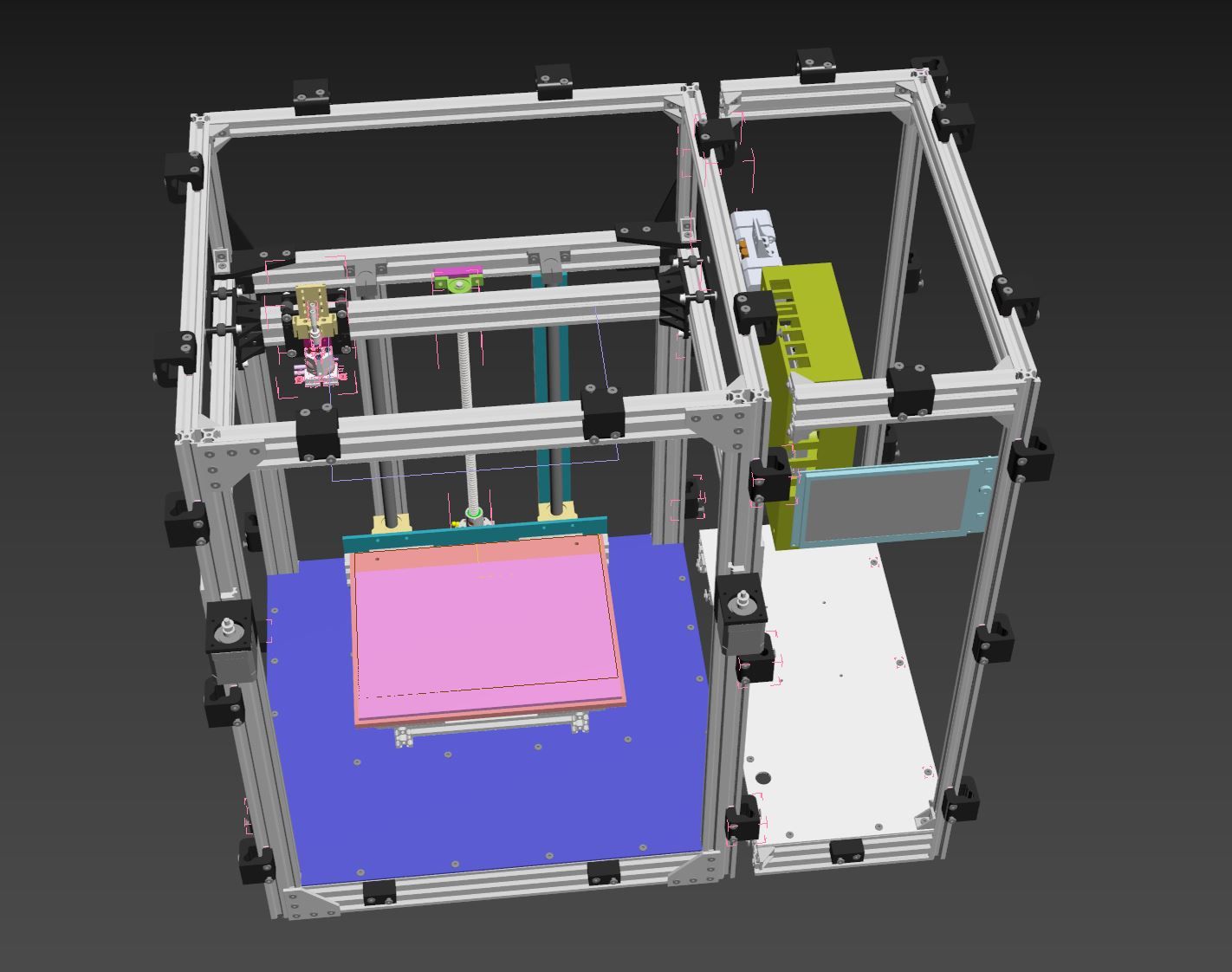

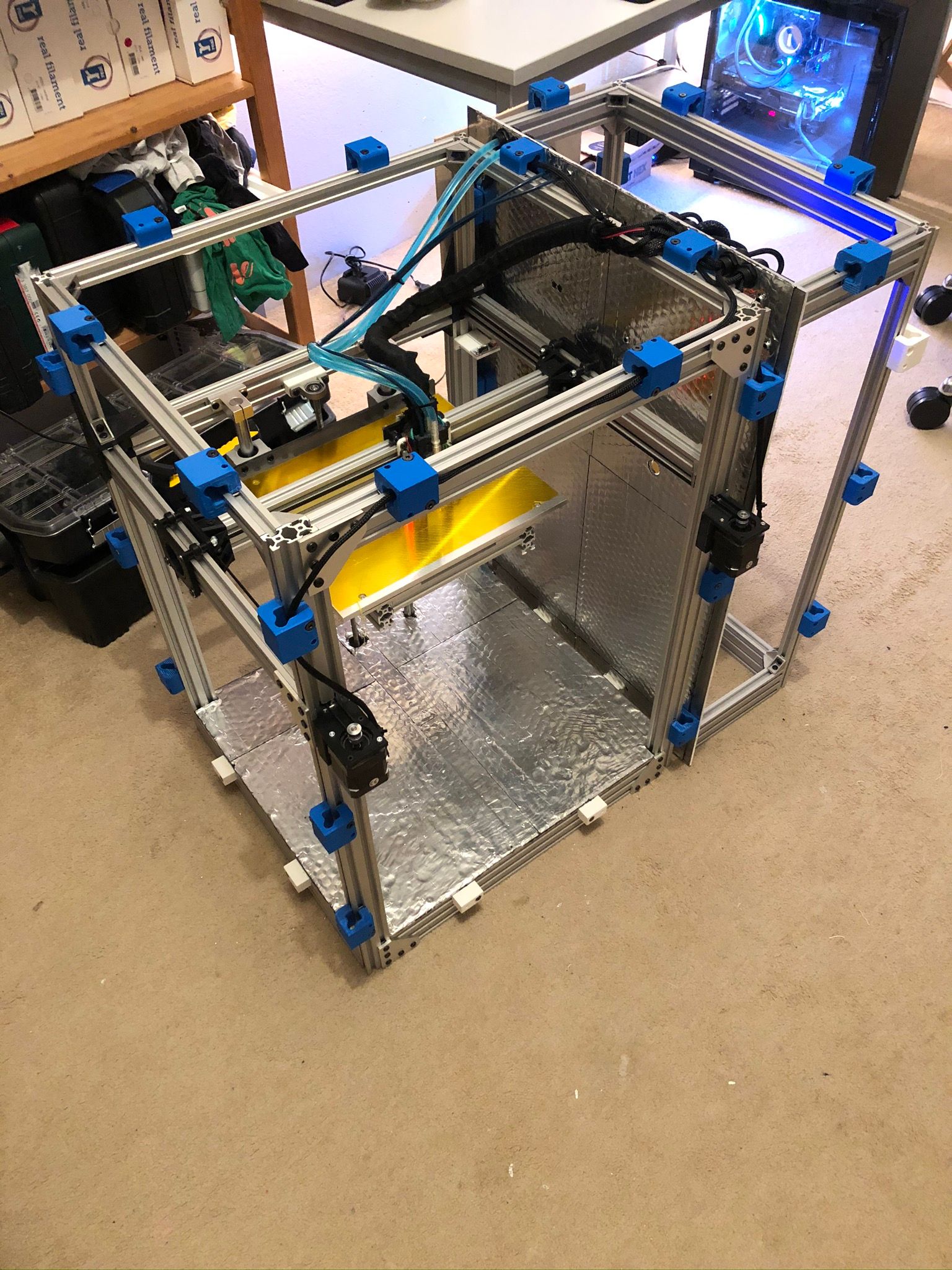

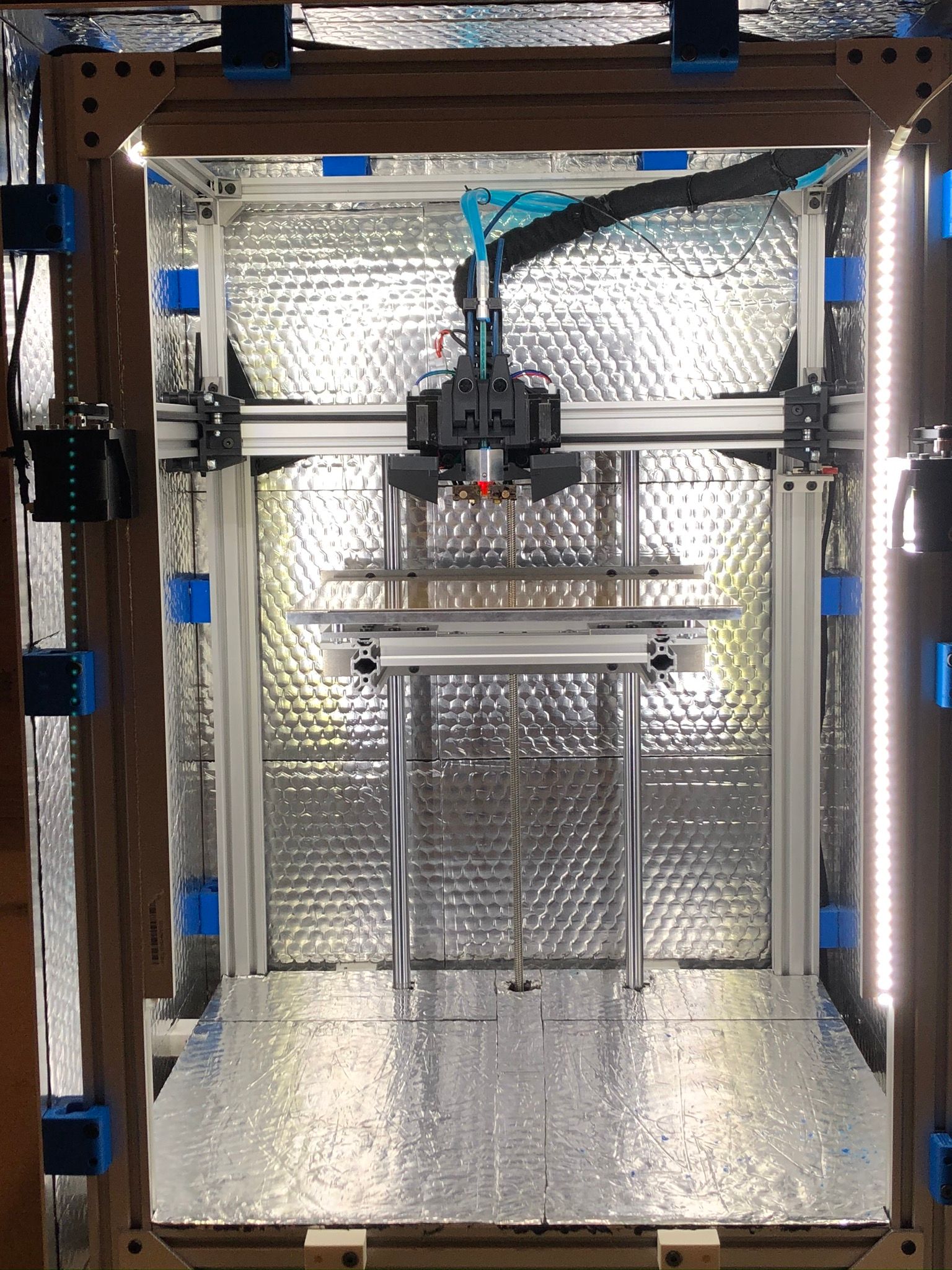

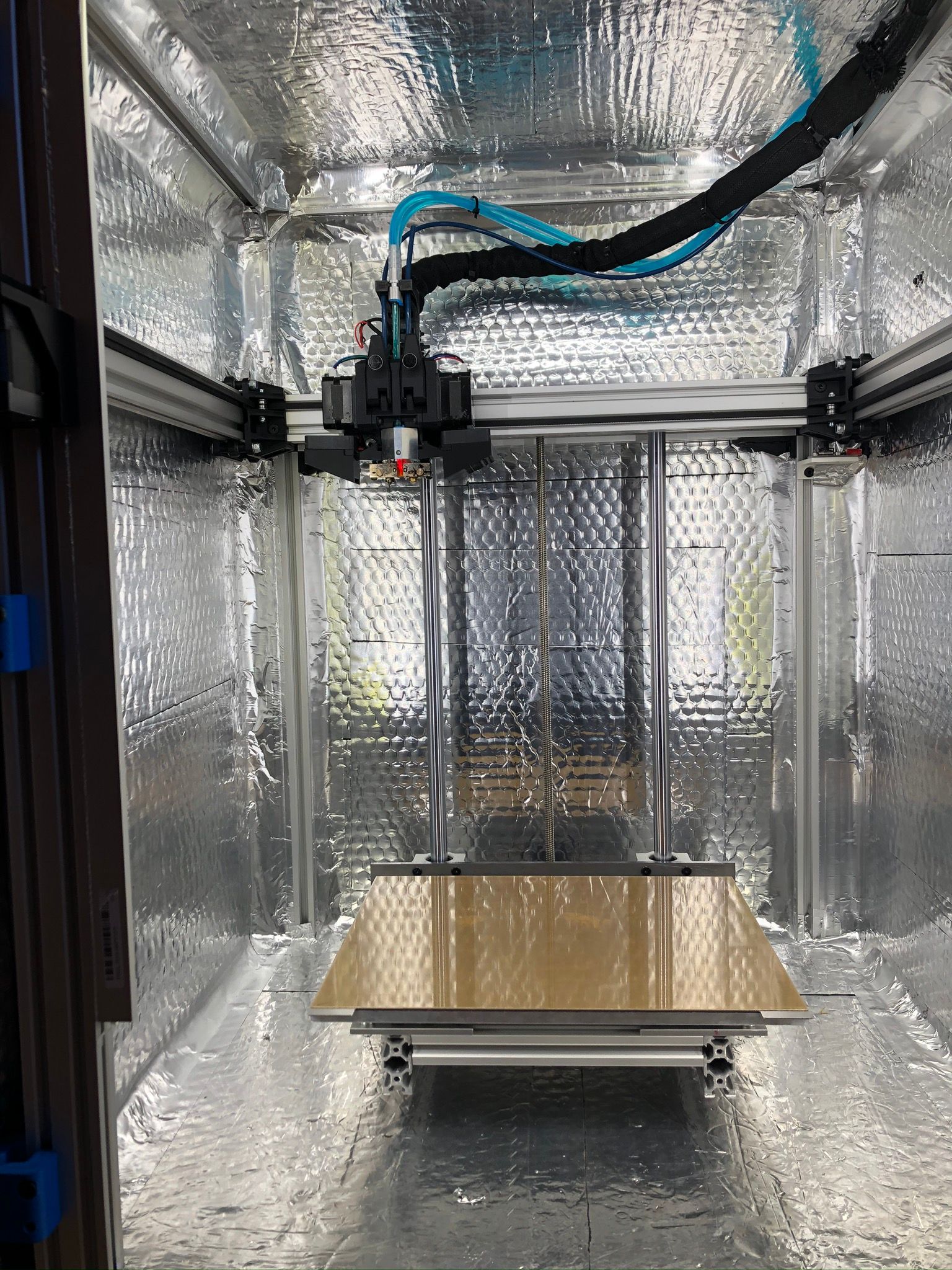

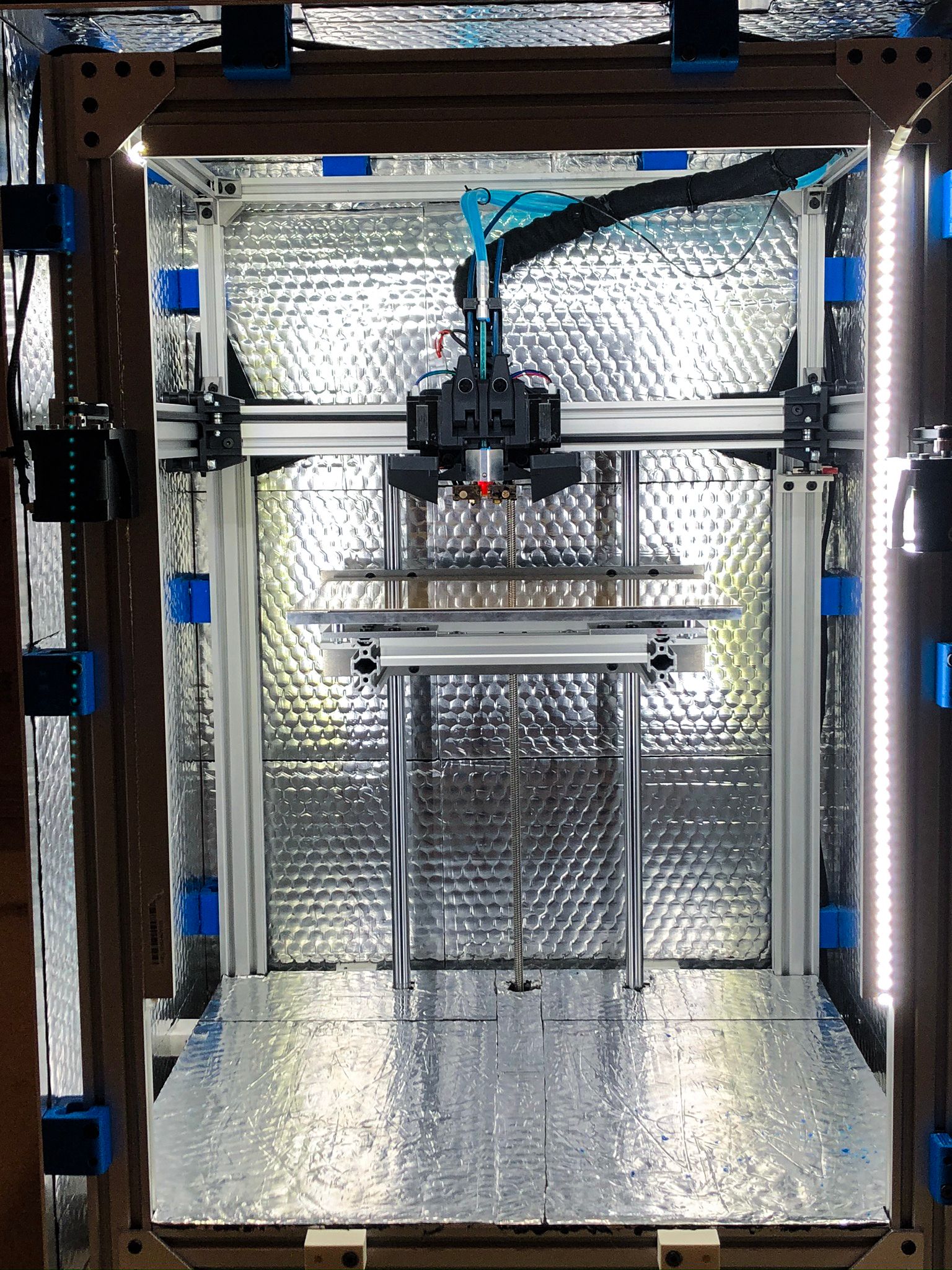

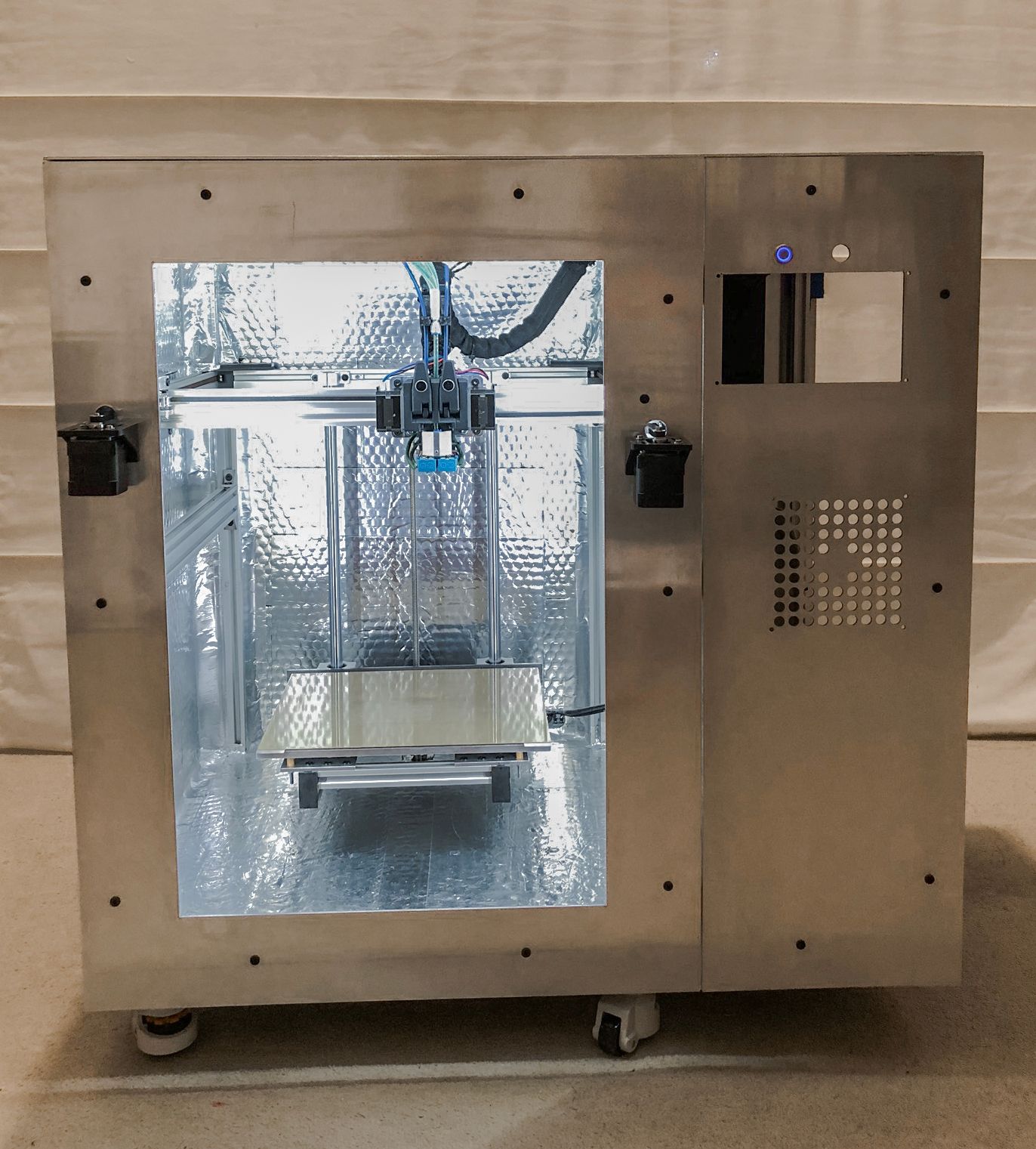

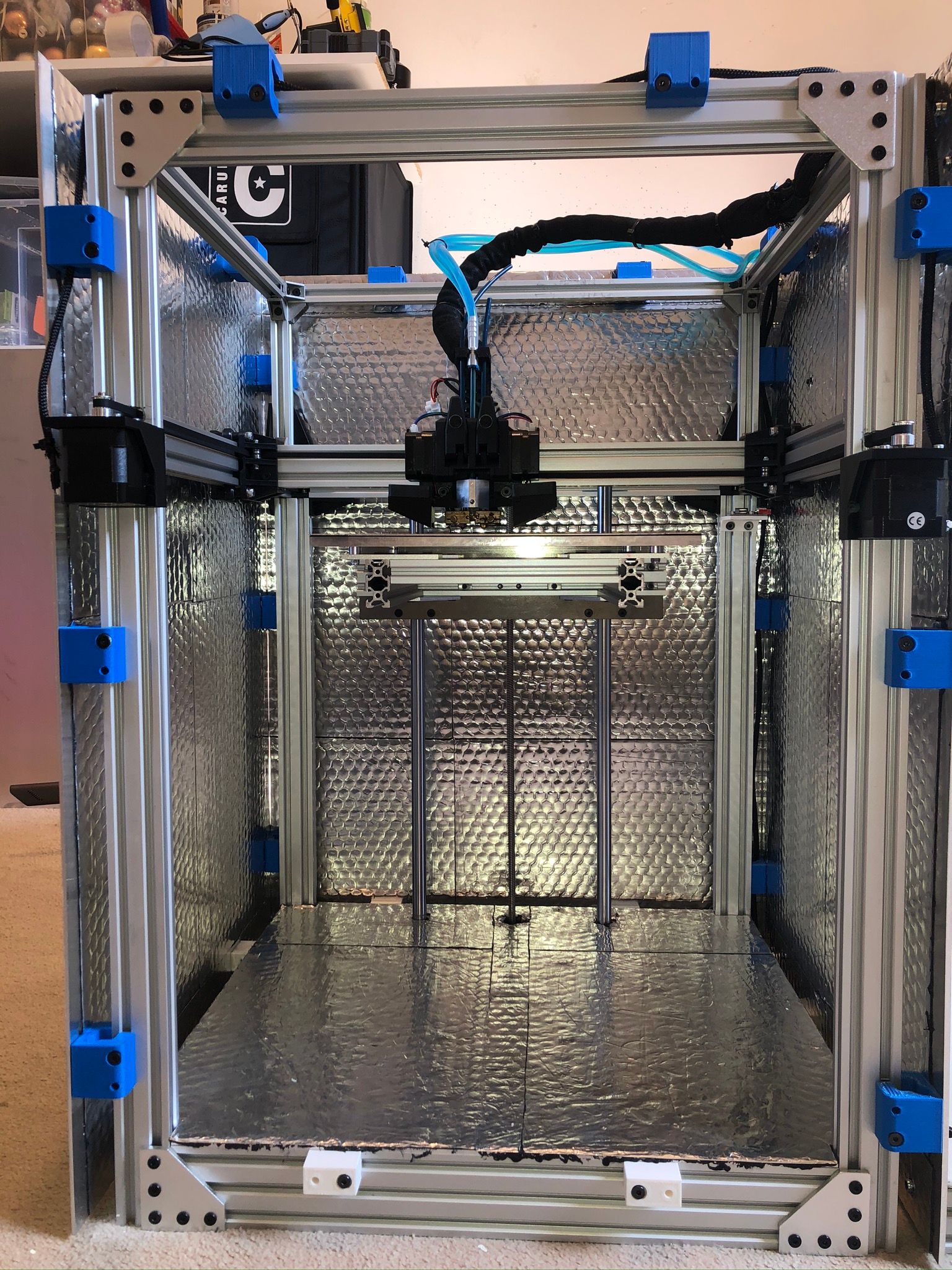

I am working on Core XY which needed to have a certain specification, this is my first build ever:

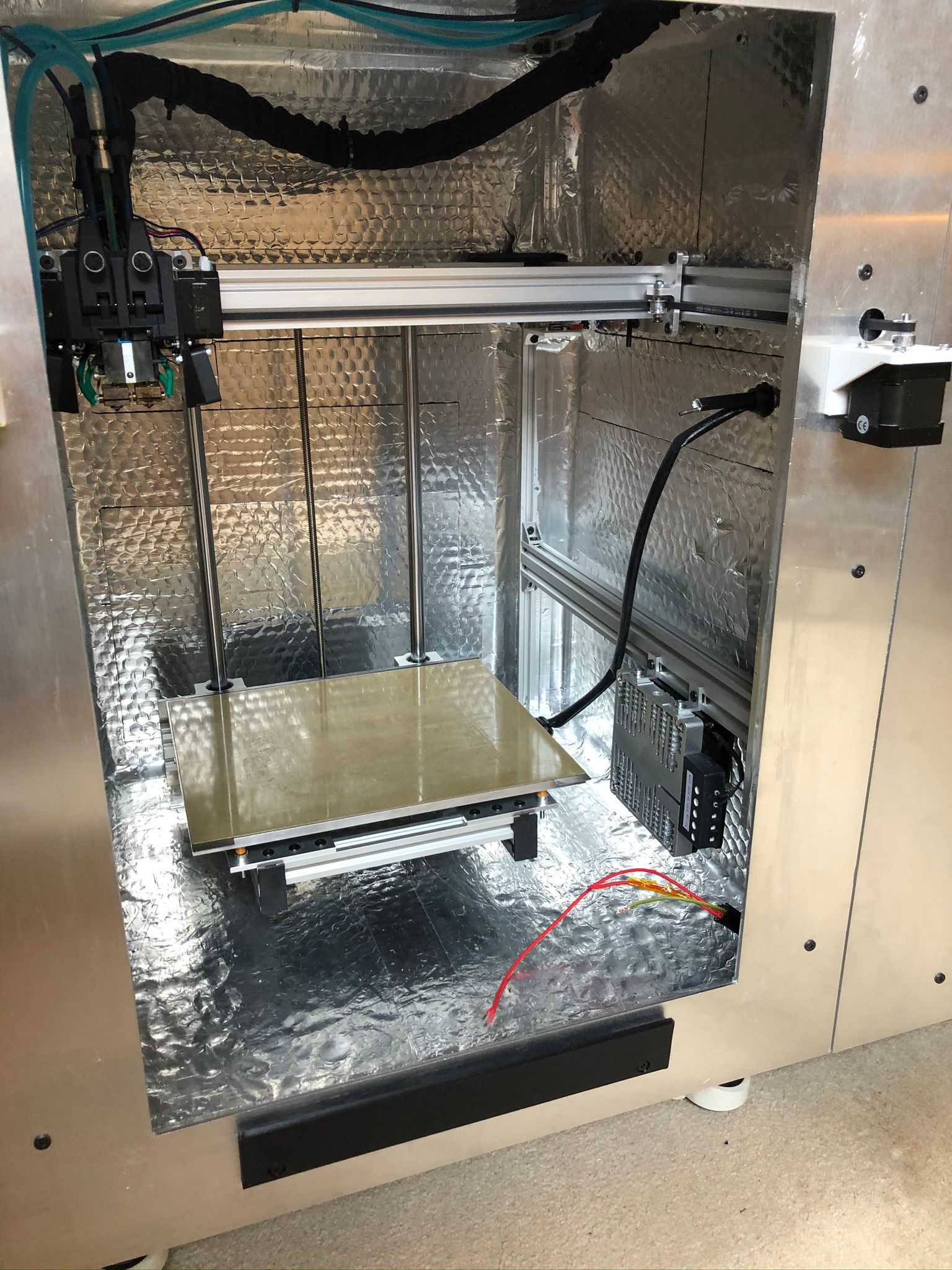

- 1 Z-axis for simplicity and clean look;

- Build volume 300x250x300;

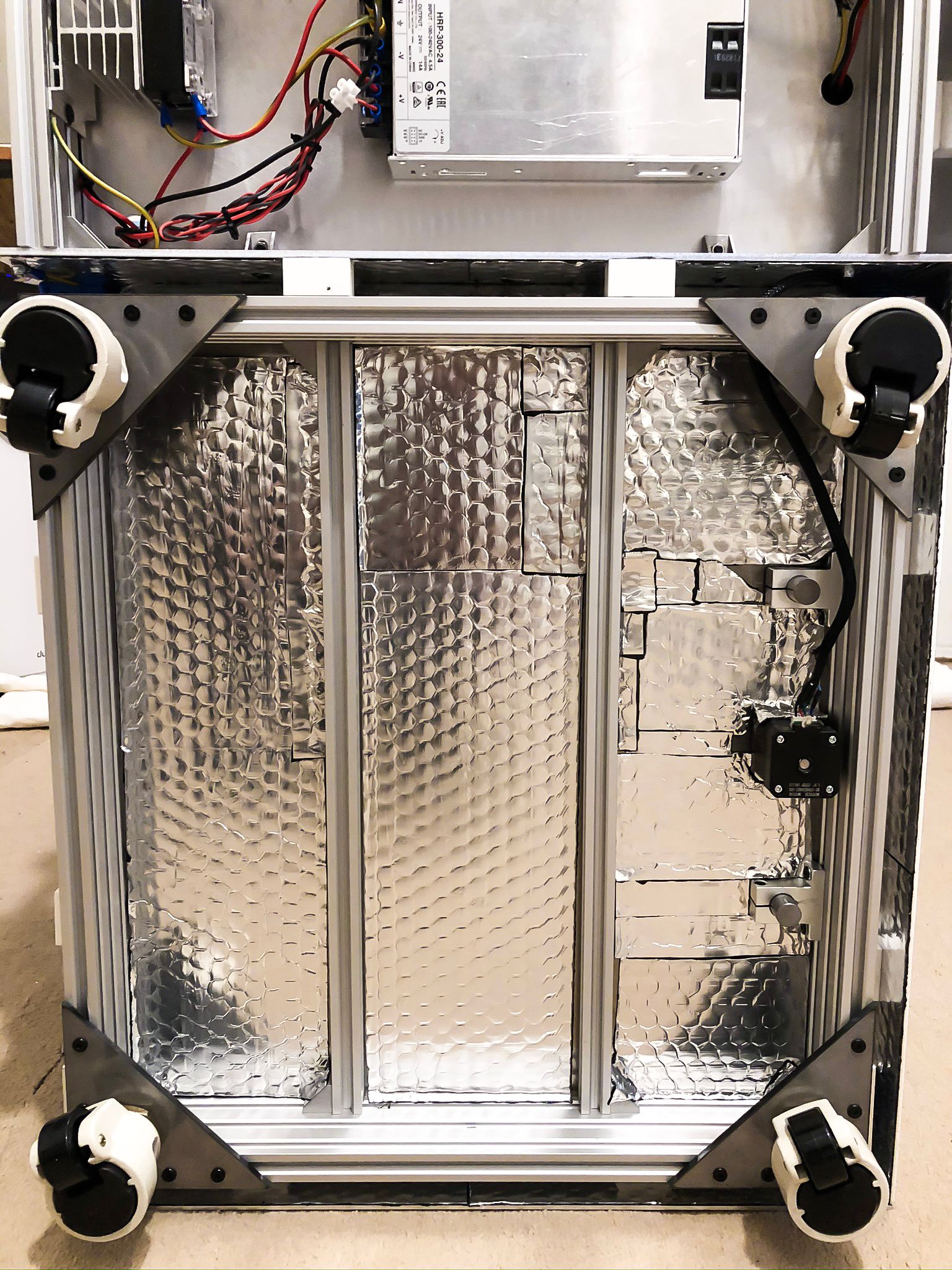

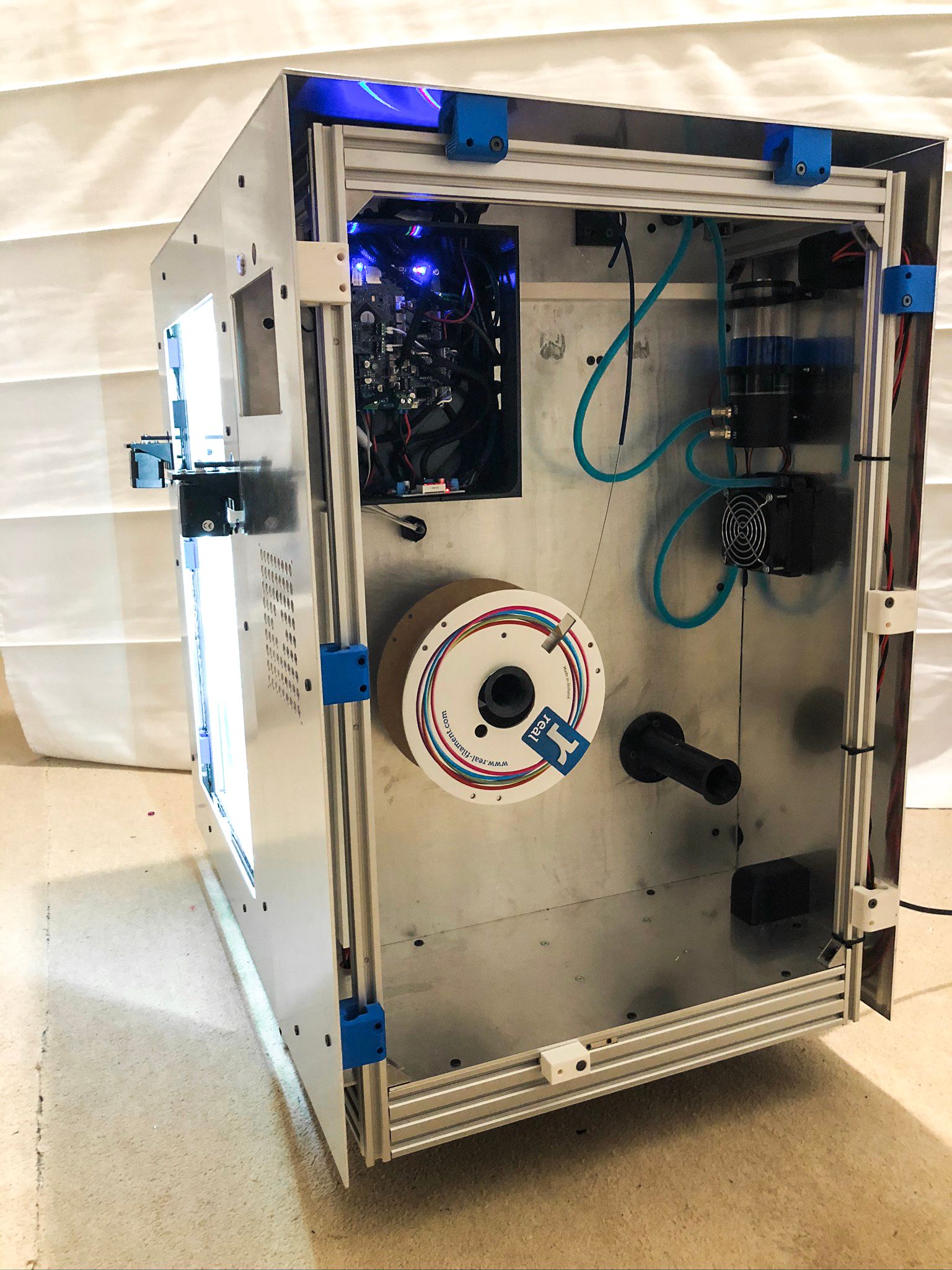

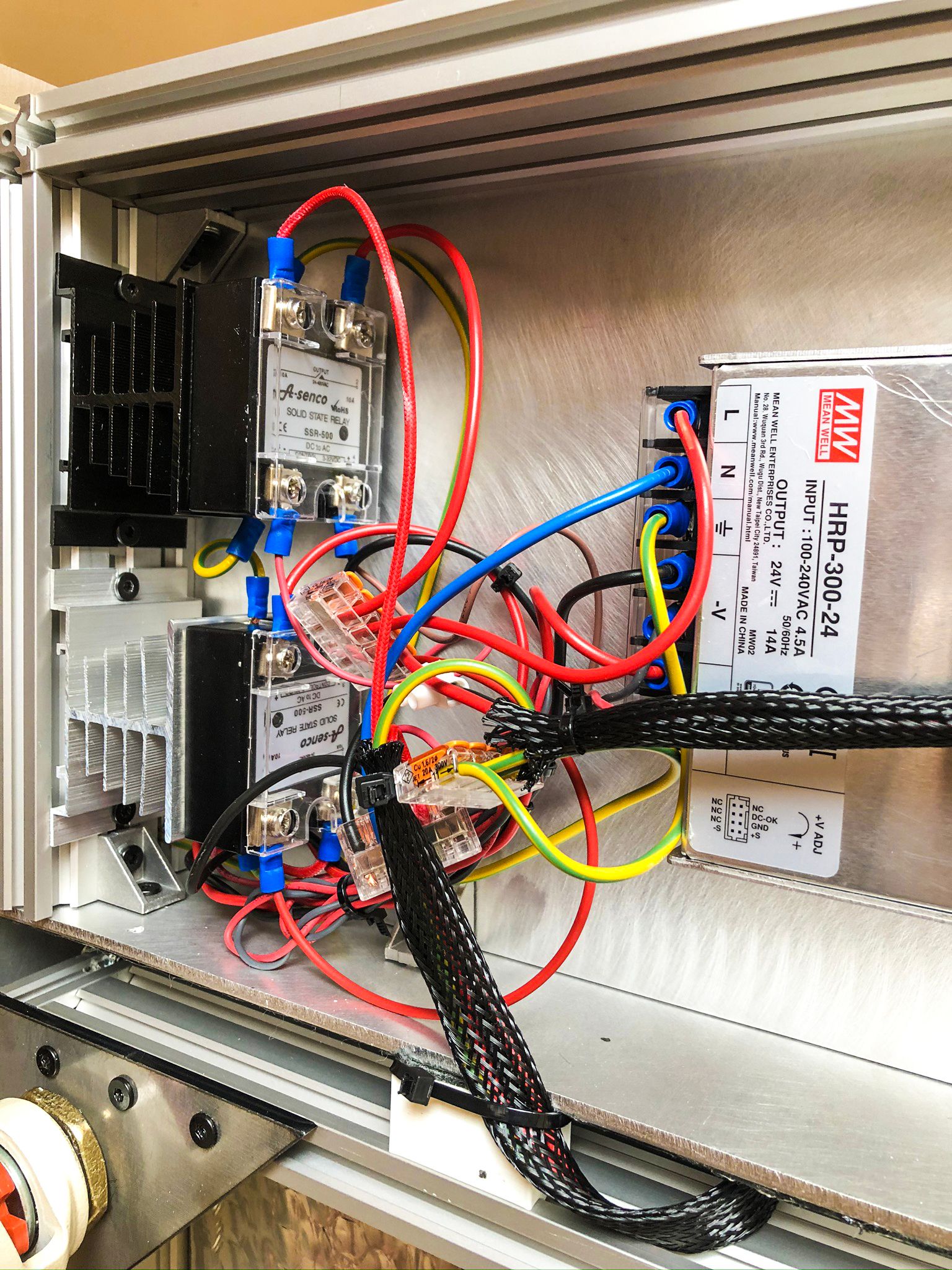

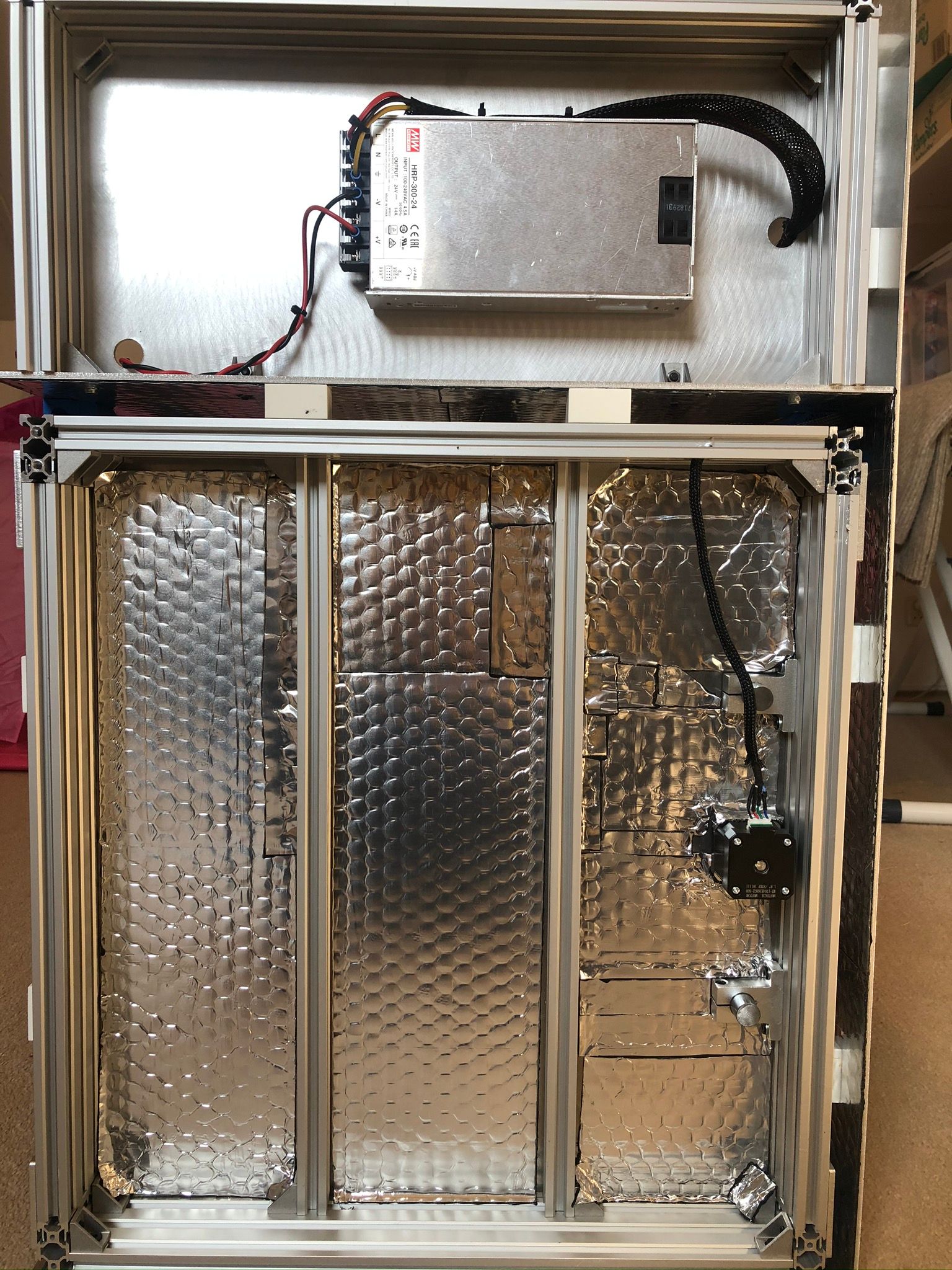

- Heated Chamber 70C;

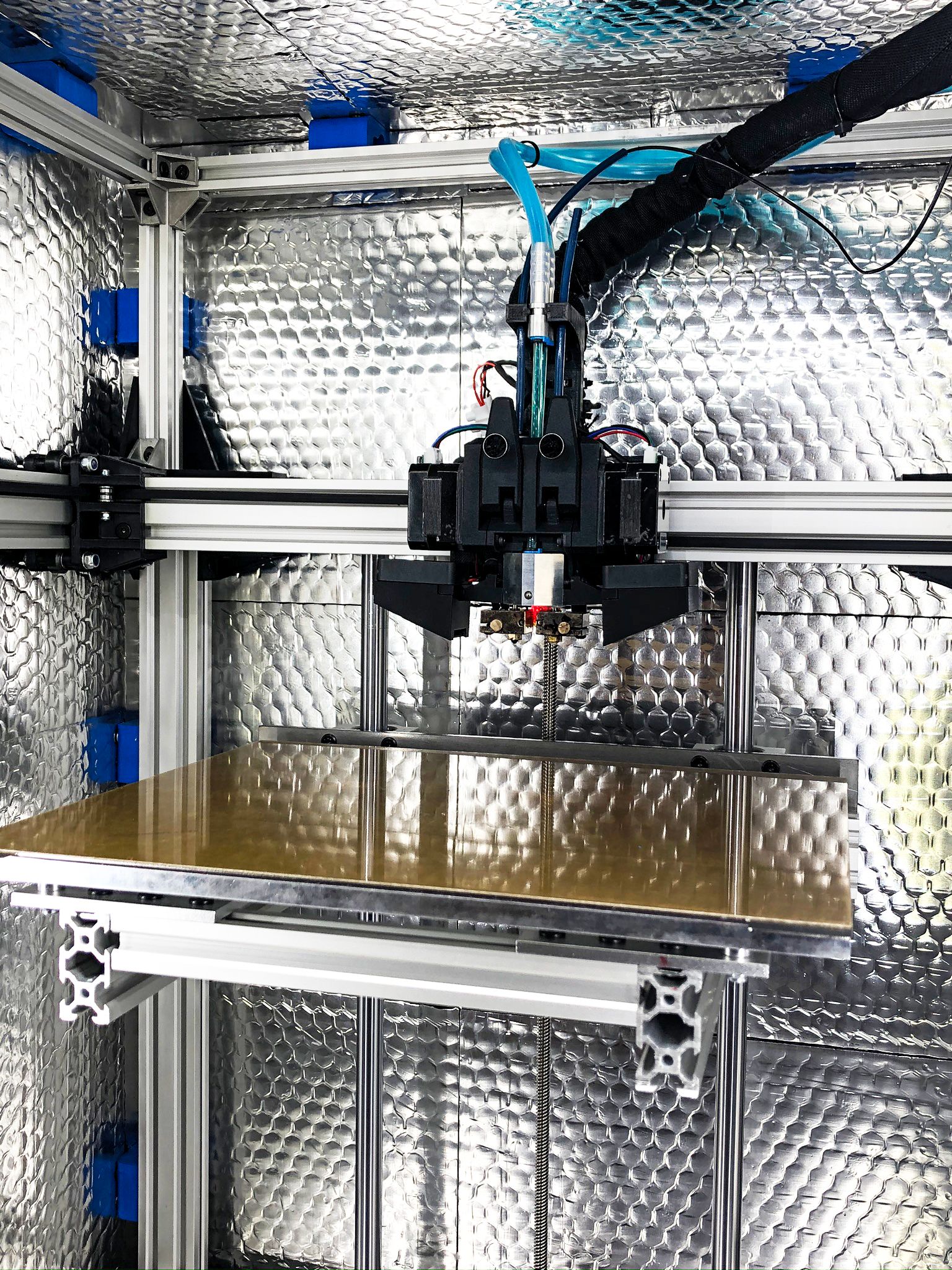

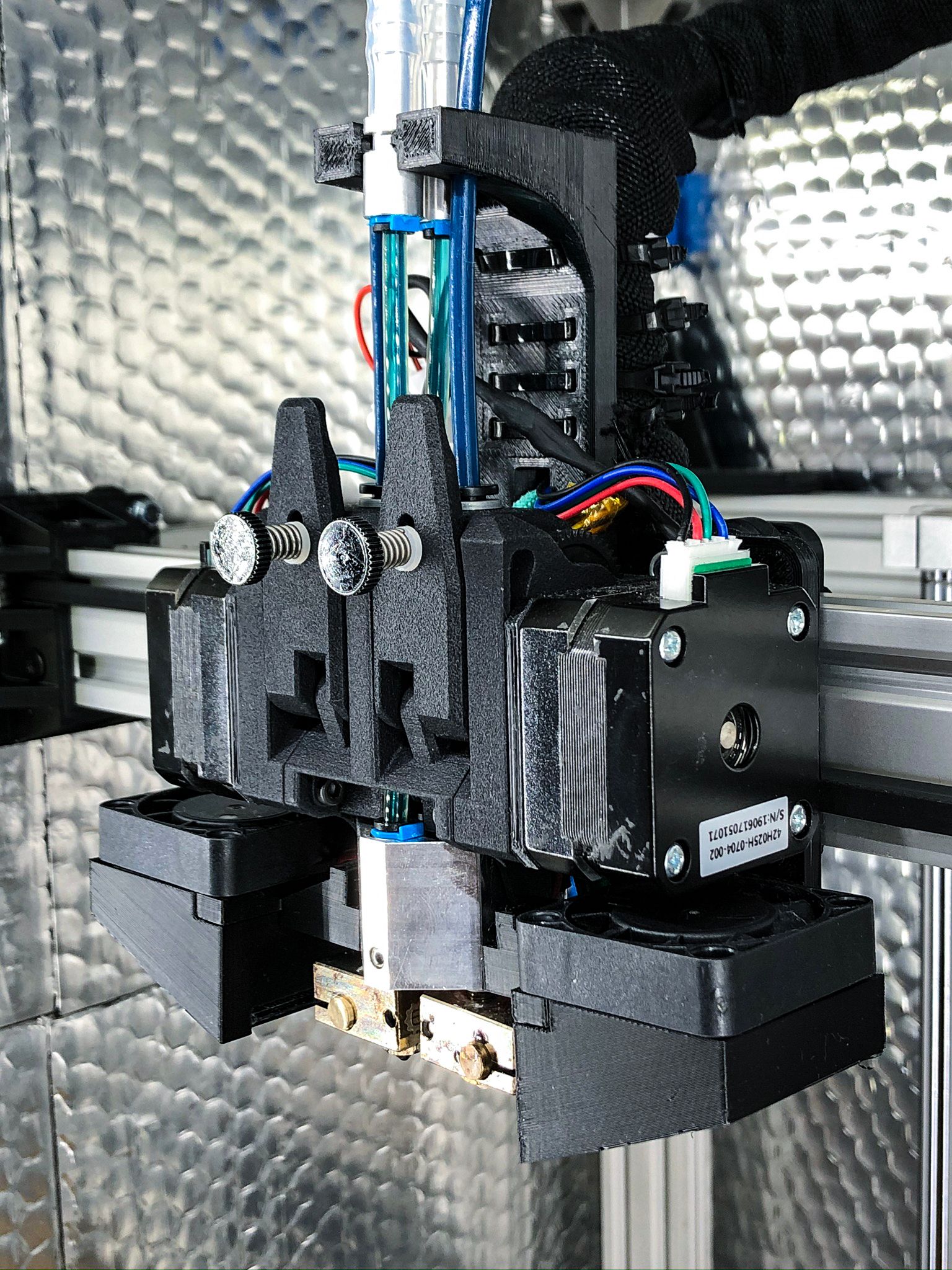

- Dual extrusion mainly for water-soluble supports;

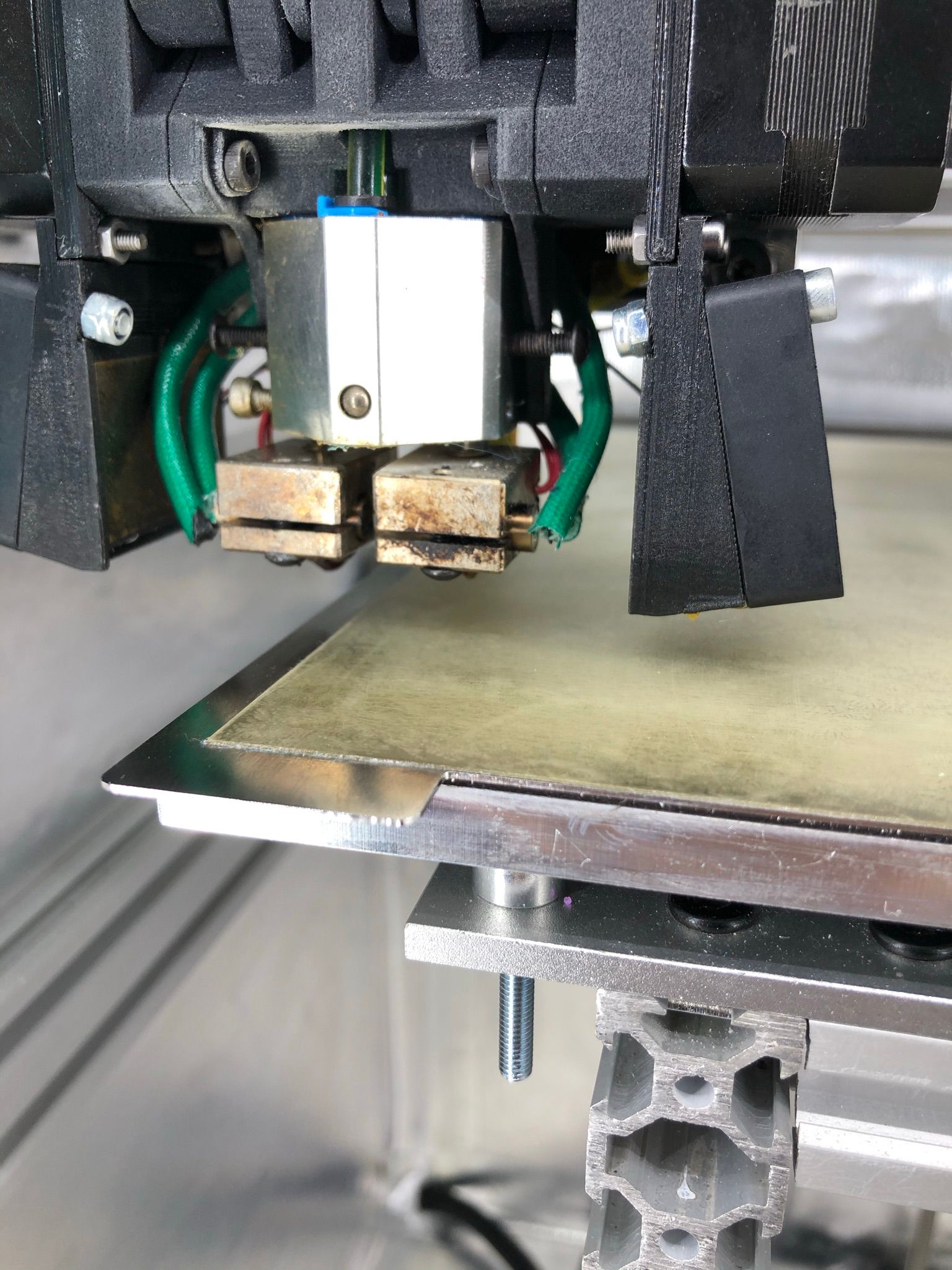

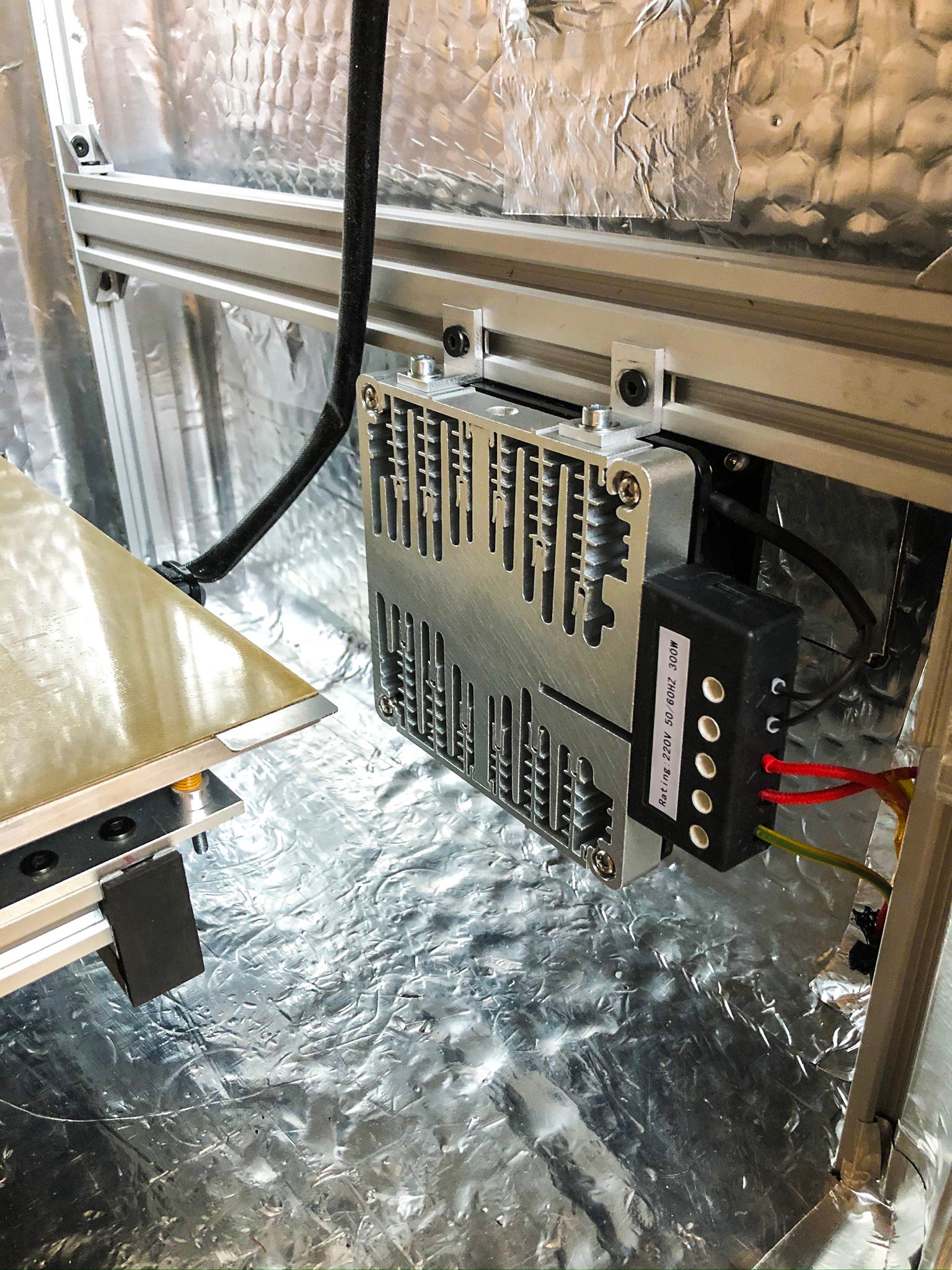

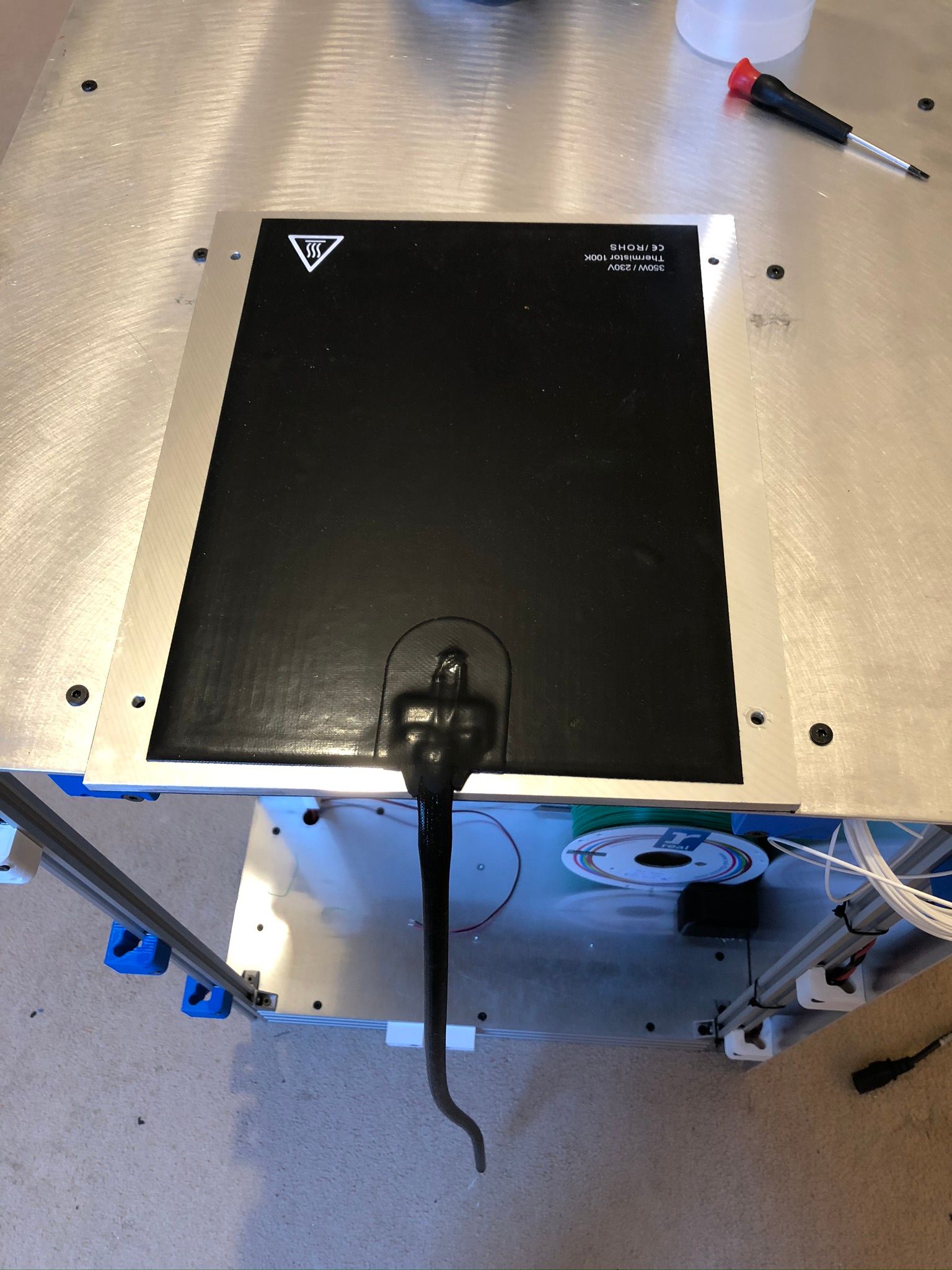

- AC heated bed - 500W from Filafarm;

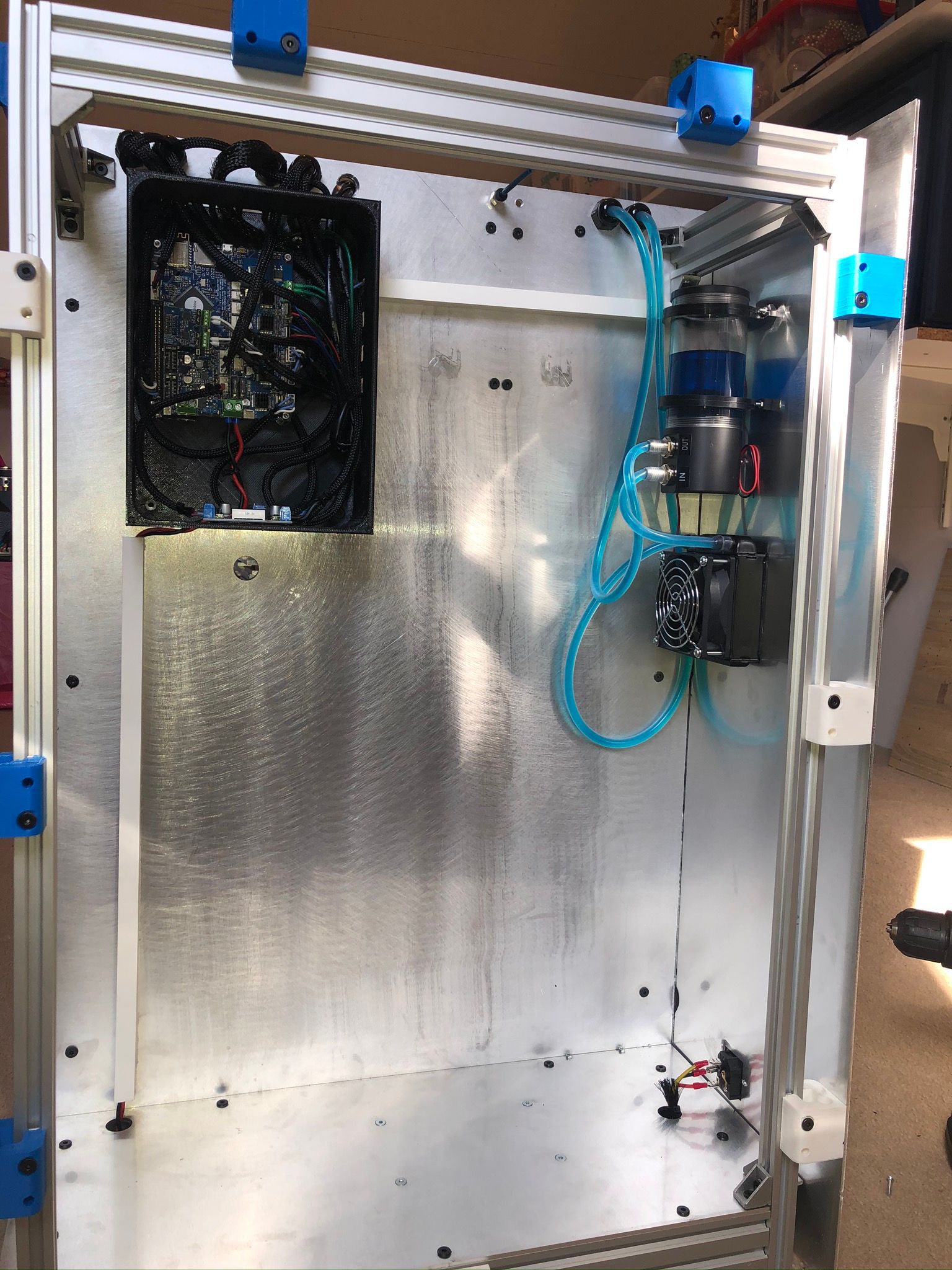

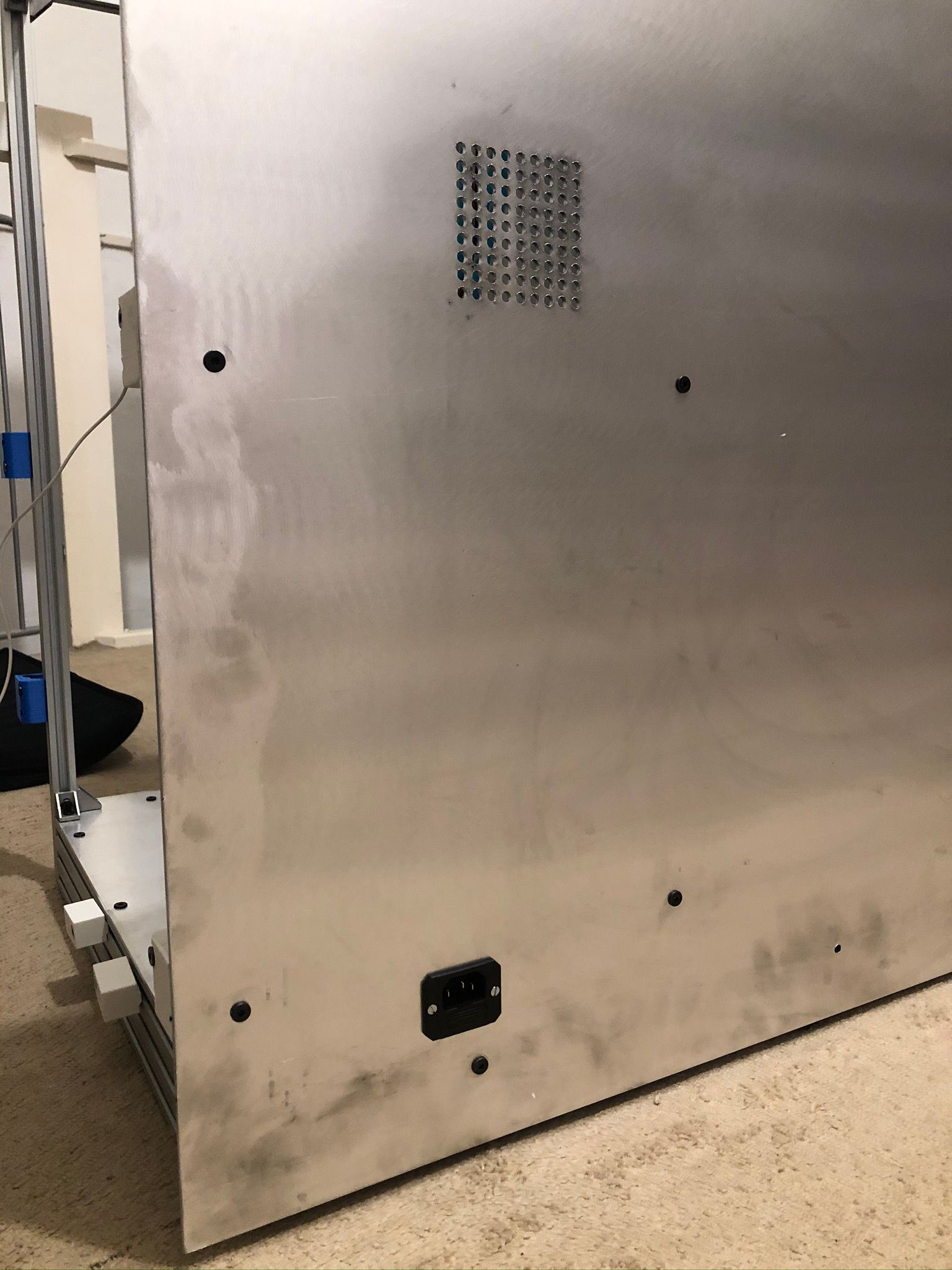

- Charcoal filtration;

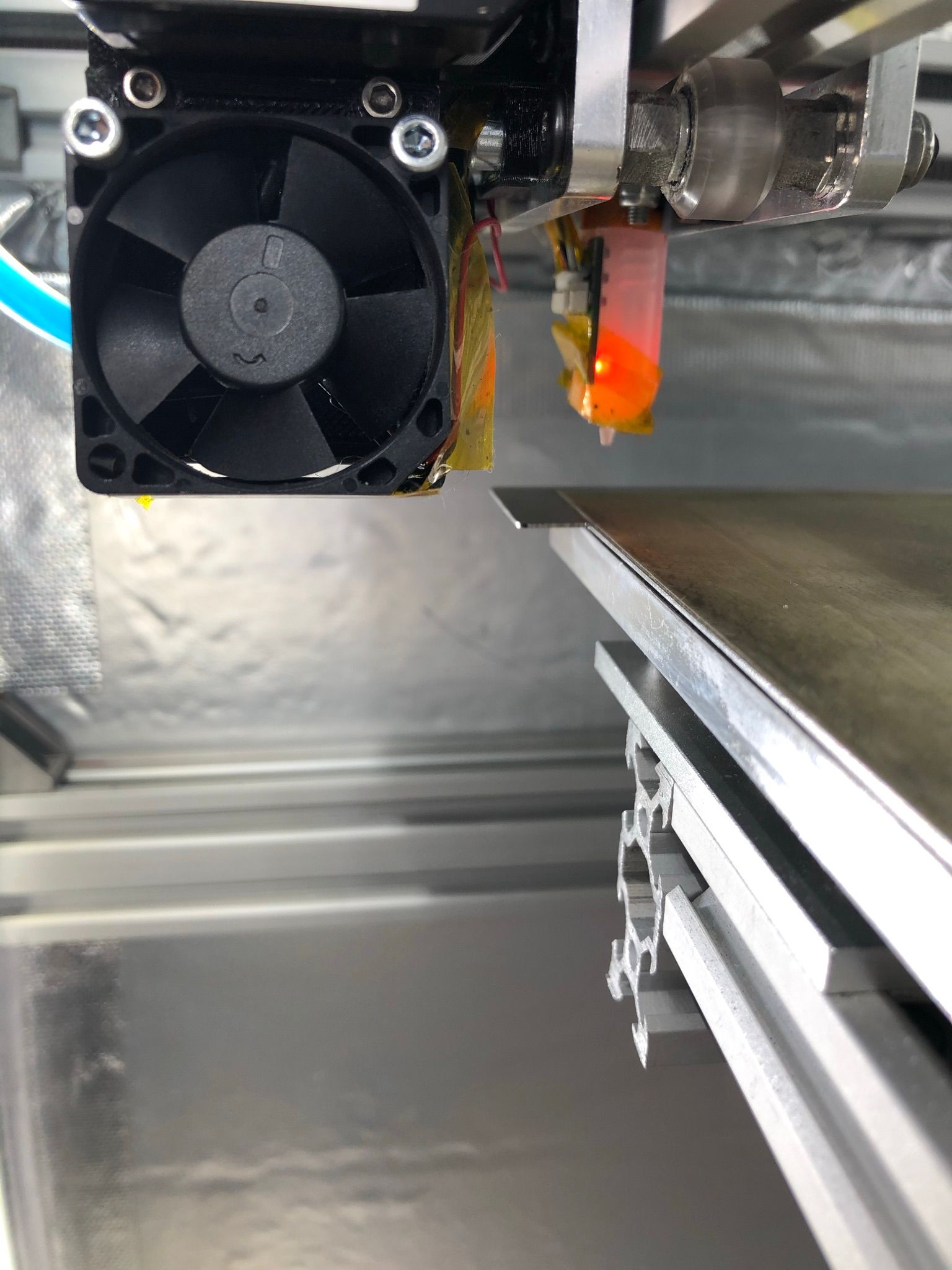

- Hotend - 450C with PT100;

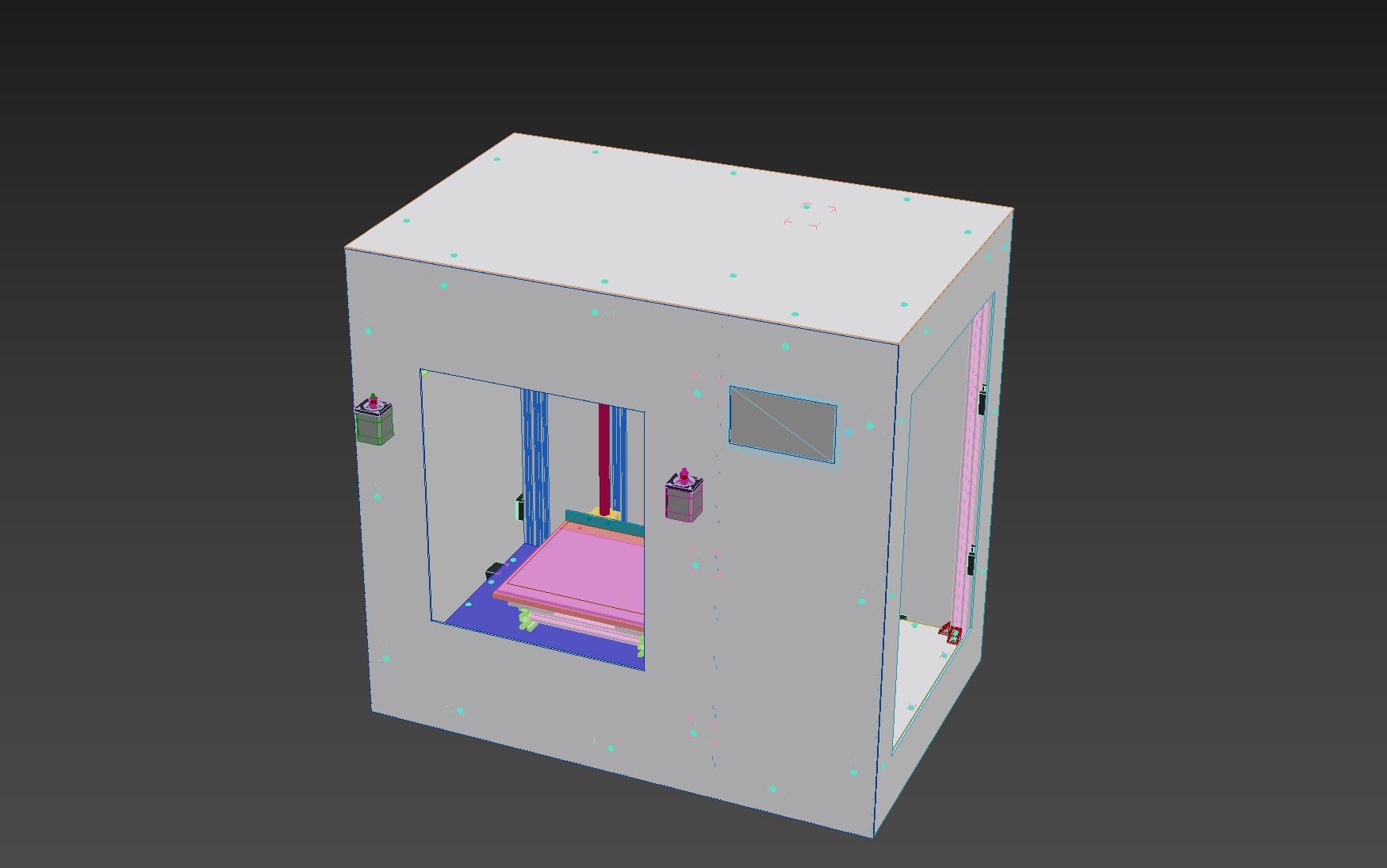

- Fully enclosed machine with Electronic compartment and PanelDue 7";

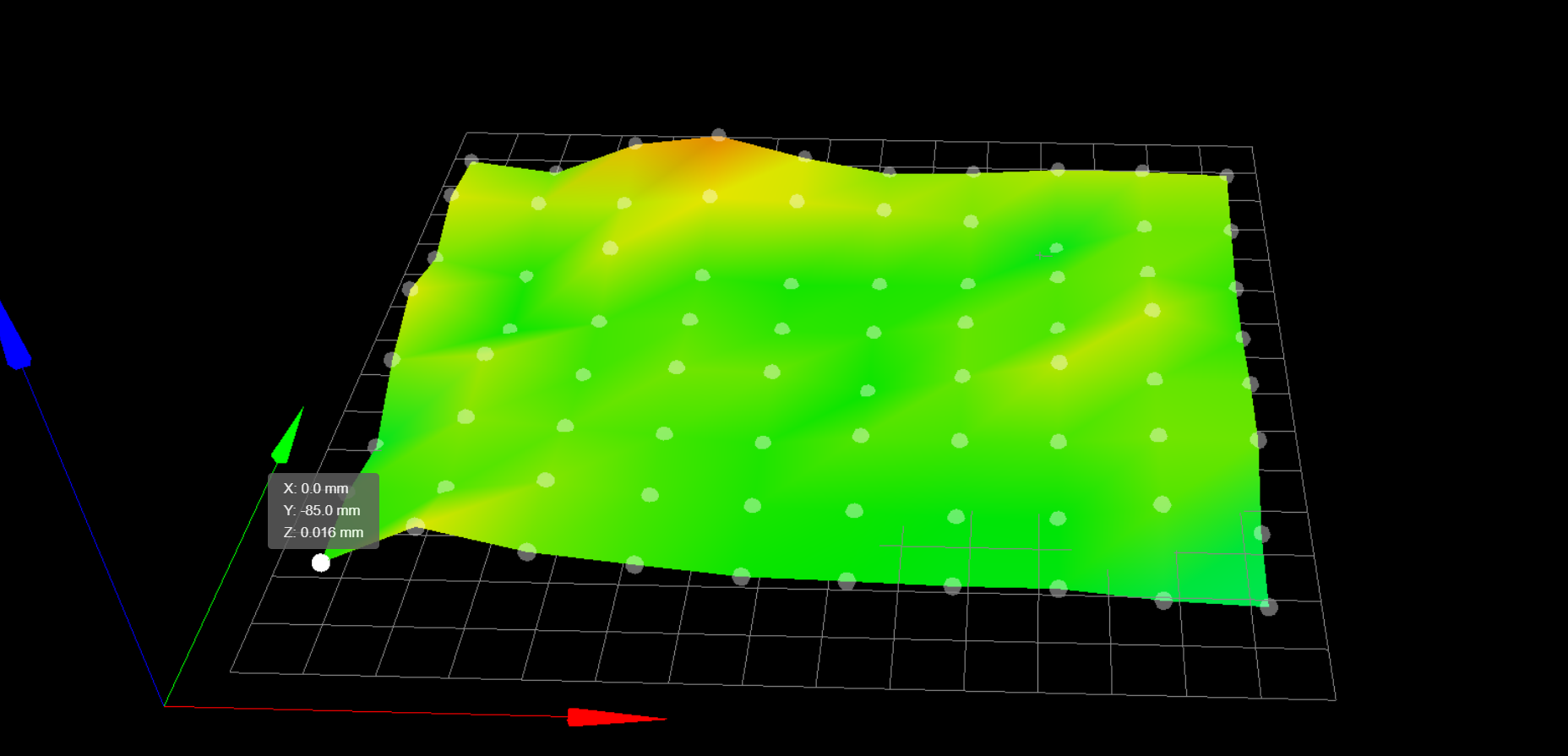

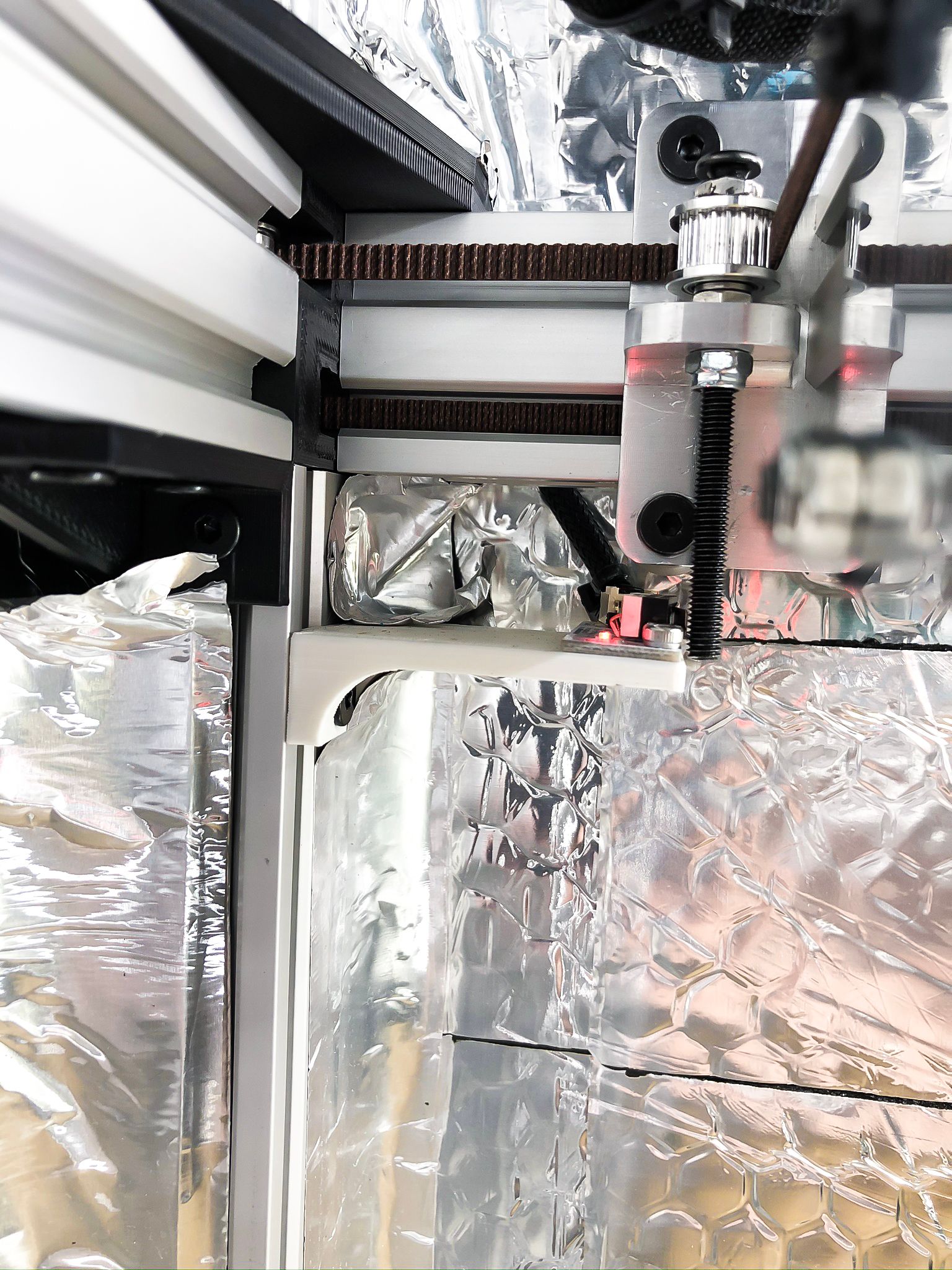

- BL touch for now - later Metrol as they are rated 80C+;

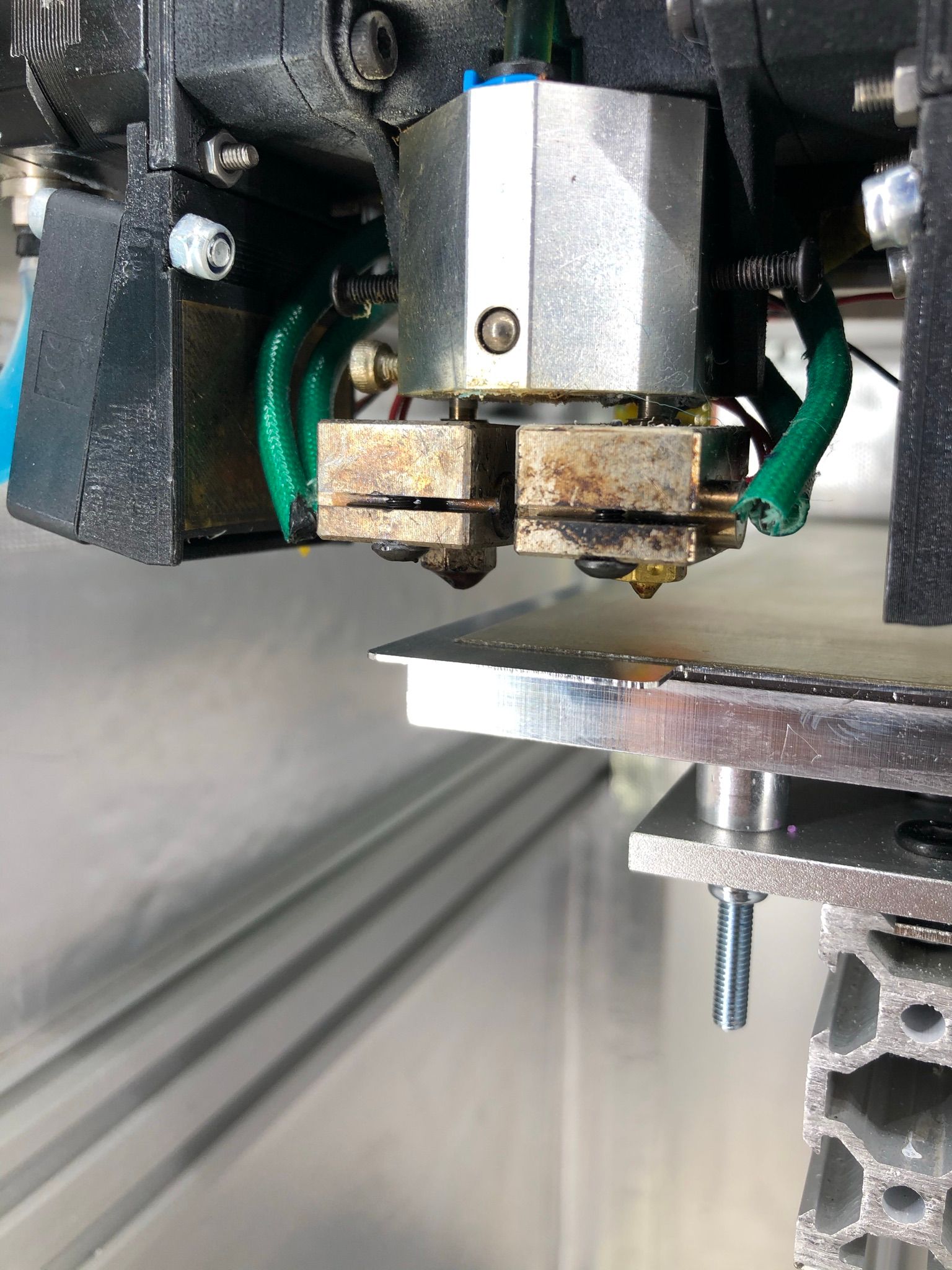

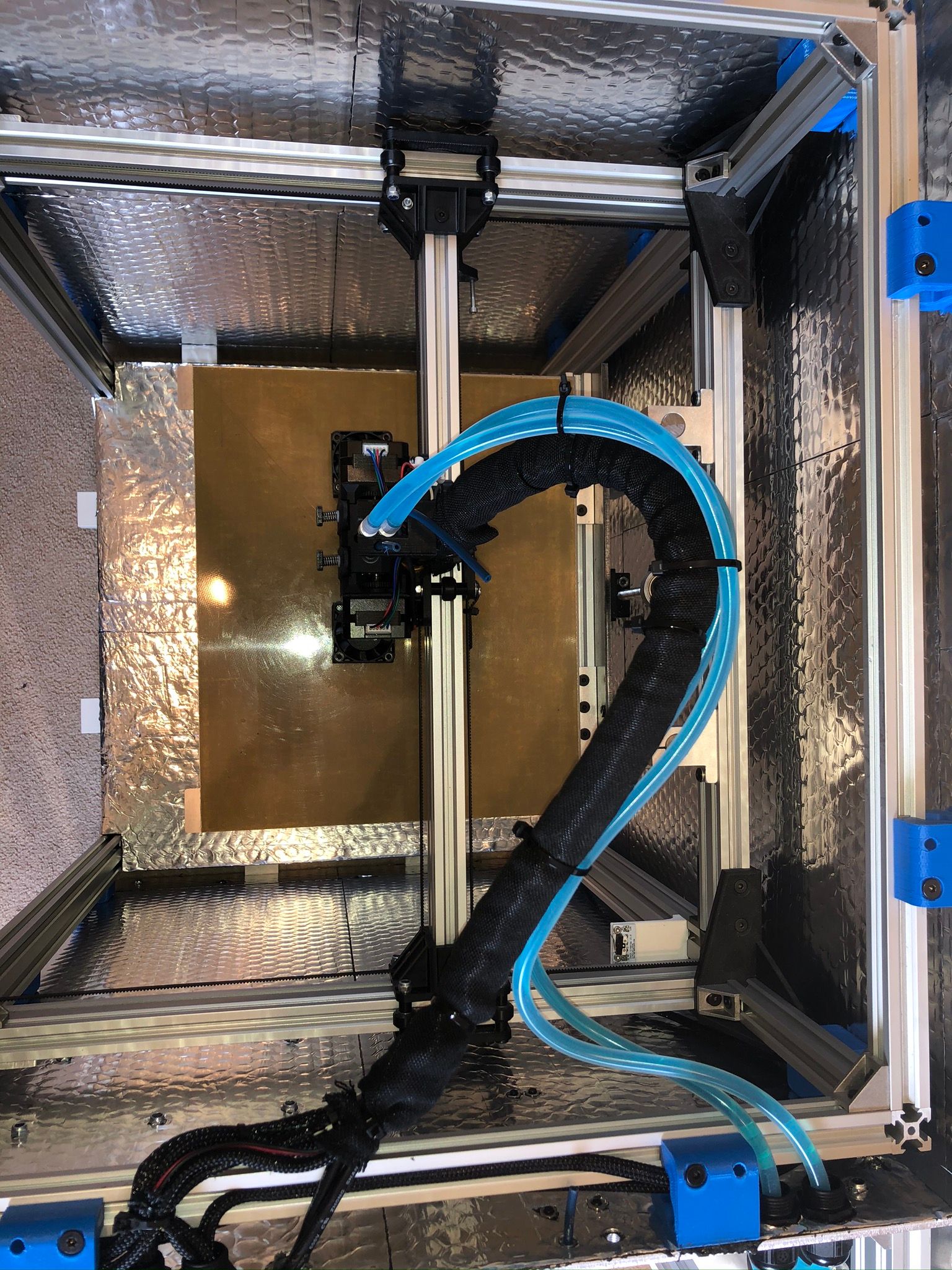

- Water Cooled hot end - Chimera;

- DuetWifi main electronic;

- Dual Bondtech Extruders used as a

Bowdenbecame direct; - Able to print PEEK/PEI/PSU small objects of ~70x70x50mm;

- Magnetic build plate from Filafarm with Filaprint surface;

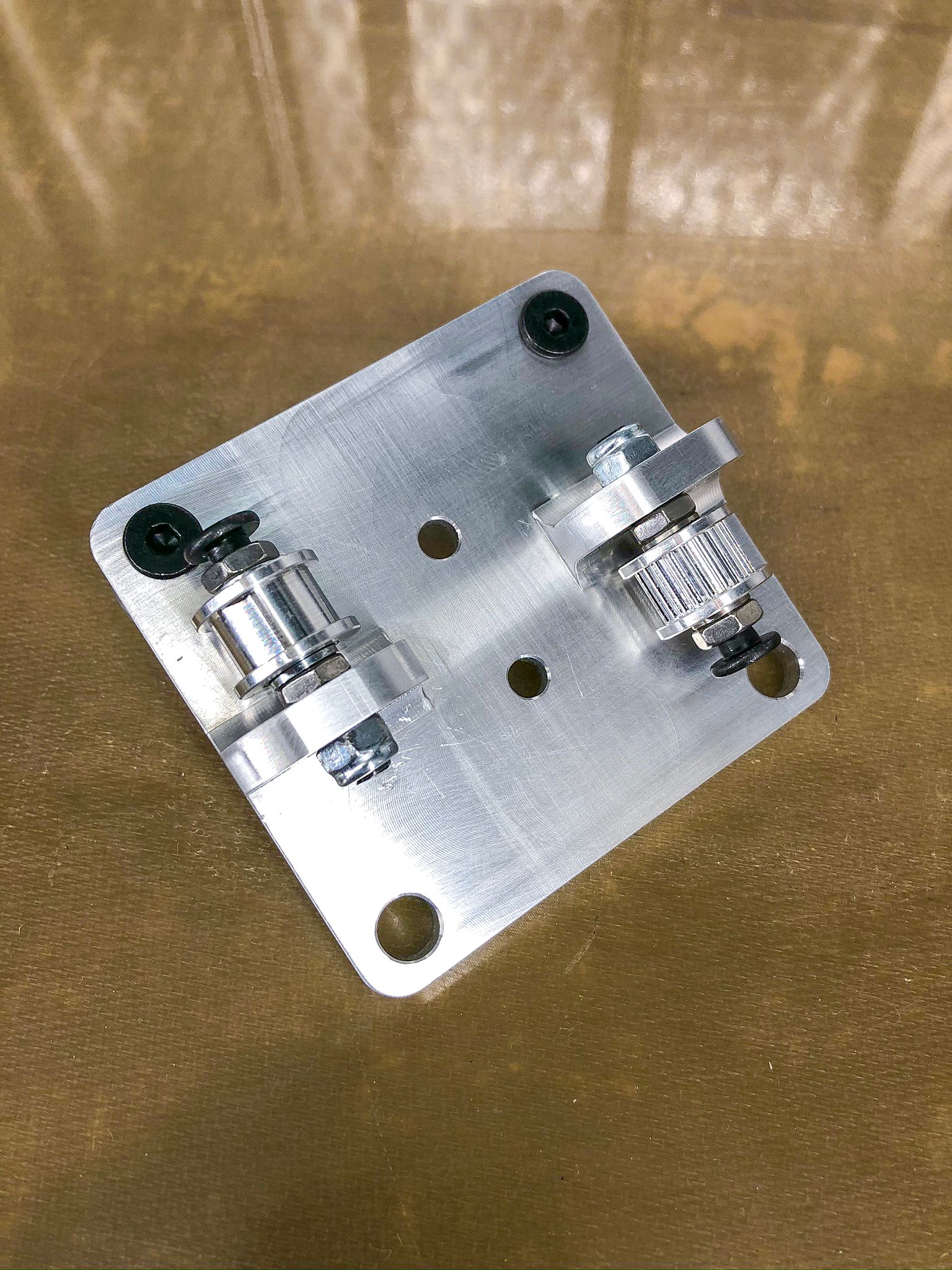

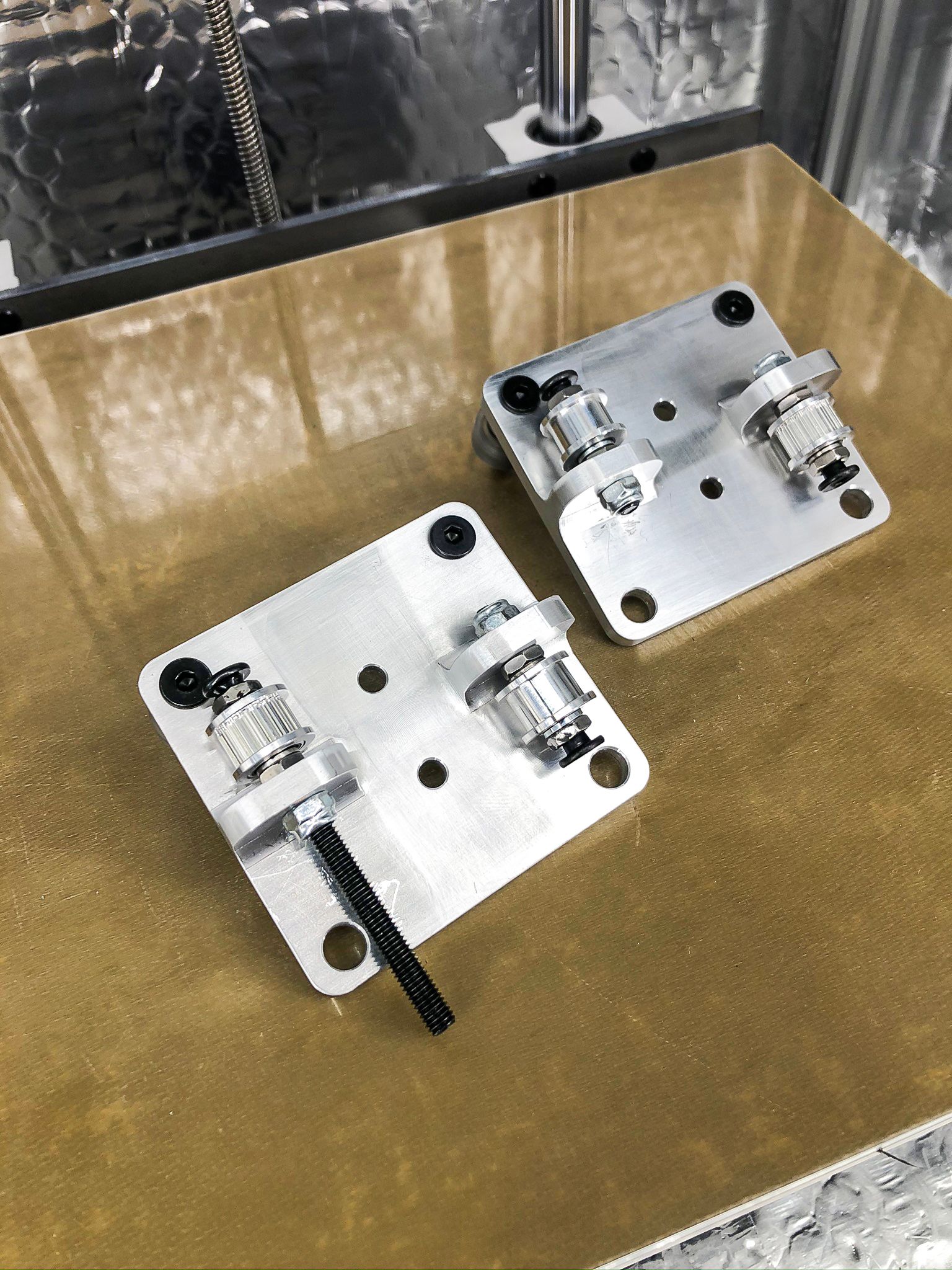

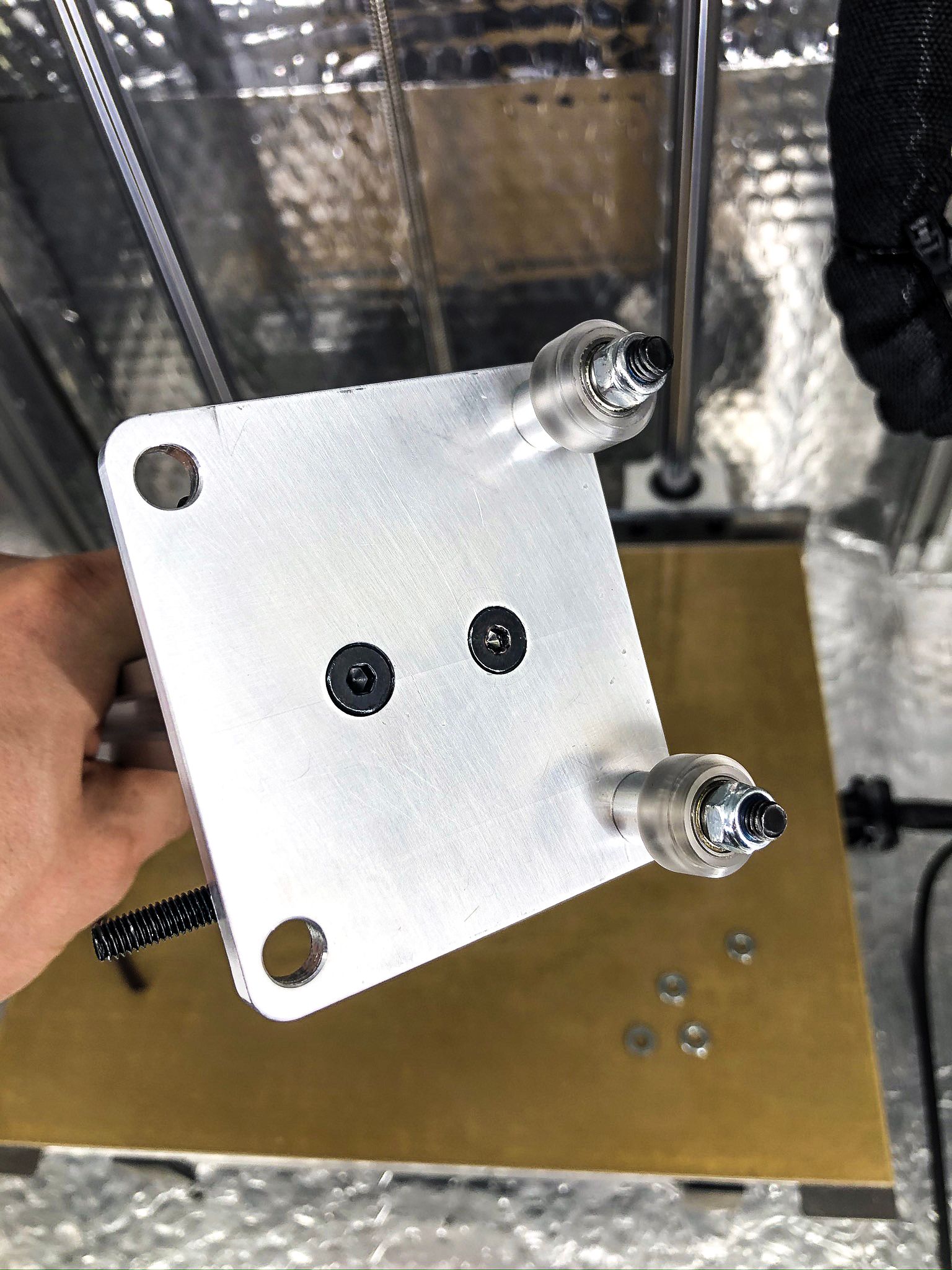

- All printed parts would be replaced with milled Aluminium, I am already close to this stage as I am happy how everything working out so I can continue without worries

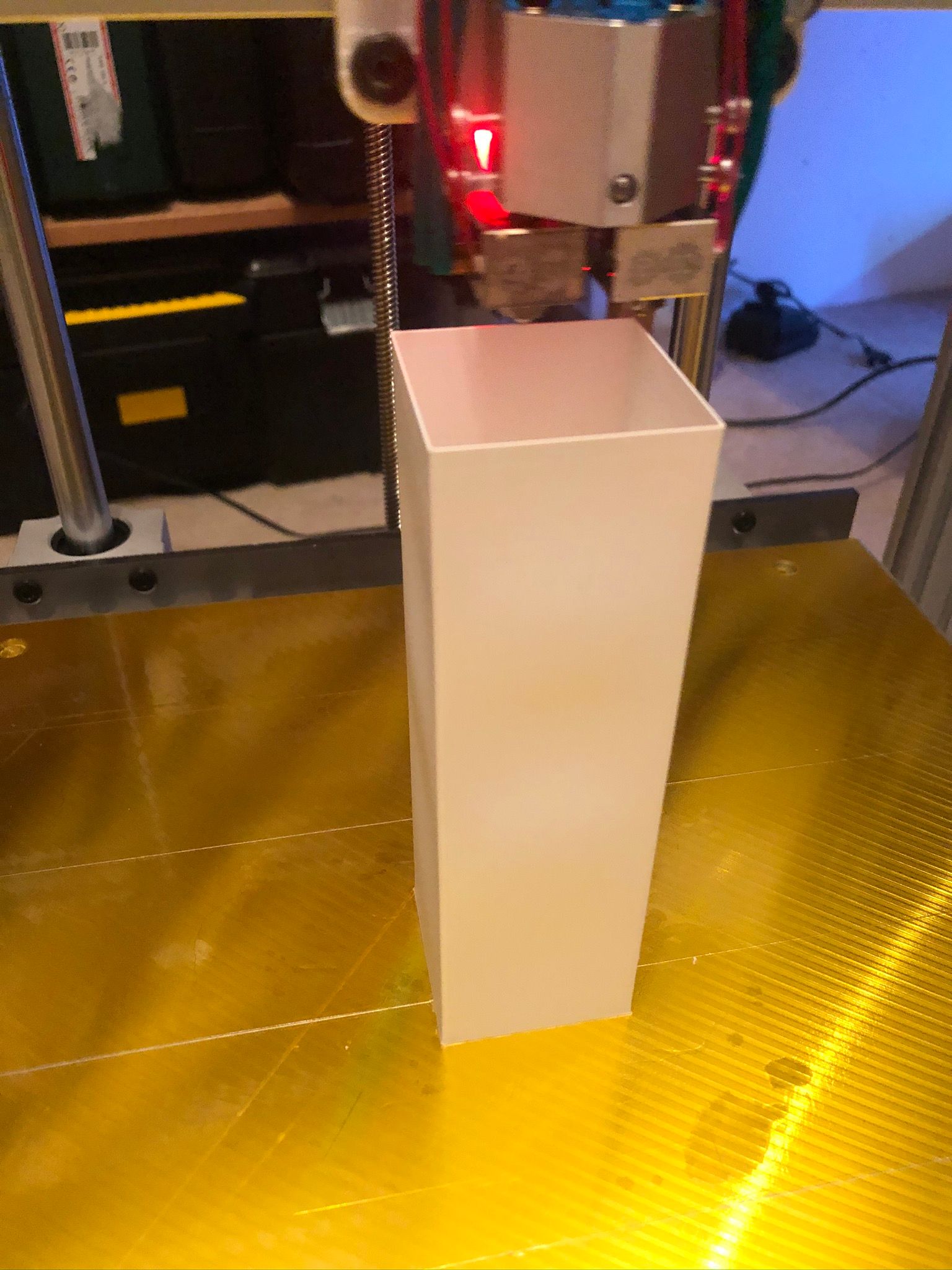

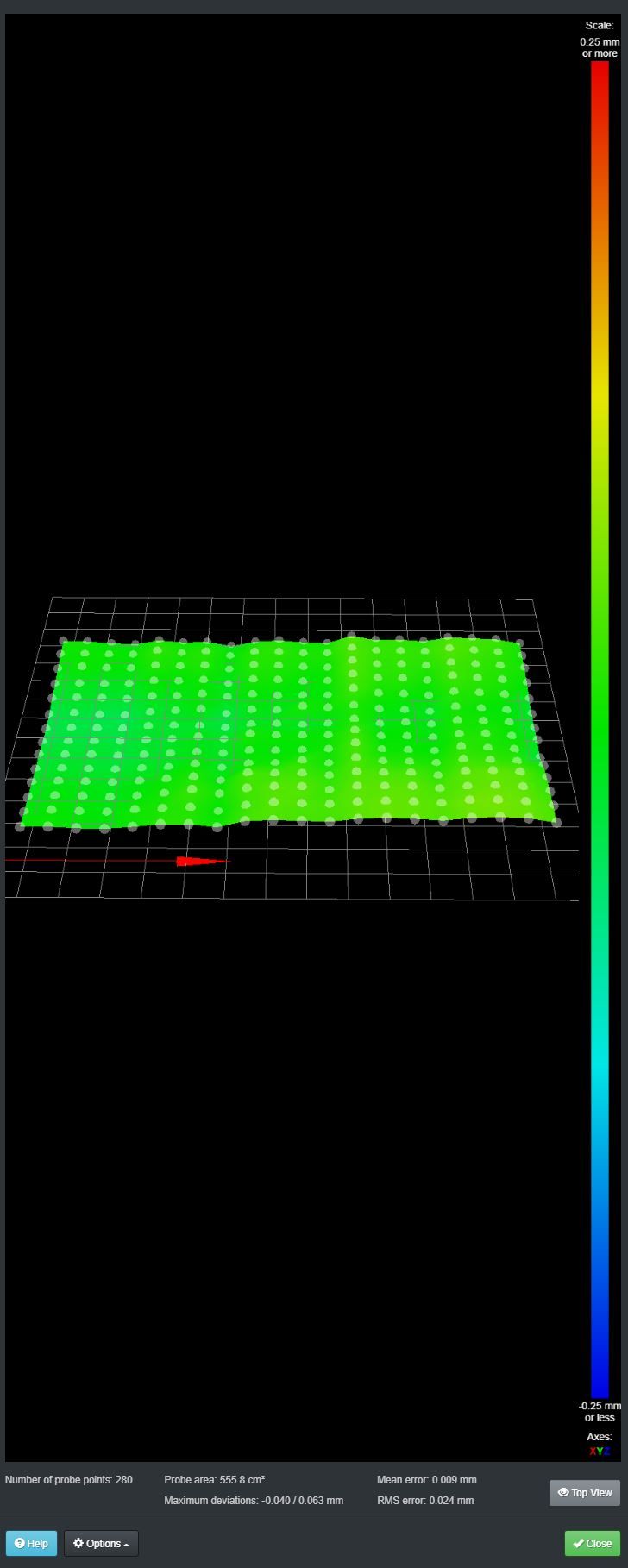

The whole build itself comes out fairly aligned from the beginning, minor tweaks required to achieve 100x100mm cube printed with 100.06x100.04mm - which is sufficient I think.

What is left to think about:

My bed is fairly plane and BL touch does a great job I can print around the whole bed with a consistent width. What worrying me is it would be the same with a bigger object which has more weight 1kg+? I do have 16mm rods and 8mm trapezium lead screw, would it be better to put 12mm trapezium lead screw, or I am losing resolution this way?

The filtration system, how to heat a chamber and control temperature, would it be enough 70C for PEI/PEEK/PSU. I saw a thread on ultimaker forum that somebody able to print those filaments with a 60C air temperature, small objects.

Dual extrusion doesn't really work as I expected - maybe my tool change files should be adjusted properly. But it does leak then it switching tool then it goes to continue print - but I think this is just spending more time on tweaking feed rates and pressure advance.

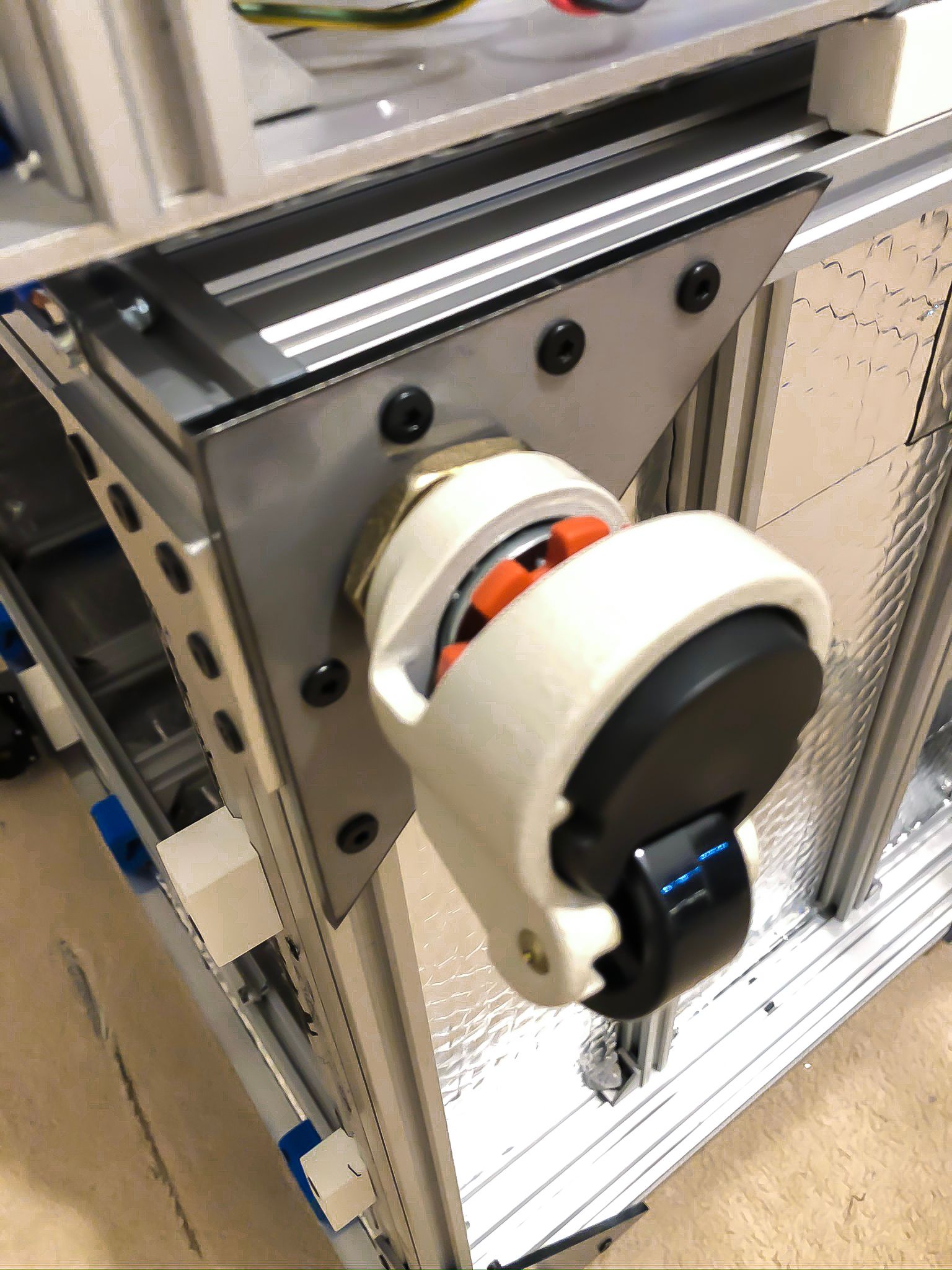

Still figuring out how to properly make a sealed front door.

More images here:

(https://share.icloud.com/photos/0B3qJiJsvmaQ44aGGL3YA_zAw)

-feel free to always check it as it will update with new images as I have new stuff to share

If somebody has critics or comments please share knowledge and experience!

077-671d0cf8-066a-46e8-9c76-5b216a9b77ed-resized.jpeg)

077-671d0cf8-066a-46e8-9c76-5b216a9b77ed-resized.jpeg)