Help: CoreXY design review? My first CoreXY attempt.

-

@pipersw the belts are not on one plane, please use the 3D model and rotate the view.

Why must the belts be perpendicular on the bottom? I'm following the layout on the CoreXY website, which has the belts criss-cross

Actually, don't most designs cross the belts?

EDIT: I found this page https://greghoge.com/portfolio/large-format-3d-printer/corexy-gantry-system/ , but the advice there does not apply, my belts are not rubbing each other, they are on two different planes

...wait... this means there have been people who actually had belts rub together? That's insane lol aren't they going to turn into bandsaws on each other?

-

@frank26080115 That arrangement is fine. I expect someone will soon post a picture of what needs to be parallel and what doesn't, but in a nutshell you can do whatever you like at the back.

-

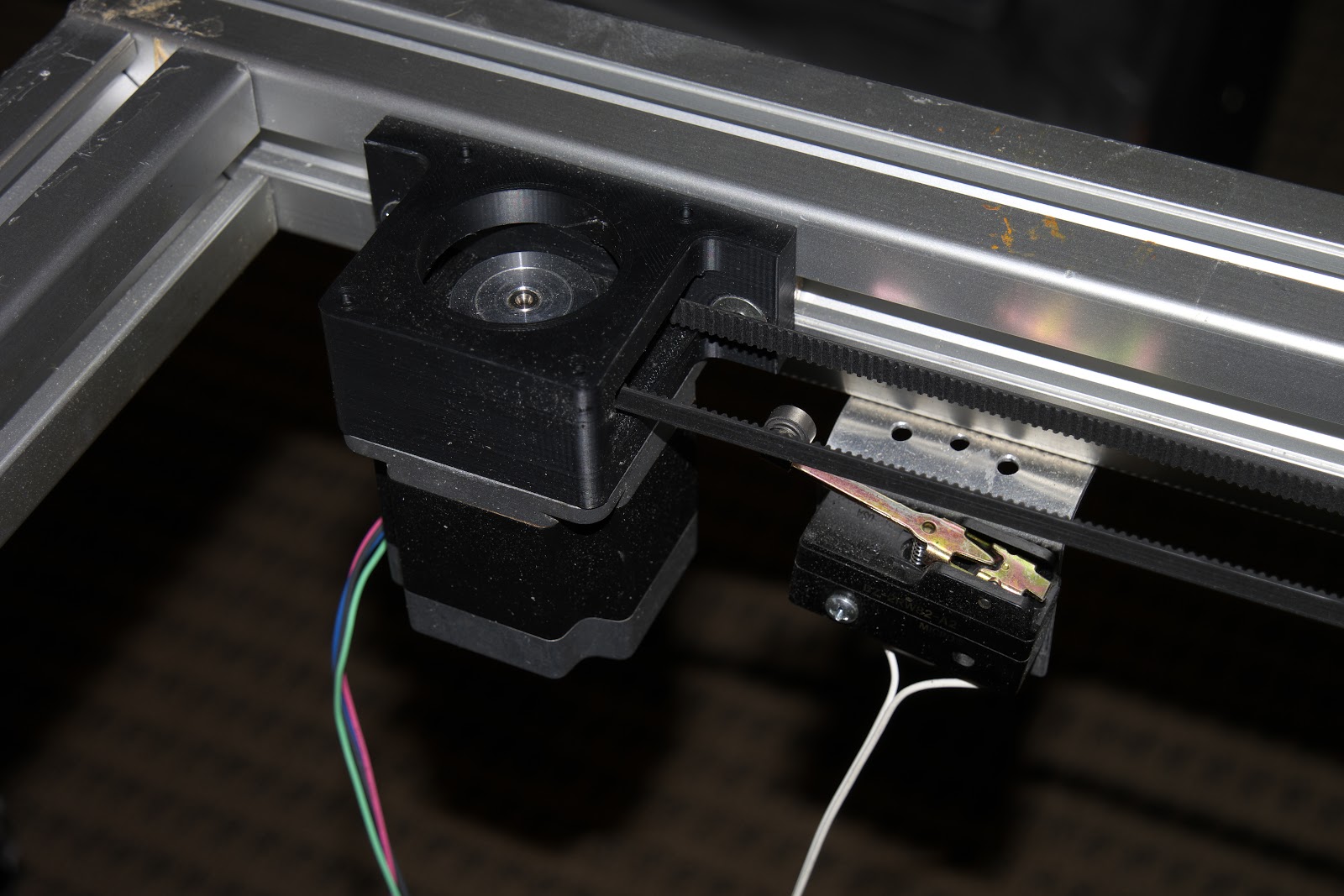

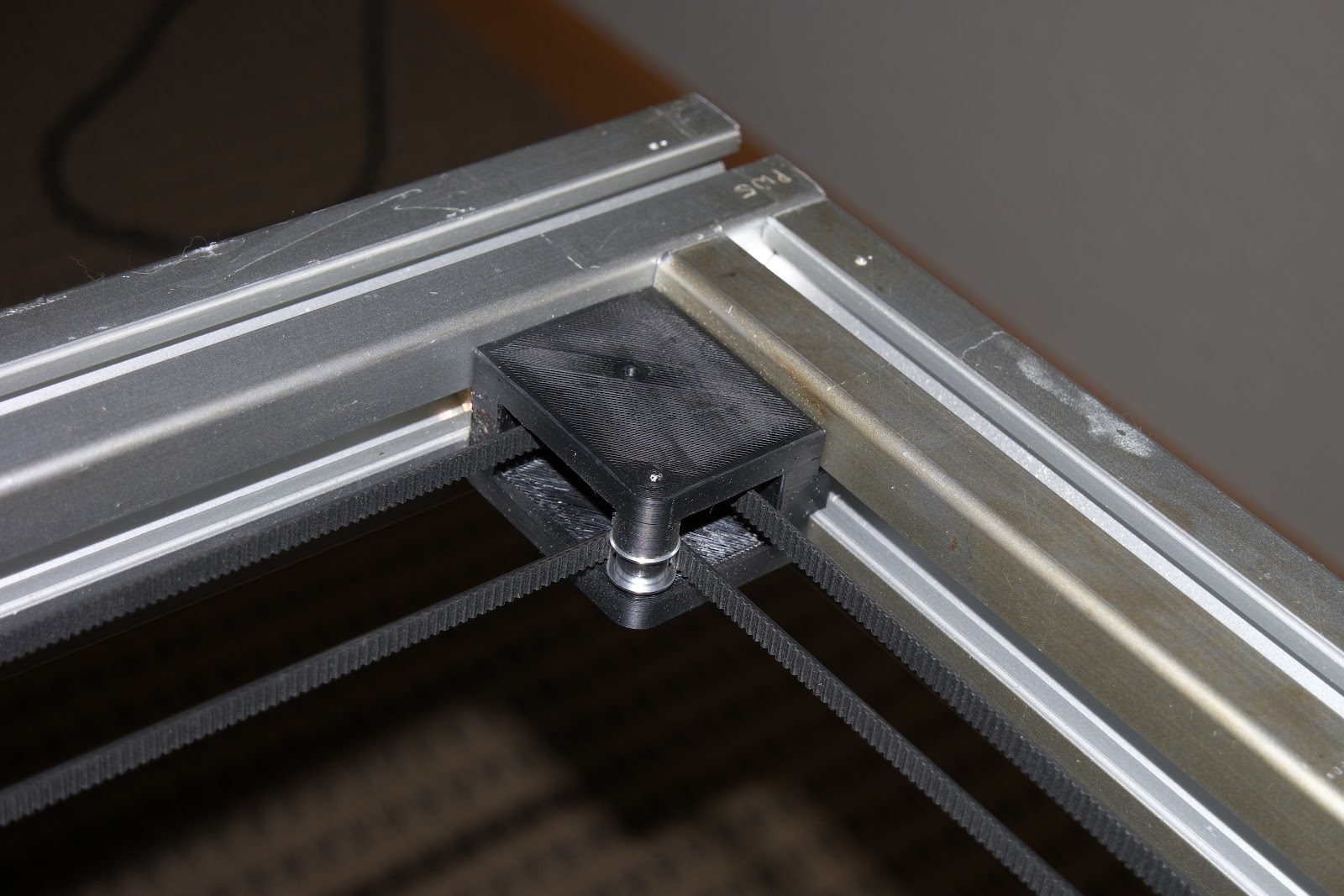

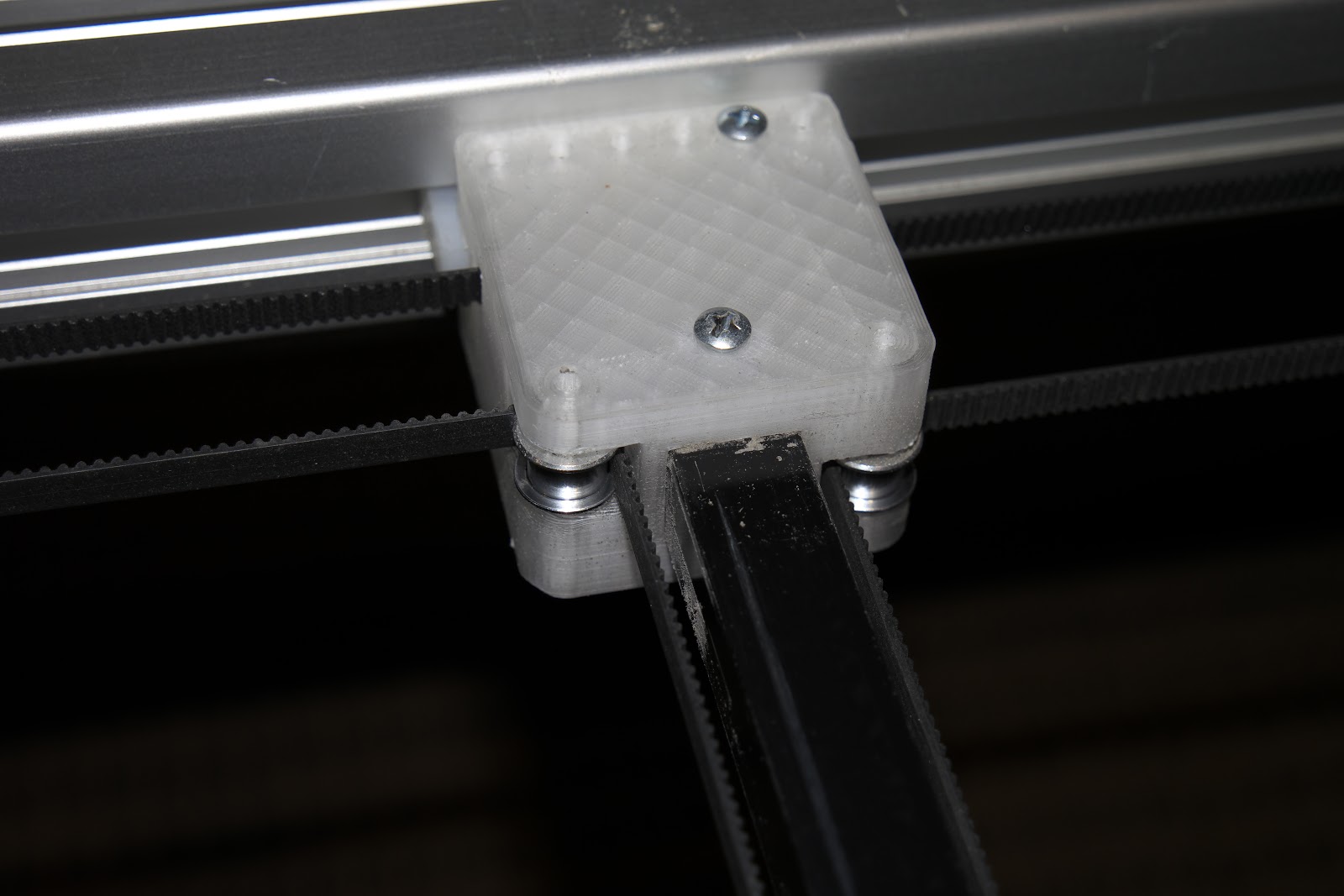

I have them crisscrossed too:

No issue at all.

You want the belts from the motors to the gantry and the belts leaving the gantry toward the rear parallel with the axes, the rest is not important.

-

@frank26080115 said in Help: CoreXY design review? My first CoreXY attempt.:

two 6mm diameter rods for the X axis

That is for sure to weak for a Hemera

I’m using two 8mm rods on a Hevo and even that is too weak for a direct extruder.

I’m currently in progress of designing a new printer based on rails and would recommend that. -

The only reason the belts "cross" is because you put their pulleys on separate posts. If you stacked the corner pulleys the belts would not "cross".

Your pulley and motor mounts look like they'd be fine if they were made of steel, but you're going to use printed plastic (hopefully not PLA!). They are going to flex under belt tension. If you have to use plastic, start with a solid block and make cuts to allow space for pulleys and belts. It will be much more rigid that way.

6mm end-supported rails are going to flex every time you look at or even think about them.

Is the frame made of 20 mm t-slot? I think you'd better go bigger...

Mounting the Y axis rails on t-slot and getting them parallel might be tricky. - linear guides are intolerant of misalignment. It is easier to ensure that they are parallel and stay that way if you mount them on either a single plate or on plates that have a t-slot subframe. You can then bolt that frame into the printer's frame as an assembly.

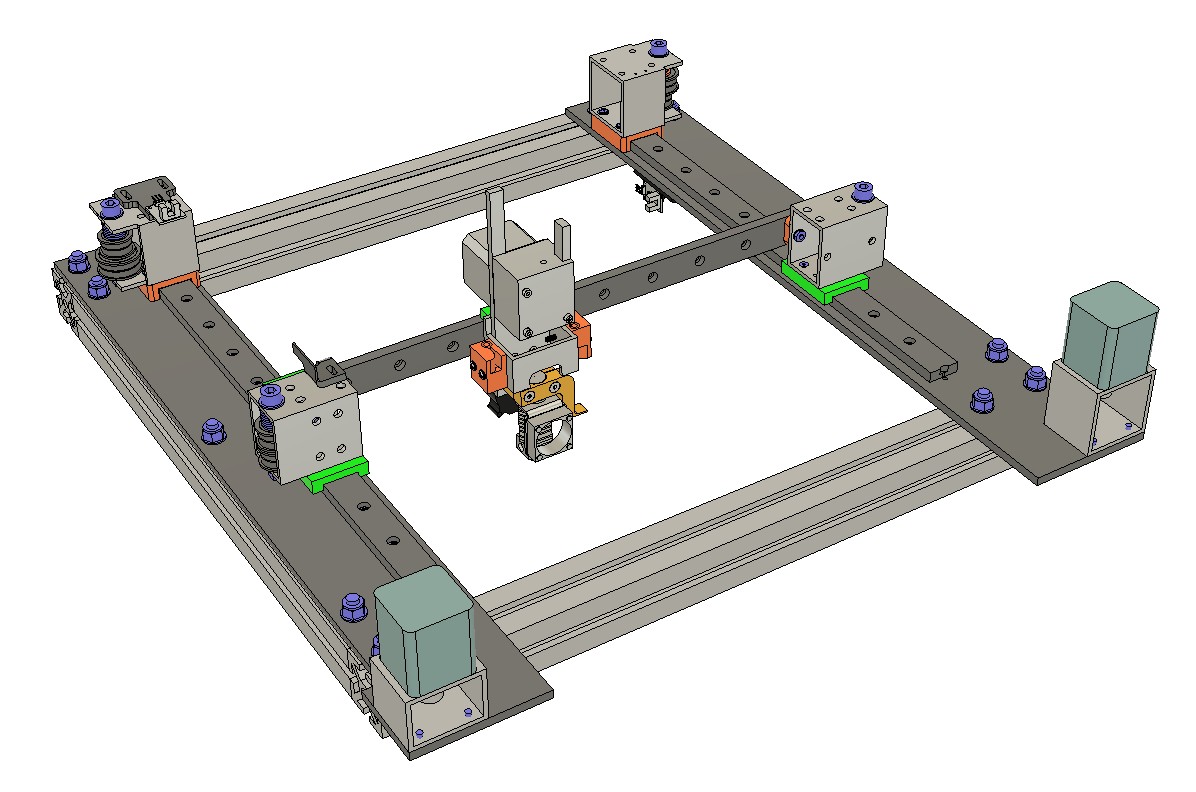

Here's mine: https://a360.co/2RSFDWq

Pulleys and motors are mounted using aluminum tubing for rigid support of the pulley posts/axles and motors. The aluminum tube also helps remove heat from the motors (though they really shouldn't get hot anyway). All you need to fabricate the aluminum tube pulley mounts is a saw to cut the tube to length and a drill press to make the holes, though if you're careful you might even be able to use a hand drill. The motor mounts will require a hole saw, too.

-

Lots of CoreXY, including some that are sold commercially, are not parallel in places where they should be. To put it bluntly, they are wrong. Therefore, be very careful what you look at for examples.

There are also some "known good" ones. I will point out Jubilee because full CAD is available in their github.

-

If you haven't had the opportunity, take a look at the theory and reference mechanism of corexy kinematics located at https://corexy.com/

The reference mechanism has the bottom belts crossing over. I believe that all the other belts need to be in parallel.

I have seen commentary if you attempt to put both belts on the same plane, then the two belts will rub where they cross over. Otherwise, I have not seen any additional pros and cons with the bottom belts being parallel or crossing over.

-

Take a look at this: https://drmrehorst.blogspot.com/2018/08/corexy-mechanism-layout-and-belt.html

-

Thanks guys

the 6mm rods were a cost-down from using a linear guide rail right in the middle. I am not familiar with the performance of rail bearings and how they'd handle roll loads, and both research and just intuition says it'll handle roll loads worse than moment loads.

Would a single 12mm wide x 8mm tall linear guide rail for the X axis suffice? (MGN12H, only one bearing race on each side, also probably Amazon quality)

I see there's a torque rating for these for roll loads, but what about play/backlash?

And are you serious that dual 8mm rods across 300mm is still not good enough to handle a Hemera? My other printer is two 8mm rods in a cross configuration (like an Ultimaker 2) with a Titan Aero and it's fine, although the belt configuration is much tougher than CoreXY.

-

@frank26080115 said in Help: CoreXY design review? My first CoreXY attempt.:

in a cross configuration

That's the point

Edit:

The Problem is torsion. You can improve that by increasing the distance between the rods.

You can find this improvement for the HEVO, also going to 10mm rods or switching to rail.