Help tuning my Ender 5 Plus with Titan

-

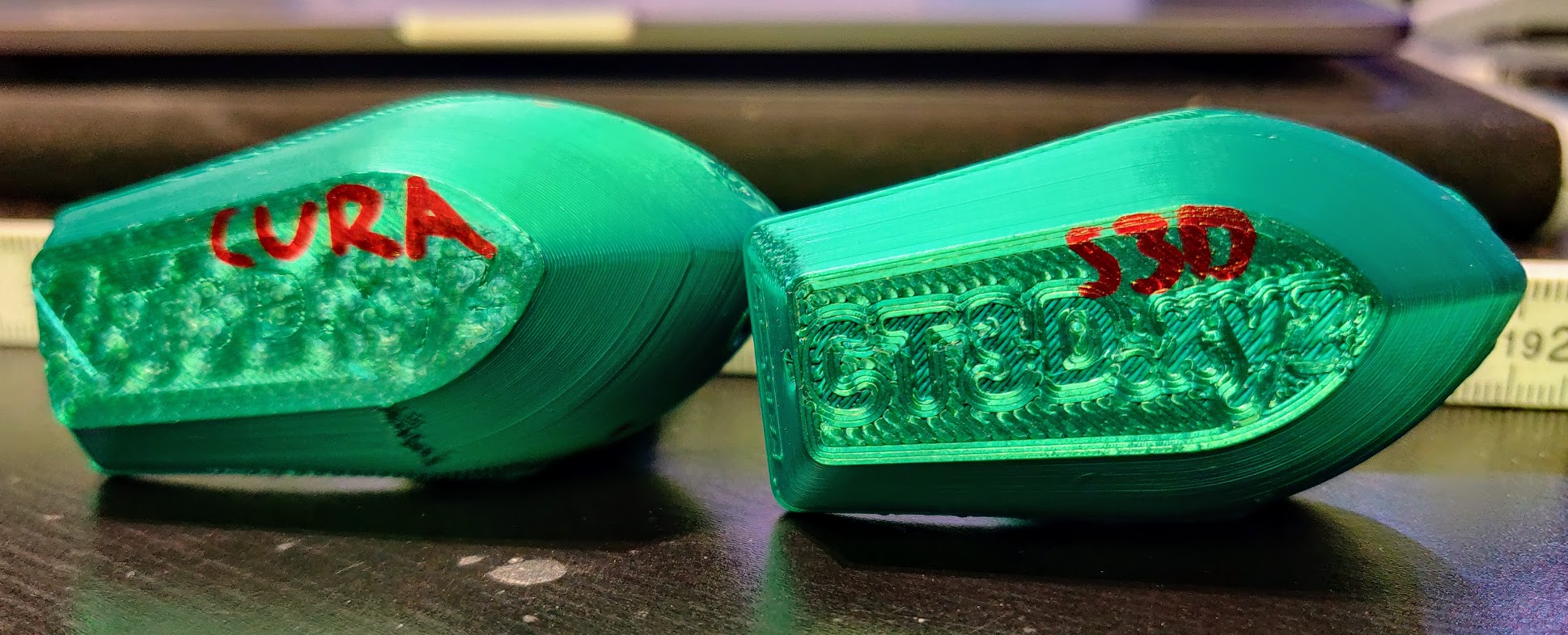

My temp tower doesn't look good. I did an initial e-steps tuning and startet to print a simple hollow box and a cone with one wall. These looks great but had 0.51 mm walls instead of expected 0.48. So I reduced extrusion factor to 0.92 on the last tower.

This is a Titan extruder with stock hot end. Bowden. Gear ratio 1:3.

Where do I start? Slowing down acceleration? Speed? Jerk?

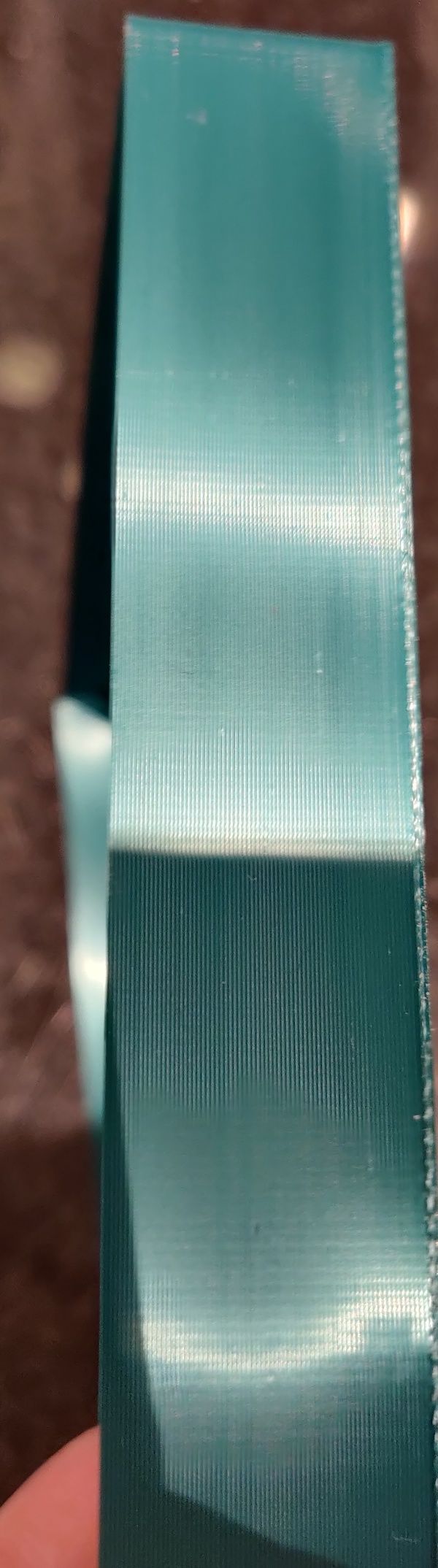

Hollow box and cone (cancelled because started to loosen)

The short one was printed first and cancelled as I saw it was no good. The second one does not look any better.

Duet config

M584 X0 Y1 Z2:4 E3 ; drive mapping, two Z motors connected to driver outputs Z and E1 M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E396.38 ; set steps per mm M566 X1200.00 Y1200.00 Z24.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z500.00 E3600.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E1000.00 ; set accelerations (mm/s^2) M906 X600 Y800 Z600:600 E700 I30 ; set motor currents (mA) and motor idle factor in per centFirst (short)

; extruderDiameter,0.4 ; extruderAutoWidth,1 ; extruderWidth,0.48 ; extrusionMultiplier,0.92 ; extruderUseRetract,1 ; extruderRetractionDistance,3 ; extruderExtraRestartDistance,0 ; extruderRetractionZLift,0 ; extruderRetractionSpeed,6000 ... ; defaultSpeed,4800Second (long, finished)

; extruderDiameter,0.4 ; extruderAutoWidth,1 ; extruderWidth,0.48 ; extrusionMultiplier,0.92 ; extruderUseRetract,1 ; extruderRetractionDistance,3 ; extruderExtraRestartDistance,0 ; extruderRetractionZLift,0 ; extruderRetractionSpeed,6000 ... ; defaultSpeed,4800

-

@strips , Have you seen this guide on calibration?

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

It is written for the Ender3 but is relevant for the Ender5 also.HTH

Paul -

@PaulHew said in Help tuning my Ender 5 Plus with Titan:

@strips , Have you seen this guide on calibration?

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

It is written for the Ender3 but is relevant for the Ender5 also.HTH

PaulThanks for the suggestion.

I've done all those steps or similar but I will double check the extrusion one more time doing a square vase to measure single wall thickness.

-

-

@PaulHew said in Help tuning my Ender 5 Plus with Titan:

@strips I use this as well sometimes.

http://www.thingiverse.com/thing:3397997Regards,

Paul

Thanks but I had made my own. Decided to make it wide to test adhesion over a larger area. I must say it stuck good over the whole area and leveling is spot on. Any unevenness is my fault for microstepping a bit too close.

Extrusion is spot on. Walls are measured to 0.49 to 0.51 mm in thickness when I set it to 0.5 in S3D.

They looks incredible smooth. Iove this material! 0.3 mm layer height.

-

Download latest Cura and tested the profile linked to here.

Printet a Benchy in standard size and I'm not that bad off as I thought. There is some artifacts on some overhangs but mostly on the far side of the pary cooling fan. Maybe find an improved cooler design and put on a bigger fan.

-

@strips They do look good. What did you need to change?

What filament is it?

I do not use Creality's build platforms. I have instead 2 Borosilicate glass beds and 3D Lac as I had problems getting first layers to stick properly.

Well done otherwise.

P.

-

@PaulHew said in Help tuning my Ender 5 Plus with Titan:

@strips They do look good. What did you need to change?

What filament is it?

I do not use Creality's build platforms. I have instead 2 Borosilicate glass beds and 3D Lac as I had problems getting first layers to stick properly.

Well done otherwise.

P.

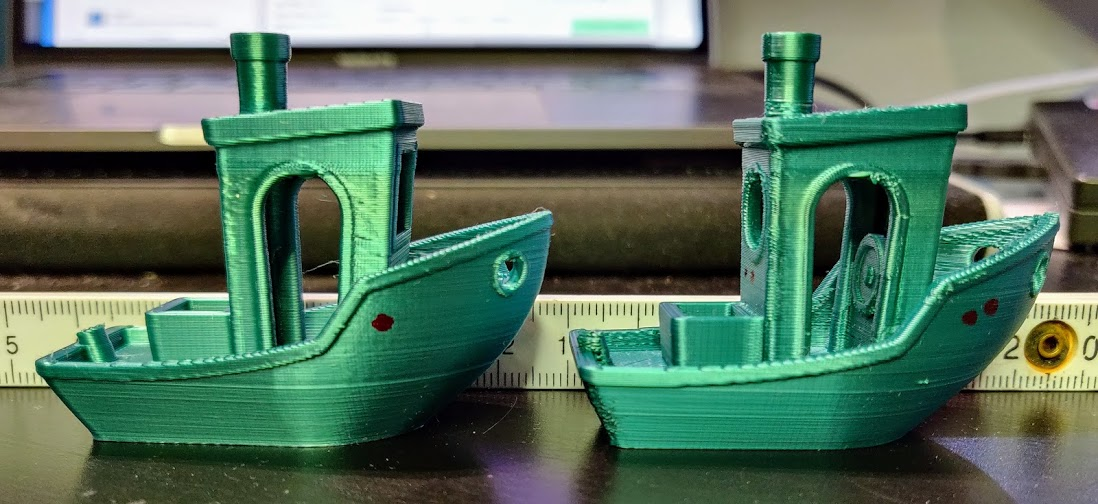

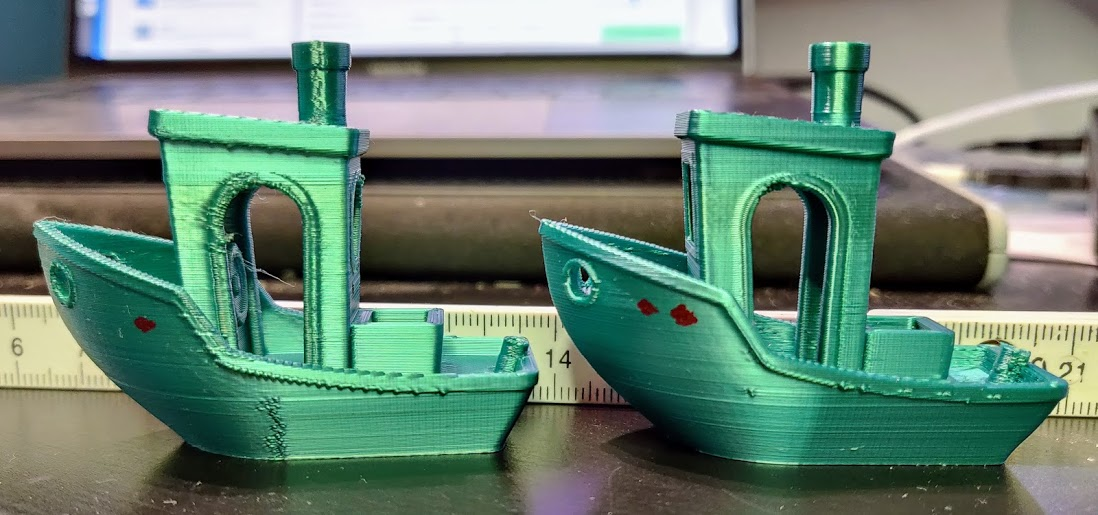

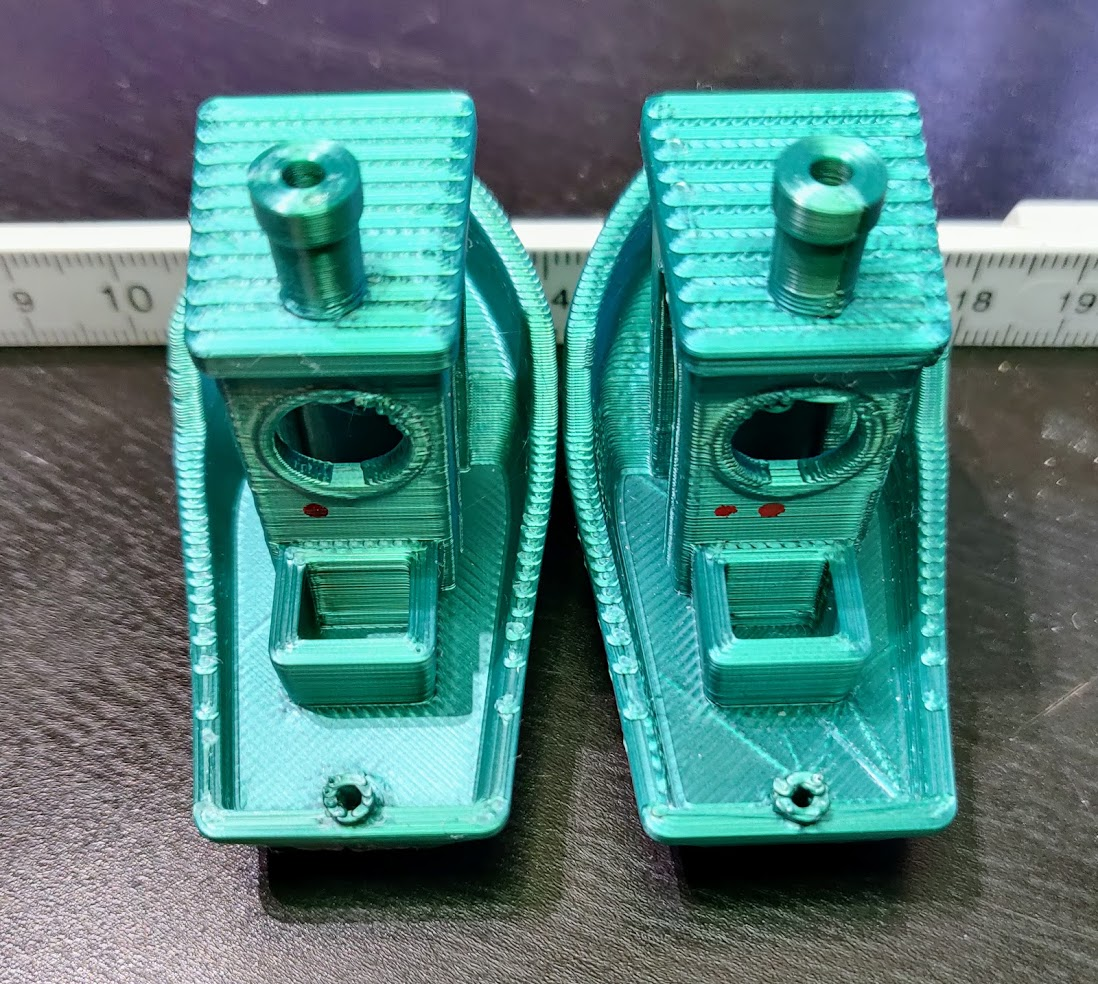

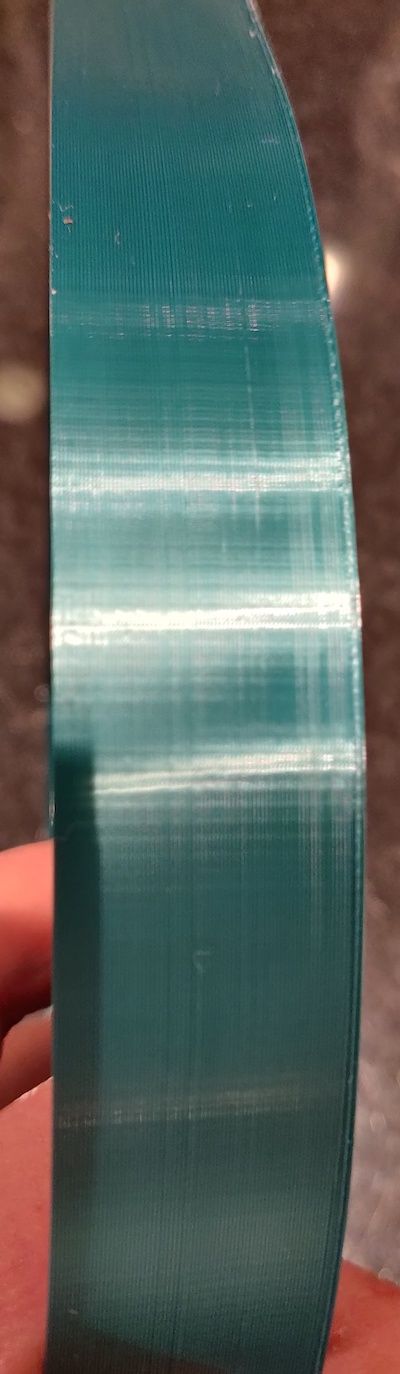

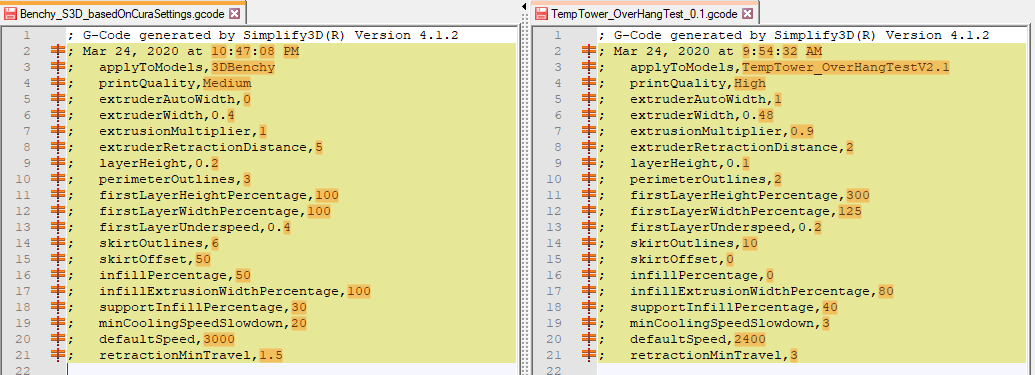

In cura I went with pretty much the default that came with the ender3 profile. But for the fun of it I made a Benchy with Simplify3D but trying to duplicate the settings in the Ender 3 profile for Cura. It came out a bit better than the Cura version. I think maybe the printer is lacking on print cooling and that might be why the temp-tower looks so bad.

I did a comparison on the temp tower gcode and the benchy sliced on S3D. There are some changes here but nothing that stands out.

I have printed the Ender 3 Tusk Part Fan Nozzle on Thingiverse and it came out pretty ok. I do have some 4 mm alu tubing to test. https://www.thingiverse.com/thing:3055926

Here I have the Benchies for comparison. The print settings are as similar as I could make them. I think S3D came out on top but Cura has much better finish on the boat deck. They both are printed with 100% extrusion so there is about 8% over extrusion here. Some of the door/window overhangs look bad but thats the worst.

Cura on the left and S3D on the right on all the pics.