Y-stepper noise

-

-Maybe the same Duet Wifi problem as "core x y stepper noise"-topic here.

Yes, I tested the issue by an extra handheld steppermotor. No doubt the Y-signal gave more noise and vibration than the x-signal.

I think the running printer should sound like

a purring cat rather than a screaming one. -

Please post your config.g, so we can check that there's no settings that might be causing this issue.

Ian

-

Here´s my config.g

0:/sys/config.g

; Configuration file for Duet Maestro (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.4 on Tue Dec 31 2019 15:34:36 GMT+0200 (Itä-Euroopan normaaliaika); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DUET2 Leapfrog dual" ; set printer name

M918 P1 E4 F2000000 ; configure direct-connect display; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

M552 S1 ; connect wifi;M555 P2 ; set output to look like Marlin

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P3 S0 ; physical drive 3 goes backwards

M569 P4 S0 ; physical drive 4 goes backwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X66.67 Y66.67 Z654.02 E93.00:93.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z24.00 E300.00:300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z180.00 E6000.00:6000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00:5000.00 ; set accelerations (mm/s^2)

M906 X800 Y1600 Z1600 E1000:1000 I50 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X235 Y235 Z260 S0 ; set axis maxima; Endstops

M574 X1 Y1 Z1 S1 ; set active high endstops; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M303 H1 S240 ; auto tune heater 1, default PWM, 240C target or maximum temperature

M303 ; report the auto-tune status or last result

M307 H0

Heater 0 model: gain 199.0, time constant 962.6, dead time 4.5, max PWM 1.00, calibration voltage 12.3

M307 H0 A199.0 C962.6 D4.5 V12.3 B0

M570 H1 P4 T30

M570 H2 P4 T30

M305 P0 T80000 B4092 R2200 ; set thermistor + ADC parameters for heater 0

M143 H0 S150 ; set temperature limit for heater 0 to 150C

M305 P1 T80000 B4700 R2200 ; set thermistor + ADC parameters for heater 1 vB4092

M143 H1 S275

; set temperature limit for heater 1 to 275C

M305 P2 T100000 B4700 R2200 ; set thermistor + ADC parameters for heater 2

M143 H2 S275 ; set temperature limit for heater 2 to 275C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1:2 T30 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1:0:2 T30 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ;F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 ;F0 ; define tool 1

G10 P1 X10 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0CM703

; Custom settings are not defined

DUET2 Leapfrog dual

Send code...

Status

Idle

Tool Position

X

0.0

Y

0.0

Z

0.00

Extruder Drives

Drive 0

0.0

Drive 1

0.0

Speeds

Requested Speed

0 mm/s

Top Speed

0 mm/s

Sensors

Vin

24.2 V

MCU Temperature

23.5 C

Fan RPM

0

Tools

Extra

Control All

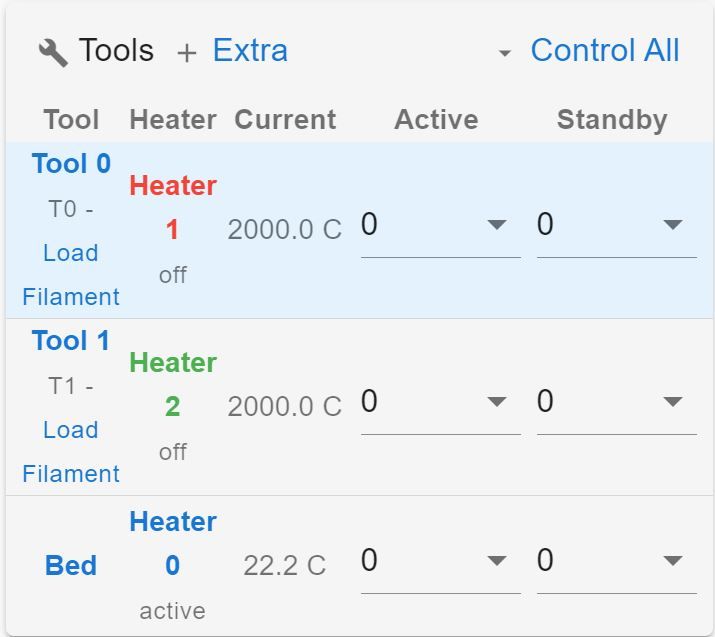

Tool Heater Current Active Standby

Tool 0

T0 - Load Filament Heater 1

off 32.1 C

0

0

Tool 1

T1 - Load Filament Heater 2

off 36.8 C

0

0

Bed Heater 0

off 33.0 C

0

0

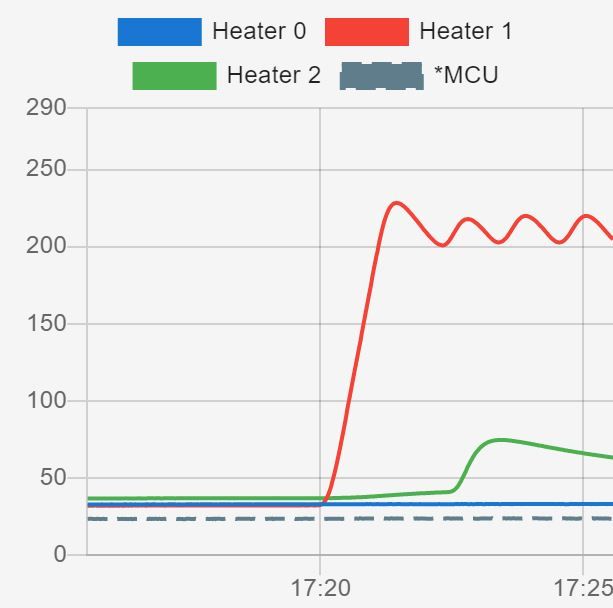

Temperature Chart

System Directory -

@Pertti said in Y-stepper noise:

M906 X800 Y1600 Z1600 E1000

What stepper motors do you have on X, Y and Z? You've set the current on the Y to double X, which will make it noisier, though I'd expect Z to be noisy too.

What Duet board do you have? You said Duet Wifi, but your config says you have a Maestro, and is set up for Ethernet, not Wifi. send M115 and post response.

Also, 1.6A is the maximum on a Maestro, though in my testing I couldn't get the driver to overheat at this setting.

Ian

-

I have two parallel nema 17 motors in y-axis. Z has Nema 23.

@droftarts said in Y-stepper noise:

M115

M115FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2019-12-13b1

-

There are some other problems like the heater 2 is not fast enough and cuts the heating because of too slow heating. (green line). Does the red curve look ok?

-

@Pertti said in Y-stepper noise:

I have two parallel nema 17 motors in y-axis.

I expect that's where the noise is coming from, due to the high current you're using. You could wire them in series, which is recommended, and reduce the current. What happens when you connect the X motor to Y stepper driver, and set M906 Y800? Does it go quiet then?

Remember to turn off power when you disconnect/reconnect motors, or you may damage the stepper driver.

Ian

-

@Pertti No, that doesn't look right for heater 2, and heater 1 should be more stable than that.

As you have Duet Wifi, but your config.g is set for Duet Maestro, there are some errors:

M918 P1 E4 F2000000 ; configure direct-connect displayNot needed, you can't connect this display to Duet Wifi

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCPNot needed, M552 S1 does this for Wifi

M303 H1 S240 ; auto tune heater 1, default PWM, 240C target or maximum temperature M303 ; report the auto-tune status or last result M307 H0 Heater 0 model: gain 199.0, time constant 962.6, dead time 4.5, max PWM 1.00, calibration voltage 12.3 M307 H0 A199.0 C962.6 D4.5 V12.3 B0 M570 H1 P4 T30 M570 H2 P4 T30Remove this whole section, it's causing problems. Because...

M305 P0 T80000 B4092 R2200 ; set thermistor + ADC parameters for heater 0 ... M305 P1 T80000 B4700 R2200 ; set thermistor + ADC parameters for heater 1 vB4092 ... M305 P2 T100000 B4700 R2200 ; set thermistor + ADC parameters for heater 2Your thermistor settings (ie temperature monitoring are incorrect for Duet Wifi. The R value should be R4700 for Duet Wifi; it's R2200 for Duet Maestro. What thermistors are fitted, or what hot end is this? E3D V6 or something similar? Getting the thermistor settings correct should give you accurate temperatures.

Once you have corrected these, then try tuning your hot ends with M303.

Ian

-

@droftarts said in Y-stepper noise:

M906 Y800

I have tried all kinds of setups, parallel and serial, x,y,z etc.

I changed the y current to 800 but then the other motor refused to turn. I changed back to 1600 and bingo, no noise!!!!!!!!!!!!

I really don´t know what happened.

Thanks!

Next I´m trying to dualextrude.

Heating needs also some study. -

Here is my thermistor and hotend. The belong to Leapfrog Creatr. That´s all can tell.

Seems that I can settle the undulating red heath curve flat by M303 H1 S240 but it helps until I switch the machine off. I´d like to start the heating automatically by the uploaded gcode.

I also wonder how can I cold extrude the second extruder, what is the code? -

@Pertti said in Y-stepper noise:

Here is my thermistor and hotend. The belong to Leapfrog Creatr. That´s all can tell.

measure the resistance at room temperature (25C) then using a known thermometer bring water to boiling (100C) and measure the resistance. that will let you caluculate the beta value.

-

E1: 116.5 kOhm 22 degrees C , 7.0 kOhm at boiling water

-

from the table it seems to match a B3950 thermistor

https://www.makeralot.com/download/Reprap-Hotend-Thermistor-NTC-3950-100K.pdf

-

Thanks Veti. Next step?

-

For some reason my thermistors lost their resistance after boiling them in hot water...

-

@Pertti Maybe they need to dry out?

-

Yes indeed, now that they are dry they work fine. But the board has something wrong. The bed thermistor pins work ok with boiled thermistors, but the heater thermistor pins give 2000 degrees when tested with the "unboiled" bed thermistor.

-

I also made changes to the config.g. I wonder if it has something to do with the problem.

; Heaters

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100 B3950 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M305 P2 T100 B3950 R4700 ; set thermistor + ADC parameters for heater 2

M143 H2 S280

; set temperature limit for heater 2 to 280C

M307 H1 A455.9 C183.2 D17.7 S1.00 V24.1 B0

M307 H2 A499.7 C172.7 D10.4 S1.00 V24.1 B0 -

I think there´s something wrong with the board.

Some fuse I guess? -

@Pertti that just means you haven't set up the temperature sensor correctly.

Your T values look a little low.

Can you post your latest config settings?