Core XY homing.

-

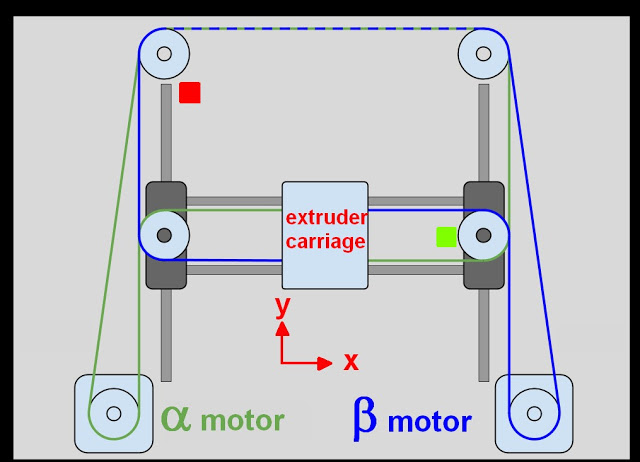

Home can be in what ever corner you choose. Normally it is in X0 Y0 and this is always above the A motor in the machine. X positive is buildplate going away from the nozzle

https://vkingprinter.com/knowledge-base/corexy-coordinate-system/

-

Which corner do you have your endstop switches in (if you are not using stall detection)?

-

Hi

I havnt installed them as yet they are still to be assigned a position.

But i have been triggering them manually as they home to the top right corner.

If i swap the X and Y connectors the print head homes towards the A motor top left as i look down which Im seeing as correct to the previous diagram so Z positive is towards me as i look down ?

Many thanks -

-

@pro3d Thanks for the reply so at X,Y zero Z axis positive movement is towards us as viewing this diagram.

Or if my physical print area height is say 500 am i Zero on high at +500 where X and Y zero is. -

@mrehorstdmd Thank you appreciated info

-

So its a bit further on from this to be fair but Im just trying to understand where Z positive movement starts and in which direction this is up or down ?

-

Typically z=0 is with the nozzle touching the bed.

Increasing the distance between the nozzle and bed is always a posative movement. So when you add 10 to z the elevator will move down as you are looking at the machine - assuming the elevator is moved in z, rather than the x/y axis.

Edit: This may seem counter intuative, but this saves the slicer needing to know whether it is the head, or elevator moved to form the z axis motion.

-

Z positive is when buildplate and nozzle travels away from each other. If you have a moving bed that means downwards - i.e negative Z direction in the vertical direction if bed is starting up top as normal with moving beds. If you have a moving gantry then Z positive is away from the buildplate. So always nozzle moving away from buildplate is positive Z

-

More up to date picture so the motor at the back left is home for X and Y at present and x and y positive movement brings the head to the front right as in picture.

Need to figure out where home offset is in the configurator to move the head into the middle of the print bed !

This would marry up with y+ being 90 deg to x+in anticlockwise direction and this would have z positive movement in an upward direction.

Bed moves south to create that layer up movementThanks for the help

-

You achieve the offset with the maximum and minimum limits. In the config file you specify whether your limit is at the maximum or minimum position (z-limit switch positioned low on the frame would be maximum) and during homing the firmware will set the current position to the defined max or mim of that axis.

https://duet3d.dozuki.com/Wiki/Gcode#Section_M208_Set_axis_max_travel

Note this has been tidied up recently so you only need one line to specify maxiumum an minimum limits such as:

M208 X-110:100 Y-116.5:106.5 Z0:180 ; set axis minima and maxima

In that example the limits were at minimum x and y and the nozzle at the mimimum position was 10mm before the bed. (0,0) would be centre of a 200mm x 213mm bed.

-

@stevo said in Core XY homing.:

More up to date picture so the motor at the back left is home for X and Y at present and x and y positive movement brings the head to the front right as in picture.

That will give you mirrored prints. Home can be wherever you want it, but +X and +Y must form a right-hand coordinate system. I suggest you make +Y move towards the back of the printer. You will need to swap the X and Y motor connections to achieve this.

-

@dc42 Apologies so please excuse my ignorance so to retain the Y+ 90 deg anticlockwise to X+ the Z axis in this needs to be pointing upwards,

So trigger Z axis at max with the endstop. -

@stevo said in Core XY homing.:

@dc42 Apologies so please excuse my ignorance so to retain the Y+ 90 deg anticlockwise to X+ the Z axis in this needs to be pointing upwards,

So trigger Z axis at max with the endstop.For a printer with a bed moving in the Z direction, +Z must be the bed moving down. But as seen from the bed, +Z movement of the nozzle is up.

-

Thank you all for the helpful info have now got the machine setup as per picture below homes to top right, pinched picture off Mark Rehorst's Tech topics and also set the centre of the bed as the origin.

-

Looks good!