Service life of heater cartridges and thermistors

-

@DaBit said in Service life of heater cartridges and thermistors:

Indeed, the regular manufacturers do not provide much above 240C

I tested some of the PRC made and some of the "brand name / expensive" ones from DigiKey... the "up to 140C" ones they behave according to specs. PRC ones too melt just like they suppose to at temps they suppose to melt. Above 240C I did not find anything on digikey as they sell 220/240C max. Mouser usually max at 140C...

Anyhow the PRC 300C ones I tested behaved pretty good but unfortunately I only had 5 of them so I tested 3, incorporated 1 and left one spare.

Just note that "240C" ones, for e.g. NTE (solid brand) they are 240 holding temp, so they can sit for a long time (not indefinetely) on 240C and they will melt at 290C. I'm not sure they are a safety solution for the hotends. I personally run mains powering the whole printer trough bed fuse and since I have huge heaters on beds I assume if the MCU fails it will fail with bed too and bed will trip the fuse before the hotend makes any serious damage

-

Still, something has changed... But fairly subtle; if I did not get a heater error with the have the cooling fan running to accelerate inactive nozzle cooldown I would not have noticed.

I don't believe the thermistor is bad; both of them seem to react normal, also to 'cross-heating' between the heater blocks. But I will check the temperature with an external thermocouple once I receive my tiny one.

I also ordered two 40W cartridges. I can use the extra power anyway.

Chimera is not an ideal multimaterial solution, but for now I will live with it. The best results are obtained when the inactive nozzle is cooled really far down before continuing the print with the active nozzle. I intend to increase airflow over the heaterblocks during toolchange even more to accelerate cooldown of the inactive nozzle, but the active nozzle is also affected. I could put some effort in shielding the active nozzle from the airflow, but just a bit more power is far simpler.BTW: I tried simulating the Chimera heat transport in Fusion360, but the simulation results do not match reality. Even with no convection heat load on the block F360 says the heaterblock only gets up to 113C with 30W input. We all know that is not true.

And adding a realistic convection load is not trivial either in F360, so I decided it was not going to give any useful results. -

@DaBit, have you conjugated the resistance of the two heaters and the current through them when they start heating?

-

Not yet, I needed the printer to print.

I will do that as soon as I have replacement cartridges so I only have to open it up once. -

@dc42, since you are in contact with E3D, suggest to them to come with cartridges with built in thermal fuse?

E3D are market leader and are in good position to bring innovations like this to the market.

-

I've asked E3D. I'll let you know what response I get.

-

Resistance 'slow' heater cartridge, cold: 27.3 ohms

Resistance 'normal' heater cartridge, cold: 20.6 ohmsVoltage to the heaters is 23.6V, measured on the screws of the terminals. I did not measure the current; forgot to take the (DC-)current clamp with me from work.

That results in a calculated power to the heater of 20.4W for the slow one, and 27W for the quicker one.

The 40W heaters I ordered also differ 10% in cold resistance. But the results of a PID autotune are much closer together now for both heater blocks.

M307 H1 A675.5 C232.3 D2.8 S1.00 V23.7 B0 M307 H2 A650.8 C253.7 D3.6 S1.00 V23.8 B0 -

@DaBit said in Service life of heater cartridges and thermistors:

That results in a calculated power to the heater of 20.4W for the slow one, and 27W for the quicker one.

That's a significant difference.

Anybody knows if the resistance of a nozzle heater changes significantly when it get hot?

-

@zapta said in Service life of heater cartridges and thermistors:

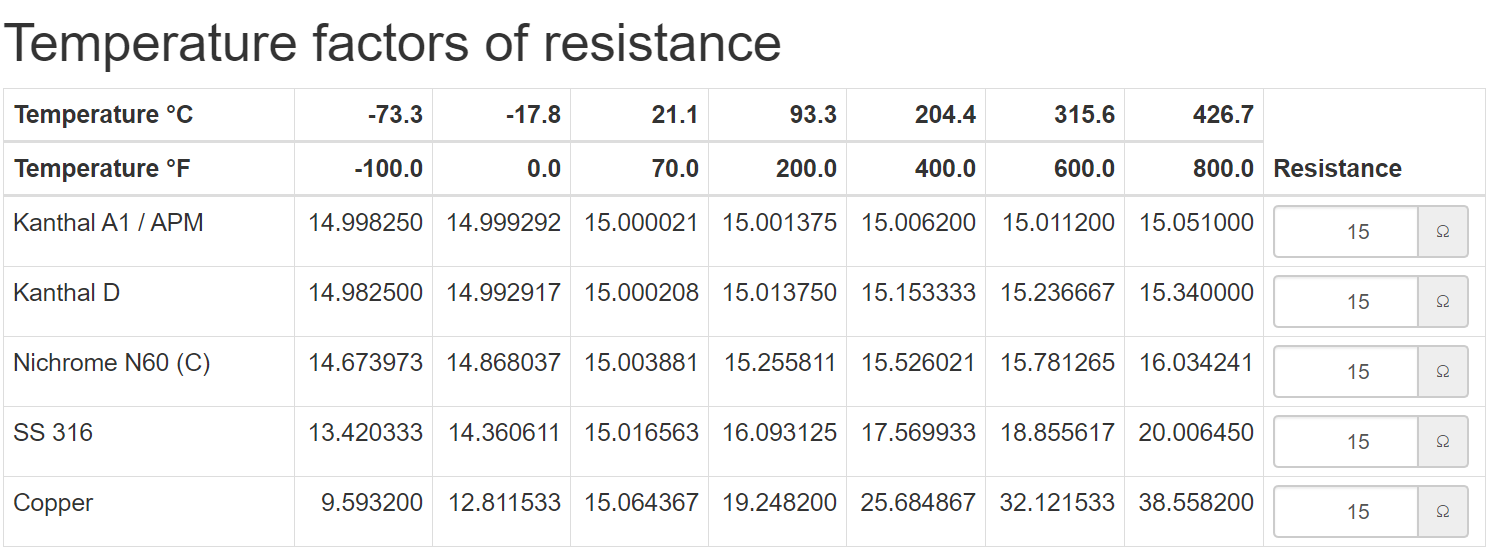

Anybody knows if the resistance of a nozzle heater changes significantly when it get hot?

Would depend on what it's made from, kanthal and that type of proper heater wire does change, but much less than say copper.

To quote Wikipedia

Ordinary Kanthal FeCrAl alloy has a melting point of 1,500 °C (2,730 °F). Special grades can be used as high as 1,425 °C (2,597 °F). Depending on specific composition the resistivity is about 1,4 μΩ. m and temperature coefficient is +49 ppm/K.

50ppm and generally quite low resistance to start with, the absolute change would be small but measurable methinks

-

50ppm and >300C temperature difference with room temperature (the heating wire in the cartridge becomes a lot hotter than the heater block) is still a few percent.

-

-

That is less than I expected, especially for Kanthal A1.

It might still be interesting to hook up the current clamp on a running Duet, see if the heater current drops.

-

If you assume they'd used something like the Nichrome to save some cost as the temperature of Kanthal isn't needed, you'd see about 100mA drop on a 40w/24v heater.

(But the current clamp would probably show a lot more current reduction as it would likely average out the pwm'ed current as the PI loop starts regulating)