BL Touch leveling a bit off

-

So it's been a while since I setup my machine but never got to print an item that used the whole bed on my printer, it's a 700 x 500 x 700mm build volume.

Today I tried printing something only to notice that after doing the automatic bed leveling with independent 3 leadscrew Z motors and doing the BL Touch mesh, my print is still too close on 1 corner.

I thought something must have gone wrong, stopped the print and redone the routine. Restarted the print and got the exact same result.

Any ideas where to even start looking for issues / fixes?

A bit confused since it seems to be working but just not working right on that one corner for some reason. TIA.

-

If you run G32 several times, do the results get smaller and smaller?

The points described in M671 should be the points at which the bed pivots. This may or may not be the leadscrews, depending on your exact bed setup. Anyway, it is generally not possible to probe exactly at these points. Therefore, a single pass of the calculations based on the probe points may not exactly level the bed.

As long as the before and after get smaller and smaller, running G32 multiple times is an easy solution to this. I find I have to run it 3 times (and maybe more if the bed started way off).

-OR-

Are you confident the various mechanics of the printer are completely square and level (really, flat)? Even if the bed is 'matched' to the carriage via 3 point bed leveling, it may not be able to fully match to an out-of-square mechanism.

Those are the two most common places to start.

-

Yeah it does get smaller although never reaches 0. quite a really big bed so i would be surprised if it got it to a point where it's fully flat.

Either way though, even if the 3-leadscrew leveling is off the mesh after G32 should take care of it no?

That's what's confusing me even more. -

Good point, yes, I'd expect mesh to help quite a bit.

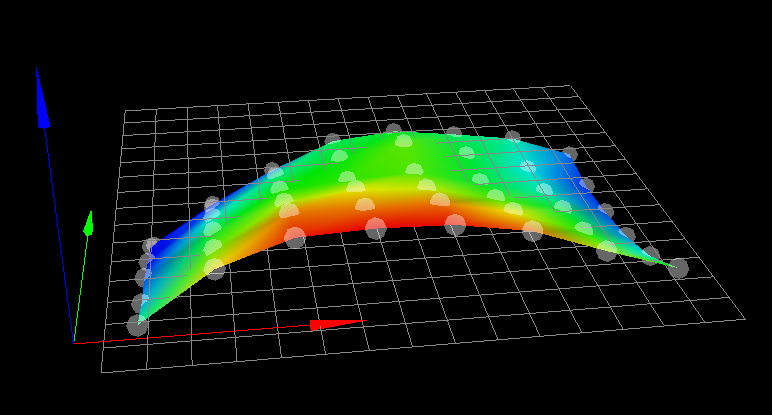

What does "Height Map" look like? You can use the windows 'snip' tool if you want to post the map here.

-

@Danal doesnt look very good to me, especially since it's running on glass. if there was something wrong mechanically or with the bltouch though i'd assume that the point at which the probing is off would be random rather than the same section every time.

Here's the screenshot! The bottom right corner in the picture is the one too close to the nozzle.

-

yes, that does look a bit taco-ish for a piece of glass.

Hmmm....

-

What supports the glass?

-

And, have you tried printing the first layer or two with mesh OFF?

If bottom right corner is too CLOSE, I'm suspicious the mesh is overcompensating.

-

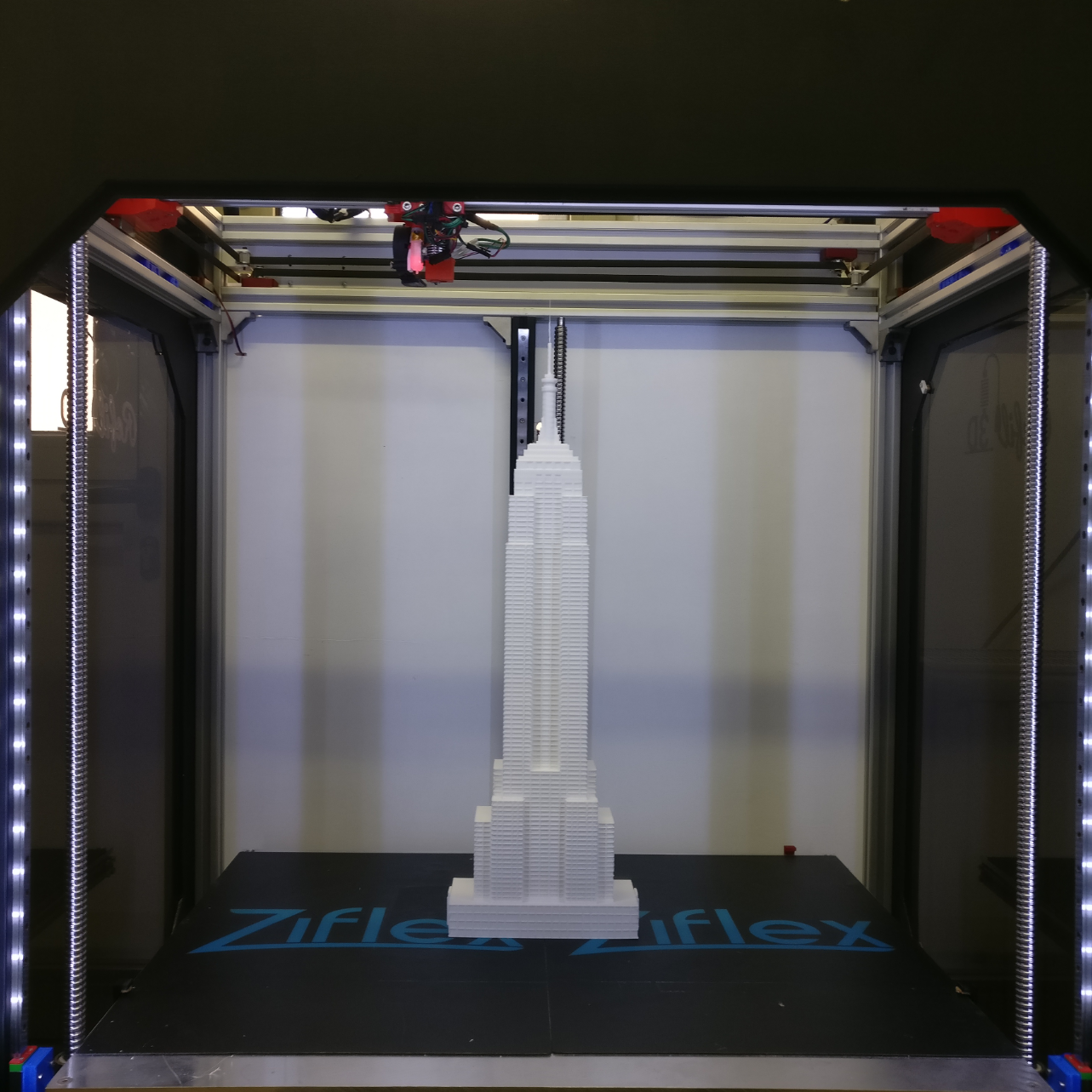

A mic6 plate, supported on 2020 extrusions as well. The glass is on top of the bottom magnet pads of the ziflex surfaces. i no longer use ziflex so i might remove the magnet pads as well.

-

Yeah, then that mesh map really doesn't look right. I'd either try a test pattern with it off, or tram the bed some other way as a cross check.

-

@Danal thanks For your help

i will try a test print with the mesh off just to check, if there's still issues i might try switching out the BLtouch might just be a bad one idk.

i will try a test print with the mesh off just to check, if there's still issues i might try switching out the BLtouch might just be a bad one idk.i got some switches as well (the ones that e3d uses on the toolchanger) which might be more accurate and reliable, but still waiting on them to release the TC plates for all printers, otherwise i cant use them due to not clearing the tools as is. you can only use it with the tools detached.

-

Post your full config and homing files so we can see what’s going on.

-

Here's my config

Let me know what homing files you'd like to see

-

That height map looks like a sagging x gantry to me. Basically as the print head gets closer to the middle it will sag more and bring it closer to the bed thus making it look like the bed is higher in the middle.

-

@MrSparrow said in BL Touch leveling a bit off:

Here's my config

Let me know what homing files you'd like to see

Homeall, homex, homey, homez, bed.g. All of them.

Also your slicer start gcode

-

; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M558 P5 H5 F400 T8000 X0 Y0 Z1 ; Set Z probe type/mode 5. H=Dive Height. F=Speed the bed moves; IR SENSOR M558 P1 H5 F120 T6000 ; Set Z probe type to unmodulated and the dive height + speeds

G31 P500 X-16 Y-45 Z0.48 ; ; Set Z probe trigger value, Z offset and trigger height Z bigger is closer

M557 X10:610 Y10:470 S80 ; Define mesh gridYour config for BLTouch is a little off. Try this instead.

; Z-Probe M574 Z1 S2 ; Set endstops controlled by probe M558 P9 H5 F100 T8000 A5 R0.5 G31 P25 X-16 Y-45 Z0.48 ; M557 X10:610 Y10:470 S50 ; Define mesh gridThat should help the probe be a little more accurate, but it probably won't change the shape of the resulting heightmap too much.

And yes, your heightmap could be a result of a sagging X gantry. Mesh compensation is perfect for correcting for that though.

-

Thank you for the reply @Phaedrux i will test that.

-

@JamesM there's no way for the X gantry to be sagging in the middle to be honest. it's a 2020 extrusion mounted with a 15mm linear rail which makes it even more rigid. i will have to check it but im fairly certain it's not sagging

-

@MrSparrow said in BL Touch leveling a bit off:

but im fairly certain it's not sagging

In that case, then it's the bed. Again, mesh compensation should be able to correct for it. Checking your files now.

-

@MrSparrow said in BL Touch leveling a bit off:

Thank you for the reply @Phaedrux i will test that.

Your pastebin is set to private. Can you just copy and paste them into a post here? Much easier to work with.