Thermostatic controlled fan coming on at 50%

-

I think there is something in your print file that is causing it. Please post the first 50 lines or so, not counting the comments at the start.

-

@dc42 right, getting somewhere

Where is that first M106 S0 coming from? There must be some extra settings in Simplify3D somewhere.

Where is that first M106 S0 coming from? There must be some extra settings in Simplify3D somewhere.G90 M83 M106 S0 M140 S70 M190 S70 M104 S230 T0 M109 S230 T0 ; My start gcode M106 P0 S0 ; Turn part fan off G28 ; Home all ;G32 ; True Bed Levelling G0 X0 Y0 F9000 ; Go to front G0 Z0.15 ; Drop to bed G92 E0 ; zero the extruded length G1 X200 E25 F500 ; Extrude 25mm of filament in a 4cm line G92 E0 ; zero the extruded length G1 E-1 F500 ; Retract a little G1 X220 F4000 ; Quickly wipe away from the filament line G1 Z0.3 ; Raise and begin printing. ; process Process1 ; layer 1, Z = 0.450 T0 G1 E-1.0000 F1800 ; feature skirt ; tool H0.450 W0.480 G1 Z0.450 F1002 G1 X93.300 Y88.189 F7200 G1 E1.0000 F1800 G1 X98.689 Y82.800 E0.6844 F600 G1 X191.311 Y82.800 E8.3176 G1 X196.700 Y88.189 E0.6844 G1 X196.700 Y102.431 E1.2789 G1 X196.686 Y102.792 E0.0324 G1 X196.566 Y104.310 E0.1368 -

@dc42 ok figured it out.

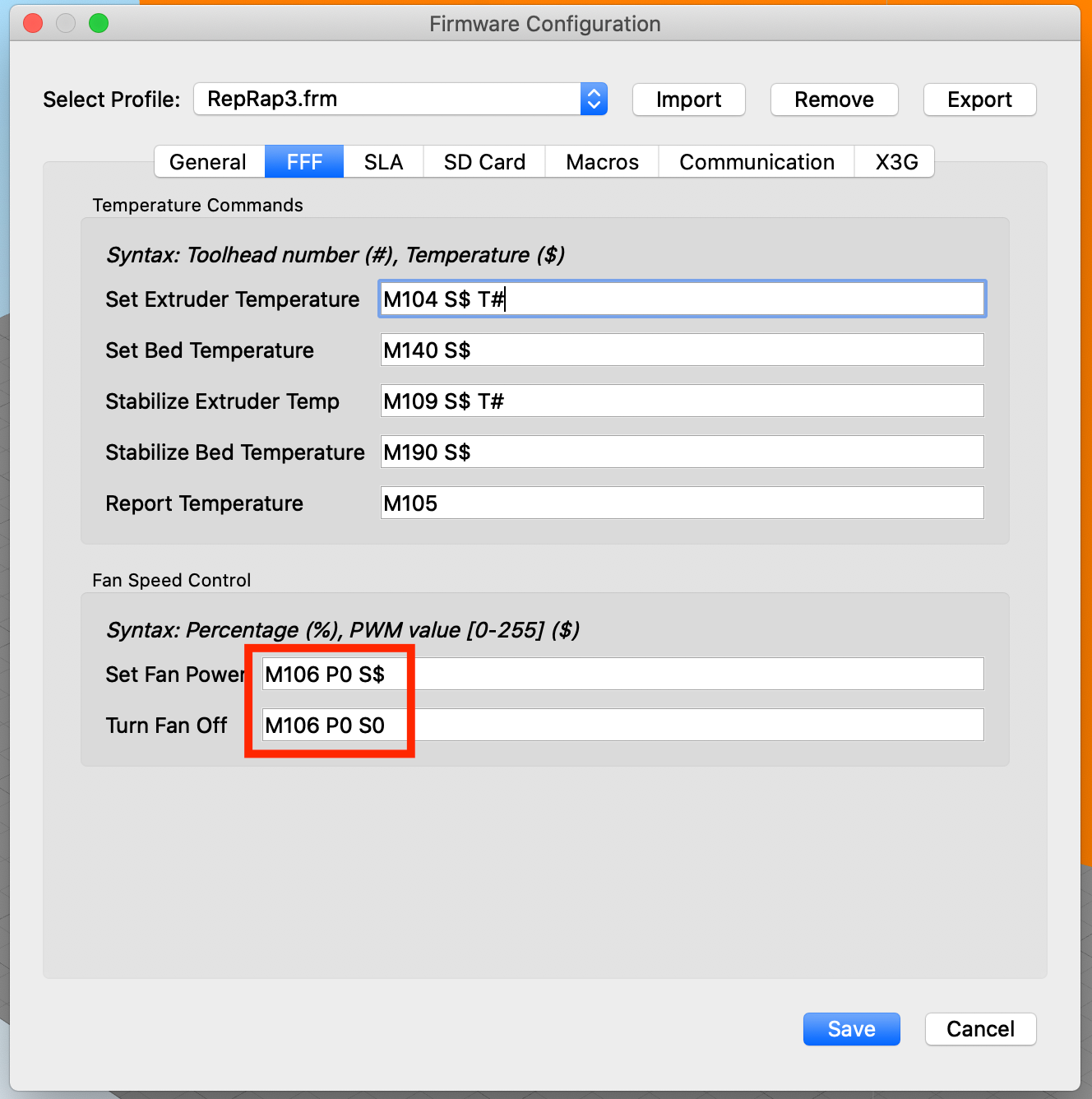

I had to create a custom firmware config in Simplify3D which had custom gcode for turning the fan on/off.

Then use that firmware config in my process. Never needed to do that before so didn't realise.

Thank you and everyone else for all your help.

-

@richardmckenna That's still not making sense because M106 P0 refers to the part cooling fan not the hot end fan. To set the speed of the hot end fan it would need to be M106 P1. An M106 generated by the slicer with an S parameter but no P parameter will still control the part cooling fan(s) and not the hot end fan. To set the speed of the hot end fan, there needs to be an explicit P1 in the M106 command. Or alternatively and as DC said, if fan 1 gets mapped to a tool with an M563 P1.

-

@deckingman I'm not sure then as changing the slicer to set that first M106 S0 to M106 P0 S$ has fixed the issue.

GCode

G90 M83 M106 P0 S0 M140 S70 M190 S70 M104 S230 T0 M109 S230 T0 ; My start gcode M106 P0 S0 ; Turn part fan off G28 ; Home all ;G32 ; True Bed Levelling G0 X0 Y0 F9000 ; Go to front G0 Z0.15 ; Drop to bed G92 E0 ; zero the extruded length G1 X200 E25 F500 ; Extrude 25mm of filament in a 4cm line G92 E0 ; zero the extruded length G1 E-1 F500 ; Retract a little G1 X220 F4000 ; Quickly wipe away from the filament line G1 Z0.3 ; Raise and begin printing. ; process Process1 ; layer 1, Z = 0.450 T0 G1 E-1.0000 F1800 ; feature skirt ; tool H0.450 W0.480 G1 Z0.450 F1002 G1 X61.184 Y78.054 F7200 G1 E1.0000 F1800 G1 X61.811 Y77.602 E0.0694 F600 G1 X64.932 Y75.731 E0.3268 G1 X65.496 Y75.444 E0.0568 G1 X67.621 Y74.540 E0.2074When starting a print, it gets up to temperature and starts the fan at 100%

-

In RRF3 does M106 without P default to P0 like it does in RRF2?

-

@deckingman wait so if you look at my config in my original post.

should my tool definition be

M563 P0 S"Hemera" D0 H1 F1or

M563 P0 S"Hemera" D0 H1 F0 -

@richardmckenna The latter - F0. The fan that gets assigned to a tool is the part cooling fan and this is normally fan 0. Slicers often insert M106 commands with an S (speed) parameter but no P parameter (fan number). When the firmware see such an M106 Snn (but no "P") command it will default to setting the speed for fan 0 unless you have explicitly assigned some other fan to a tool using M563.

Edit. So if slicer generated M106 commands start to control the hot end fan (Fan 1) then it means that somewhere, there is an M563 command that is assigning fan 1 to a tool, and that is overriding the M563 F0 that is in your config.g. Places to look for such a command are config_override, the slicer start gcode (doesn't look it that's the culprit though), any pre-print macros that get run (including homing files) or any tool change macros (tpre etc).

-

@deckingman ah right ok so I have read something wrong somewhere along the line.

Thank you for your help with this

-

@richardmckenna It's easy to get confused with the distinction between tools and heaters when discussing fans. It also doesn't help that different commands use different parameters to refer to the same thing (i.e. F0 in M563 but P0 in M106). It would be nice if a heater was always an "H", a tool was always a "T", a fan was always an "F", an extruder was always an "E", a drive was always a "D" etc but for various reasons, that's not possible.

-

@richardmckenna said in Thermostatic controlled fan coming on at 50%:

In RRF3 does M106 without P default to P0 like it does in RRF2?

It's the same as in RRF2: if a tool is selected, and the M563 definition for that tool has an F parameter, then it uses the fan(s) specified in that F parameter; otherwise it uses fan 0.

-

Just noticed this too on both of my machines although on the first machine this didn't create any problems so far with a few 100 hrs of print time. This thread helped me find the cause of this tho and I figured I'd put my findings here:

I set up both machines using the rrf config tool. Turns out that the config tool assigns both the hotend fan and the part cooling fan to the tool so if then the slicer puts in any M106 command without a P parameter (which most don't by default) the hotend fan will be influenced too by that, down to the minimum fan speed of 50% for thermostatic fans that David mentioned above (which isn't actually reported in M106 btw) -

@schild0r said in Thermostatic controlled fan coming on at 50%:

Turns out that the config tool assigns both the hotend fan and the part cooling fan to the tool ...

It should only do that of you tell it to. If you think it is assigning the hot end fan to the tool without you telling it to, then please post a screen shot of the relevant pages of the config tool, and also the generated config.g file.