I got the printer working!

But then it follows a bunch of new questions.

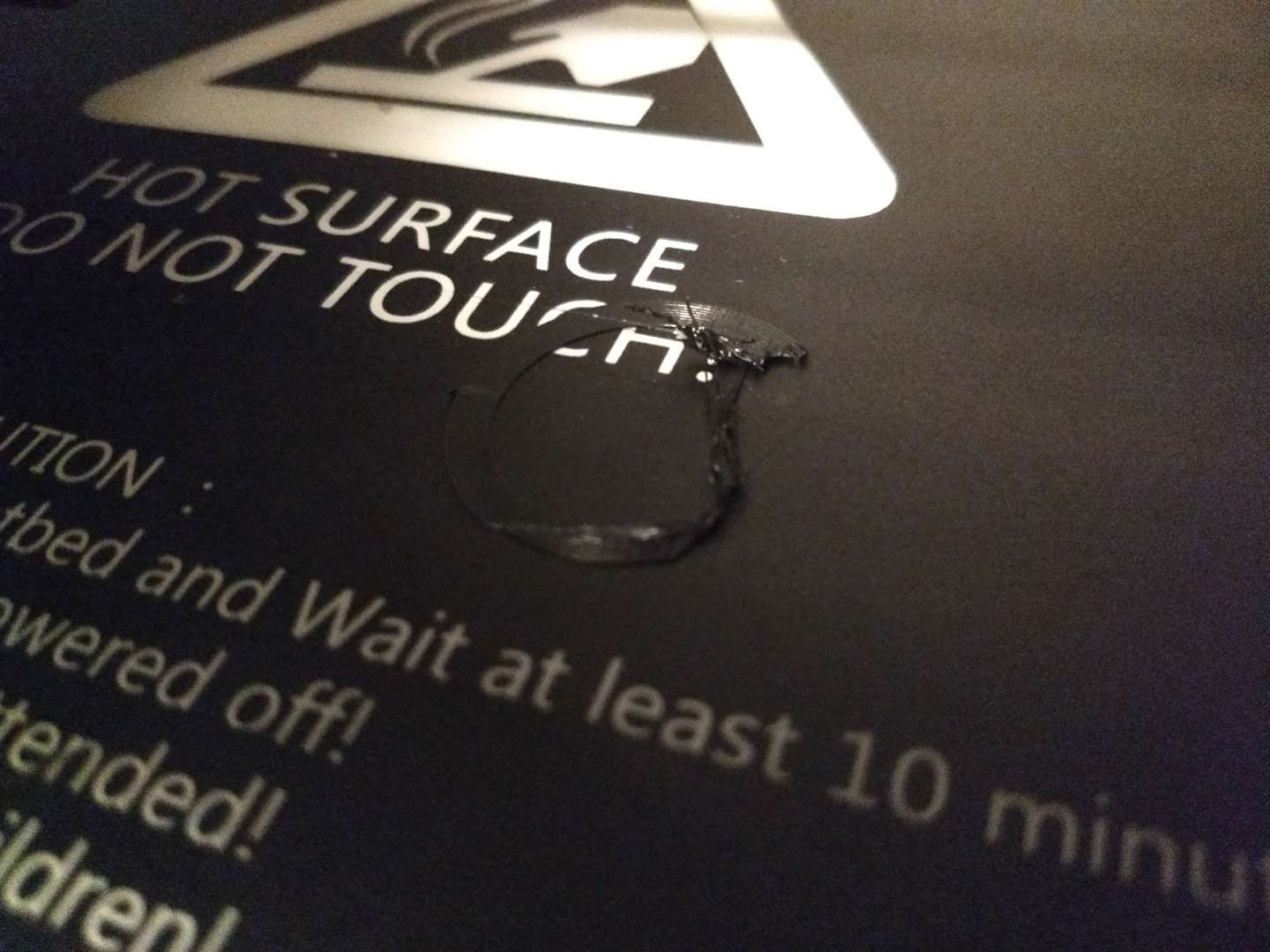

1: I am struggeling with first layer adhersion. Do i set z=0 with a paper between the bed and the nozzle?

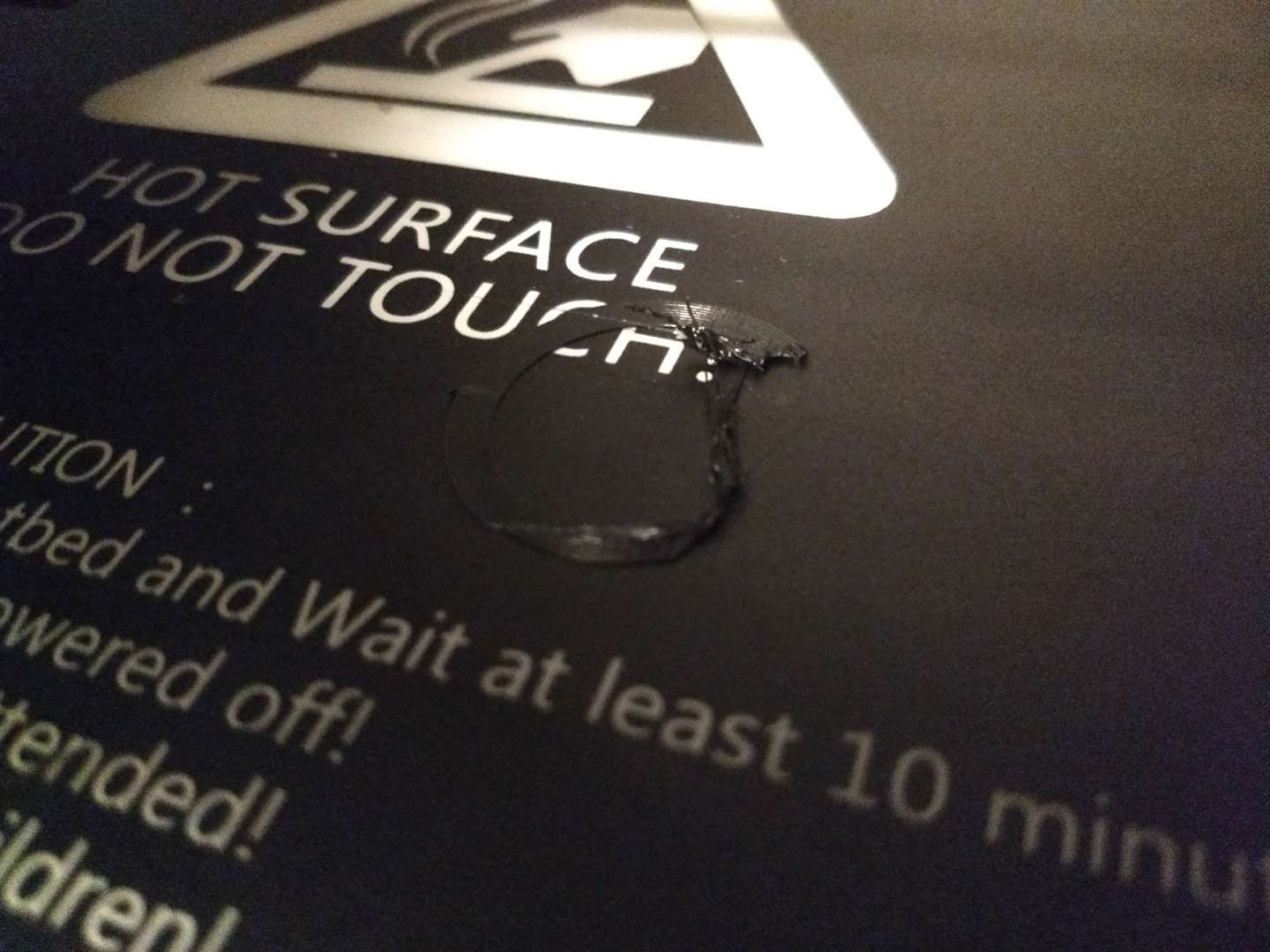

2: The print with PLA is sticking to the bed, but I am struggeling with PC. PC is sticking to the nozzle. Is this taped on bed sheet bad?

This is PC.

This is PC.

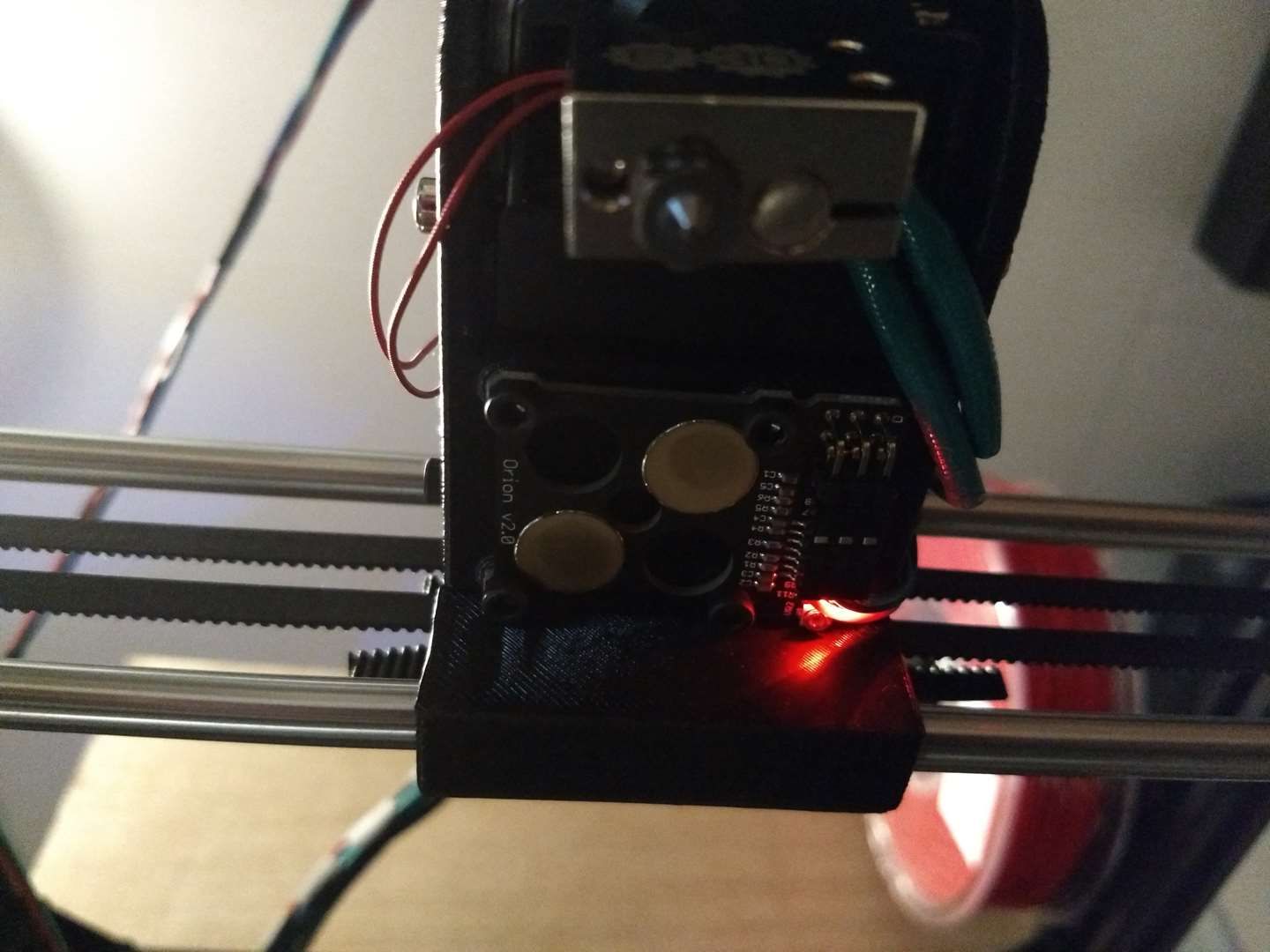

3: The probe seems to measure inconsistent depending on temperatur. Is it because I have a cheap probe, or should they only be used for low temp printing? PC is printing at 260C hot end and 90C bed temp.

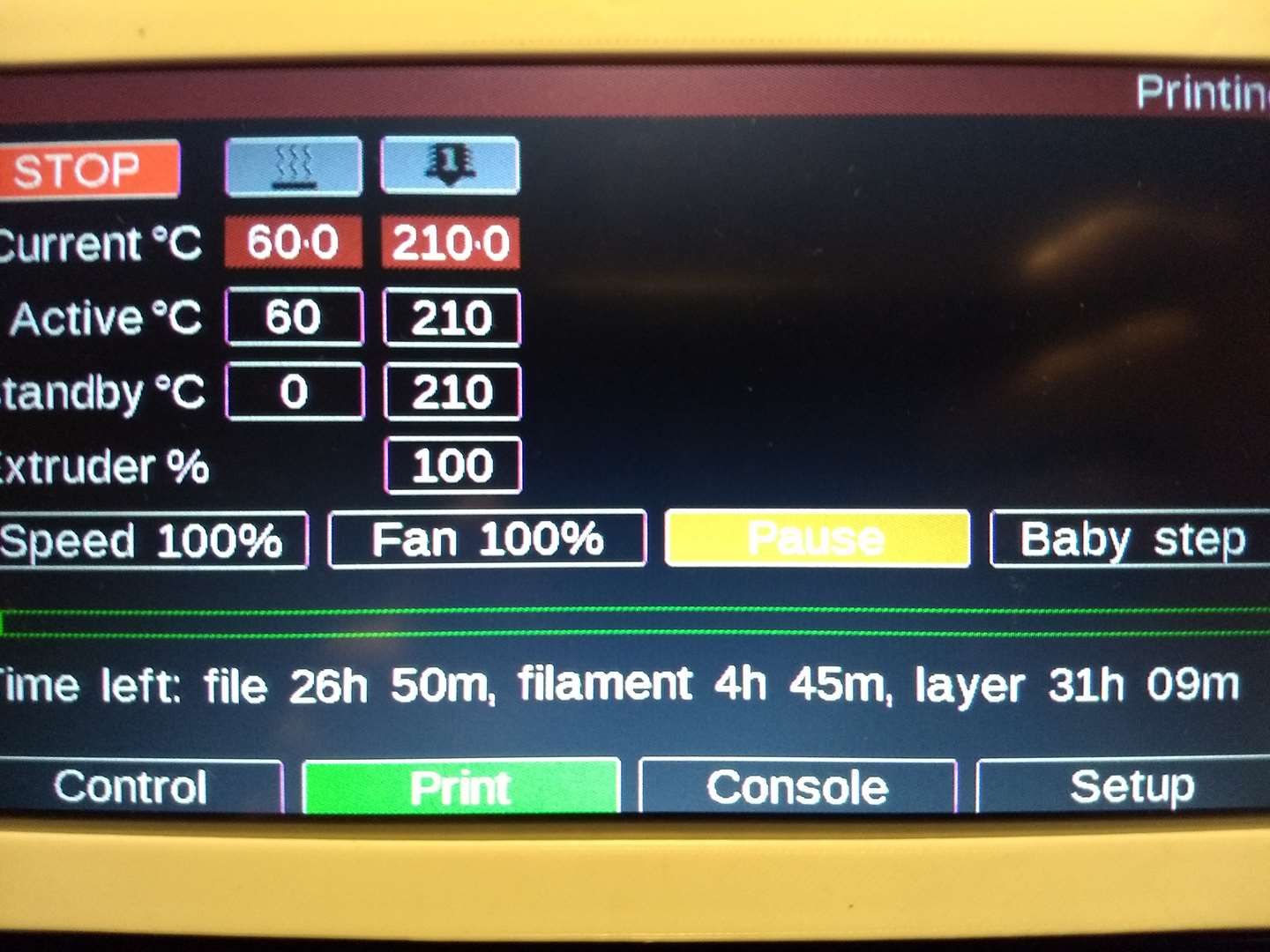

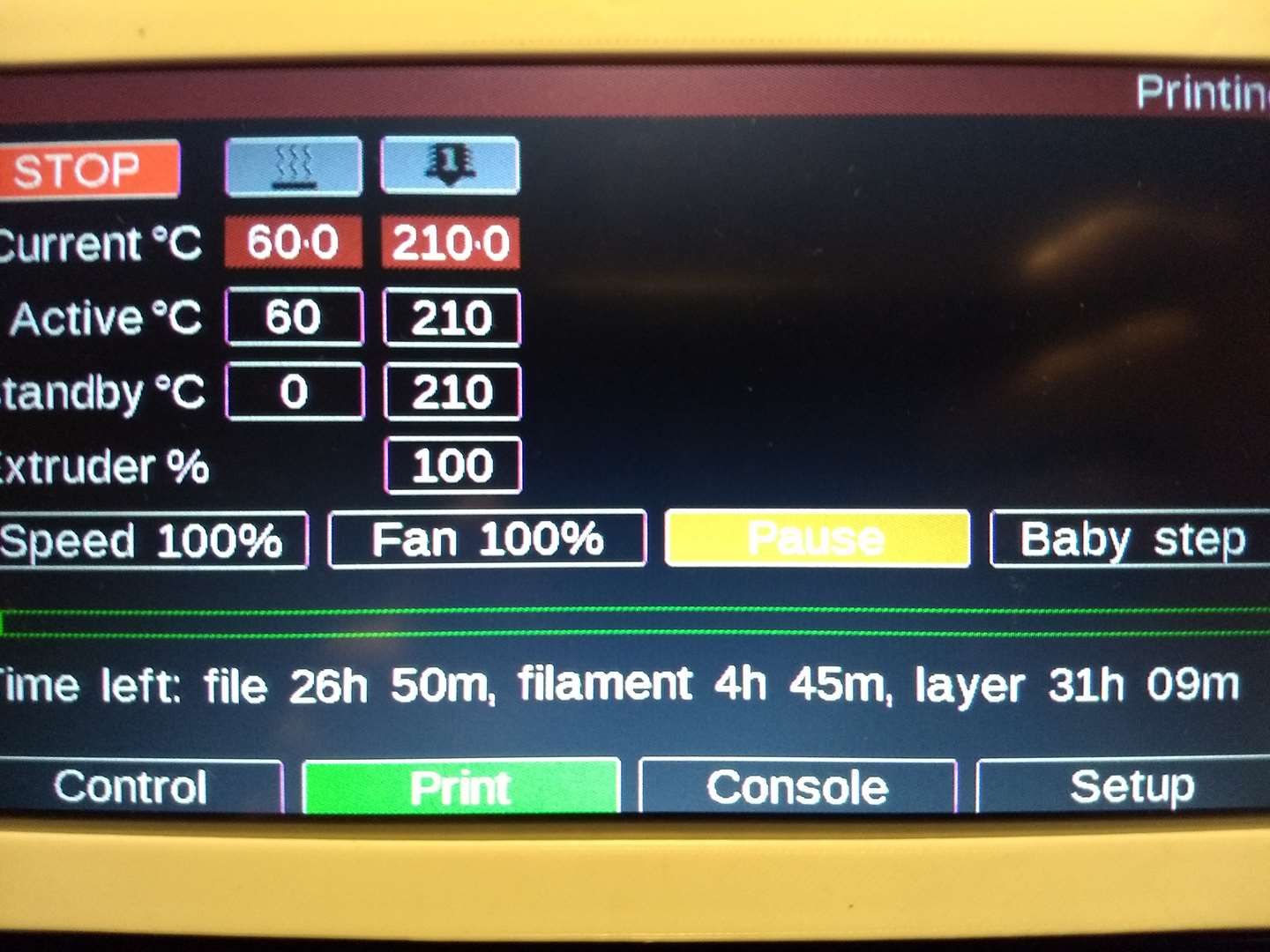

4: How do i set up time left the right way? After some time the countdown seems to be on point.

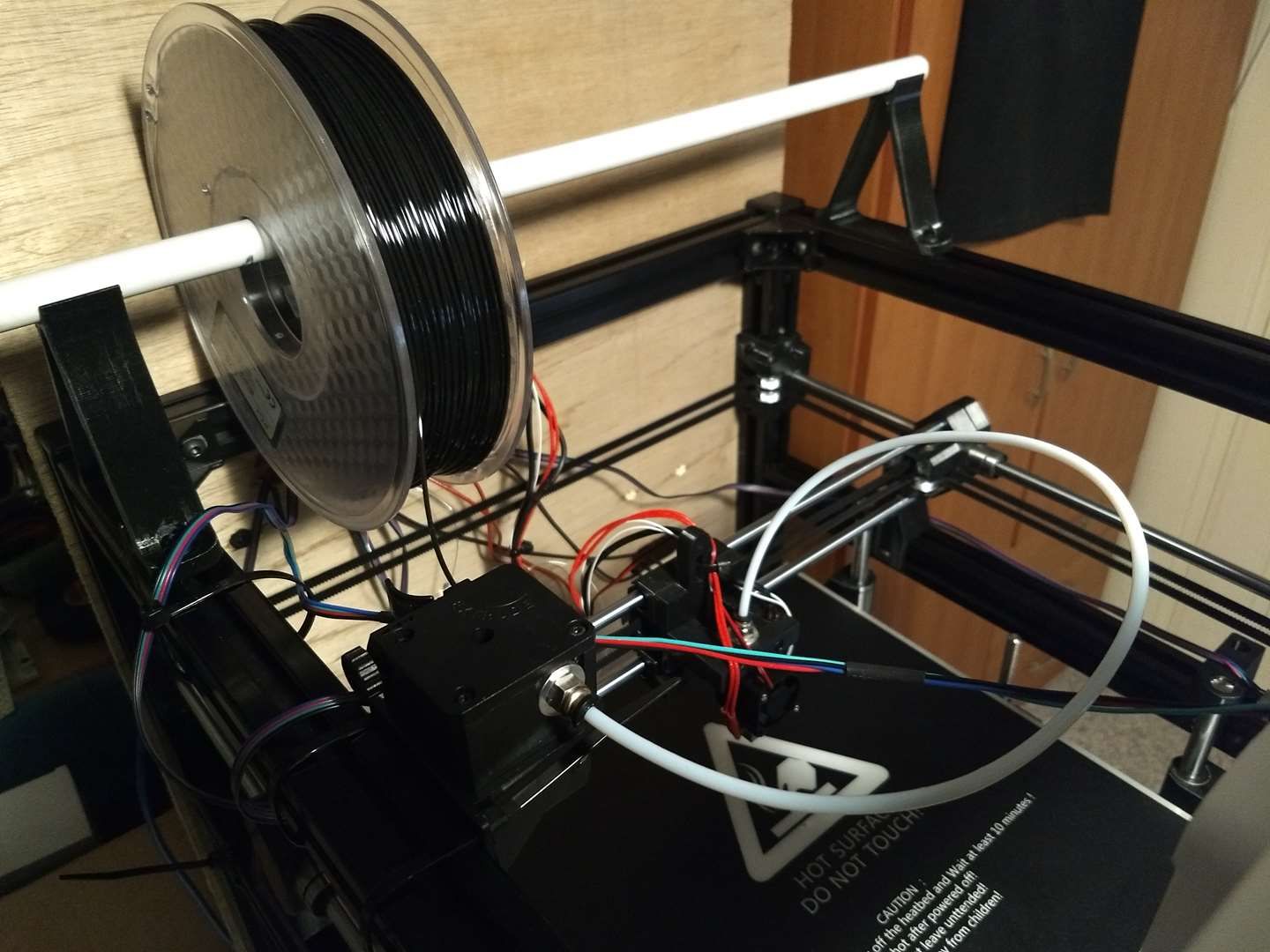

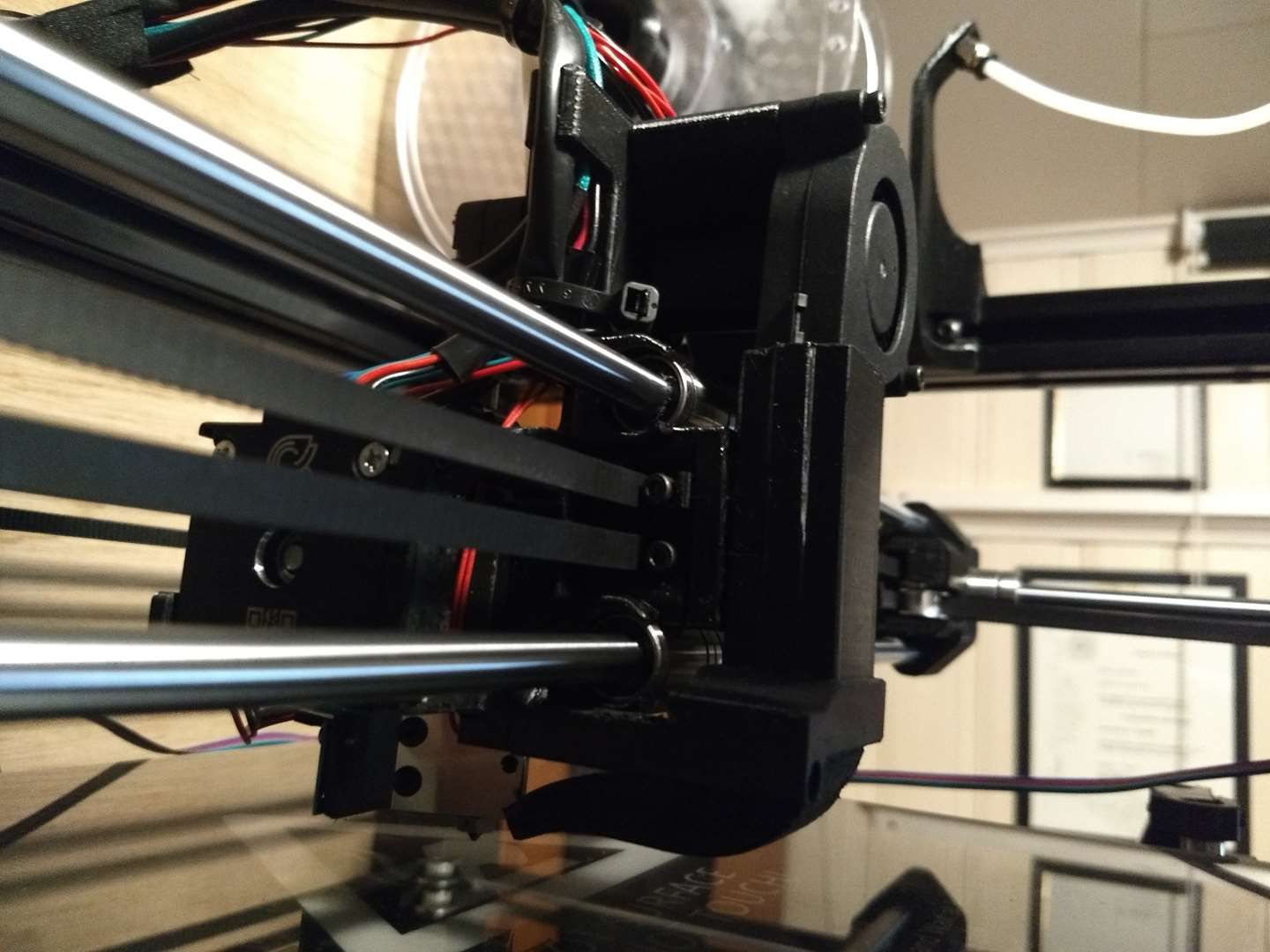

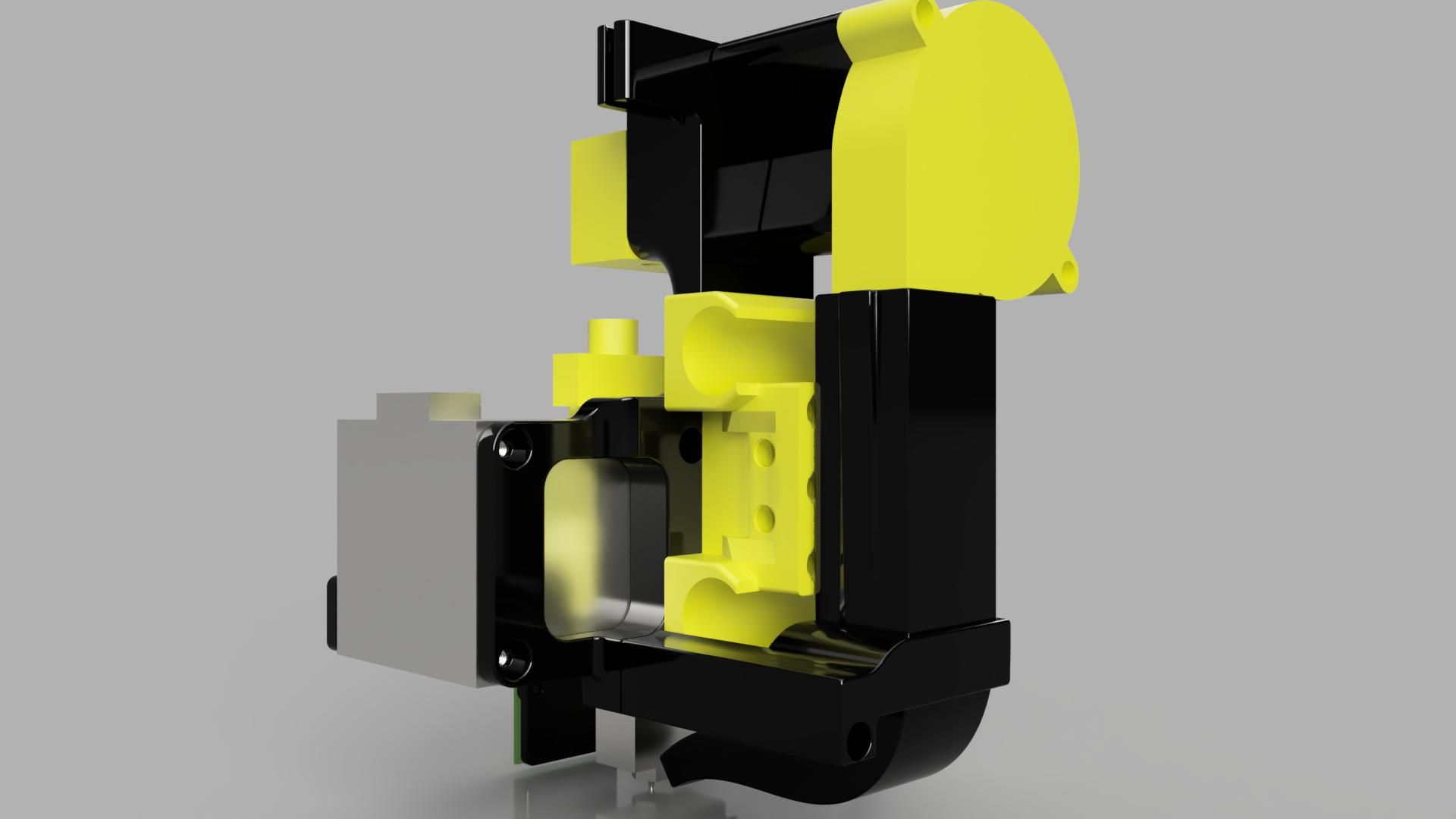

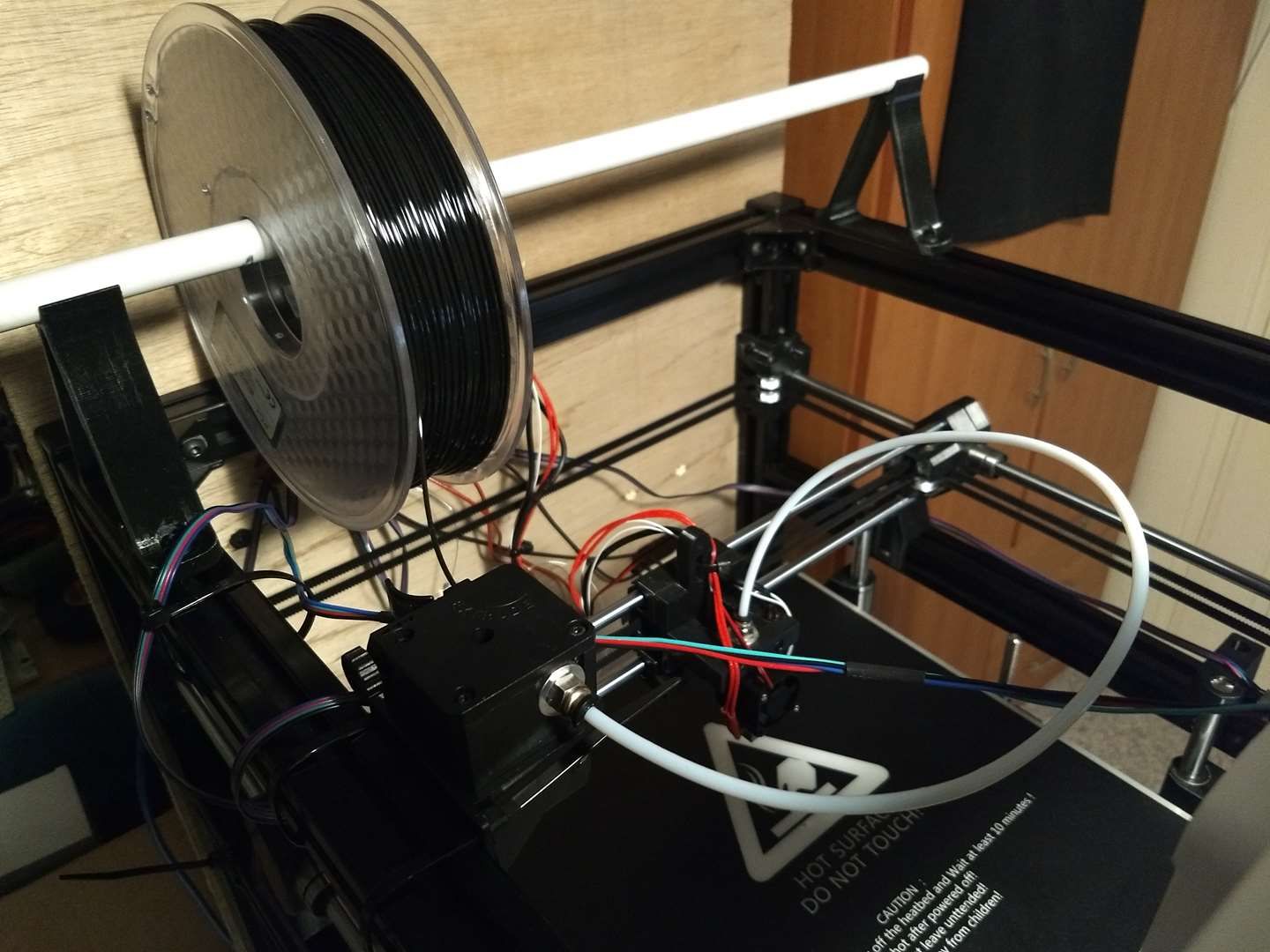

5: This is my temporary rigged extruder and filament holder.

Any suggestion how I should change this setup for a direct extruder? I am going to heat up the chamber and have the filament inside the case.

Any suggestion how I should change this setup for a direct extruder? I am going to heat up the chamber and have the filament inside the case.

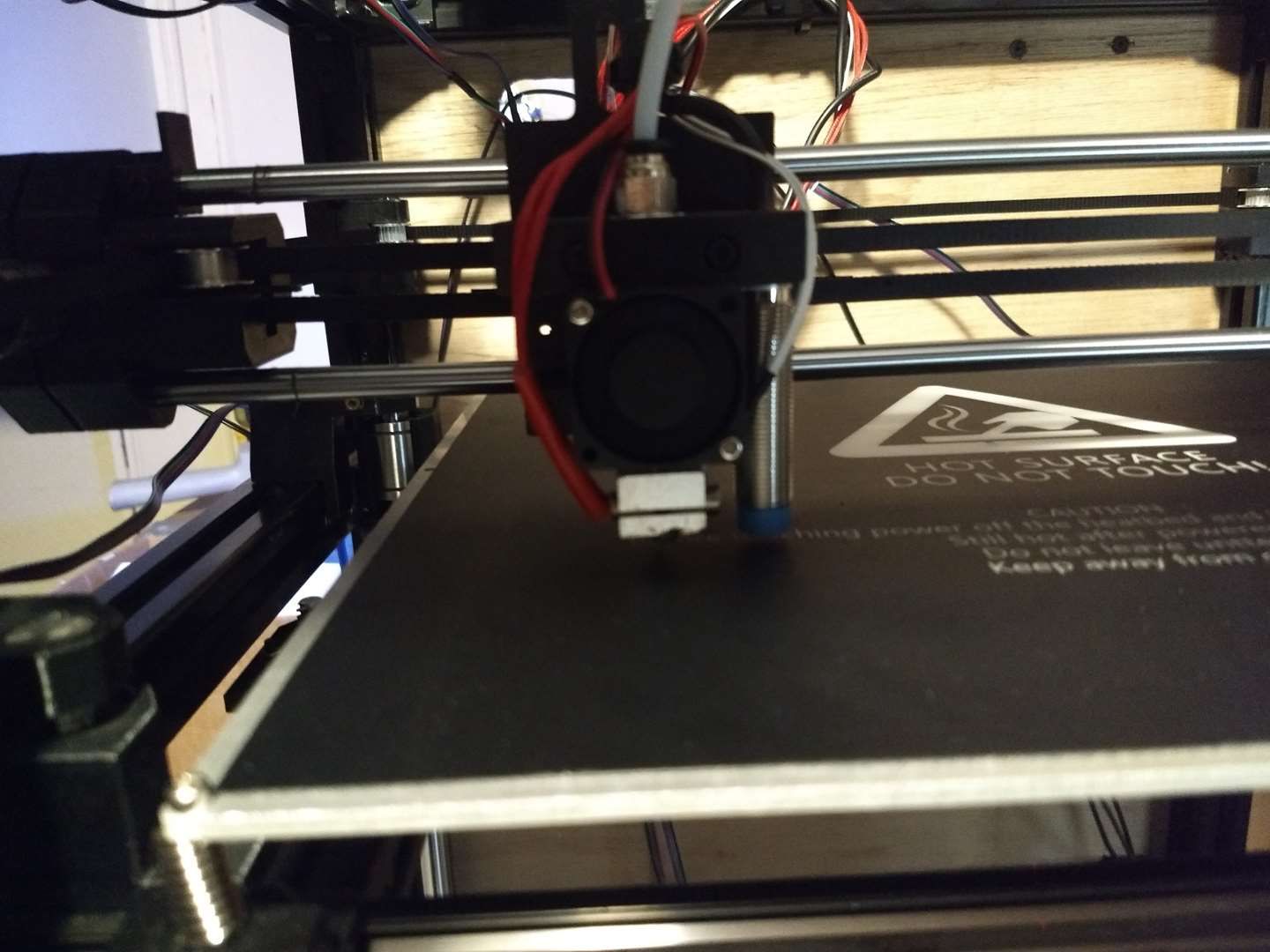

6: How do you guys attach the cables for the hot end, to the case?

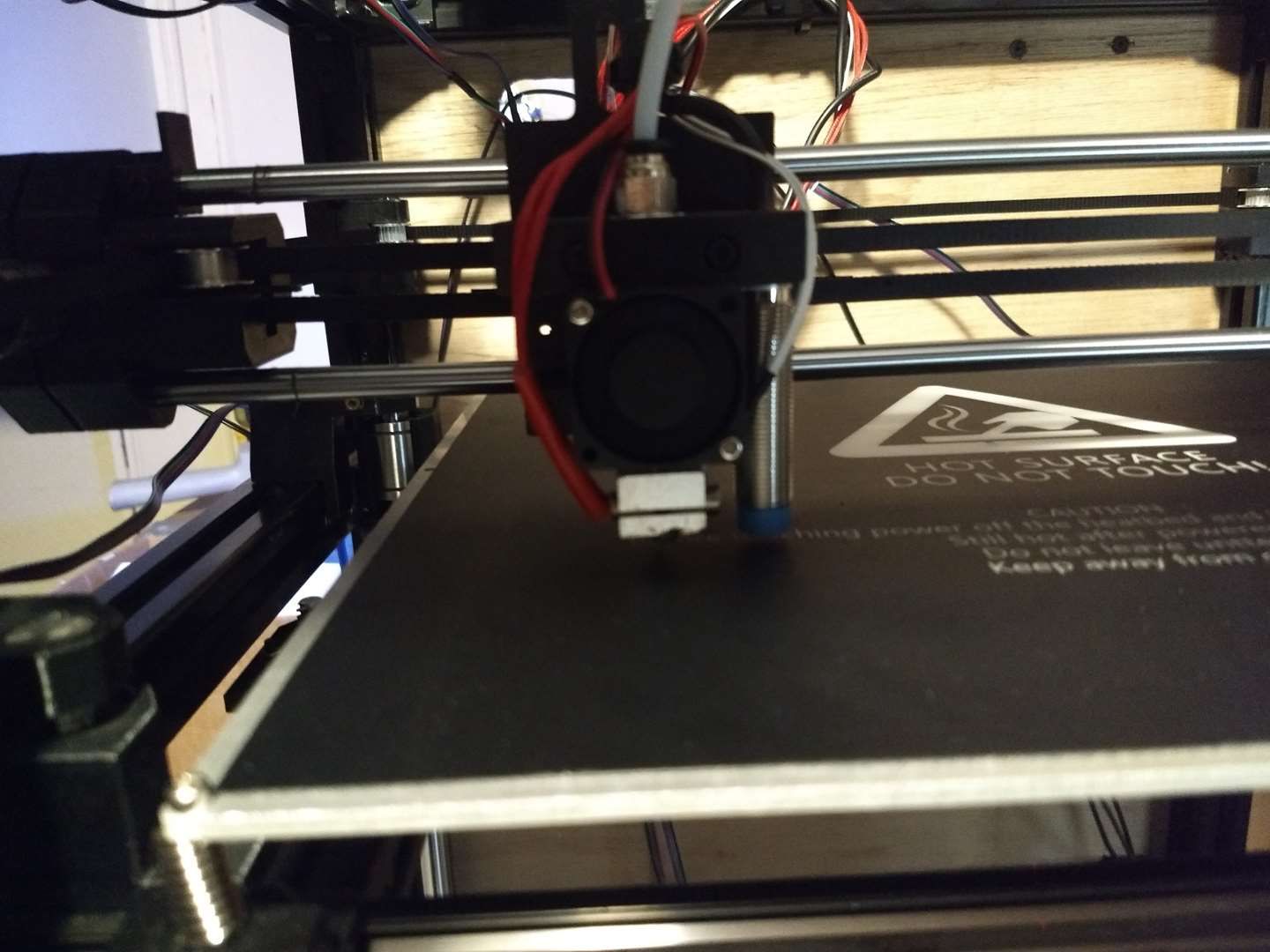

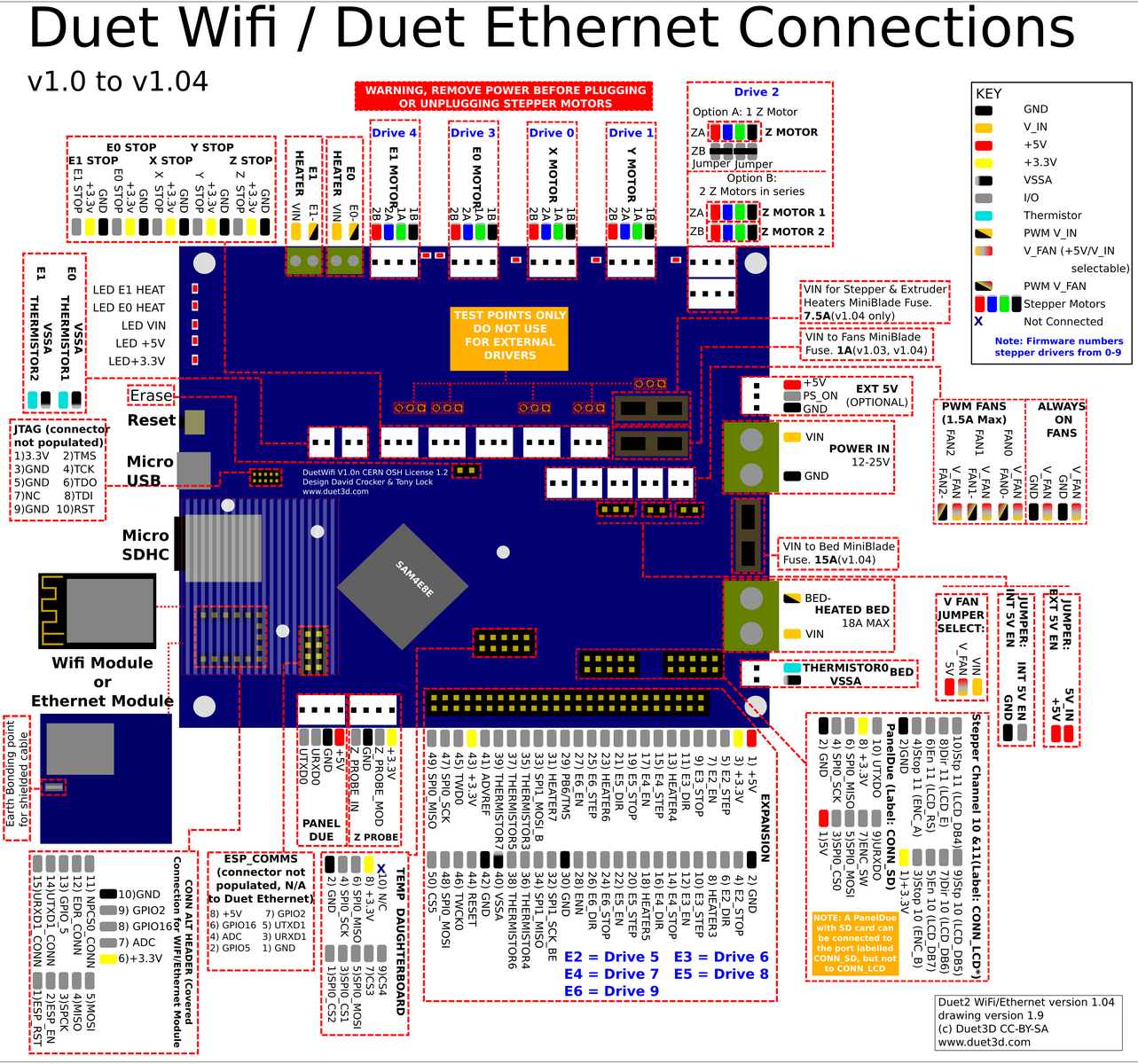

7: I am struggeling with the setup for bed mesh leveling.

The probe won't measure more to the left than this. If I change the probe X-offset from minus to plus, then I can. What is wrong?

The probe won't measure more to the left than this. If I change the probe X-offset from minus to plus, then I can. What is wrong?

8: Should i use set up m671 to get better compensation for the prints?

9: The parts are printing to small. Where is the best place to calibrate the print size? I printed a cylinder with Ø: 25mm and height 25mm and the part became Ø: 24.56mm and height: 25mm.

10: Does the g-code for the test print seem OK?

This is the first lines, the whole file was to big to upload.

G1 X3.0 Y3.0 Z1.0 F8000.0 ; prepare to prime

G92 E0 ; reset extrusion distance

G1 Z0.2 F1000.0

G1 X60.0 E9.0 F1000.0 ; priming

G1 X125.0 E12.5 F1000.0 ; priming

G1 Z0.5 F1000.0

G92 E0 ; reset extrusion distance

M109 S260 ; set temperature and wait for it to be reached

G21 ; set units to millimeters

G90 ; use absolute coordinates

M82 ; use absolute distances for extrusion

G92 E0

; Filament gcode

G1 Z0.200 F7800.000

G1 E-2.00000 F2400.00000

G92 E0

G1 X75.972 Y94.032 F7800.000

G1 E2.00000 F2400.00000

G1 F1800

G1 X76.739 Y93.412 E2.03092

G1 X77.716 Y92.727 E2.06832

G1 X78.570 Y92.211 E2.09963

G1 X79.455 Y91.748 E2.13093

G1 X80.548 Y91.269 E2.16835

G1 X81.488 Y90.931 E2.19966

G1 X82.447 Y90.652 E2.23096

G1 X83.612 Y90.397 E2.26837

G1 X84.600 Y90.251 E2.29967

G1 X85.595 Y90.167 E2.33099

G1 X86.788 Y90.147 E2.36841

G1 X87.785 Y90.199 E2.39971

G1 X88.777 Y90.312 E2.43102

G1 X89.951 Y90.528 E2.46845

G1 X90.919 Y90.775 E2.49976

G1 X91.869 Y91.082 E2.53106

G1 X92.977 Y91.525 E2.56848

G1 X93.877 Y91.958 E2.59979

G1 X94.748 Y92.445 E2.63109

G1 X95.747 Y93.098 E2.66850

G1 X96.544 Y93.700 E2.69981

G1 X97.302 Y94.350 E2.73112

G1 X98.152 Y95.187 E2.76854

G1 X98.815 Y95.934 E2.79984

G1 X99.430 Y96.721 E2.83115

G1 X100.099 Y97.709 E2.86857

G1 X100.601 Y98.572 E2.89988

G1 X101.049 Y99.464 E2.93119

G1 X101.510 Y100.565 E2.96860

G1 X101.832 Y101.510 E2.99991

G1 X102.096 Y102.473 E3.03122

G1 X102.331 Y103.643 E3.06863

G1 X102.460 Y104.633 E3.09994

G1 X102.528 Y105.629 E3.13123

G1 X102.529 Y106.795 E3.16779

G1 X102.462 Y107.805 E3.19953

G1 X102.331 Y108.808 E3.23125

G1 X102.102 Y109.952 E3.26785

G1 X101.836 Y110.929 E3.29959

G1 X101.511 Y111.886 E3.33127

G1 X101.082 Y112.917 E3.36627

G1 X100.570 Y113.938 E3.40211

G1 X100.063 Y114.800 E3.43344

G1 X99.498 Y115.638 E3.46514

G1 X98.773 Y116.568 E3.50213

G1 X98.107 Y117.313 E3.53345

G1 X97.387 Y118.024 E3.56517

G1 X96.493 Y118.793 E3.60214

G1 X95.694 Y119.391 E3.63343

G1 X94.859 Y119.939 E3.66475

G1 X93.819 Y120.524 E3.70218

G1 X92.917 Y120.954 E3.73349

G1 X91.991 Y121.326 E3.76479

G1 X90.856 Y121.695 E3.80221

G1 X89.888 Y121.938 E3.83351

G1 X88.906 Y122.121 E3.86482

G1 X87.721 Y122.258 E3.90223

G1 X86.723 Y122.306 E3.93354

G1 X85.725 Y122.291 E3.96485

G1 X84.536 Y122.193 E4.00226

G1 X83.549 Y122.043 E4.03356

G1 X82.573 Y121.832 E4.06488

G1 X81.426 Y121.501 E4.10230

G1 X80.488 Y121.159 E4.13360

G1 X79.572 Y120.760 E4.16491

G1 X78.514 Y120.210 E4.20232

G1 X77.662 Y119.690 E4.23362

G1 X76.843 Y119.118 E4.26494

G1 X75.913 Y118.369 E4.30237

G1 X75.180 Y117.691 E4.33368

G1 X74.490 Y116.969 E4.36498

G1 X73.726 Y116.052 E4.40240

G1 X73.141 Y115.243 E4.43371

G1 X72.607 Y114.400 E4.46501

G1 X72.039 Y113.350 E4.50243

G1 X71.625 Y112.442 E4.53373

G1 X71.268 Y111.509 E4.56504

G1 X70.918 Y110.368 E4.60247

G1 X70.691 Y109.396 E4.63378

G1 X70.524 Y108.411 E4.66508

G1 X70.406 Y107.224 E4.70248

G1 X70.375 Y106.227 E4.73378

G1 X70.406 Y105.228 E4.76510

G1 X70.524 Y104.040 E4.80252

G1 X70.691 Y103.056 E4.83383

G1 X70.918 Y102.084 E4.86514

G1 X71.268 Y100.943 E4.90256

G1 X71.625 Y100.010 E4.93387

G1 X72.039 Y99.102 E4.96517

G1 X72.607 Y98.052 E5.00259

G1 X73.141 Y97.208 E5.03390

G1 X73.726 Y96.400 E5.06519

G1 X74.448 Y95.529 E5.10065

G1 X75.239 Y94.703 E5.13650

G1 X75.928 Y94.072 E5.16580

G1 X76.214 Y94.321 F7800.000

G1 F1800

Should I just buy a Bl touch so i can use a glass bed? Should i buy a E3D Hemera and new sensors? What filament sensor should I buy? Any tips for good webshops for parts?

homez.g config.g bed.g

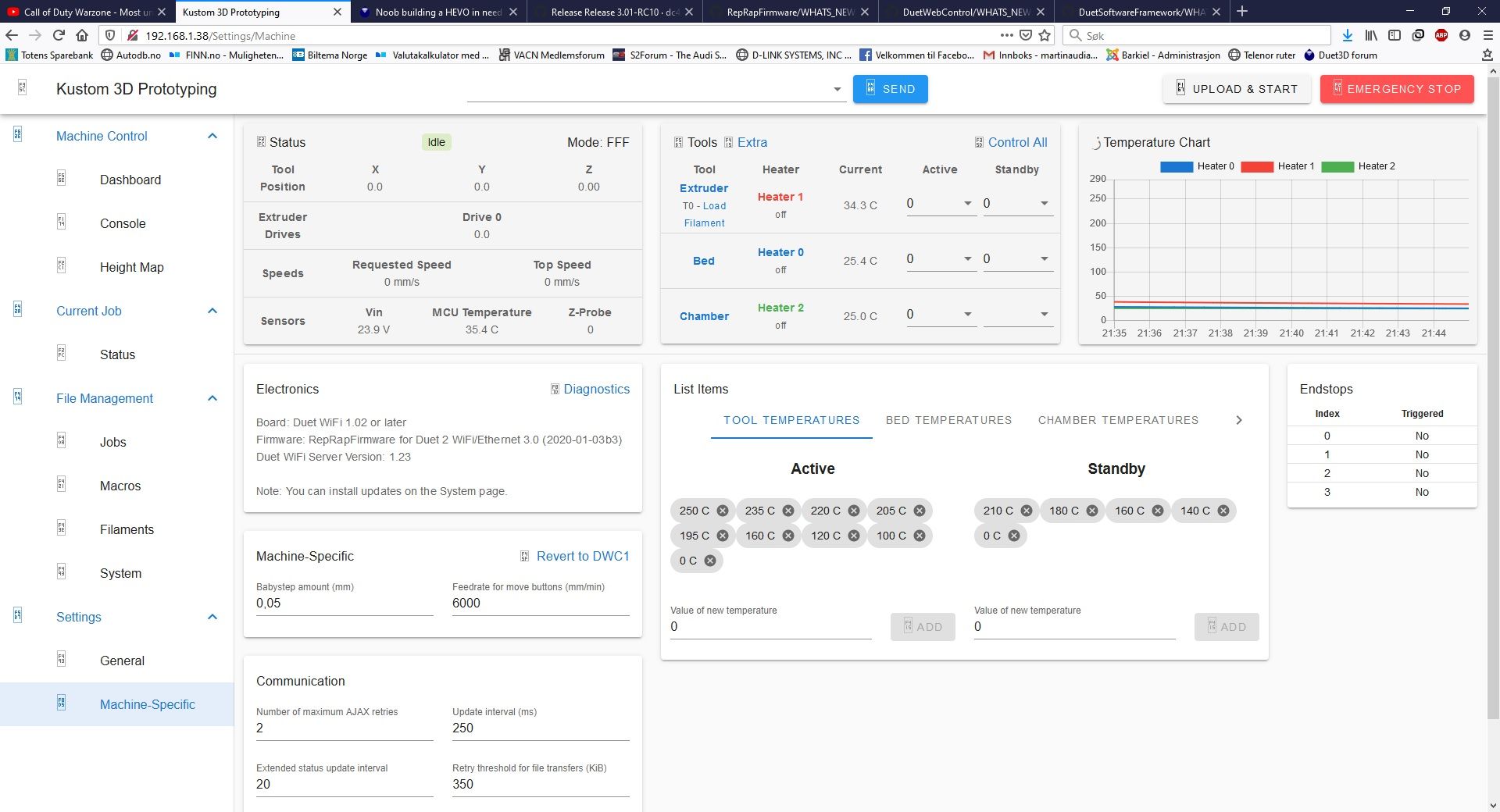

This is the error message that was generated in the load and unload filament macro.

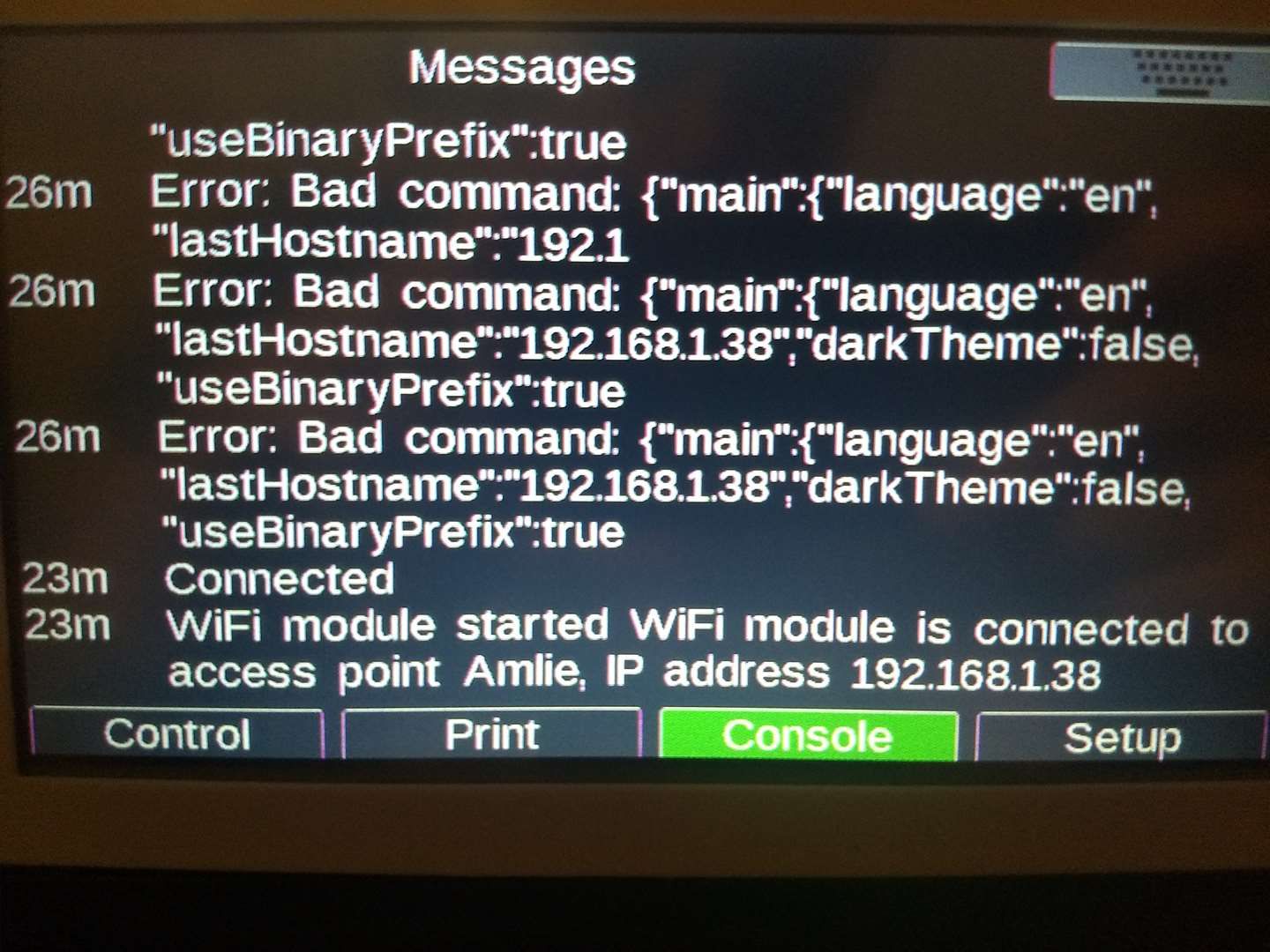

This is the error message that was generated in the load and unload filament macro. The printer is up and running with a Hemera, IR probe, PT100, magnetic filament sensor and a chamber heater. I never got the Piezo to work with my setup. The enclosure is painted white to reflect a light source inside. Plexi glass and 4mm plywood. Magnetic door "lock".

The printer is up and running with a Hemera, IR probe, PT100, magnetic filament sensor and a chamber heater. I never got the Piezo to work with my setup. The enclosure is painted white to reflect a light source inside. Plexi glass and 4mm plywood. Magnetic door "lock". The chamber heater connected with a SSR relay controlled by the Duet.

The chamber heater connected with a SSR relay controlled by the Duet. During the building process.

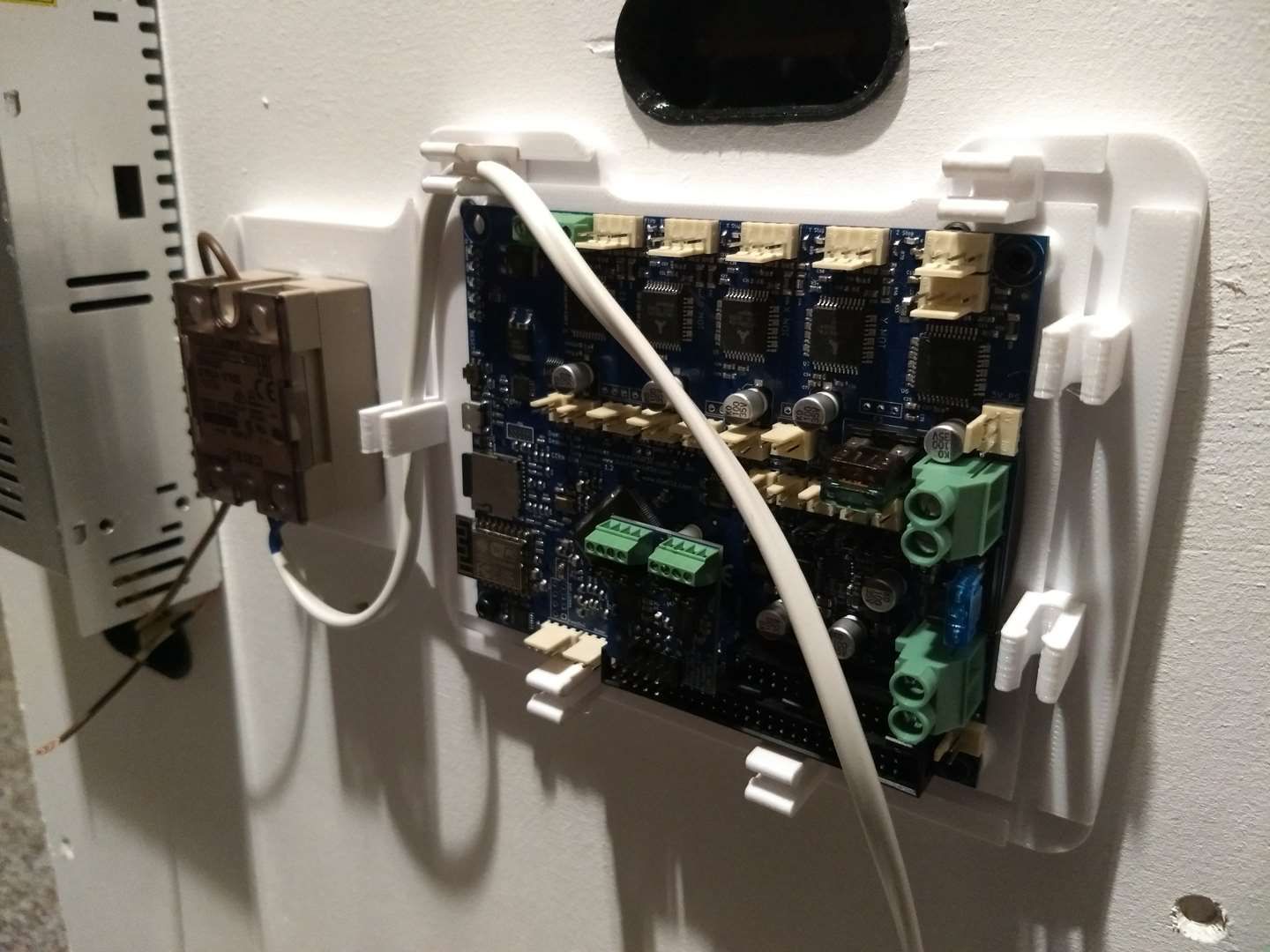

During the building process.

I made a cable support and the filament holder with bowden holder.

I made a cable support and the filament holder with bowden holder. This is where i noticed the wobbling.

This is where i noticed the wobbling.

This is PC.

This is PC.

Any suggestion how I should change this setup for a direct extruder? I am going to heat up the chamber and have the filament inside the case.

Any suggestion how I should change this setup for a direct extruder? I am going to heat up the chamber and have the filament inside the case. The probe won't measure more to the left than this. If I change the probe X-offset from minus to plus, then I can. What is wrong?

The probe won't measure more to the left than this. If I change the probe X-offset from minus to plus, then I can. What is wrong?