Conductor rail

-

That's an interesting idea. I wonder how hard it would be to make something similar. You could use suitably insulated copper strips or tubing for the conductors and motor brushes on the bed support to make electrical contact. The trick would be making it safe to use in a printer that might get fondled by kids or dopes.

-

Interesting indeed. Brushes tend to be electrically noisy in motor applications not to mention releasing carbon dust but in a low speed environment where they're not crossing commutator gaps at high speed they should be fine.

-

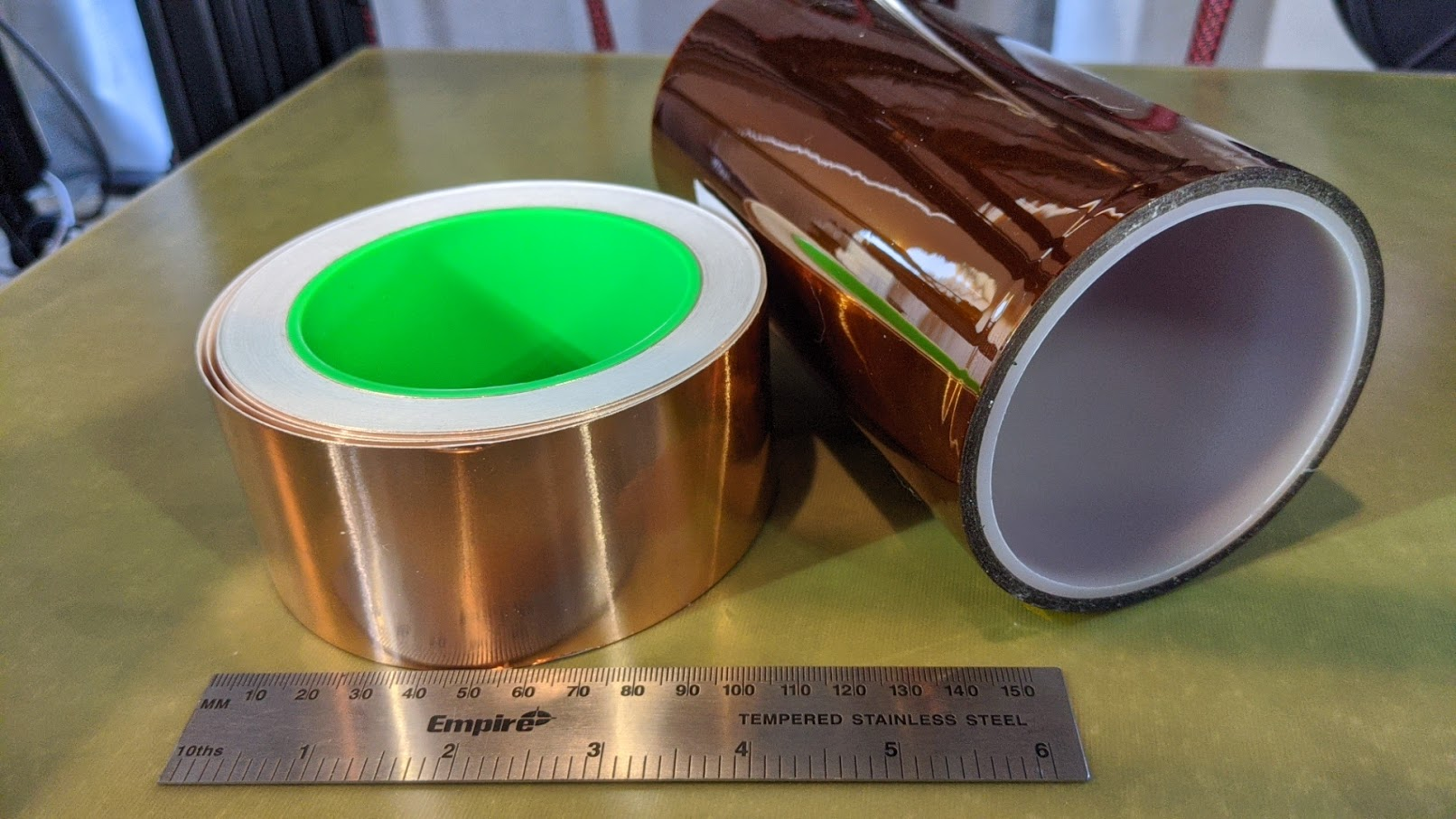

While we're on the subject of getting power to the bed heater, a while back, after using a flex ribbon to carry power/signals to the extruder carriage in a bed flinger I built, I thought it would be nice to have a similar flex ribbon cable to deliver power to the bed heater. I couldn't find a suitable cable off the shelf but I had some copper tape and 5 mil thick kapton tape that I was using to cover the bed, so I thought I'd try making my own high current flex ribbon. This is what I came up with:

At the time I was using a 24V, 450 W heater so I selected the width of the conductors to handle the 20+ amps. I never did put it in the printer, but I think it would be OK. I still have it somewhere- I'll have to pull it out and see if the adhesive on the kapton tape is still holding it together. It's been at least 5 years since I made it.

Even if it weren't used for a print bed, it would be great stuff to run speaker cables under carpets...

-

Due to safety concerns I'd rather buy one that was properly tested but if that does not work out I might build one myself. I like the idea to use motor brushes, that should be available. My original idea was to use copper strips enclosed in some insulator and the contact would be just one copper strip pressing the other. I've seen this design in led lightbulbs albeit this does not move but spring loading it should do the job albeit I'm not sure how long it would last. @mrehorstdmd copper tape is probably even better for the idea then what I had since the bed is mains powered so there is not need for thick conductor. Btw why not some other insulating tape instead of kapton tape?

-

Kapton is a great electrical insulator, has some rigidity, withstands heat of soldering wires to the ends of the ribbon, and was transparent so I could see what was going on inside the tape (maybe see breaks in the copper?). The rigidity means it will naturally form a large radius loop so I don't have to worry about excessive flexure breaking the copper strips inside the tape. The big question is whether the adhesive would hold up to frequent flexing.

-

The International Space Station is pretty much held together with Kapton tape.

In the early days when they were having trouble with the solar arrays, Kapton tape was a critical part of the repairs.

In the early days when they were having trouble with the solar arrays, Kapton tape was a critical part of the repairs. -

I've used laminations of copper and kapton tape to sneak charging cables through doors and windows - works a treat. The only difference to a real flat flex is the adhesive and soldermask instead of lamination, wouldn't be too concerned about using something like that - on the other hand you can also just buy flat flex with enough conductors and use them in parallel.

-

I think I can smell my house burning and I haven't even done anything yet.

-

-

@mrehorstdmd said in Conductor rail:

it would be great stuff to run speaker cables under carpets

You can get kits that are basically the same thing intended to be glued to the wall and plastered and painted over for stealthy surround speaker installations for when you can't get into the walls to run cables.