WIP CoreXY with heated chamber

-

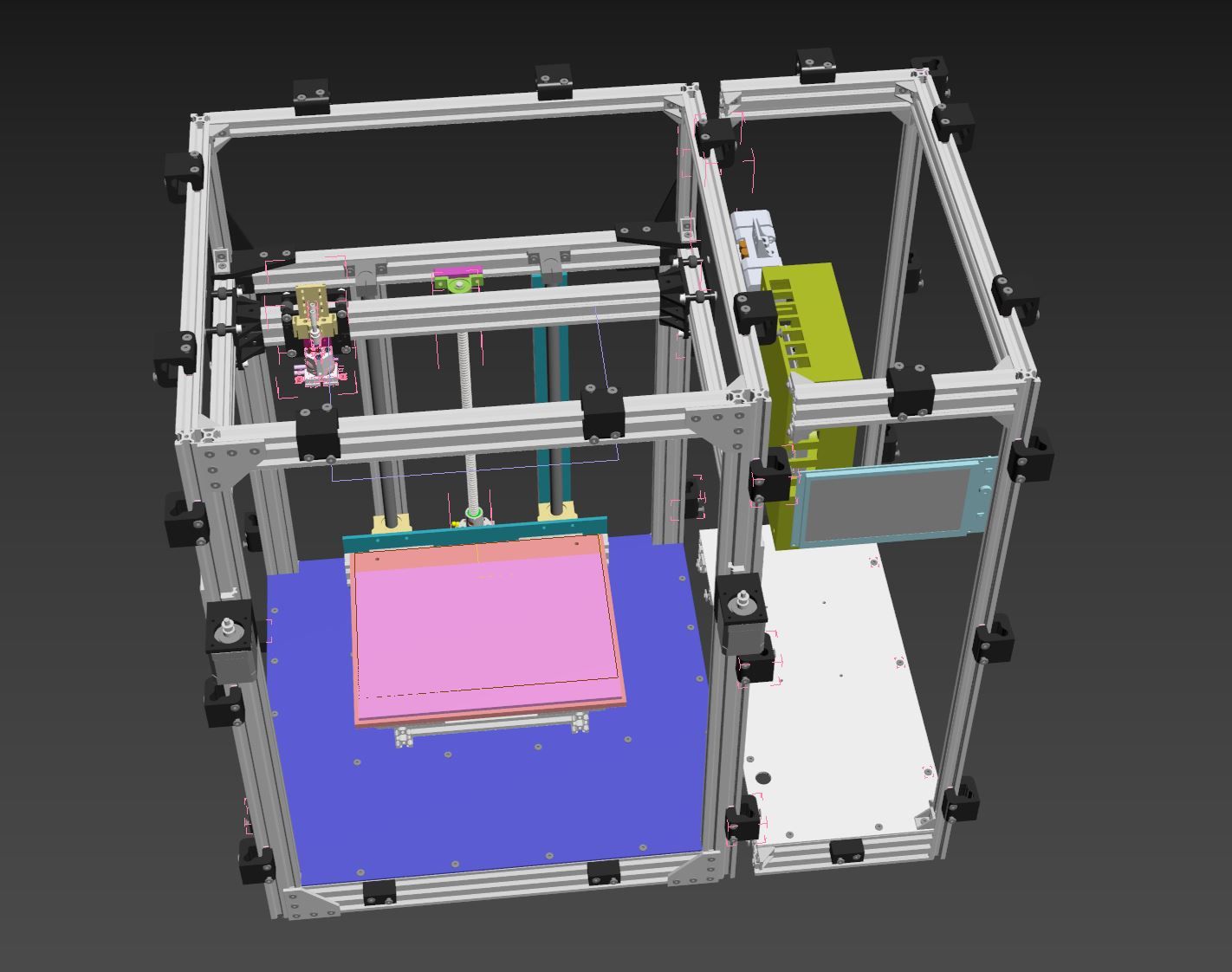

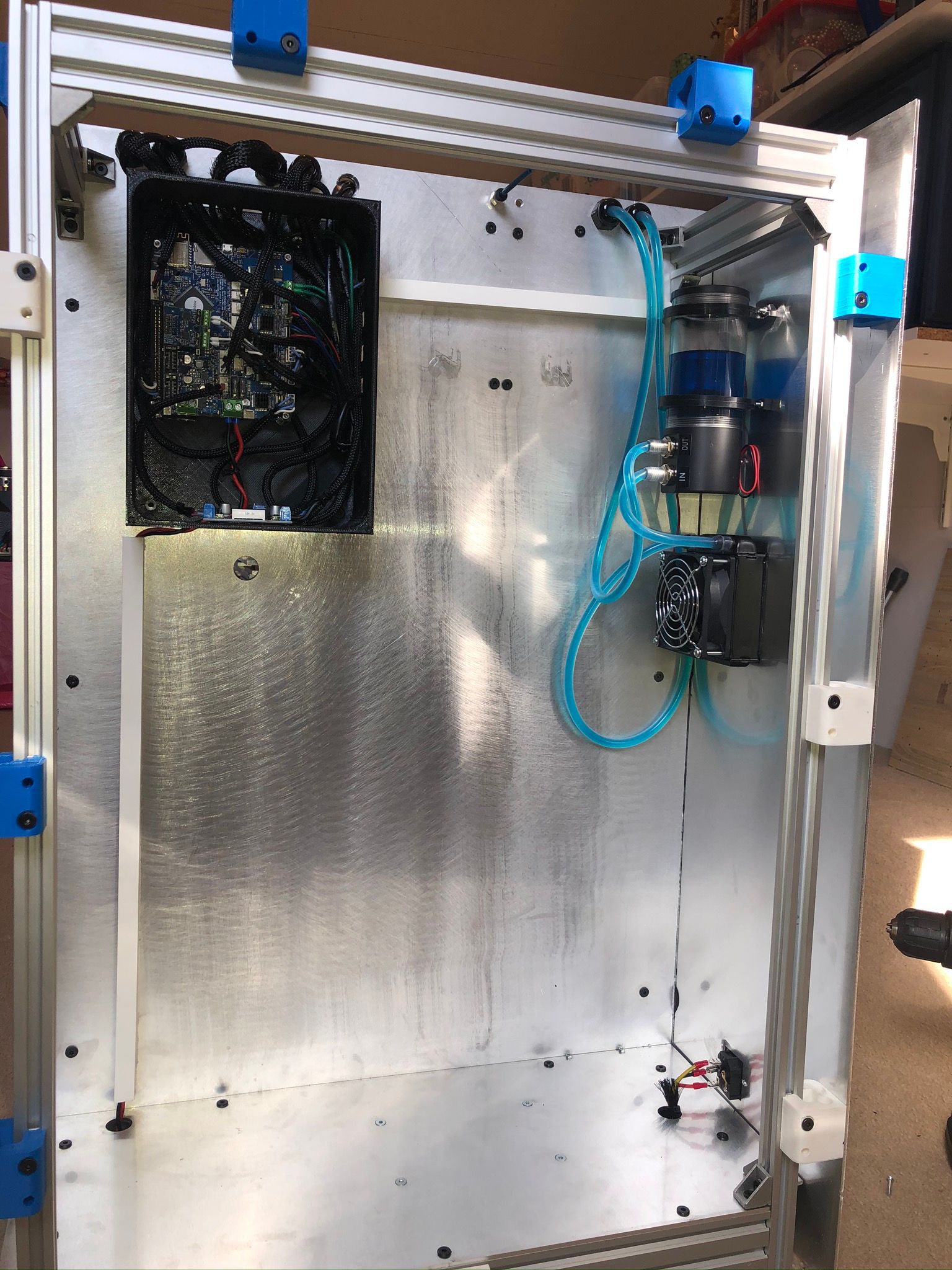

I am working on Core XY which needed to have a certain specification, this is my first build ever:

- 1 Z-axis for simplicity and clean look;

- Build volume 300x250x300;

- Heated Chamber 70C;

- Dual extrusion mainly for water-soluble supports;

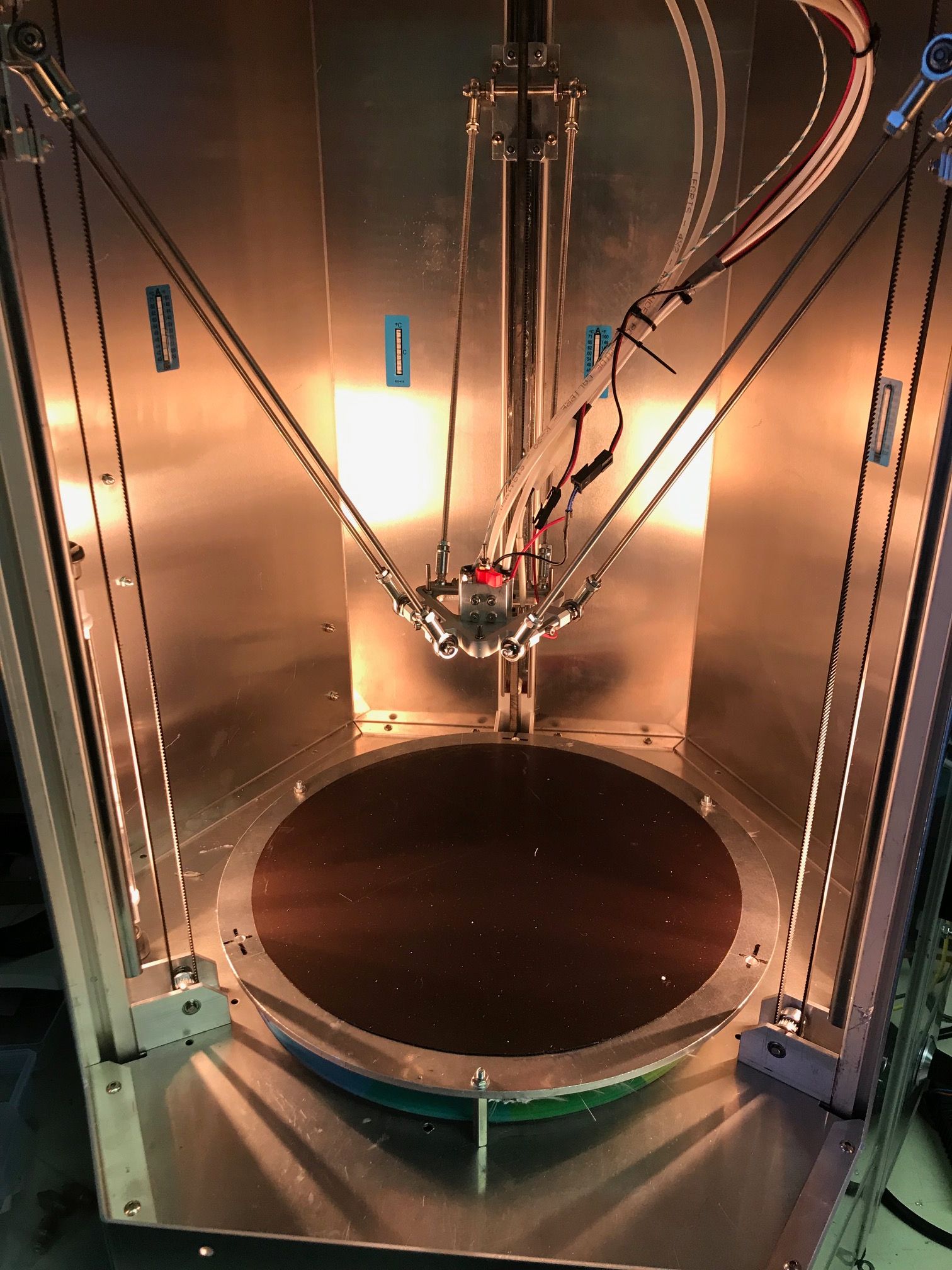

- AC heated bed - 500W from Filafarm;

- Charcoal filtration;

- Hotend - 450C with PT100;

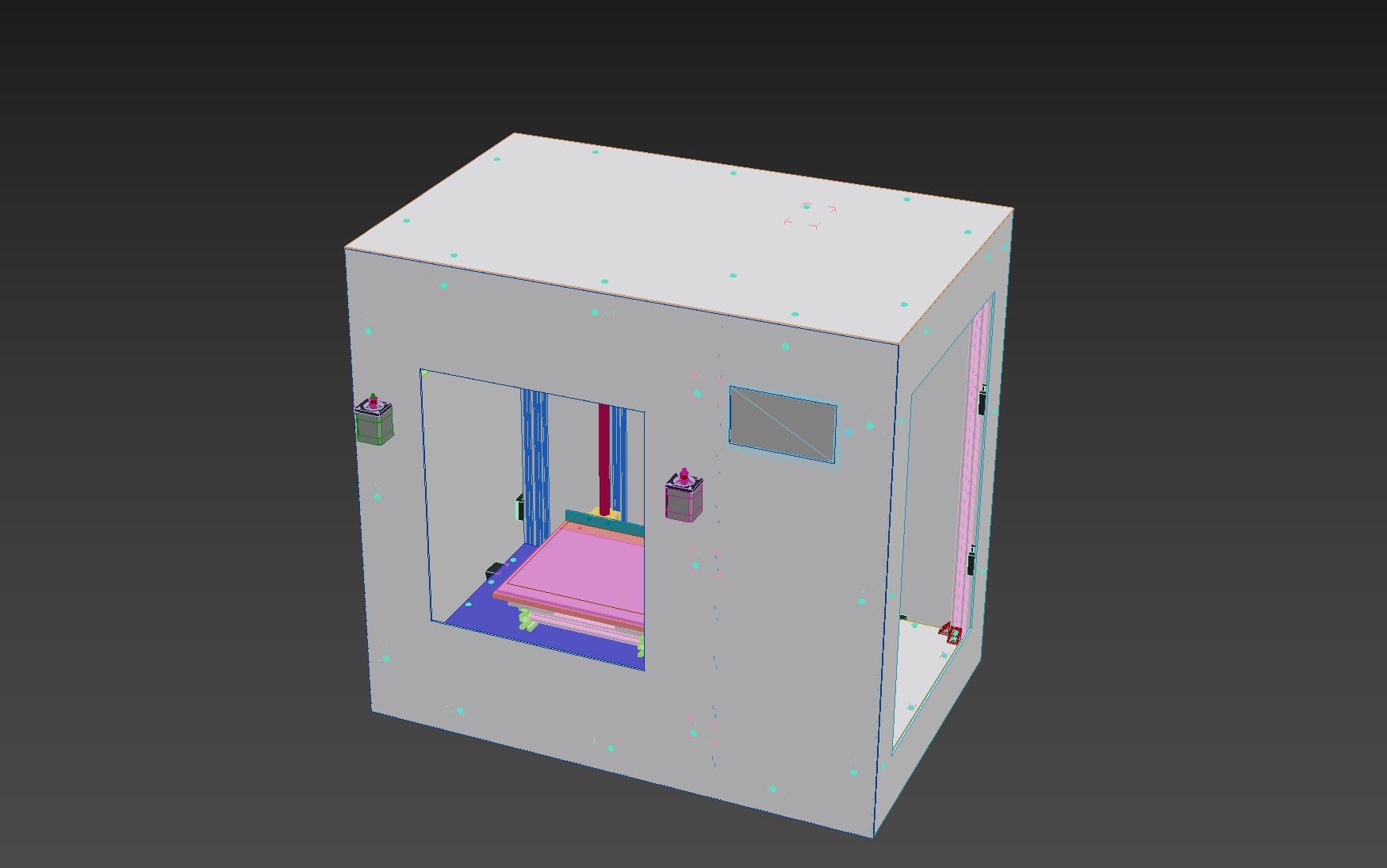

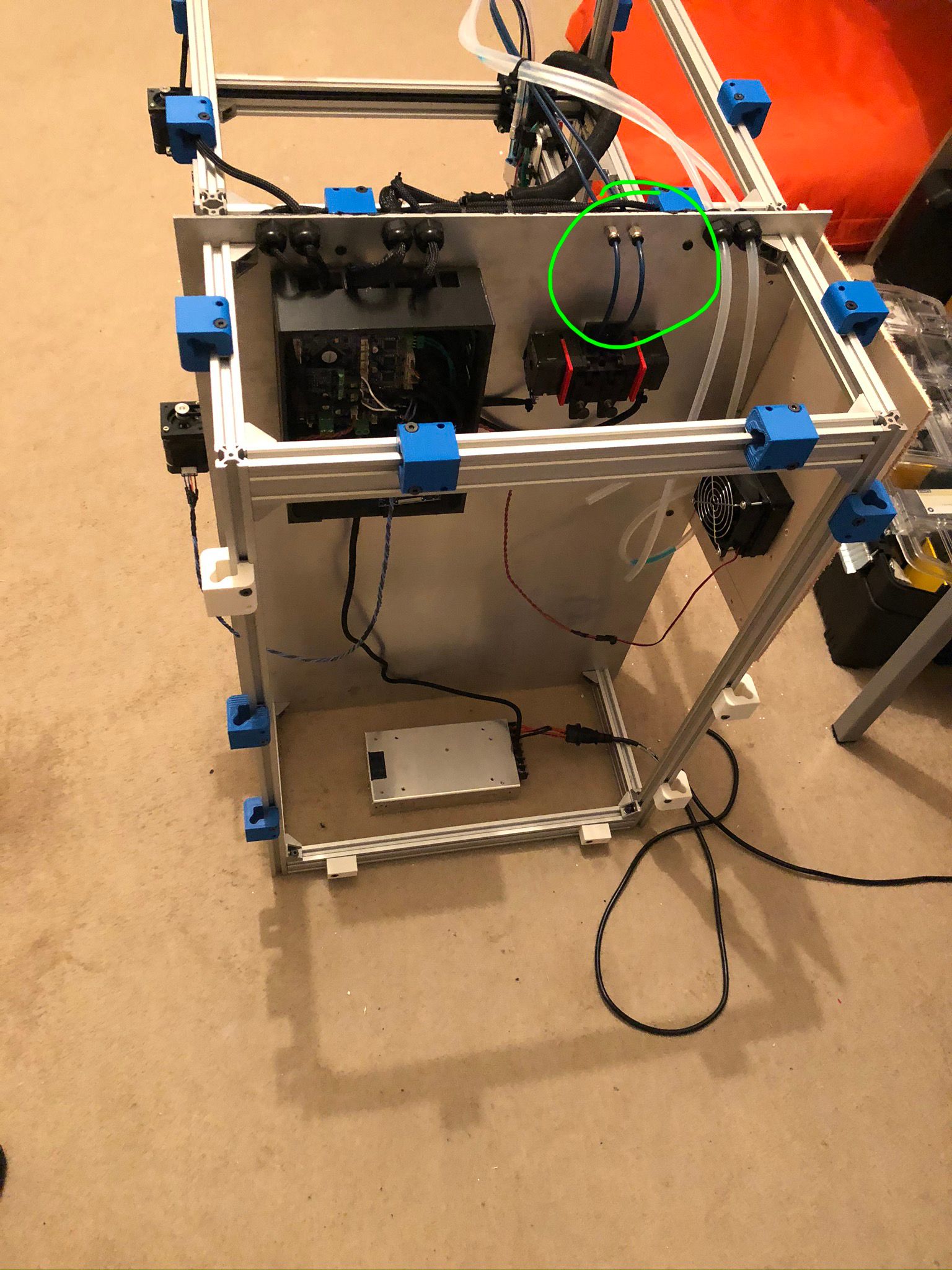

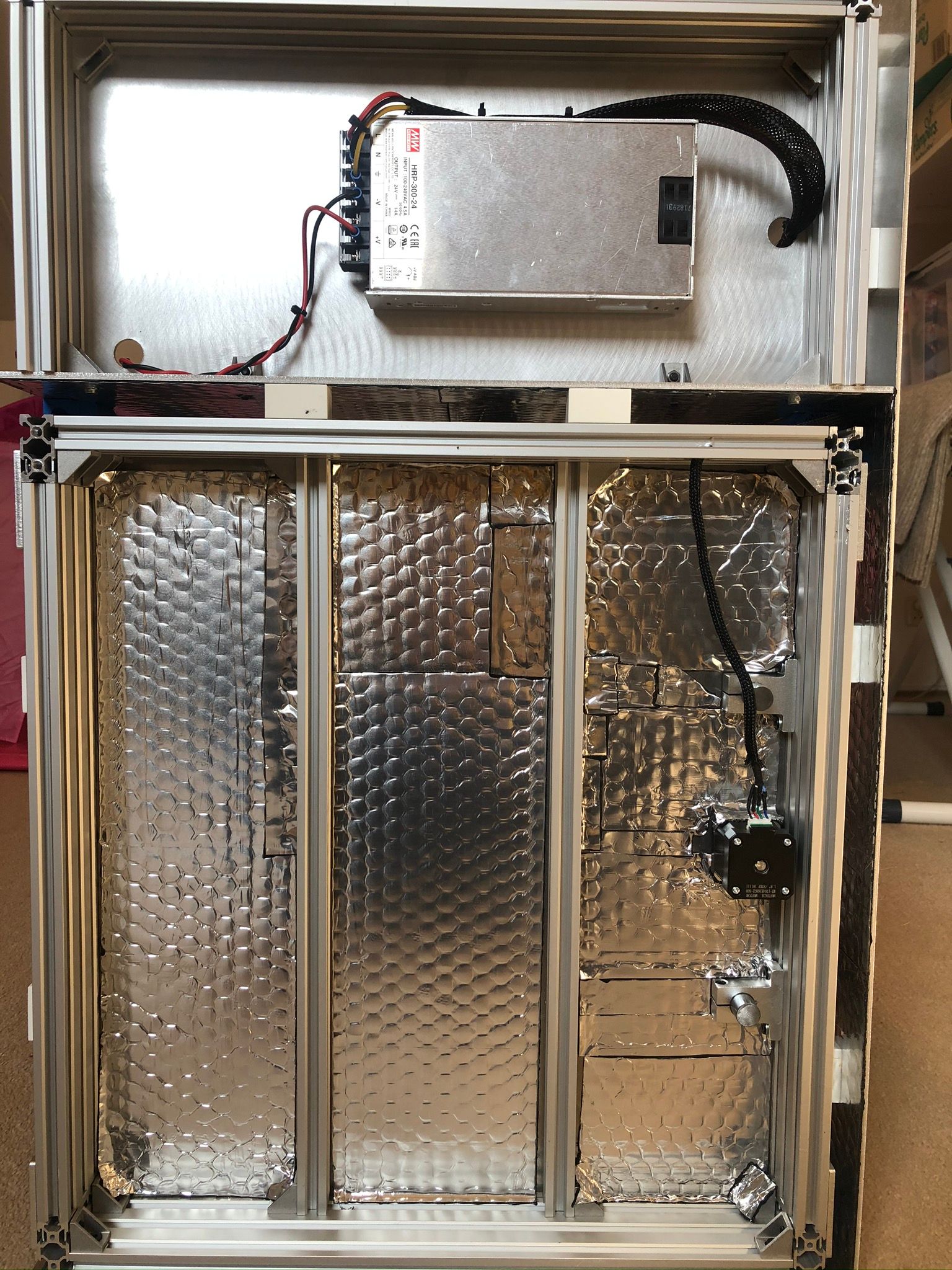

- Fully enclosed machine with Electronic compartment and PanelDue 7";

- BL touch for now - later Metrol as they are rated 80C+;

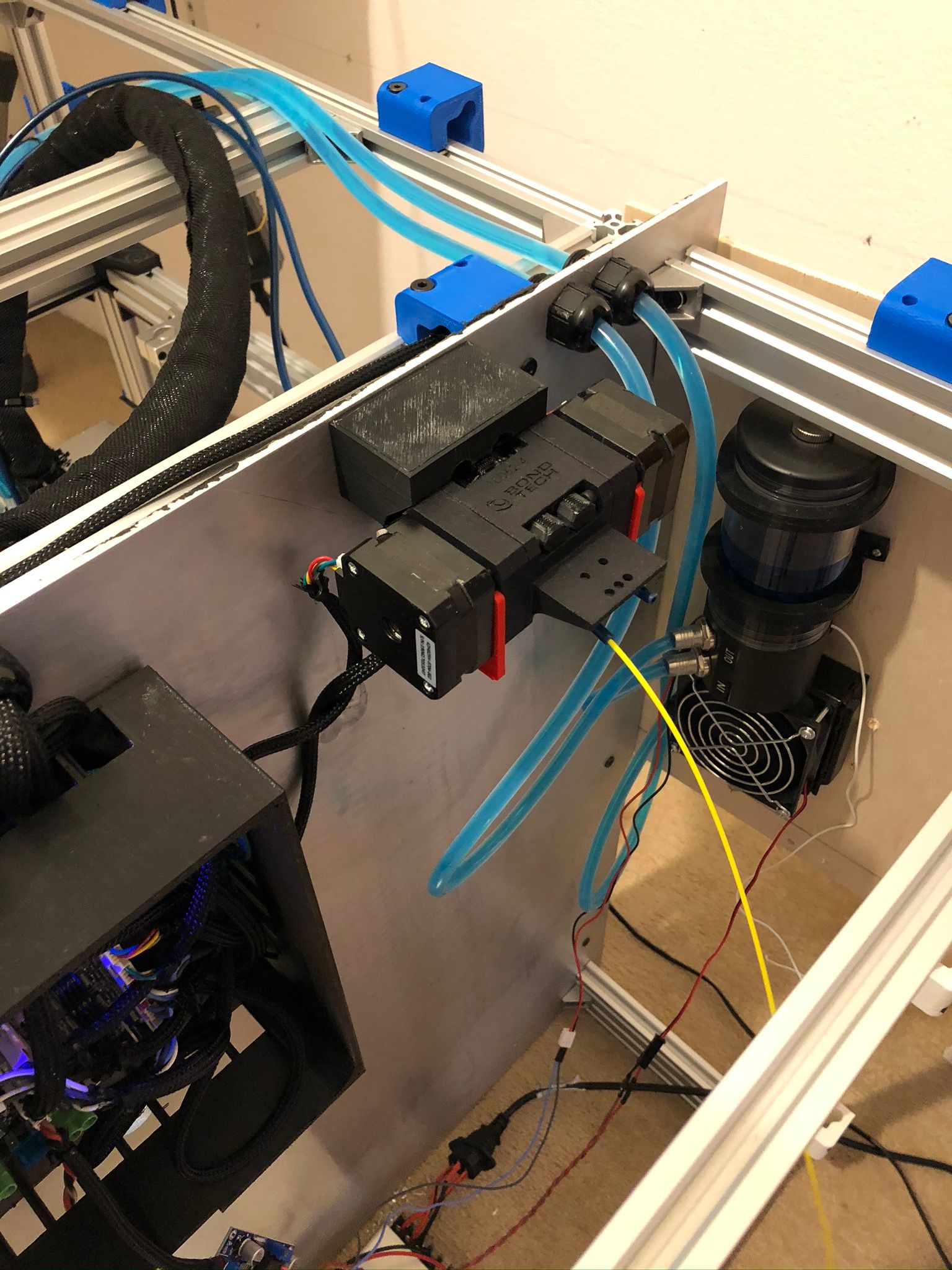

- Water Cooled hot end - Chimera;

- DuetWifi main electronic;

- Dual Bondtech Extruders used as a

Bowdenbecame direct; - Able to print PEEK/PEI/PSU small objects of ~70x70x50mm;

- Magnetic build plate from Filafarm with Filaprint surface;

- All printed parts would be replaced with milled Aluminium, I am already close to this stage as I am happy how everything working out so I can continue without worries

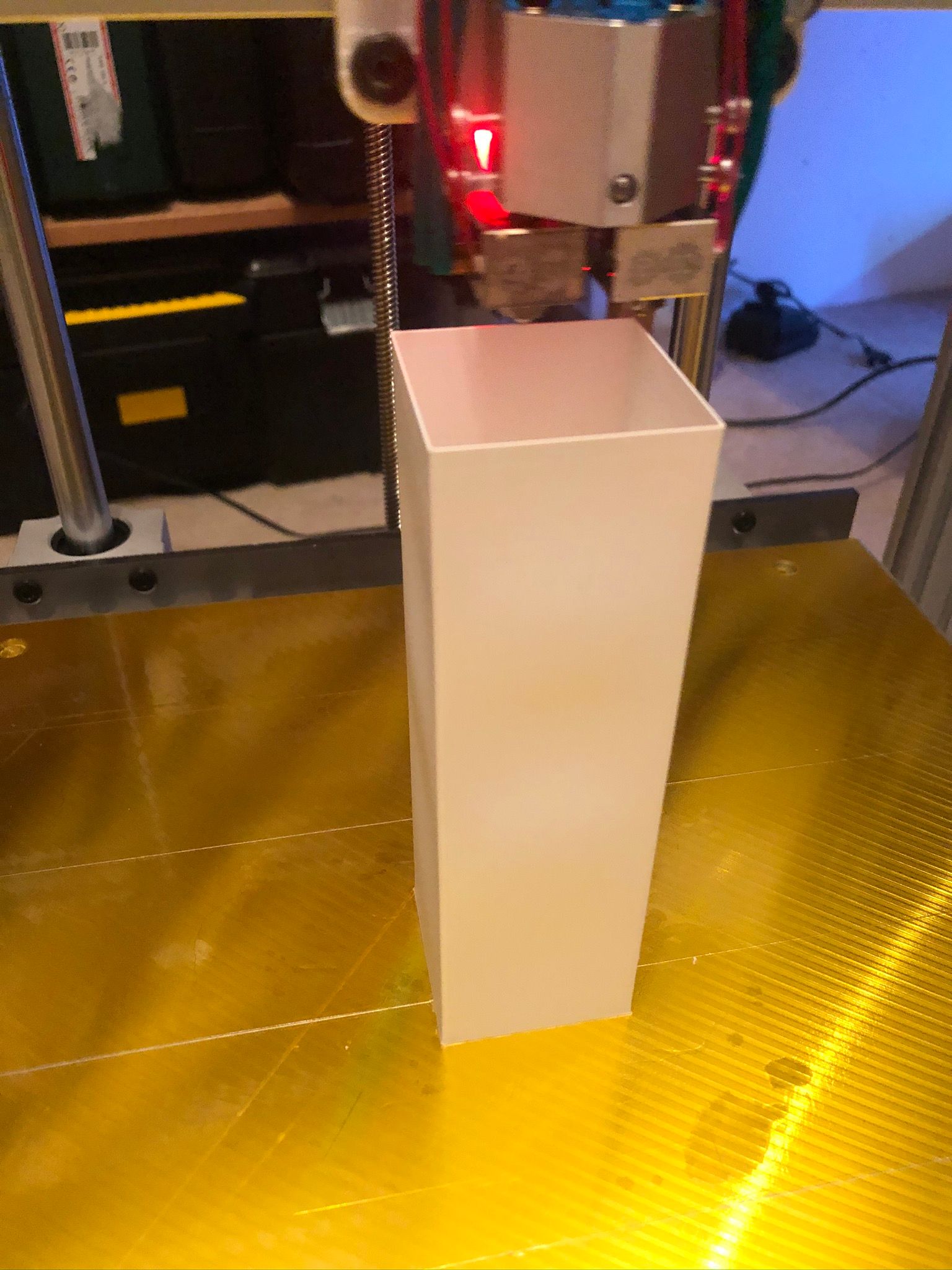

The whole build itself comes out fairly aligned from the beginning, minor tweaks required to achieve 100x100mm cube printed with 100.06x100.04mm - which is sufficient I think.

What is left to think about:

My bed is fairly plane and BL touch does a great job I can print around the whole bed with a consistent width. What worrying me is it would be the same with a bigger object which has more weight 1kg+? I do have 16mm rods and 8mm trapezium lead screw, would it be better to put 12mm trapezium lead screw, or I am losing resolution this way?

The filtration system, how to heat a chamber and control temperature, would it be enough 70C for PEI/PEEK/PSU. I saw a thread on ultimaker forum that somebody able to print those filaments with a 60C air temperature, small objects.

Dual extrusion doesn't really work as I expected - maybe my tool change files should be adjusted properly. But it does leak then it switching tool then it goes to continue print - but I think this is just spending more time on tweaking feed rates and pressure advance.

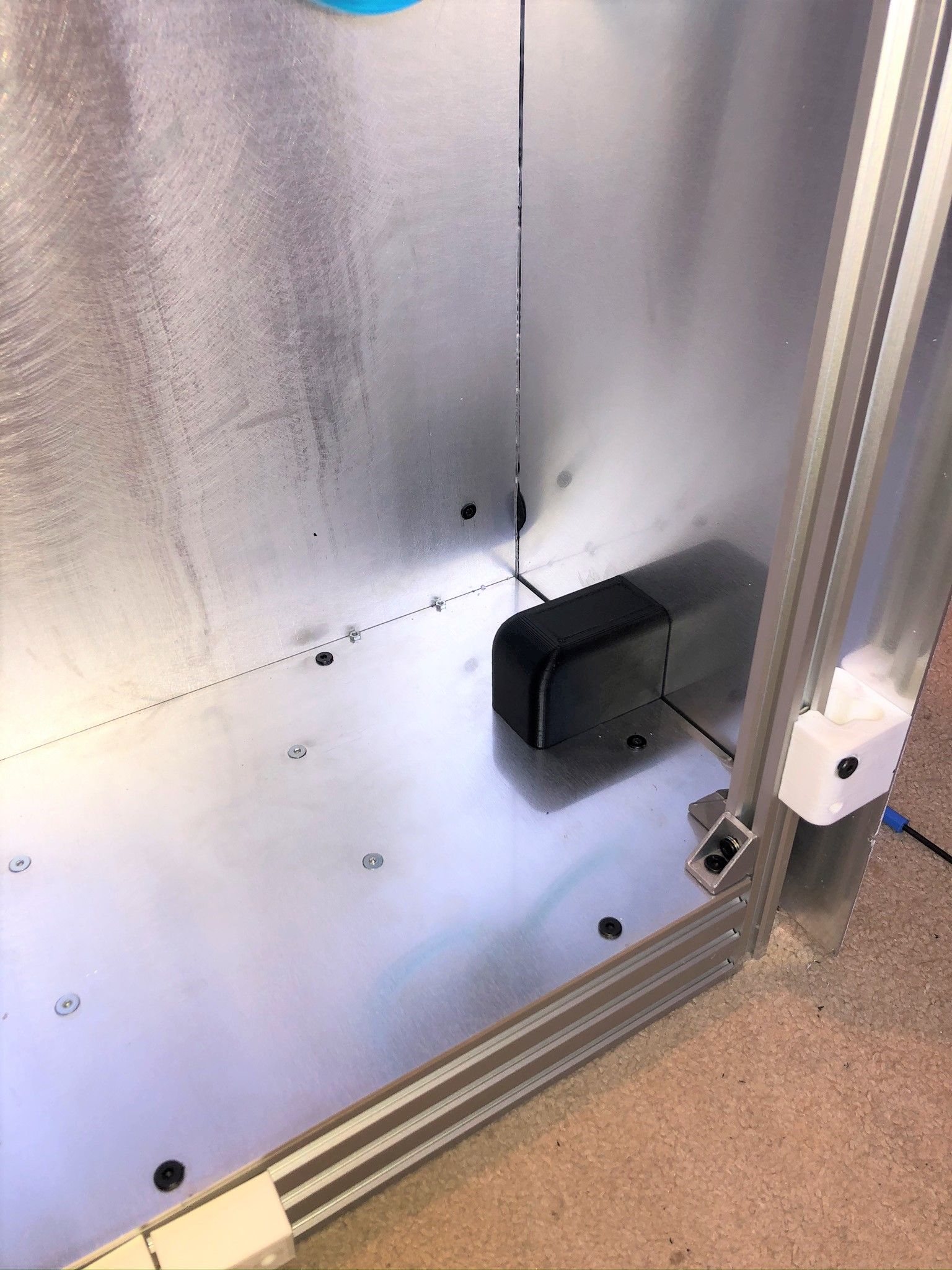

Still figuring out how to properly make a sealed front door.

More images here:

(https://share.icloud.com/photos/0B3qJiJsvmaQ44aGGL3YA_zAw)

-feel free to always check it as it will update with new images as I have new stuff to share

If somebody has critics or comments please share knowledge and experience!

-

Nice design.

How are you heating the chamber? I use IR to heat the part you are printing.

i have modified a delta printer for printing PEEK, PEKK and ultem. The heated chamber needs to be 100 degrees plus to reduce the thermal stresses whilst printing or you have to anneal your plastic parts . -

Thank you!

I was planning to heat chamber with silicone pad from let's say keenovo attached to the heatsink 250x250mm mounted somewhere on the left side and use a fan to blow air around. But still open to ideas.

How did you control IR lamp? What wattage was of the lamp? I am thinking about what it can overheat some parts on the gantry? Does it need to be above 100 degrees if I am not planning to print big objects with it? Thanks!

-

I use 500w keenovo heater for the heated bed. Ir setup is two 300w ir strip lamps but i am adding another two to ensure all the print bed is covered. These intend to be controlled by phase angle controller with PWM input and thermocouple on the print head, but currently they are controlled manually. All parts (will be all parts) either shiny or covered by shiny parts to reflect the ir. Picture below:

-

That looks great!

In this way, I would need to think about how to shield moving gantry from IR light or somehow focus an IR only on build plate... tough, especially when the bed is always moving or wrap whole set with hotends into reflective foil?

-

@felt342 sorry i forgot you had a moving bed, much easier on a delta. You could possibly use ir bulbs mounted off the bed.

-

Yes I do like this method with IR as it cheap to try and easy to assemble to see how it works.

-

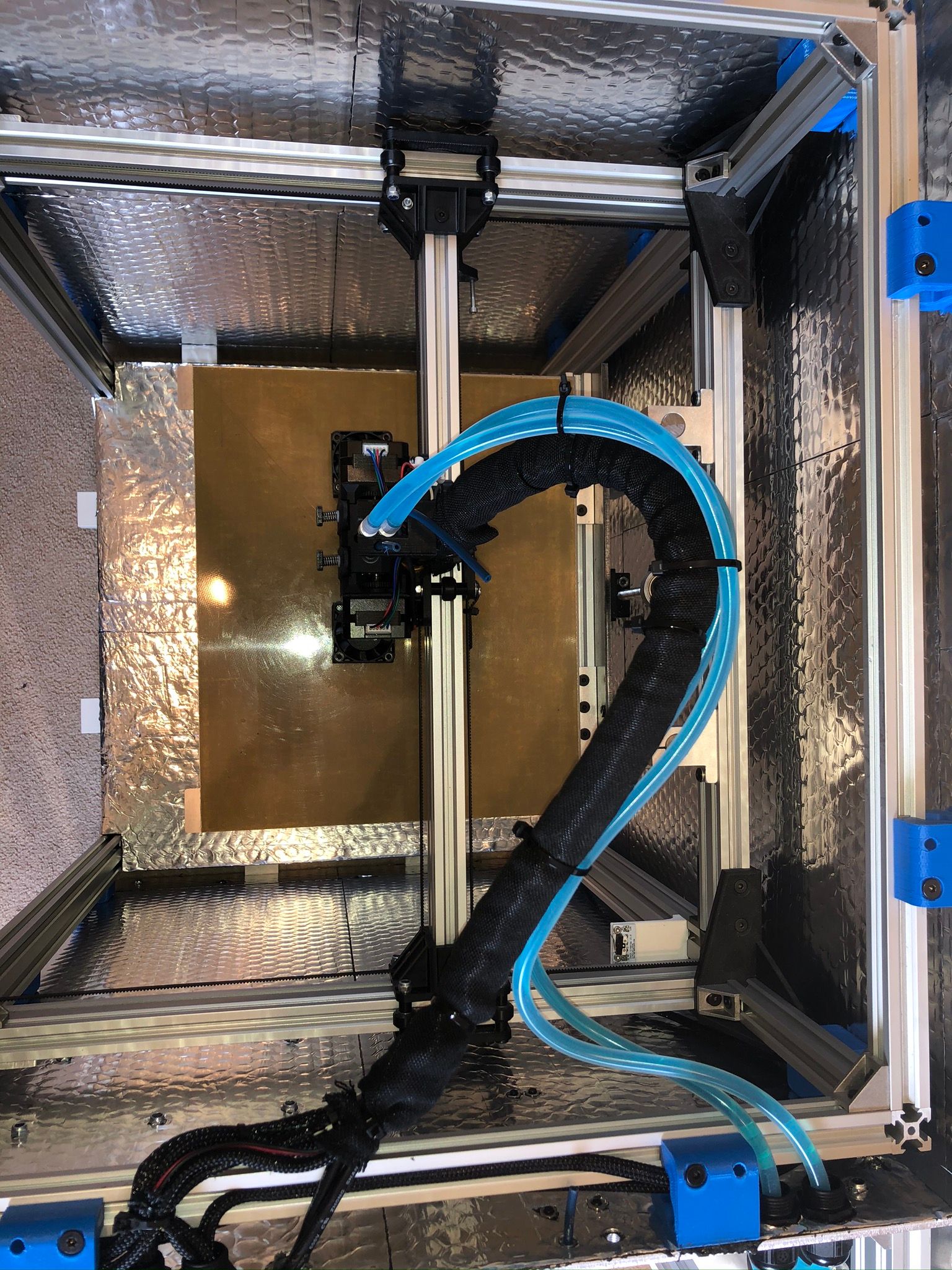

I found another problem with my bowden tube, that bend on the picture was causing all unnecessary blobing... I also managed to shorten bowden tube to 650mm.

This was before:

This is a new mount for extruder eliminating that bend:

And my first Marvin with 50microns layer height

Tomorrow I should get magnetic flexplate from FIlafarm, after almost two months of waiting!

-

@felt342 said in WIP CoreXY with heated chamber:

Dual extrusion doesn't really work as I expected - maybe my tool change files should be adjusted properly. But it does leak then it switching tool then it goes to continue print - but I think this is just spending more time on tweaking feed rates and pressure advance.

I found that dual extrusion can work well under the following conditions:

- Use a large amount of retraction when retracting filament from the unused tool. This only really works with PTFE-lined hot ends, which are great for PLA but limiting with other filaments (E3D quotes max 240C for the Lite6).

- Use the standby temperature facility of RRF to keep the non-printing nozzle at a lower temperature, e.g. 160C when printing PLA.

A remaining disadvantage of dual nozzle printing is that when the non-printing nozzle passes over filament that has just been laid down, it leaves a mark.

IDEX dual extrusion printers do not have these disadvantages. Perhaps your printer can be converted to IDEX?

-

IDEX - that looks like a proper way to do it, I even will not lose any building volume as I do have good free spacing on a side! Thanks for a suggestion. I investigated a bit and found Dyze hotends exist with liquid cooling addition, sadly I didn't find anything similar from E3D. Do you maybe have a suggestion of another single liquid cooling hotends?

Haven't look yet for a CoreXY conversion to IDEX, but it should be doable with just Duet wifi what I have now?

-

@felt342 said in WIP CoreXY with heated chamber:

IDEX - that looks like a proper way to do it, I even will not lose any building volume as I do have good free spacing on a side! Thanks for a suggestion. I investigated a bit and found Dyze hotends exist with liquid cooling addition, sadly I didn't find anything similar from E3D. Do you maybe have a suggestion of another single liquid cooling hotends?

Haven't look yet for a CoreXY conversion to IDEX, but it should be doable with just Duet wifi what I have now?

E3D doesn't sell a water cooled version of the V6 (except for a water-cooled version of the Titan Aero), but if you search "water cooled e3d v6 heatsink" then there are a few hits, such as this one https://youprintin3d.de/hotendszubehoer/e3d/wasserkuehlung/792/water-cooled-heatsink.html. I've no experience of either those or the Dyze hot ends.

An IDEX printer requires at least 6 stepper drivers, so one more than you have on your Duet WiFi.

-

Oh yes I see, will need an extension board

Thanks for a E3D water-cooled heatsink! -

So far I am having decent results using a Chimaera for different support material. I placed the support nozzle ~30u higher than the main nozzle, which prevents dragging. Extensive cooling and wiping during a toolchange takes care of the ooze.

It is slow as hell though. Idex or toolchanger would be way better.

-

Can you post your tool change files, please?

-

Sure: https://www.icecoldcomputing.com/directlink/3dprinter/Dabit3D_config_10feb2020.zip

Mind you, these files are a work-in-progress also. I reworked the tpostX.g files yesterday to improve the wiping process, and did not test them yet.

-

Thank you! I will give a try to it.

-

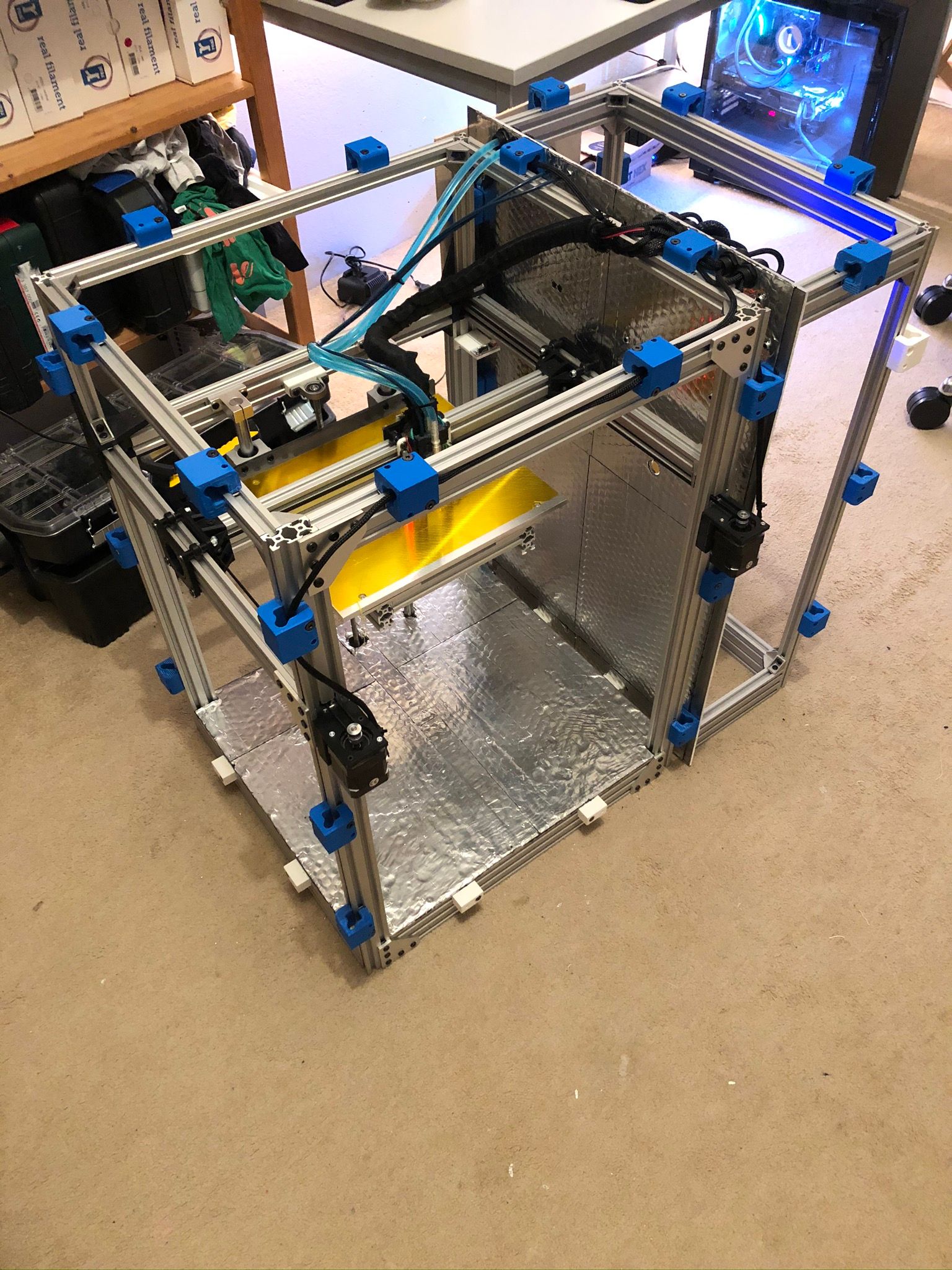

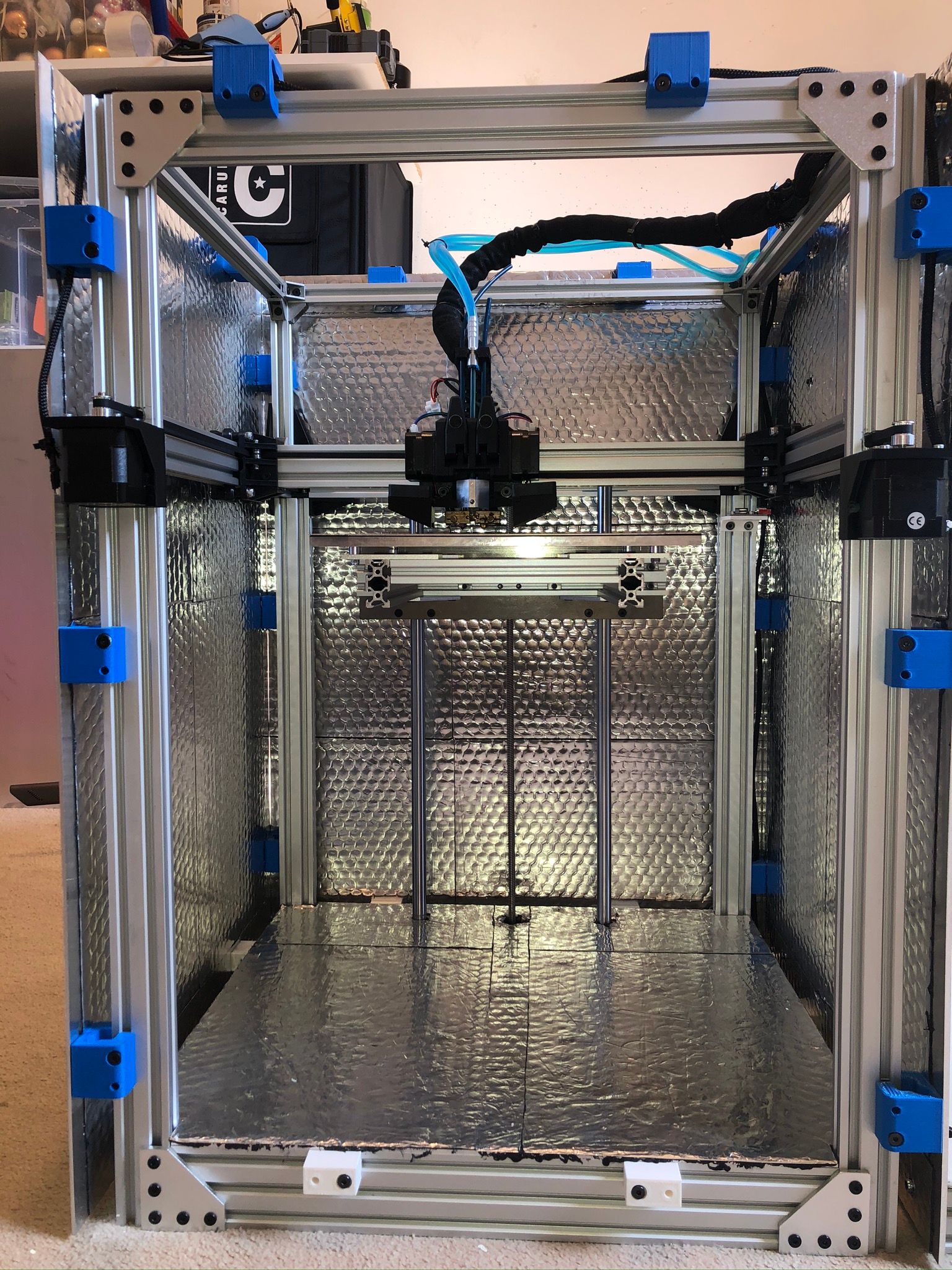

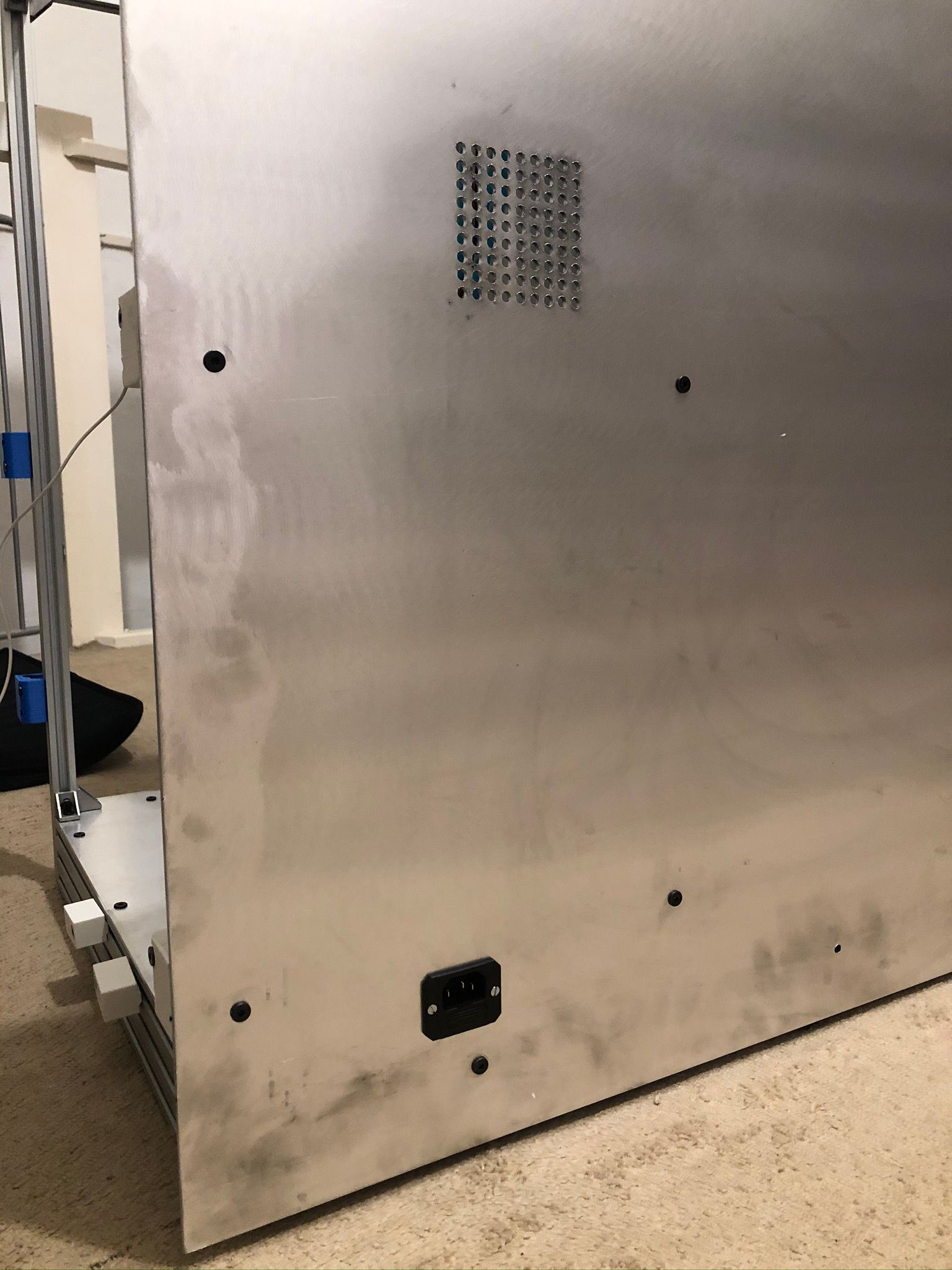

Some updates on work in progress machine

At this moment I am - working on lighting, sealing the chamber with aluminum foil, figuring out the door mechanism, wheels, and feet! Eventually, it became direct drive extruder, much happier with results!

https://www.icloud.com/photos/#07fyEOQcG_z7WxKabaN22UowA -

Nice! Looks like you're getting great print quality, too.

Does that center frame member on the top of the machine interfere with the extruder carriage cables/hoses? It looks like it might depending on the position along the X axis.

-

Thank you!

Yes indeed it looks like it might, but I moved it to the right so it does not interfere. In the end, I will remove it, otherwise, the cable hose and liquid hose will be in touch with top cover and probably will mount cable chain.

The big thing I want to mount and test is a heated bed, but with this world situation of Corona I am already in a delay of 3 months...There is my latest benchy

-

A bit of safety first! Kids around...