Noob building a HEVO in need of help.

-

Hello! I am building a HEVO, and its my first own printer. I have been printing and drawing in CAD about a year now, with a borrowed Prusa. I am not sure if this is the right forum category to post this, but i need help with my config-file and some wiring.

I will post the info that i think you will need to help me, but ask if you need more. Maybe i made it hard for myself by updating the Duet 2 Wifi before i made it work with the firmware that was on the board, but I thought that i might do it right from the start, because there was a beta firmware on the Duet.

This is the "plug and pray" kit that i bought:

Duet 2 Wifi

PanelDUE (I don't know the version)

MK2A Heated Bed 300x3003mm with Glass 300300*3mm

100kohm NTC3950 thermistor

5V NPN M12 inductive sensor

Nema 17 for x, y and double Z, W/20 teeth pulleys

Titain Extruder with motor+E3D V6 hotend with Nozzels

Optical end stopsI got the codes for the bed, heater and both the heat sensors right after 9 hours yesterday, that must be a new record! I think i got the newest firmwares on the bord flashed aswell.

config.g

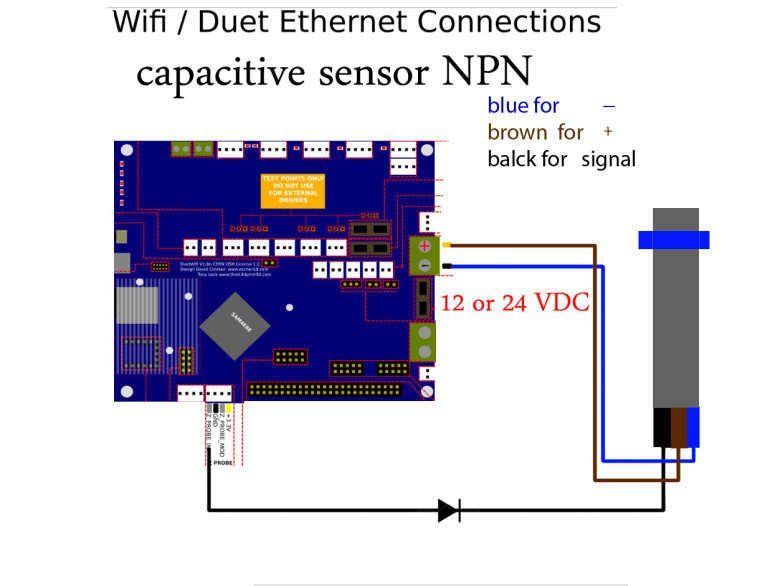

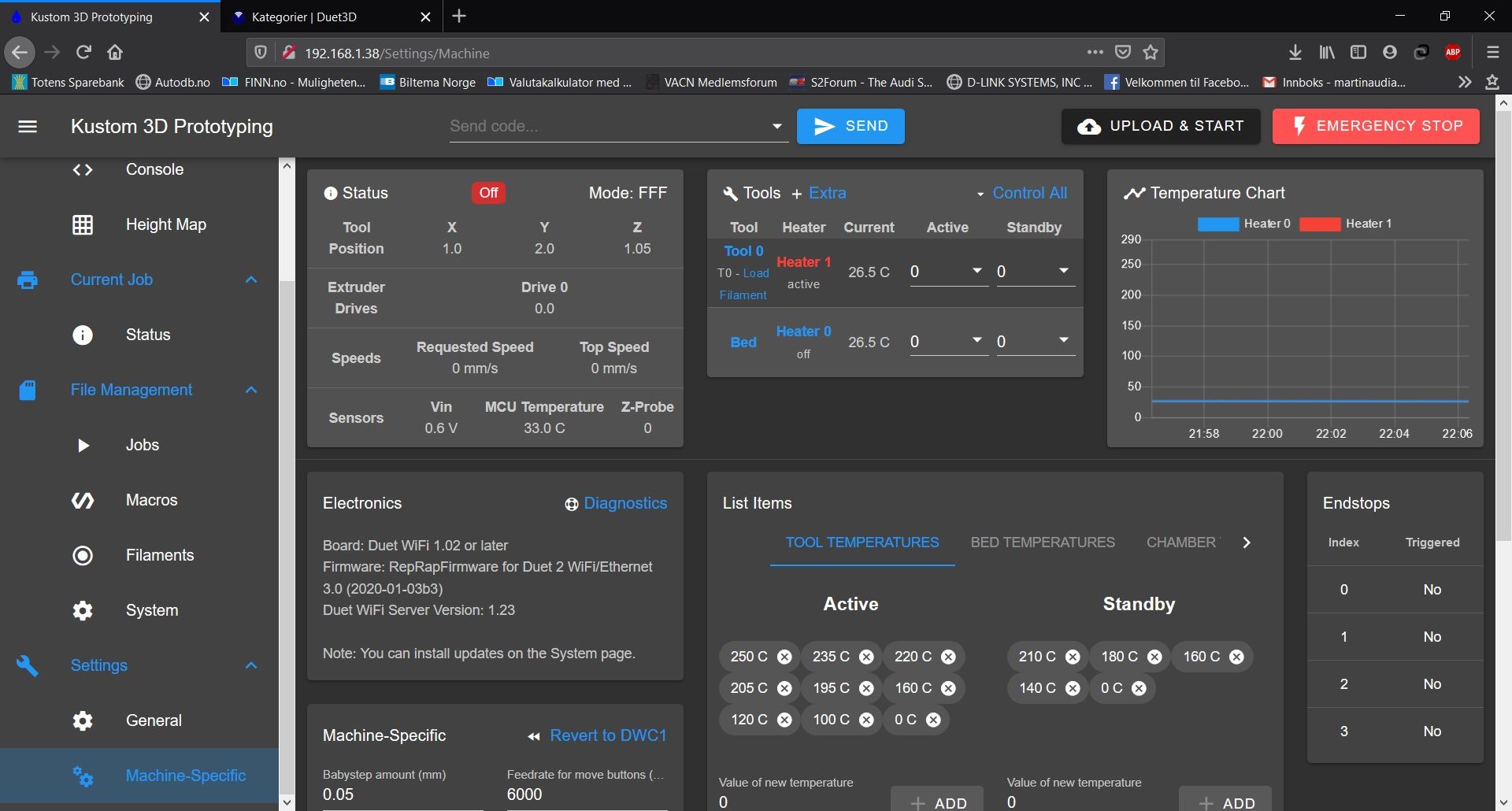

The sensor is connected like this, but the power goes to the 5V ext/fan output.1: Did i connect the wires right, and is the config right for the inductive sensor? It says distance 0 when i test it with M401 and G31 even with a object right under the sensor.

2: How can i make the static IP work? It seems like my change in IP is ignored.

3: How do i know if the motors turn the right way? Z goes up when i move it in minus(-) direction.

Y moves the right motor clockwise with pluss (+) movement (looking at it from the front of the printer) and left motor anti-clockwise, and oposite when i move X in pluss (+) direction. Is CoreyXY set up the right way? The belt is not connected yet.4: The two Y end-stops/homing sensors change the index in the webinterface when i try to trigger them. I have to extend the cables for the X-sensors. They are not connected yet.

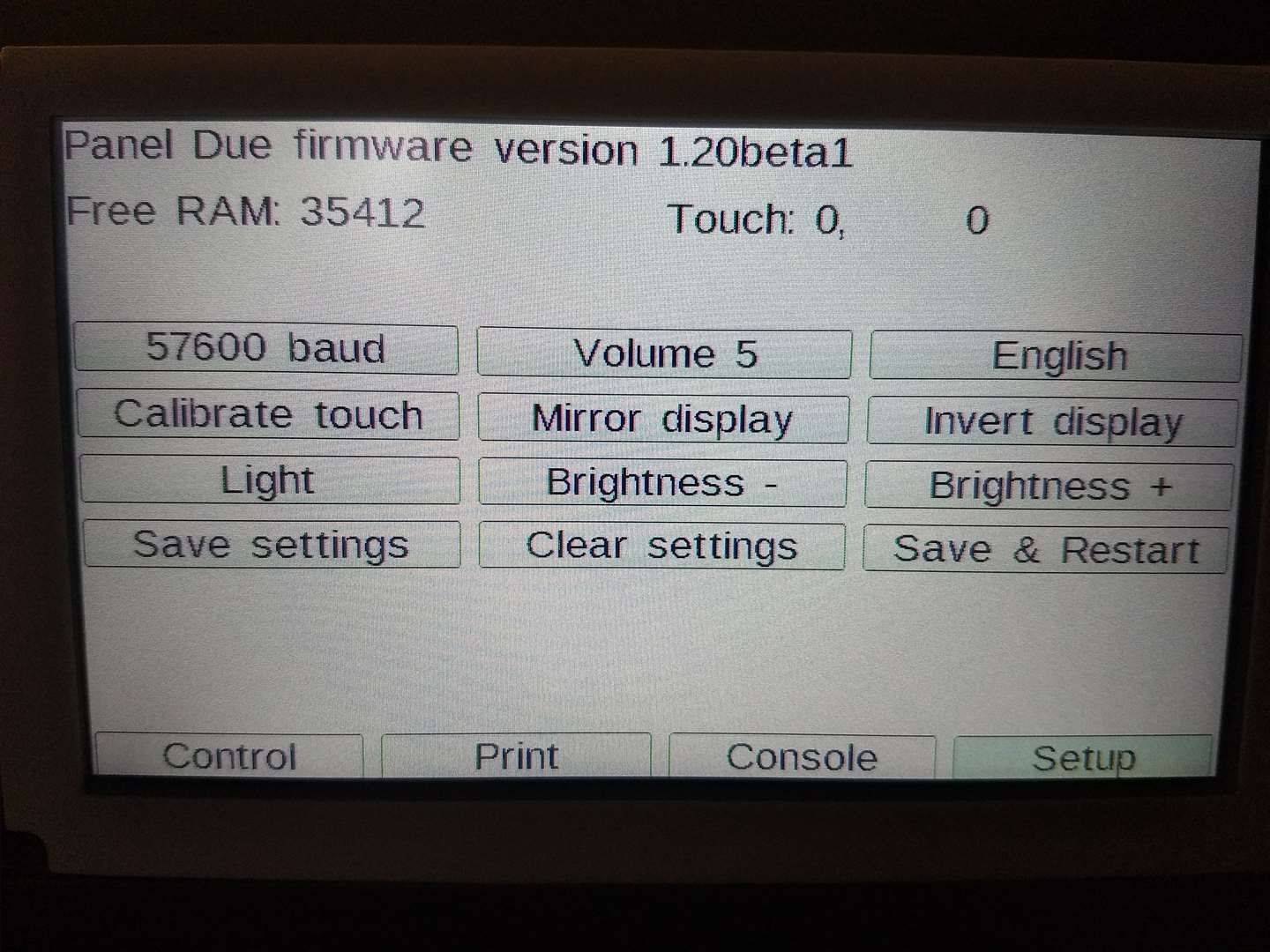

5: How do i know what version my screen is? Does it say a version number on the back of the board, it has a beta firmware version aswell.

If you find something wrong els, please tell me. I will be very grateful for all the help i can get.

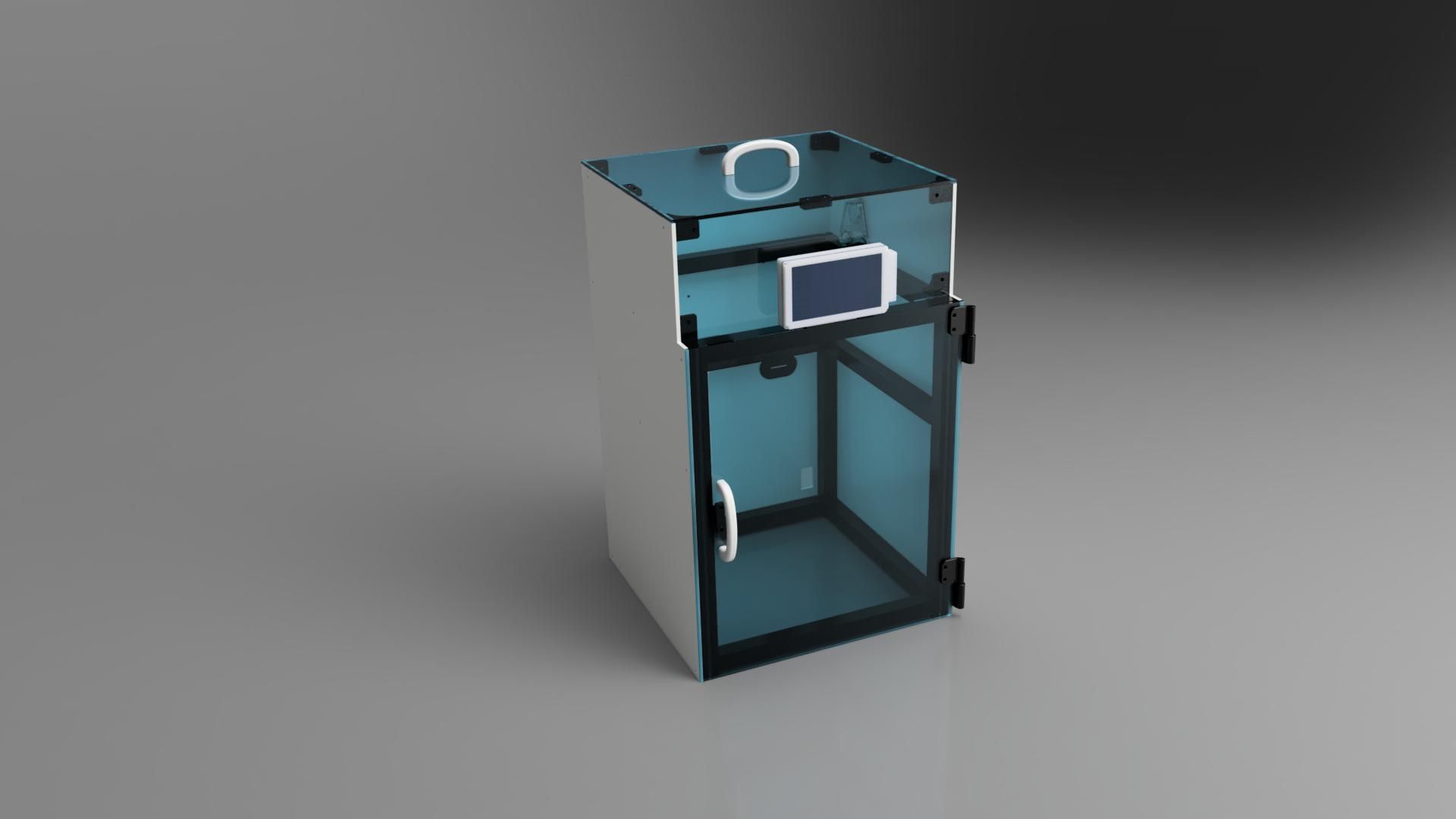

This is how it will look on the outside when i am done. I will install a heater inside aswell, because i print alot of PC. -

I can comment on the motor direction

G1 X50 H2 F2000 ;only left motor turns CCW

G1 Y50 H2 F2000 ;only right motor turns CCWWhile looking from the top of the computer.

BTW, did you use the online configurator? It provides a good starting point for manual tweaking.

Edit: yes, z (-) means up. It's confusing but correct.

-

M92 X80 Y80 Z2560 ; Set axis steps/mm

Is your z axis really 2560 steps? thats an unusual number.

M564 H0

remember to remove this once you are finished configuring your printer.

M574 X1 Y1 Z0 S1 ; set endstop configuration (X and Y endstops only, at low end, active high)

you have a probe configured but its not active.

in general i would advise you to start of with the configurator

https://configtool.reprapfirmware.org/Start

since your config looks a bit out of date. i.e no mesh configuration, but bed config in the config.g etc. -

@Quattro

I think you have mounted the Y-axis the wrong direction or do you want the motors to be mounted on the backside?

And please do yourself a favour and use reinforced idler and motor mounts as the original ones are to weak.

You will find several on thingiverse. -

@zapta said in Noob building a HEVO in need of help.:

I can comment on the motor direction

G1 X50 H2 F2000 ;only left motor turns CCW

G1 Y50 H2 F2000 ;only right motor turns CCWWhile looking from the top of the computer.

BTW, did you use the online configurator? It provides a good starting point for manual tweaking.

Edit: yes, z (-) means up. It's confusing but correct.

No, i did not use the online configurator, because i don't know what values to use. But its maybe better to use that instead of the one i have. Should i add these G1-codes to the config?

@Veti said in Noob building a HEVO in need of help.:

M92 X80 Y80 Z2560 ; Set axis steps/mm

Is your z axis really 2560 steps? thats an unusual number.

M564 H0

remember to remove this once you are finished configuring your printer.

M574 X1 Y1 Z0 S1 ; set endstop configuration (X and Y endstops only, at low end, active high)

you have a probe configured but its not active.

in general i would advise you to start of with the configurator

https://configtool.reprapfirmware.org/Start

since your config looks a bit out of date. i.e no mesh configuration, but bed config in the config.g etc.I haven't changed much in the config, i don't know how many steps it is. How do i know? How do i set the probe to actice? What is wrong about the M574 line?

@DIY-O-Sphere said in Noob building a HEVO in need of help.:

@Quattro

I think you have mounted the Y-axis the wrong direction or do you want the motors to be mounted on the backside?

And please do yourself a favour and use reinforced idler and motor mounts as the original ones are to weak.

You will find several on thingiverse.I did not notice they where the wrong way, i will switch them around. I will replace the parts with reinforced ones, thank you for the advice.

-

@Quattro said in Noob building a HEVO in need of help.:

Should i add these G1-codes to the config?

No. That code is only for testing.

-

@Quattro said in Noob building a HEVO in need of help.:

I haven't changed much in the config, i don't know how many steps it is. How do i know? How do i set the probe to actice? What is wrong about the M574 line?

it depends on your stepper motor 0.9 degree or 1.8 degree and your lead screw pitch.

normal values are 400 or 1600. -

@Quattro said in Noob building a HEVO in need of help.:

No, i did not use the online configurator, because i don't know what values to use. But its maybe better to use that

The online configurators has a sequence for web forms where you enter the data and then it generates the config file for you. I would recommend going through it and if you have questions about specific fields ask here. This will give you a good baseline that you can tweak.

Even if you already have a manual config file, you can generate one from the configurator and compare.

As for the G1 codes in my post, they are for testing through the console, not for the config file. Enter them via the console and watch the direction of the motors.

Also, here are a few things I learned over time from my HEVO build

- Direct extruder (BMG, Hemera, etc) give much better results than bowden.

- Stall detection works great instead of X/Y endstops.

- Bltouch or similar good prod works great as Z endstop and for bed leveling/compensation.

- 0.9 deg X/Y steppers and 16T pulleys everywhere provide more accusation positioning.

- Dampers on the X/Y steppers makes the movements significantly quieter.

- Being proficient with Fusion 360 and being able to modify parts is very useful (I used Fusion for this purpose).

- Bearings and rods from reputable vendors such as Misumi are better than cheap chinese stuff (though the Chinese stuff does work and is getting better and better)

- It takes a lot of work and patient to tweak a printer but it's also fun.

YMMV.

-

@Quattro

Maybe the best way to calculate the steps is to use the online calculator

https://blog.prusaprinters.org/calculator/ -

@DIY-O-Sphere said in Noob building a HEVO in need of help.:

Maybe the best way to calculate the steps is to use the online calculator

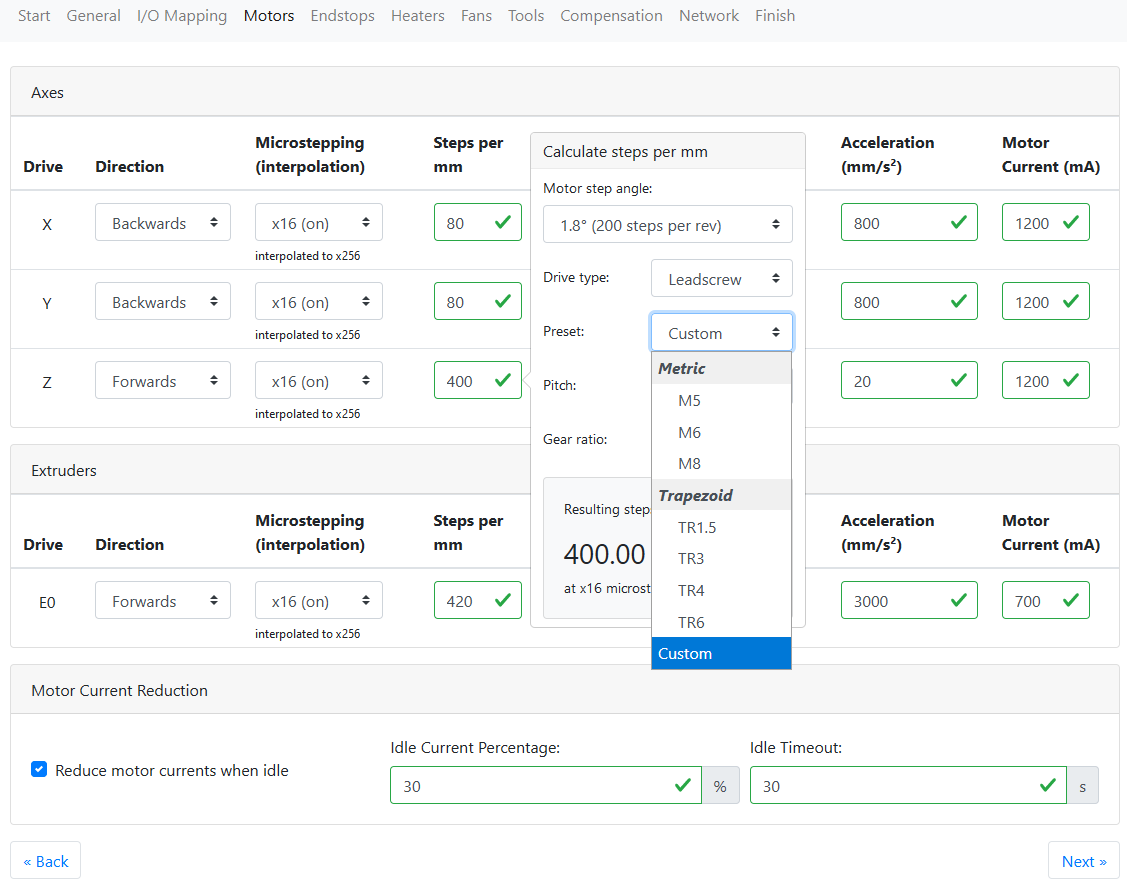

thats included in the configurator. just click on the steps per mm field. it opens up a calculator.

-

@Veti

You are right I have forgotten that... -

@Quattro said in Noob building a HEVO in need of help.:

No, i did not use the online configurator, because i don't know what values to use.

I have prepared a json file, witch you can load into the configurator.

You have to adept steps and the dimension for the Z-axis.

Also the typ of extruder (geared or direct). And typ of end stops.

Then you are able to generate all required sys files.We have to adepted the config.g later on, as some parts of configuration aren't saved propper in the json file, eg. network settings or should be tweaked a little bit....

Edit: I have change the json, as there was a mistake in probe configuration

-

@Veti said in Noob building a HEVO in need of help.:

@Quattro said in Noob building a HEVO in need of help.:

I haven't changed much in the config, i don't know how many steps it is. How do i know? How do i set the probe to actice? What is wrong about the M574 line?

it depends on your stepper motor 0.9 degree or 1.8 degree and your lead screw pitch.

normal values are 400 or 1600.Ok. The motors are 1.8 degrees, but the threads on the screw has some wierd info, it says "TR8x8 (P2)" The other ones for sale is 8x2. I assume 8mm x 2mm pitch. What does "lead" mean?

@zapta said in Noob building a HEVO in need of help.:

@Quattro said in Noob building a HEVO in need of help.:

No, i did not use the online configurator, because i don't know what values to use. But its maybe better to use that

The online configurators has a sequence for web forms where you enter the data and then it generates the config file for you. I would recommend going through it and if you have questions about specific fields ask here. This will give you a good baseline that you can tweak.

Even if you already have a manual config file, you can generate one from the configurator and compare.

As for the G1 codes in my post, they are for testing through the console, not for the config file. Enter them via the console and watch the direction of the motors.

Also, here are a few things I learned over time from my HEVO build

- Direct extruder (BMG, Hemera, etc) give much better results than bowden.

- Stall detection works great instead of X/Y endstops.

- Bltouch or similar good prod works great as Z endstop and for bed leveling/compensation.

- 0.9 deg X/Y steppers and 16T pulleys everywhere provide more accusation positioning.

- Dampers on the X/Y steppers makes the movements significantly quieter.

- Being proficient with Fusion 360 and being able to modify parts is very useful (I used Fusion for this purpose).

- Bearings and rods from reputable vendors such as Misumi are better than cheap chinese stuff (though the Chinese stuff does work and is getting better and better)

- It takes a lot of work and patient to tweak a printer but it's also fun.

YMMV.

I am going to use the configurator now, i have to figure things out first. Thanks for the upgrade advice. I am going to upgrade the printer when i can afford it. The first on the list is a direct extruder. I am drawing alot of car parts in Fusion. I just made some tweakes on reinforced brackets and printing them on the Prusa now.

@Veti said in Noob building a HEVO in need of help.:

@DIY-O-Sphere said in Noob building a HEVO in need of help.:

Maybe the best way to calculate the steps is to use the online calculator

thats included in the configurator. just click on the steps per mm field. it opens up a calculator.

@DIY-O-Sphere said in Noob building a HEVO in need of help.:

@Quattro said in Noob building a HEVO in need of help.:

No, i did not use the online configurator, because i don't know what values to use.

I have prepared a json file, witch you can load into the configurator.

You have to adept steps and the dimension for the Z-axis.

Also the typ of extruder (geared or direct). And typ of end stops.

Then you are able to generate all required sys files.We have to adepted the config.g later on, as some parts of configuration aren't saved propper in the json file, eg. network settings or should be tweaked a little bit....

Edit: I have change the json, as there was a mistake in probe configuration

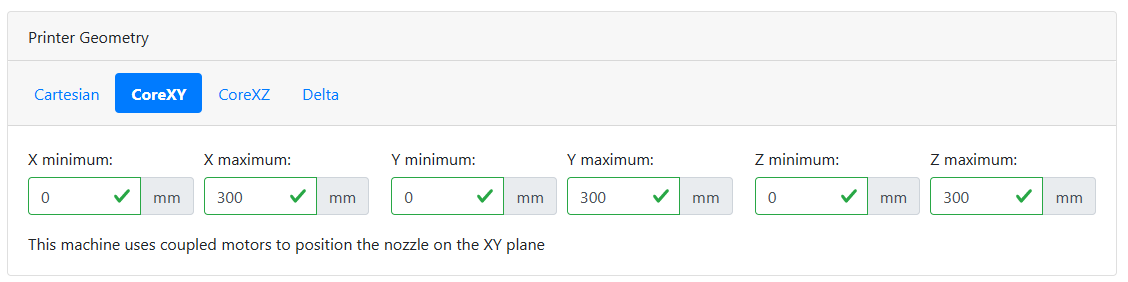

Thank you. I have loaded in the file in the configurator but i need help to understand a few things first.

Do i measure "Z maximum" when the bed is on the bottom and up to the nozzle?Do I have to change the X and Y minimum and maximum if I want to skip the "end stops" and use sensorless? The Y and X axis must be a little bit shorter i think, because both axis is longer then the glass plate on the bed. When I move the Y axis to the back (minimum?) it is aligned to the edge of the glass plate where the extruder stops, but the other way the extrudes goes further then the edge of the plate.

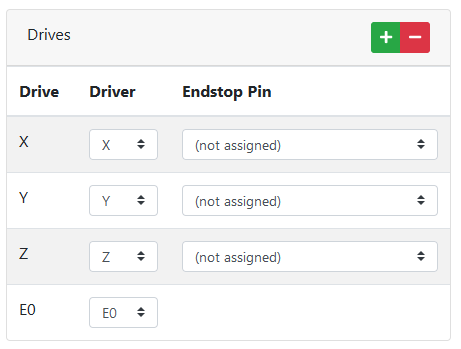

Do I select not assigned here if i want to use sensorless?

I changed the motor current to 1.2A, The Z-motor is probably 1.67A, does it matter only for the sensorless homing?

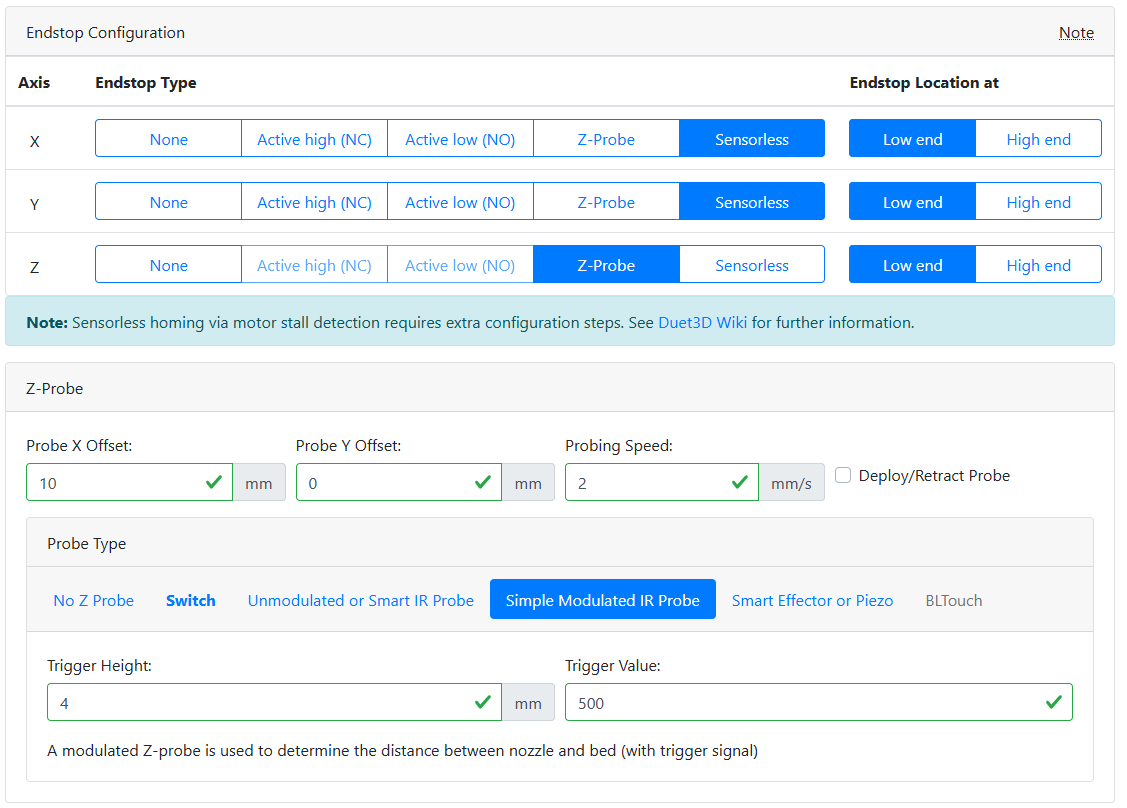

The Z-motor specs is still confusing, there is no TR 8 in the list, should i use M8x2?Do i select sensorless on X and Y? What kind of Z-probe is NPN? "Simple modulated IR probe?"

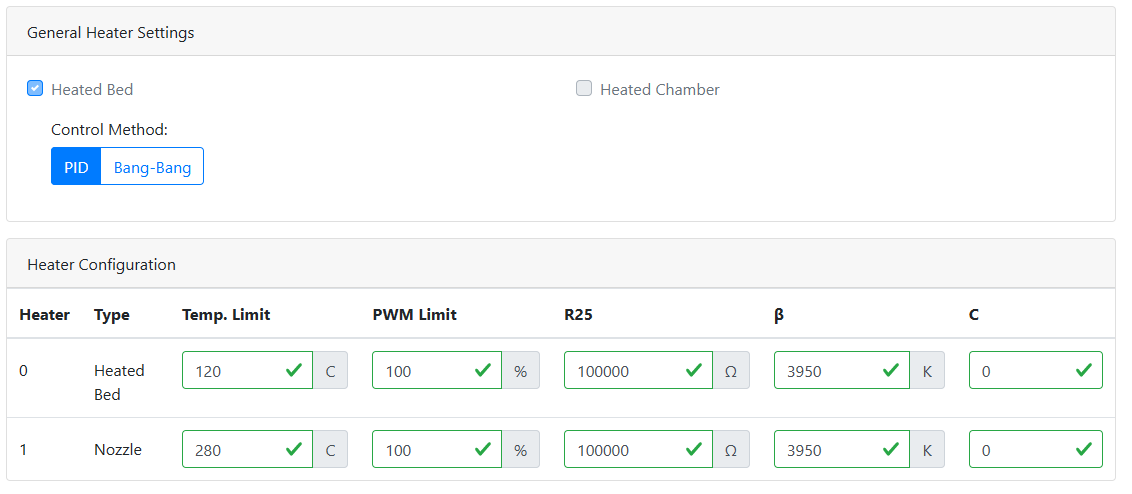

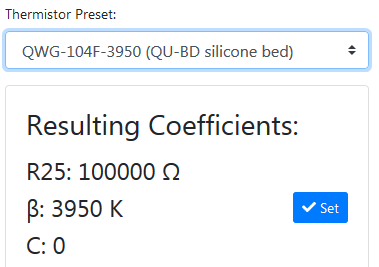

Does it matter if I use the "standard values" for resistance? I have measured them to be around 113k with a multimeter.

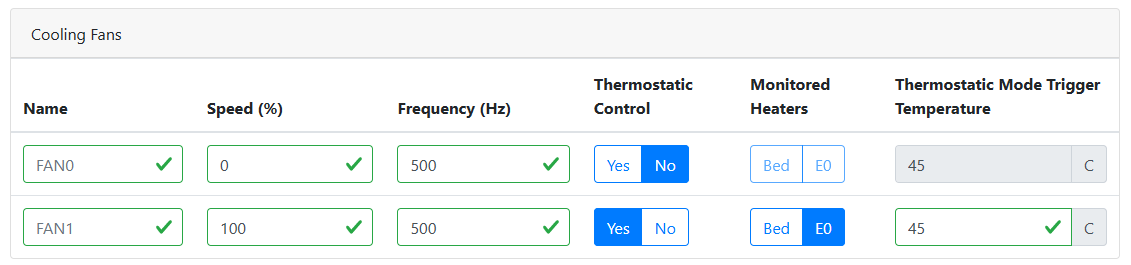

Should i change this if I am going to use a fan for part cooling and one fan for the extruder heat sink?

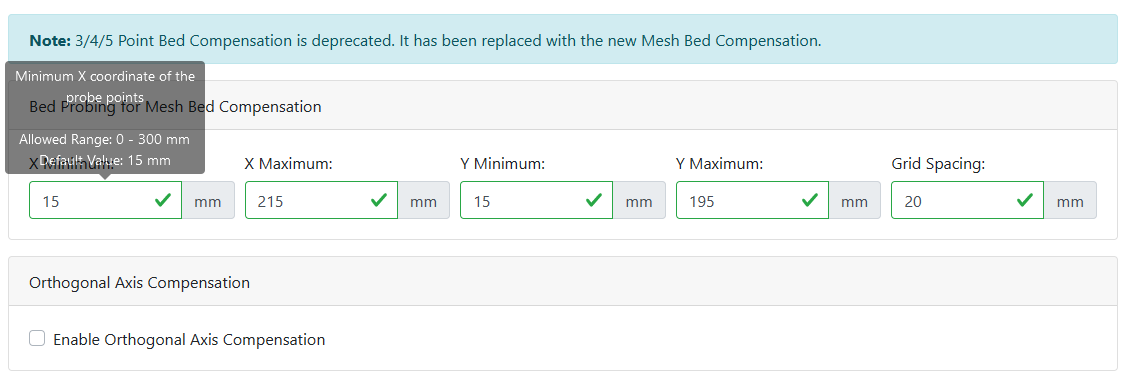

Should the maximum values be changed to 300 - 15mm offset on both X and Y axis? This seems to only measure some of the bed.Thank you all for helping me!

-

@Quattro said in Noob building a HEVO in need of help.:

TR8x8

that means 8mm diameter. lifting 8mm per revolution.

with that you have 400steps/mm using a 1.8 degree motor at x16 interpolation. -

@Quattro said in Noob building a HEVO in need of help.:

Does it matter if I use the "standard values" for resistance? I have measured them to be around 113k with a multimeter.

If you click into a value field a menu pops up where you can select the sensor typ

For the bed I think this one

For the heater you can select the E3D if it is a genuine. -

@Quattro said in Noob building a HEVO in need of help.:

Do i measure "Z maximum" when the bed is on the bottom and up to the nozzle?

-

@Quattro said in Noob building a HEVO in need of help.:

Do I have to change the X and Y minimum and maximum if I want to skip the "end stops" and use sensorless?

The homing procedure will do that for you. The file is generated by the tool.

In the homing sequence the axis are allowed to move outside the print aera. (Till they hit the end stop or sensorless homing takes in place) -

@Quattro said in Noob building a HEVO in need of help.:

Do I select not assigned here if i want to use sensorless?

For me it seams to be right. But I have never set up a system with sensorless homing.

So you better should read her

https://duet3d.dozuki.com/Wiki/Stall_detection_and_sensorless_homing -

@Quattro said in Noob building a HEVO in need of help.:

Should i change this if I am going to use a fan for part cooling and one fan for the extruder heat sink?

That is set as standard. FAN0 is for part cooling

FAN1 is for the hotend. Configured like that the fan will start to rotate when then hotend reaches 45 °C -

@Quattro said in Noob building a HEVO in need of help.:

Should the maximum values be changed to 300 - 15mm offset on both X and Y axis? This seems to only measure some of the bed.

That is depending where you will mount the probe.

Normaly the probe sits on the side or behind of the hotend.

So if the aera is set to big it could go beside the bed.

I would keep the sandard values and adept them when the printer is set up.