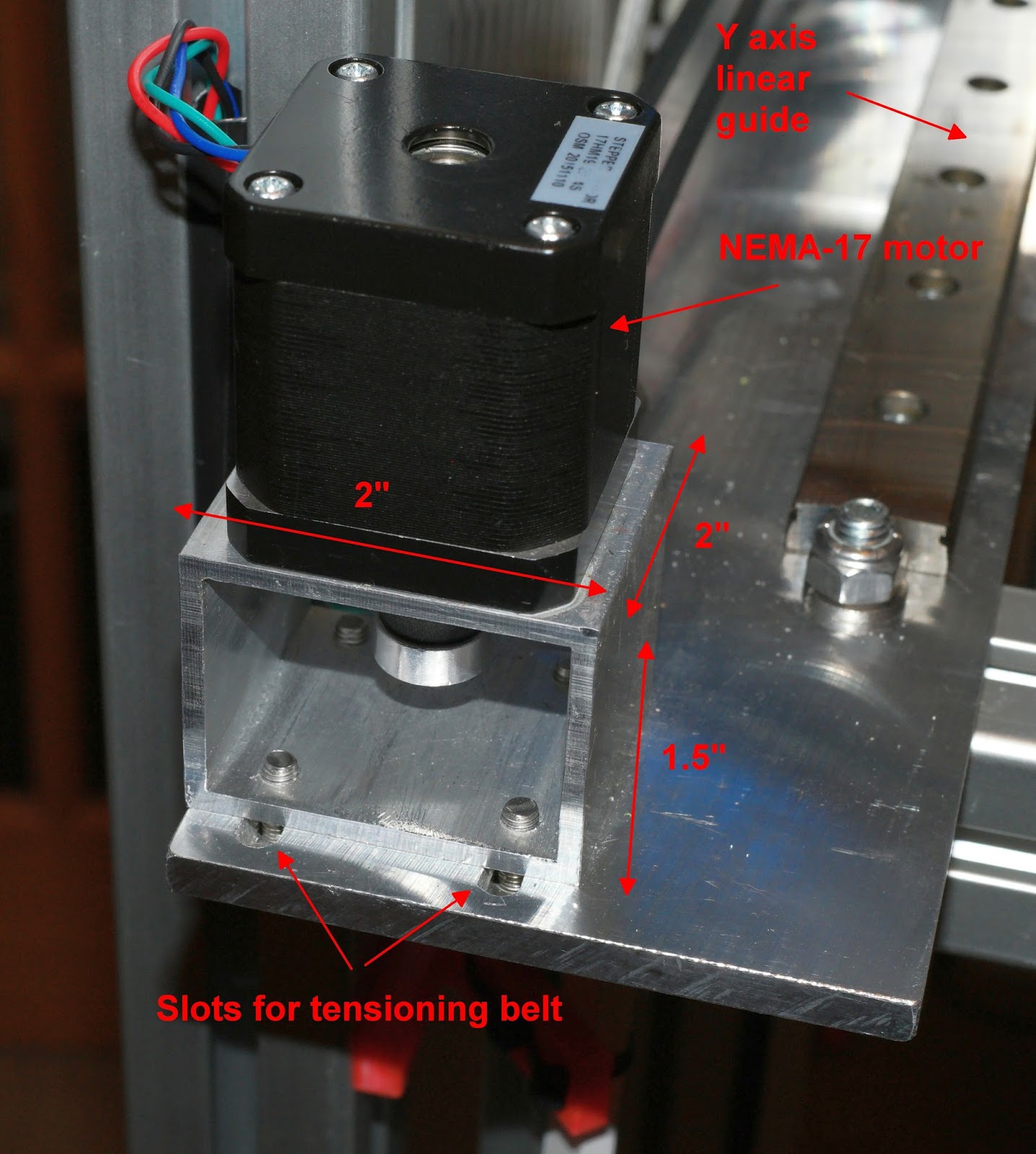

- The belt is running on the motor shaft. I'll explain my current setup. With some images:

-

@nemesis ah your printer is set up like an ultimaker. i am willing to bet you are fighting a little more friction than the hypercube corexy. do you have to use bushings on the rails that need to rotate?