Check out my motor specifications CNC & 3D printer

-

Well,

I ordered before I looked closely at the specifications, i need the Motor data sheet for below model.

also a question i would like to make the 3d printer all X, Y, Z axis moving with lead-screw not just Z axis, can it be made and work properly

my idea is to mix between 3d printer and CNC drilling machine on the same frame that's why i am using 17HS640 and lead-screw on all axis, i thought it might have better power from the strap

Model 17HS6401

also the full size would be as X (120cm), Y(120cm), Z (120cm)..

and please to chose for me the best power supply.

appreciate the support.. -

Yes it's possible to use lead screw on all axis. You may be limited in speed, but for your application that may not be an issue at all.

For power supply a 24v Meanwell would be a good choice. See here for determining wattage: https://duet3d.dozuki.com/Wiki/Choosing_the_power_supply

-

-

@Phaedrux said in Check out my motor specifications CNC & 3D printer:

Yes it's possible to use lead screw on all axis. You may be limited in speed, but for your application that may not be an issue at all.

For power supply a 24v Meanwell would be a good choice. See here for determining wattage: https://duet3d.dozuki.com/Wiki/Choosing_the_power_supply

i guess i need to modify the acceleration of X, Y because the speed for Both mentioned axis not such the Z axis is there is a description for the specific lines for this process if i am going to use marlin frame-ware or you advice to use another frame ware.

-

@Phaedrux

also Related to the Stepper Motor; no it's just 17HS6401 without S at least

i am searching for the Datasheet for my motor and not finding it at all

I've bought it from local market and it's not mentioned any thing else on it just it's item No and 17HS6401 it's Exactly as in below linkhttps://www.pinterest.ca/pin/591801207256803943/?autologin=true

i appreciate your support with many thanks.. -

@M-khoja said in Check out my motor specifications CNC & 3D printer:

17HS6401

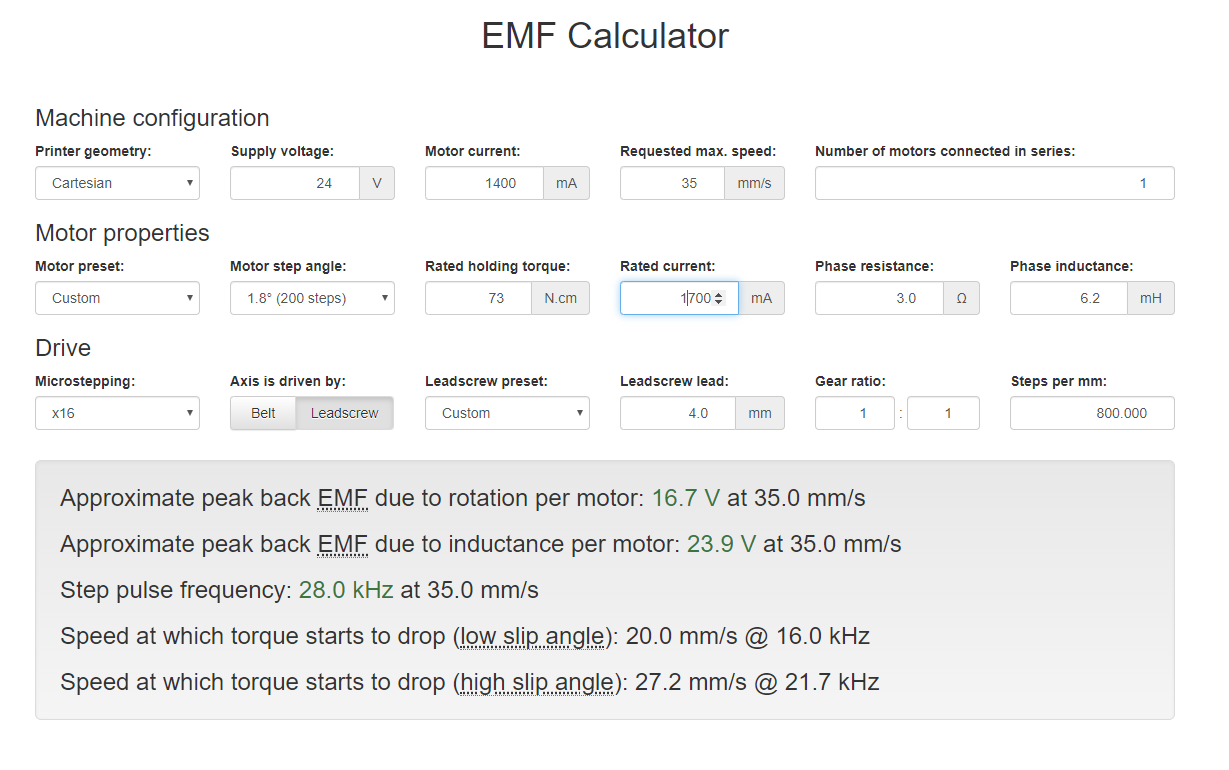

If I put the correct data in the EMF calculator for those motors, using leadscrews you will be severely limited on speed using leadscrews for X and Y axis. To the point of around 35mm/s speeds. Those steppers have high inductance which doesn't help.

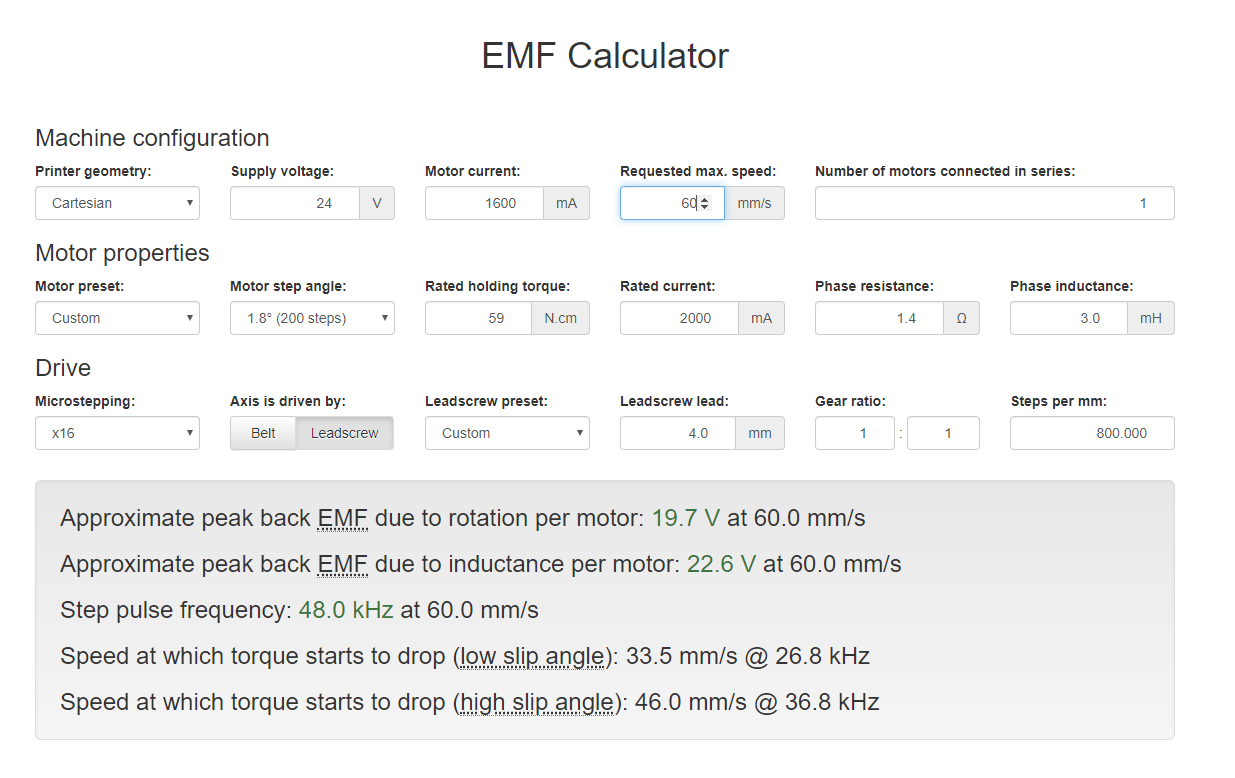

These are the motors I use for the z axis on my corexy which will allow more speed (60-65mm/s) but they don't have quite as much torque as the ones you listed.

https://www.omc-stepperonline.com/nema-17-bipolar-59ncm-84oz-in-2a-42x48mm-4-wires-w-1m-cable-and-connector-full-d-cut-shaft.html

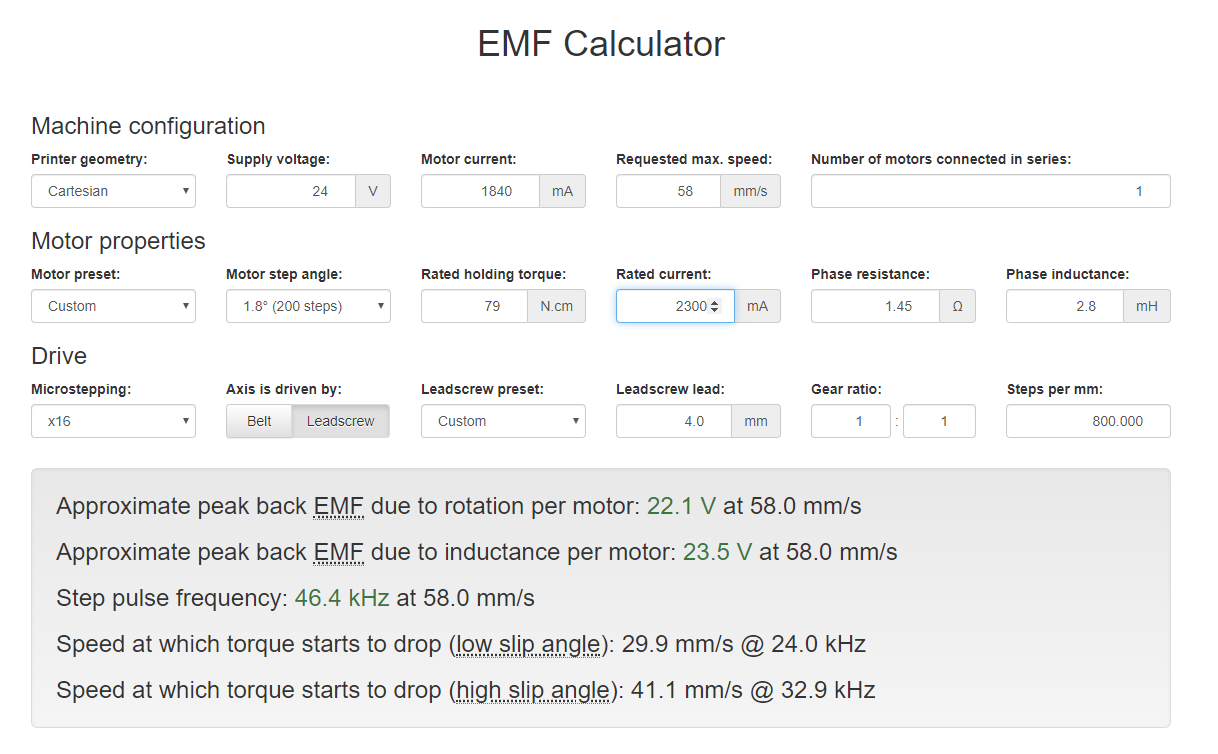

Here is a high torque stepper from stepperonline which will allow fair speeds (better torque than the one you listed) It will require active cooling for the duet board I believe due to the current Also, it has a large 8mm shaft and not the smaller 5mm that is on normal nema17 steppers. No big deal though since you can easily get couplers that are 8mm - 8mm.

-

@M-khoja said in Check out my motor specifications CNC & 3D printer:

if i am going to use marlin frame-ware or you advice to use another frame ware.

If you are planning on using a Duet you would be using rep rap firmware.

Based on the info provided by @JamesM you'll have to decide if 35mm/s is adequate for your needs. If this is a CNC mill that may be fine. For a printer that would be quite slow unless you're going to be using a very wide nozzle and therefore wouldn't be printing very fast to begin with.