Black Beauty Arises!

-

Glad to see you're still working on your Black Beauty. I had been following you on the RR Forums when you still had the cross gantry setup.

As I'm currently trying to figure out where to go with my project and actually was leaning towards a cross gantry setup: what made you switch to CoreXY?!

-

Very nice!

-

@bberger said in Black Beauty Arises!:

Glad to see you're still working on your Black Beauty. I had been following you on the RR Forums when you still had the cross gantry setup.

Seems like an age ago.

As I'm currently trying to figure out where to go with my project and actually was leaning towards a cross gantry setup: what made you switch to CoreXY?!

The size of the printer places the nozzle right at my eye level, which I like, but with a true XY cartesian setup it also placed the front rail right in front of my face. It just got annoying. My design was also touchy to align and while it worked, a single tooth slip of a belt on a drive gear would result in a racked gantry. I'm not sorry I tried it by any means. I learned so much during the process.

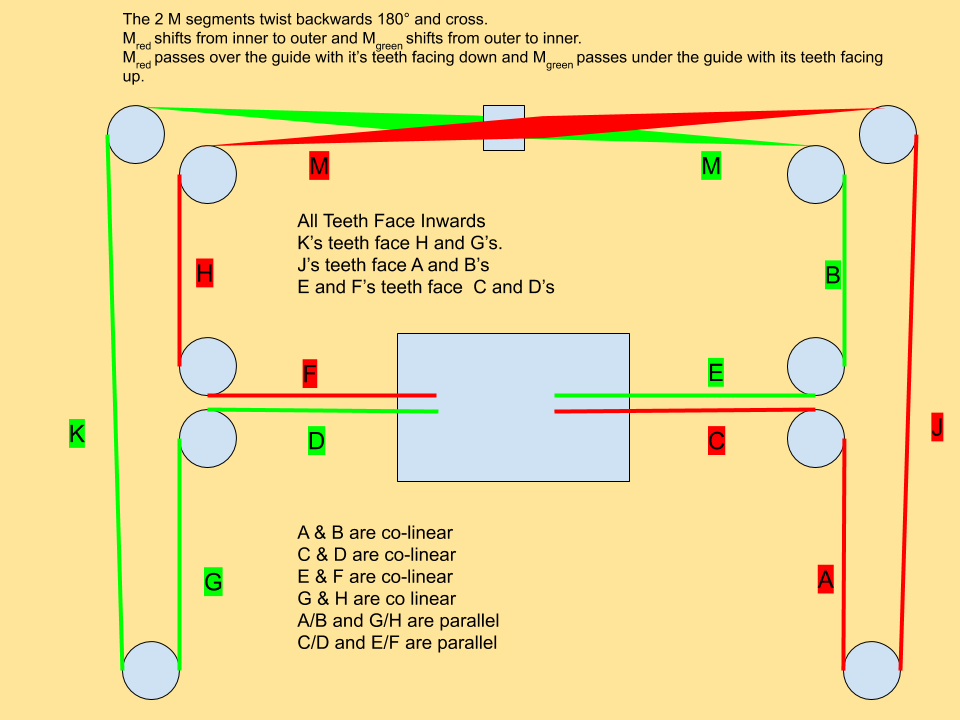

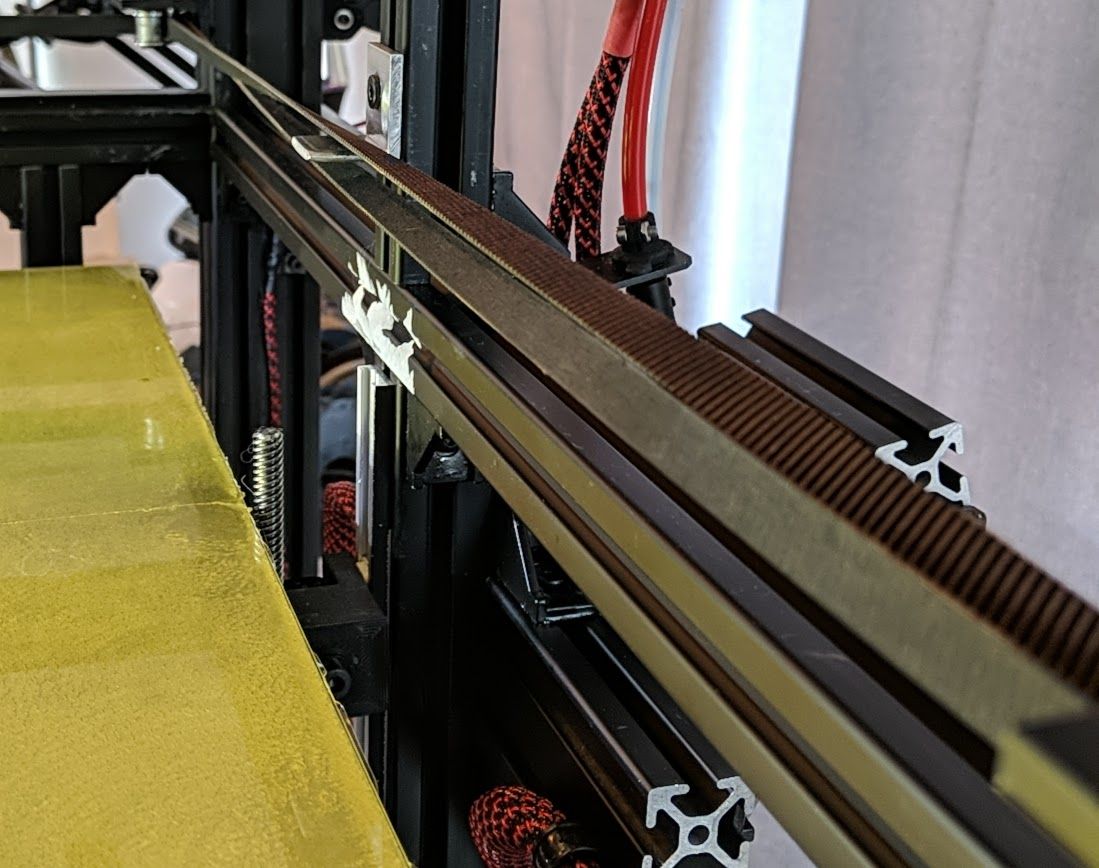

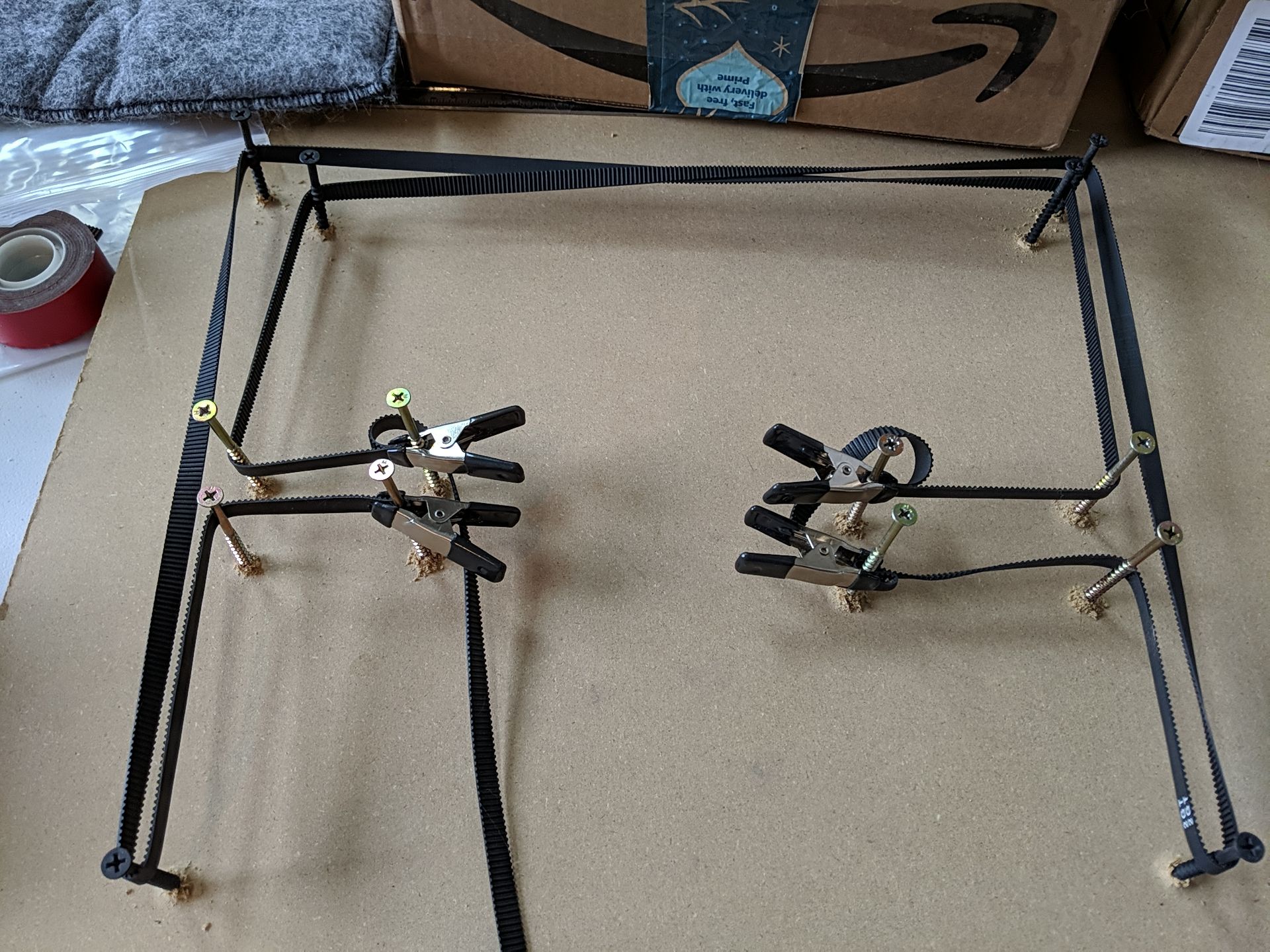

The thing about CoreXY that I didn't like that started me down the cartesian XY route in the first place was the belts on multiple planes and the complexity of the routing. Also in my case, the 2 belts would each be over 2m long and I was worried about stretching. @mrehorstdmd's excellent forum and blog posts got me thinking again though and with the realization that, with the 600mm X span, I could use a belt twist at the back to keep the belts on the same plane without putting undue stress on them, I finally figured I'd give it a shot. I'm happy I did. I can now see the nozzle/print clearly and it's just not possible for the gantry to rack. It's also 2 less motors.

The move to genuine Gates 9mm wide belts eliminated my concerns about stretching.

The move to genuine Gates 9mm wide belts eliminated my concerns about stretching. -

I think that if you twisted the belts so that the smooth back sides were dragging on the separator you be less likely to wear the toothed sides of the belts and less likely to induce bumps in your prints from the teeth hitting the separator. At high speeds there is probably a zip-zip sound coming from the separator. That will go away if the smooth backs of the belts touch it instead of the teeth.

-

@mrehorstdmd The spacer is polished and the leading and trailing edges are tapered so I don't hear anything. I thought I tried with the smooth sides facing each other but for some reason I couldn't make the routing work. Maybe I was just being an idiot. I can't see it in my mind so I'll have to actually try it which I can do later today.

-

@mrehorstdmd O Wise Dentist... it don't work.

I cannot figure out any routing that will allow the 2 M segments to cross with their smooth surfaces facing each other unless I separate the segments vertically at the center guide. That however, makes the belts interface with the idlers at too great an angle for my taste.

Got any ideas???

-

@gtj0 How about making the top belt the bottom belt and the bottom belt the top belt at the crossing point?

-

@mrehorstdmd I meant to upload this pic earlier...

If I just swap the belt positions, they rub against each other. I'd either have to separate the belts vertically at the center which cause the idler interface angle to increase, or I'd have to move the 2 "inner" corner idlers more towards the front eating up Y travel.

I suppose I could also try adding 2 more spacer/guides at the 1/4 points but that just makes things more complicated and I'd think also increase friction beyond what would be saved by having the smooth sides face each other at the center.

-

I had used coplanar belts in my sandtable and after looking at your pictures and diagram I couldn't figure out why you couldn't get it to work. Then I realized that I had put the twists in the J and K segments on your diagram so that the smooth surface of the belt rode on the smooth outer corner pulleys. You're twisting and crossing at the same location. That's the problem.

-

@mrehorstdmd Hmmm. I tried that but maybe I didn't follow it all the way through. I just started a full 441 point bed probe so maybe i'll try that again in the morning. Thanks!

-

Is this what you meant? A twist on the sides as well as the back?

Or this? The "M" segments aren't twisted any more but they have to be deflected so they can pass by each other and the deflection isn't "natural" so there'd be uneven wear against a spacer.

Either way seems overly complex.

I think I'm going to stick with what I've got and watch it. I can always add toothed idlers at the crossover point if I need to.

-

@gtj0 Not quite sure, but in my setup, the only pulleys that the belt teeth contacted were the drive pulleys. It might be that the belts have to be twisted in opposite directions. The table is so big there isn't any one photo that shows the whole belt layout. Let me see if I have some other photos that will reveal how it was done.

-

Sorry for quickly derailing the Belt Routing discussion..

However: what made you go with Igus N over the Igus W? The W kind of looks a lot more stable.

-

@bberger said in Black Beauty Arises!:

Sorry for quickly derailing the Belt Routing discussion..

However: what made you go with Igus N over the Igus W? The W kind of looks a lot more stable.

No worries! They were simply too big both in size and mass for what I wanted.

-

@gtj0 how about use a GT2 Idler Pulley without teeth?

-

@gtj0 this may seem like an odd question, but it's one thing that's been actually bugging me:

How would you rate the noise levels of especially the belt paths between your cross gantry and corexy build?I'll get a demo rail of the 40x40 drylinN hopefully at Tuesday and if that actually works out on my Delta I may be ready to dive into an actual full Igus build..

I've been happily using Igus stuff for a decade now in various (non printer) projects and I've admittedly become a fan of their stuff and to be frank - right now I don't care if they can match Hiwin/TSK/IKO/etc precision. It's readily available to me, I can get it fast and for a reasonable enough price to just tinker with it. If it fails I'll just repurpose the stuff.Right now I'm just after an as-silent-as-possible printer that doesn't have to print at insane speeds. (as long as it can run overnight in our open living room I'm good). You've actually pulled off 2 different working gantry designs off Igus rails - that's good enough for me for now.

That leaves me with basically 2 concerns:

- noise from the belt

- noise from the motors themselves

The plastic stuff should be good at dampening vibrations, so that's an added bonus.

I don't really care about cost too much on that build and I'm still undecided between going Makerbot gantry with dual Y motors (stealthchop2 on Moons motors) or corexy. I'm not looking at crazy acceleration or jerk values and if it's silent then I have no problem with it going 2 nights instead of one..

Long story short:

- does anybody feel the long belt path of CoreXY adds additional noise from the belts over a cartesian/crossgantry design?

- I'd appreciate ANY tips/insights on Igus rails. Orientation, preload, number of carriages, anything to get me a headstart.

You're the single one person I know as of yet that pulled off an Igus based printer. I want to suck up any knowledge that you're willing to share

-

@bberger said in Black Beauty Arises!:

does anybody feel the long belt path of CoreXY adds additional noise from the belts over a cartesian/crossgantry design?

Maybe if you're really going fast there can be a bit of a zip zip zip sound, but at tame speeds it's quite silent for me.

-

@bberger said in Black Beauty Arises!:

- does anybody feel the long belt path of CoreXY adds additional noise from the belts over a cartesian/crossgantry design?

No.

-

I did a lot of work on making my sand table (approx 2m x 1 m), a stacked belt corexy mechanism, run quietly.The table has UHMW PE bearings sliding in t-slot rails in the Y axis, and PTFE bearings sliding on a powder coated aluminum tube in X axis. I typically run the table at 500 mm/sec with acceleration at 2k. I found two main sources of noise: the motors themselves and the belt teeth contacting smooth pulleys. I was able to quiet the NEMA-23 motors by stepping their speed up by 5x using pulleys and loop belts, and running 256:1 ustepping. The speed step up reduced the noise more than switching to 256:1 ustepping. The motors turn at 1.25 revs/sec even when the mechanism is running at 500 mm/sec. I quieted the belts (zip-zip) by twisting them so only smooth back sides of belts contact smooth pulley surfaces. At lower speeds everything makes less noise. High acceleration/jerk tends to make things noisy too as direction changes are accompanied by banging noises, so keep those numbers down to keep things quiet (but that amy reduce print quality).

Now I am finding that the cheesy 3D printer pulleys with tiny bearings are starting to squeak and it's really annoying. I'll be replacing them with pulleys made from larger ball bearings over the next couple weeks, and that will hopefully eliminate that source of noise.

I recently ordered a couple servomotors to try in the sand table to see if I can make it even quieter. They'll arrive some time in May if I'm lucky.

-

@bberger said in Black Beauty Arises!:

@gtj0 this may seem like an odd question, but it's one thing that's been actually bugging me:

How would you rate the noise levels of especially the belt paths between your cross gantry and corexy build?In the end, the total length is the same either way. In the XY Cartesian setup, it was 4 belts, each about 1170mm. In the CoreXY, it's for all intents and purposes, 2 belts, each about 2340mm. However, no single unsupported belt span exceeds 1170mm (the back 2 belts). So belt vibration itself I feel is actually less.

I'll get a demo rail of the 40x40 drylinN hopefully at Tuesday and if that actually works out on my Delta I may be ready to dive into an actual full Igus build..

I've been happily using Igus stuff for a decade now in various (non printer) projects and I've admittedly become a fan of their stuff and to be frank - right now I don't care if they can match Hiwin/TSK/IKO/etc precision. It's readily available to me, I can get it fast and for a reasonable enough price to just tinker with it. If it fails I'll just repurpose the stuff.Right now I'm just after an as-silent-as-possible printer that doesn't have to print at insane speeds. (as long as it can run overnight in our open living room I'm good). You've actually pulled off 2 different working gantry designs off Igus rails - that's good enough for me for now.

That leaves me with basically 2 concerns:

- noise from the belt

- noise from the motors themselves

Add noise from various fans

The plastic stuff should be good at dampening vibrations, so that's an added bonus.

I can only hear my rails if I turn everything off, remove the belts, close the windows, stick the cats in another room, and push the gantry and tool carriage by hand. And even then it's only a whisper.

By far the loudest part of my printer are the fans, with the motors coming second. Having said that, my living room and work area (well dining area

) are actually one big room and I can print at 100mm/sec and watch TV at the same time. Printing gap and short infill shakes things around a bit but that's the crappy table the printer is sitting on.

) are actually one big room and I can print at 100mm/sec and watch TV at the same time. Printing gap and short infill shakes things around a bit but that's the crappy table the printer is sitting on.I don't really care about cost too much on that build and I'm still undecided between going Makerbot gantry with dual Y motors (stealthchop2 on Moons motors) or corexy. I'm not looking at crazy acceleration or jerk values and if it's silent then I have no problem with it going 2 nights instead of one..

At this point, I simply wouldn't consider any other kinematics than CoreXY. The "complicated" belt design scares people off (as it did me initially) but you never have more than 1 motor per horizontal axis so as long as your gantry is aligned well to start and your belts are evenly tightened, it can't get out of true. The worst thing that can happen if a motor misses steps or fails is the tool carriage moves diagonally.

Long story short:

- does anybody feel the long belt path of CoreXY adds additional noise from the belts over a cartesian/crossgantry design?

CoreXY is quieter in my experience.

- I'd appreciate ANY tips/insights on Igus rails. Orientation, preload, number of carriages, anything to get me a headstart.

It's hard to recommend anything specific without seeing a specific design for the gantry and tool carriage. With the 40 series N rails I'm guessing you're going to use just 1 rail for the gantry with the flat closed side of the rail vertical? If so, 2 sliders spaced as far apart as practical would be ideal. If you can make one of the mounting holes for the sliders slightly oversized that will allow you to adjust the contact area and alignment. You could also make both holes slightly oversized so that the weight of the carriage holds the sliders straight in the rails while you tighten the mounting screws.

You're the single one person I know as of yet that pulled off an Igus based printer. I want to suck up any knowledge that you're willing to share

No problem!