Negative Feed Rate

-

Hello,

Is it possible to have a value negative feed rate with the current firmware? Meaning I can play the motion path in reverse without change to the GCode.

Thanks,

Wylie -

Are you thinking about wire EDM?

-

@thewyliestcoyote said in Negative Feed Rate:

Hello,

Is it possible to have a value negative feed rate with the current firmware? Meaning I can play the motion path in reverse without change to the GCode.

Thanks,

WylieNo.

-

@NitroFreak exactly, good call. I think this would be useful for a CNC plasma that I am working on if I get a torch beak indocation.

@dc42 Wow thanks for the fast response.

Is there a way feed along a path until something is triggered to the controller and have it back up a distance? This backup distance is something that I would like to set as a parameter I could change.

Thanks,

Wylie -

Much as I love my Duet, I really think if you're building a CNC plasma you're much much better off with a purpose built controller.

Just search for something like an FLCNC F2100

A controller and an automatic height controller (with leadscrew & drive) can be had for < $1000 AUD

A good height controller is critical for good results and it has to be tightly managed by the CNC controller.

This would be the key part of having any sort of success with a Duet on plasma.Whilst a duet could easily take care of the X/Y work and start & stop the plasma, if you don't have a controller designed for the purpose, you're 100% reliant on the nesting software being able to generate correct speeds for corners, holes etc. including turning the AHC on & off for corners & holes to stop torch crashing.

A dedicated controller as above also includes a part library for all your common shapes, flanges, gussets etc so you don't have to even draw them in CAD.Then there's all the things that you need daily on a CNC plasma, like plate alignment, edge starting, moving forward/back through the Gcode file to correct errors, allow consumable changes etc.

Much of this could theoretically be done with a Duet, in the same way you could theoretically use a plasma controller to 3D print.

This is 25mm plate cut with a similar controller using a Hypertherm Powermax 85.

25mm is to thick for an 85 amp in production, but this was edge started.

-

@OwenD said in Negative Feed Rate:

and an automatic height controller

wouldn't mesh bed leveling sort of achieve this given a fine enough grid?

-

@bearer said in Negative Feed Rate:

@OwenD said in Negative Feed Rate:

and an automatic height controller

wouldn't mesh bed leveling sort of achieve this given a fine enough grid?

No,

The plate can change height whilst cutting due to thermal expansion.

In plasma cutting the height controller works in two ways.

First it "probes" the sheet, typically with a sensor that activates when the nozzle shield touches it, although cheaper ones use a micro switch.

Then during cutting, it measures the arc voltage and adjusts the torch height to maintain the set torch to work distance.

This measurement is critical and can be as low as 0.5mm, but is usually about 1.5mm on materials under about 10mm.

The tricky part is that the arc voltage varies depending not only on torch to work distance, but travel speed, so when you slow for corners (or holes) the torch controller sees a lower voltage and will lower the torch causing a crash.

The CNC controller has to anticipate this and turn the AHC on/off when speed must be dropped or when cutting across another line.

And this has to work at travels speeds of 3-5 metres per minute on a typical "low end" system.

Thin sheet (<1/.6mm) can require cut speeds of up to 8m/min -

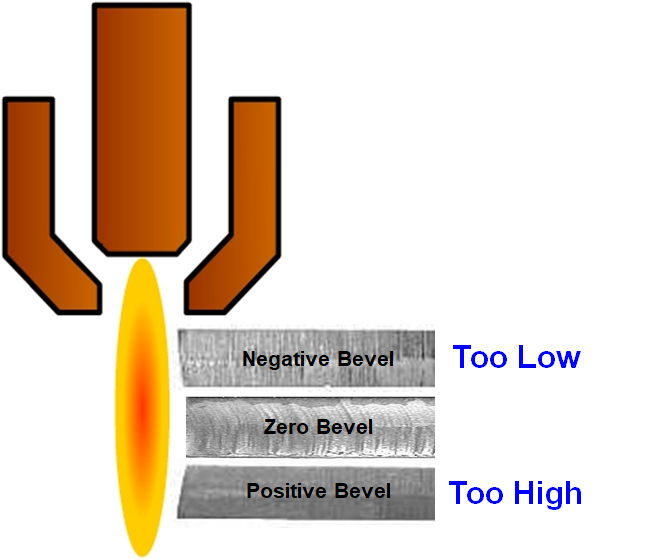

The plasma "flame" is shaped like a candle.

This is what makes proper height control so critical.

Using a Duet on a laser would be much easier (at least at the powers you're likely to use at home).

-

@OwenD said in Negative Feed Rate:

FLCNC F2100

If it does not work out for CNC Plasma project I will likely use LinuxCNC as I have some experience with it. I really like the web interface part of the Duet because I can put some simple CAD, nesting, and CAM in the Duet web interface. I have been playing around doing this and so far has some good luck in my first couple of hours of work.

The question I had was about negative feed rates was for an EDM. I was curious if it could support that.

-

Automatic height control has been an option in RRF for some time. See the M951 and M594 commands.

-

Interesting, so that is something that could be take a voltage as an input to one of the extra ADC pins to the control loop? If so this would eliminate the need for to buy a 3rd party THC (Torch Height Control). I would just have to have some level conversion from the plasma cutter to what the Duet could handle.

So how is a probing cycle handled? I mean it moves a direction till the controller receives some indication and backs up. Would this not work on a arbiary movement command? I know this works off of a binary input and would not be ideal for the EDM case but it may work.

-

The way we intend to use the height following code is that you use some sort of sensor with a linear output, for example height measurement, or arc voltage measurement. You may be able to configure a "linearAnalog" sensor type to interface that sensor to RRF. Then in M951 you specify the sensor number, PID parameters, and Z limits. To engage height following mode, move Z to approximately the correct height, then send M594 P1.

-

That sounds like a perfect match to doing THC. Thank you, that will be what I try for my CNC plasma project.

Back on the questioning the viability for the Duet as a controller for an EDM machine. Would it be possible to have this control loop apply to more then just Z axis position but have it control movement along a path. Think if it have a analog voltage as the feedback this controls how fast the machine moves along a path. If it overshots it may need to backup. The output of the EDM power supply is an analog voltage related to the arc condition and a serial port to configuration and status information.