Motor noise and print quality

-

Recently, I've been printing various thin-walled cubes to look at ways to deal with ringing on my core-xy printer.

While printing the test cubes with various print speeds and accelerations, I noticed something quite unexpected. I was printing 5mm tall sections at 60mm/s, 90mm/s and 120mm/s.

Much to my surprise, printing at 120mm/s was giving me much better print quality than the lower speeds. Also, printing at 90mm/s was more than twice as noisy as printing at 60mm/s and about twice as noisy as printing at 120mm/s.

I used a sound level meter to look at the actual noise levels at 1m from the printer and recorded the following:

60mm/s 51.5 dbA

90mm/s 55.3 dbA

120mm/s 52.5 dbALooking at the test prints is very interesting but almost impossible to photograph! In the image below, there are three 5mm tall sections, printed at 60mm/s, 90mm/s and 120mm/s repeated four times at four different accelerations (1000, 2000, 3000 and 4000 mm/s squared).

The sections printed at 120mm/s are much smoother and much more transparent than the slower sections. Looking at the 90mm/s sections with a loupe shows that the noise I'm hearing seems to manifest as a slight wavy pattern in each line of filament. It certainly feels much rougher to my fingernail than the slower or faster sections.

The printer is a core-xy and the test print was made with the sides of the print along the X and Y axes. The X and Y axes run on wheels on V-slot extrusions. The layer characteristics are the same regardless of which side I look at. The printer itself has a direct extruder which weighs around 450g for all the parts. The alpha and beta motors are 48mm long NEMA 17 types with 1.8 degrees per step and have a rated current of 2.5A (run at 1.8A) with 1.2 ohms resistance, 1.8mH inductance, a 3.1V rating and 4800 g/cm holding torque.

The extruder is a Bondtech BMG driven by a 25mm NEMA 17 1.8 degree stepper rated for 700mA current and I'm running it at 595mA. The hot end is an E3D V6.

All three stepper motors are configured for 16 microsteps extrapolated to 256. The X and Y axes are 80 steps/mm and the extruder is 411 steps/mm.Can anyone give me any insight into the behaviour I'm seeing at 90mm/s? I guess I'm seeing some kind of resonance, but what exactly is resonating and can I predict or change the speed at which the resonance will occur?

-

I had similar results that were cured by lower print temps by 15 degrees C. The problem was also cured by speeding up the print. My theory is that putting too much heat into the filament allows it to ooze out in between stepper pulses or just whenever and so that pattern results. When printing fast, the added temperature is used to increase the delta T to allow the extrudate to get heated enough to work. When printing slow, the added temperature soaks into the filament. Just a theory. Try lower temps.

-

@bot That's a good theory. I found similar but the "cure" for me was to reduce the extrusion multiplier at lower speeds (or better still leave it it high and print fast).

So my theory is that you get some under extrusion at higher speed due to pressure or possible some extruder slippage but yours could be the right one.

So my theory is that you get some under extrusion at higher speed due to pressure or possible some extruder slippage but yours could be the right one. -

@bot That's an interesting observation.

I'm not sure it would really work with the print in question. I normally print this particular PLA at 200C, but I bumped it up to 205C so that the extruder would have a chance of melting the filament fast enough to put down layers without under-extrusion at 120mm/s.Even if the quality differences were explained by the print temperature, it can't affect the sound that the motors make.

-

Yeah, I wasn't thinking of the sounds of the motor. Perhaps there is a resonant frequency being excited by particular speeds. Could be a combination of several factors. This is what makes troubleshooting prints tricky -- isolating the variables.

-

@bot Yeah, that's why I posted the question here as I know there's a wealth of knowledge and experience here on the forum.

It's interesting what you say about temperature though. If I look at the corners of the print, the layers which are printed more slowly are wider than the 120mm/s layer.

The difference is very small though. One side measures 100.00mm at 60mm/s, 99.95mm at 90mm/s and 99.91mm at 120mm/s.

I'm using pressure advance at 0.11, if that's of interest.

-

@grizewald said in Motor noise and print quality:

It's interesting what you say about temperature though. If I look at the corners of the print, the layers which are printed more slowly are wider than the 120mm/s layer.

Have you got you e-steps and linear/non linear extrusion corrections dialed well?

-

@doctrucker e-steps are calibrated. I'm not using non-linear extrusion corrections.

Would setting that up have any effect on the ringing, or just on the size mismatch? -

i had a similar problem with print quality on my corexy printer.

for me it turned out the be the stepper motors and the pulley size.

after switching to 0.9 degree steppers and 16 tooth pulley giving me 200 steps/mm the artefacts where gone.

thanks to the analysis of someone who had this problem on his prusa.

https://forum.prusaprinters.org/forum/original-prusa-i3-mk3s-mk3-user-mods-octoprint-enclosures-nozzles-.../stepper-motor-upgrades-to-eliminate-vfa-s-vertical-fine-artifacts/ -

@grizewald just the size mismatch I woud have thought.

Raising the temperature for faster extrudes could be bringing the melt to the same temperature, or the system is simply suffering from back pressure caused by trying to shove a larger volume of material through the same size hole. The back pressure will be linked to throughput, but not necessarily in a linear manner.

It's not easy to read into the required correction that much because polymer melt can be weird and exhibit non-newtonian flow and shear thinning charateristics. That said I would suggest that if extrusion rate was having a significant effect on final melt temp you may see a kick in the tail of your required correction graph, but this would be more clearly presented by weaker parts.

As others are saying the ringing is appearing to be a resonance in the system and moving faster simply pushes past the resonant frequency. It's a good reminder that an apparent upper limit may not always be so.

You could run a few no print builds with increasing speed to check where the resonance appears with your sound meter. When preparing your test make sure that all the geometry on one layer has the same feedrate and then speed can be changed ny a simple G1 F,,, command at suitable points. Also ensure you get the angles right to test both single motor and multi motor moves.

-

I guess I'll be ordering some 0.9 degree stepper motors and some new pulleys. At least I only have to order two of them with the core-xy design!

It's worth a try at least and the appearance of the cubes in the article which Veti linked to are very similar to what I'm seeing.

I'll update this thread with the results once I have received and fitted the new motors.

-

OMG. I've been wondering what those VFAs were forEVER. Nothing I did would eliminate them. I've asked on some forum before if anyone had any idea, and nobody did. My photos look exactly like those ones as far as the VFAs go. Now I even know what they're called! LOL. OK, methinks I'm going to have to order some of these .9 degree steppers. I've never thought they'd be worth the upgrade, but if they get rid of these very fine vertical artifacts they'll be worth every cent.

-

Great. More abbreviations, just what we need...

Vertical can crop up for a number of reasons so I'd warn away from piling them all under the same catagory. It is however probably getting close to needing a fault finding guide on the wiki for 'help I can't get shot of these patterns'...

-

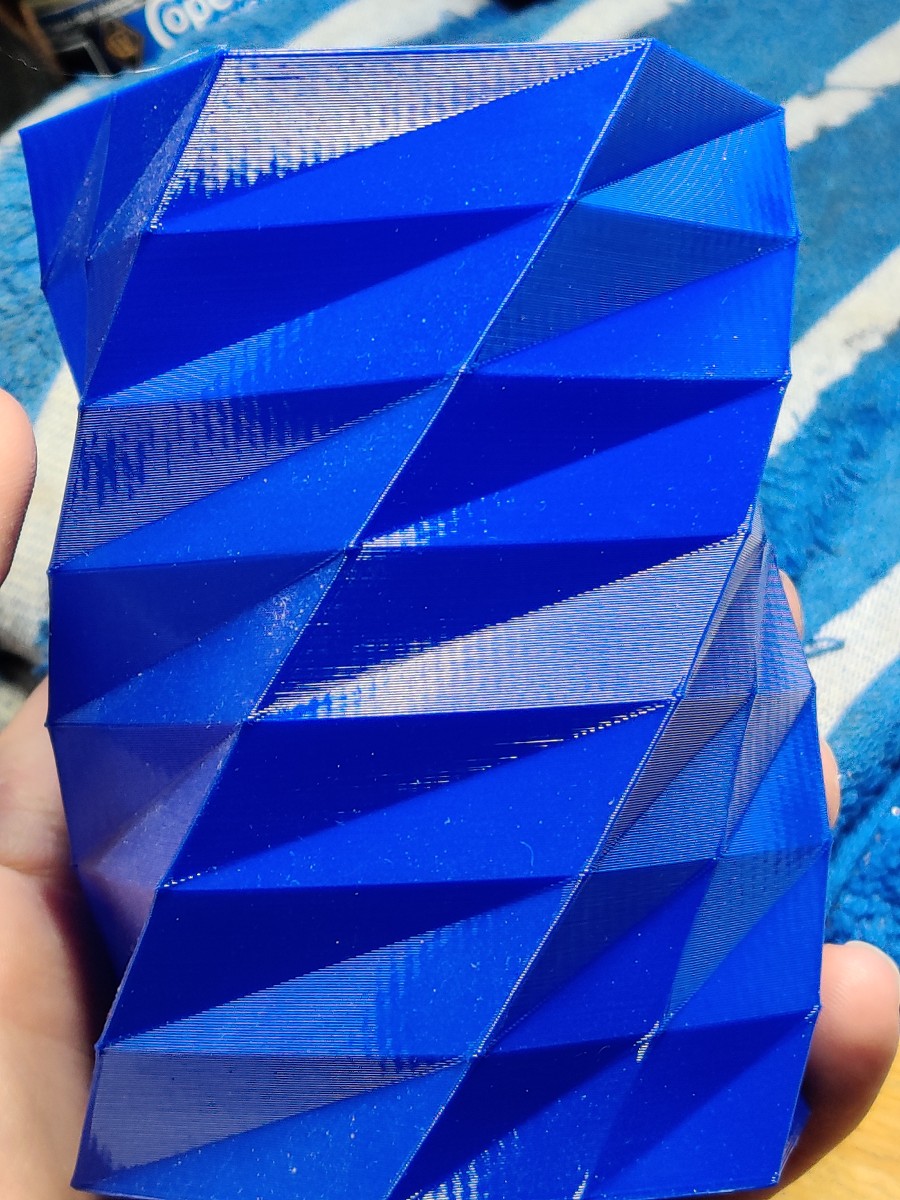

Here's a classic example of FVAs in one of my old prints, a simple vase in PETG. You see this corrugated pattern all over the enter surface. I've looked at this with a high-power loupe, and it does appear to be an issue with a very slight pulsing in the lay-down of the filament. If I'm reading the article linked by Veti above correctly, this is caused by slight accelerations and decelerations of the X/Y steppers in the course of doing their steps, not by pulsation in the extruder. If this diagnosis is correct, a switch to 0.9 degree steppers could make that mostly disappear. One might think that the frequency of the pulsation would double and I'd simply get the corrugation at twice the frequency, but if the magnitude of the changes is also cut in half it's possible that the physical difference in how much filament is laid down in each layer per "pulse" is also cut in half, with the result that its effect drops below some threshold of visibility.

Am I understanding this correctly?

-

@sethipus said in Motor noise and print quality:

Am I understanding this correctly?

thats how i understand it as well.

thats why going to a 16 tooth pulley helps as well, as it further decreases the distance between each step. -

@veti said in Motor noise and print quality:

switching to 0.9 degree steppers and 16 tooth pulley giving me 200 steps/mm the artefacts where gone.

Similar experience here.

Also switching to gates belts and adding a flip to my belts so that smooth side was riding on the smooth bearings as idlers also helped a lot. Toothed idlers didn't help. Perhaps because 16T idlers are quite small and the belt teeth didn't seem to mesh smoothly.

-

I just ordered a pair of these .9 degree steppers which should be here Sunday, so I should be able to report back sometime Sunday evening.

I'll pull out some dark-colored PETG (gotta see if I have enough of this same blue left) and print a vase like this before I do the swap, and then after with the new .9 degree steppers using the exact same g-code file, in order to compare. I will return and report. Fingers crossed.

-

It sounds like we're all going for more and smaller steps!

To an extent, this makes sense, but I've been playing today with a simple object which a member in the other active "print quality" thread is having trouble with. I thought I'd simply be able to print it with one of my standard profiles and everything would come out looking beautiful.

No such luck!

I'm seeing poor surface quality and ugly loops escaping the print at layer changes. If I can get the camera on my microscope working, I'll post some proper pictures.

For a comparison, I fired up my Anycubic i3 Mega. The print's not quite finished yet, but I think I can see similar artefacts at later changes on that printer as well, along with the infill showing through, which I don't see on my prints from the V-Core.

I guess it's time to do some slicing with Slic3r and see how those go.

3D printers are fun, but I have to say, getting them to print properly gets to be less and less fun. There are just so many variables that it makes the process painful in the end.

-

@sethipus said in Motor noise and print quality:

I just ordered a pair of these .9 degree steppers which should be here Sunday, so I should be able to report back sometime Sunday evening.

I'll pull out some dark-colored PETG (gotta see if I have enough of this same blue left) and print a vase like this before I do the swap, and then after with the new .9 degree steppers using the exact same g-code file, in order to compare. I will return and report. Fingers crossed.

Exactly the same motors as I ordered earlier today, except mine are being shipped from Germany. I ordered direct from the manufacturer's web site and they only cost me $15.89 each, plus $11.57 shipping.

I hope the price you paid wasn't anything like the $21.99 Amazon is showing me! -

@grizewald said in Motor noise and print quality:

@sethipus said in Motor noise and print quality:

I just ordered a pair of these .9 degree steppers which should be here Sunday, so I should be able to report back sometime Sunday evening.

I'll pull out some dark-colored PETG (gotta see if I have enough of this same blue left) and print a vase like this before I do the swap, and then after with the new .9 degree steppers using the exact same g-code file, in order to compare. I will return and report. Fingers crossed.

Exactly the same motors as I ordered earlier today, except mine are being shipped from Germany. I ordered direct from the manufacturer's web site and they only cost me $15.89 each, plus $11.57 shipping.

I hope the price you paid wasn't anything like the $21.99 Amazon is showing me!I can't tell if there is sarcasm lurking in here (

), but under the assumption that there isn't, I saw these steppers for like $13.something on the steppersonline website, but they'd be shipping from China, and there'd be some shipping charges. I did indeed pay the $21.99 each from Amazon, but I have Prime so the shipping was free, and I'll have them on Sunday instead of waiting a couple/few weeks. If you divide the $12 shipping charge for two steppers, add that to the $15 purchase price you paid, you're waiting for them to arrive from Germany for within pennies of what I paid to have them on Sunday.

), but under the assumption that there isn't, I saw these steppers for like $13.something on the steppersonline website, but they'd be shipping from China, and there'd be some shipping charges. I did indeed pay the $21.99 each from Amazon, but I have Prime so the shipping was free, and I'll have them on Sunday instead of waiting a couple/few weeks. If you divide the $12 shipping charge for two steppers, add that to the $15 purchase price you paid, you're waiting for them to arrive from Germany for within pennies of what I paid to have them on Sunday.Of course, if you were just acknowledging that through some subtlety that doesn't come across well through text, the above is already understood. Either way, if I could have saved a couple bucks one way or another and had to wait a while versus having them nearly immediately, I found the tradeoff acceptable.

One thing is I don't understand steppers well enough to know what specifications for them are important beyond 1.8 degree or 0.9 degree steps, the best matched to a printer, etc. I just know that if Phaedrux is using them already and they're fine, then they're fine, so those are the ones I went with.