Seeking an advise on what Z sensor to go with

-

Hi,

I'm very new in the domain.

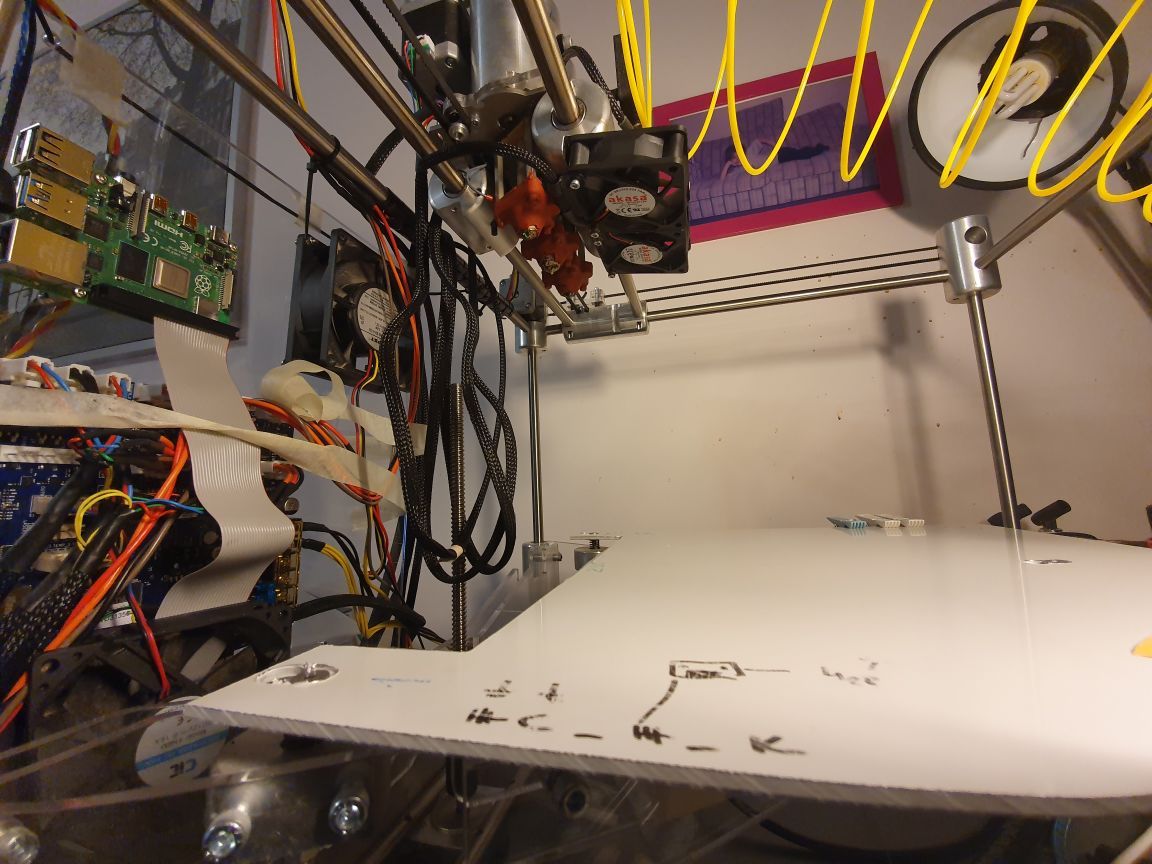

Reworking BFB Touch 3D old printer with newer controller (Duet 3 + Raspberry Pi).

This re-build is already in a state that it can print some. But I'm already managed to get a headache from leveling bed and particularly even from finding Z0.

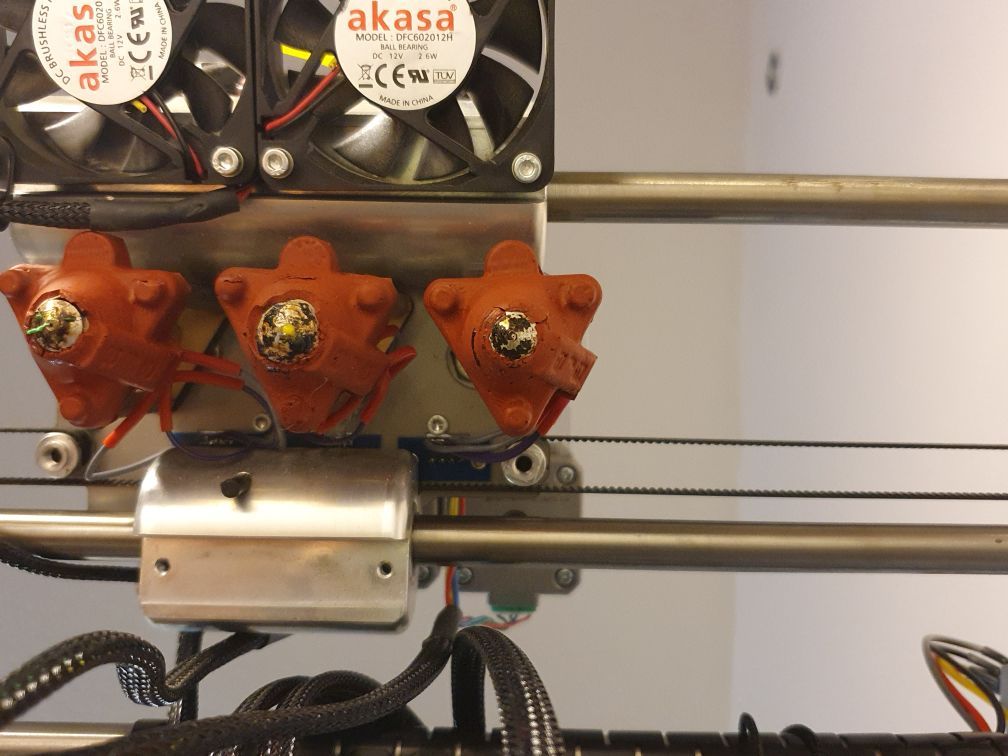

At the moment Z axis uses reed end switch (magnet is sitting right below middle of the bed). This end switch is well visible on first photo.Very often people refer to z-probe and how good to have it. And so I feel I can't live without one any longer

But which one should I go for is the question here.

Could you advise some sensor(probe) to go with considering present hardware visible in attached photos.

I also assume with some solutions I can get rid of that reed sensor and with some I still keep it?

-

All opinion here, free and worth every penny:

I've been very negative about BLtouch for some years, based on the number of questions I see on forums.

Recently based on a bunch of work to automate tool-to-tool alignment on Tool Changing printers (like the new E3D or Jubilee), I decide to purchase one. There are many clones, I chose to pay the very slight difference in cost for a "real" one.

I LOVE LOVE LOVE it. Again, just opinion... I will say it has been a strong enabler for the things that I have devloped.

Having said that, BLtouch can be a little cranky, take a bit to get going and be stable. The V3 BLtouch seems to be reasonably robust. I haven't broken a pin, or whatever. Even when I've jammed it pretty hard. And after a reasonably short learning curve, it seems to work quite well.

Summary: Give BLtouch some consideration.

-

Genuine

oneBLTouch is definitively worth it; sometimes even the official aliexpress store has some good offers; I was given a clone,and bought a genuine one. World of difference. -

You left me no choice! Ordered!

-

For when it gets here, my config.g definitions:

M558 K0 P9 C"^io4.in" H9 A5 T6000 S0.02 ; Z probe BLtouch - Set the height of the bed when homing G28. Combined with content of bed.g as invoked by G32, levels bed. Also used for Mesh. ; Hn = dive height ; A bigger dive height prevents a situation where the bed is out of alignment by more than the dive height ; on any corner, which can crash the hot-end into the bed while moving the head in XY. ; Probing speed and travel speed are similarly reduced in case the Z probe isn't connected properly (or ; disconnects later after moving to a point) giving the user more time to stop. ; An = Number of times to probe each point. ; Tnnn = Travel speed between probe points. ; Snnn = Tolerance when probing multiple times. Two readings inside this window and we move on. G31 K0 X35 Y-55 Z0 ; Probe offsets M950 S0 C"^io4.out" ; Servo Control Pin for BLtouch.deployprobe0.g

M280 P0 S160 G4 250 M280 P0 S10bed.g for a 3-motor (self leveling) bed. The key is to use G30 (not various G1 H1 or H2 moves).

G30 P0 X152.5 Y0 Z-99999 ; probe near back leadscrew G30 P1 X290 Y230 Z-99999 ; probe near front left leadscrew G30 P2 X20 Y280 Z-99999 S3 ; probe near front right leadscrew and calibrate 3 motors G1 X152.5 Y152.5 F10000 -

thanks

thanks -

I have a genuine bl touch, and just found it unreliable and results to be flakey at best, to the point that I removed it and consigned it to a storage drawer. For me it a IR sensor all the way

-

Ups, I should have bought BLTouch from you

@CaLviNx

What kind of inaccuracy you are talking about? 1mm - 0.1mm ? More or less? -

@monster I can get my IR sensors down to a resolution of 0.05mm day in day out something I could not get with a bl touch, the variance was visualising itself in my layer heights and downright pissed me off.

-

I found that the BLTouch was very sensitive to probing speed. If you run it too fast then the measurements will fluctuate. I also found that multi probing (measure the same point until two successive readings are within tolerance) is pretty much required to get a good result.

Both of these issues require extra time when doing a bed analysis and that can really add up but I scan the bed rarely so that the extra time required is not a hassle at all. If you are used to doing a bed scan before every print as some people seem to do (no idea why), the extra time will quickly drive you insane.

I also only locate z zero once in a blue moon as my steppers are powered up all the time so no position drift occurs.Edit: I probe until two successive readings are within 0.005 mm so a factor of 10 better than the IR sensor.

-

M558 P9 H3 F60 T6000 A10 R0.75 S0.003 B1With this BLTouch config I'm able to get 0.003 though it may have to probe 2 to 4 times. Perfect first layer every time.

The BLtouch also must be mounted correctly, as in:

As close to the nozzle as possible.

Bottom of probe body ~8mm above the nozzle tip

straight up and down. Tilt can make the pin rub. -

If your bed top material is compatible with the Duet IR sensor you may want to check it out since it has no mechanical parts. https://duet3d.dozuki.com/Wiki/IR_Probe

On my printer I use a PEI sheet so went to with the bltouch and it works very well. I use it for both z homing and mesh compensation, without any z stop switch.

Don't know if it was already mentioned here but I make sure to reset the bltouch from previous errors before homing. This takes care for example of the error state if the head was too close to the bed when you turn the printer on.

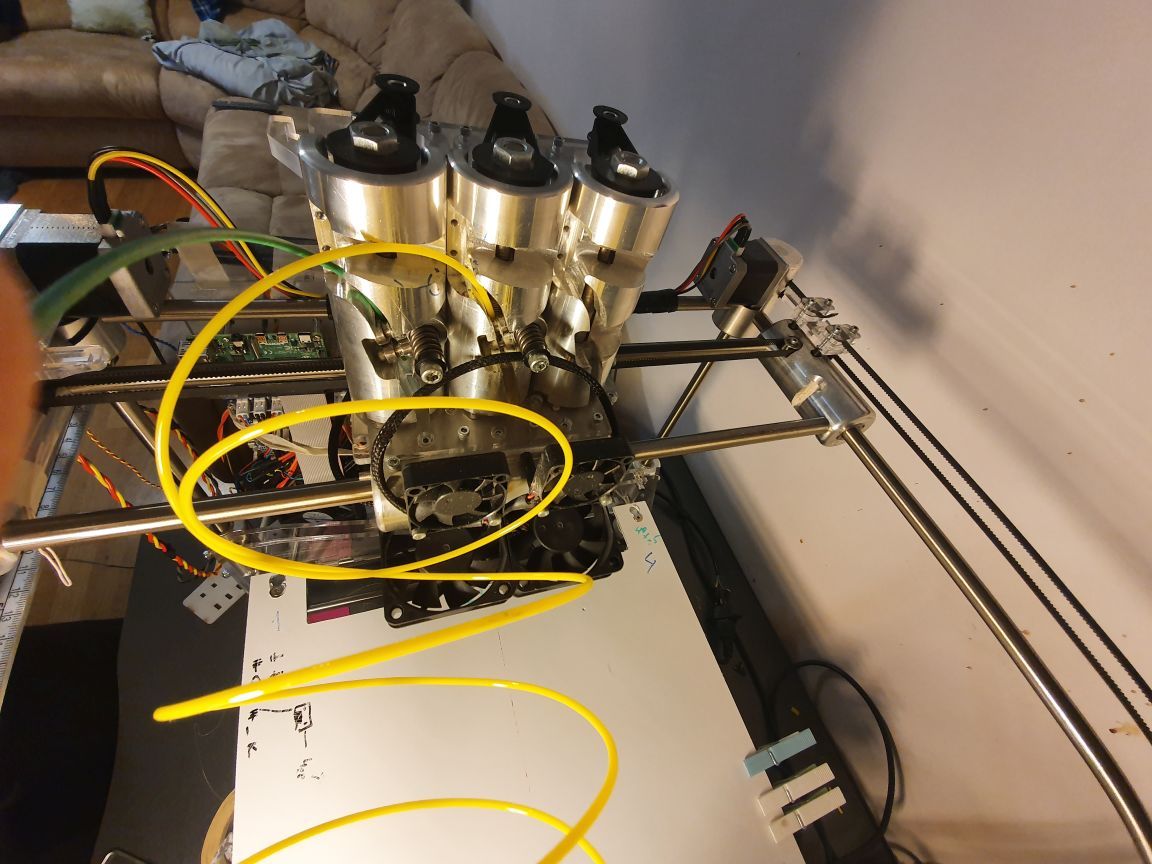

M280 P3 S160 I1BTW, your design looks very unique, e.g. the overall round shape of parts.

-

I practically don't know how bed is going to look like. At the moment it is:

- Polycarbonate sheet (PLA sticks to it well and it bendable - easier to get part out)

- Below it some fire resistant "thing" from construction/building domain I assume.

- "Thing" sits on 3 leveling bolts which held by acrylic arm.

I'd like to get heated bed eventually as I would need to print ABS.

- So for now I see a glass or some designed specially for 3d printing surface or again polycarbonate - need to test if it holds bed temperature.

- Which will sit on top of I guess an aluminum which will be adjusted by same leveling bolts. But bolts will be not anymore sitting on the acrylic arm (arm is too shaky) - they will be on brackets. One bracket already there. Another bracket I'll make and it will be moved by second Z ball screw&stepper.

- Under aluminum there will be a heated silicon mat I guess.

-- I guess heated PCB would be lot better but I'd need 35cm x 35cm (about) size which isn't standard for anything neither for silicon mats. Not sure if I wanna dive in making one myself with nichrome string...

So I'm not sure that future surface will be like.

Will it be compatible with inductive proximity sensor or IR. But mechanical sensor should do in any case. -

@monster said in Seeking an advise on what Z sensor to go with:

size which isn't standard for anything neither for silicon mats

You can order custom size/shape/voltage/power/holes silicon mat from vendors such as Keenovo. I ordered a custom 12" x 12" one and it cost about $80 IIRC.

You may consider also magnetic sheets, they make it easier to remove large prints.

-

@jens55 said in Seeking an advise on what Z sensor to go with:

I found that the BLTouch was very sensitive to probing speed. If you run it too fast then the measurements will fluctuate. I also found that multi probing (measure the same point until two successive readings are within tolerance) is pretty much required to get a good result.

BLTouch is sensitive to magnetic fields. The impression I have is that mostly this isn't a problem, but some bed heaters generate enough magnetic field to affect it. That's why we provide the B1 parameter in the M558 command, to make RRF turn off the bed heater temporarily during the bed probing move. Might that have been the reason for your inconsistent results, or were you already using the B1 option?