Why doesn't this M574 configuration work

-

Thanks Nuramori, what slicer do you use?

-

@luckyflyer I use Cura 4.6.1 That actually reminds me, just for giggles, do you have any start code in your slicer, and if so, perhaps posting it may help too. You never know.

-

look above I just posted it.

-

Do you happen to also have an override.g file in your sys folder on the duet?

-

I can execute this part of my start code from the console, it works perfectly, but not from within s3d.

G92 E0

G1 X130.0 Y5 Z0.0 F2000

G1 X40.0 E20.0 F1000.0 -

No override .g

-

@luckyflyer I think the issues you're experiencing could caused by the lack of a T0. Here's a few thoughts.

Recommend adding these to the top to make sure typical defaults are set.

G90 ; absolute positioning M83 ; set extruder to relative mode - enable relative extruder distances in the slicer T0 ; select tool M107 ; part fan off M220 S100 ; reset speed multiplier M221 S100 ; reset extrusion multiplier On the G-Code tab enable "Relative extrusion distances"

Not sure I'd recommend this unless your mesh stays incredibly consistent.

G29 S1 ; load bed meshThis is not necessary.

G92 E0 ;set extruder to 0This prime line is extruding at Z0, and it's pushing out quite a bit of filament in only 90mm.

G1 X130.0 Y5 Z0.0 F2000 ; move tool G1 X40.0 E20.0 F1000.0 ; extrude 40 mm of filament to prime nozzle If you're using a 0.4 nozzle try this instead.

G1 X130.0 Y5 Z0.3 F2000 ; move tool G1 X40.0 E10 F1000 ; prime nozzle This isn't necessary.

G92 E0 ; set extruder to 0 -

Thanks mwolter, So my revised start code should look like this,

G90 ; absolute positioning

M83 ; set extruder to relative mode - enable relative extruder distances in the slicer

T0 ; select tool

M107 ; part fan off

M220 S100 ; reset speed multiplier

M221 S100 ; reset extrusion multiplier

M109 S195 ; wait for hotend temp

M190 S60 ; wait for bed temp

G28 ; home all axes

G1 X130.0 Y5 Z0.3 F2000 ; move tool

G1 X40.0 E10 F1000 ; prime nozzle -

Also I must say that S3d was and still would work correctly when the Y endstop is configured to Y1 and all associated homing data is reset to the way it was before the Max Y endstop change.

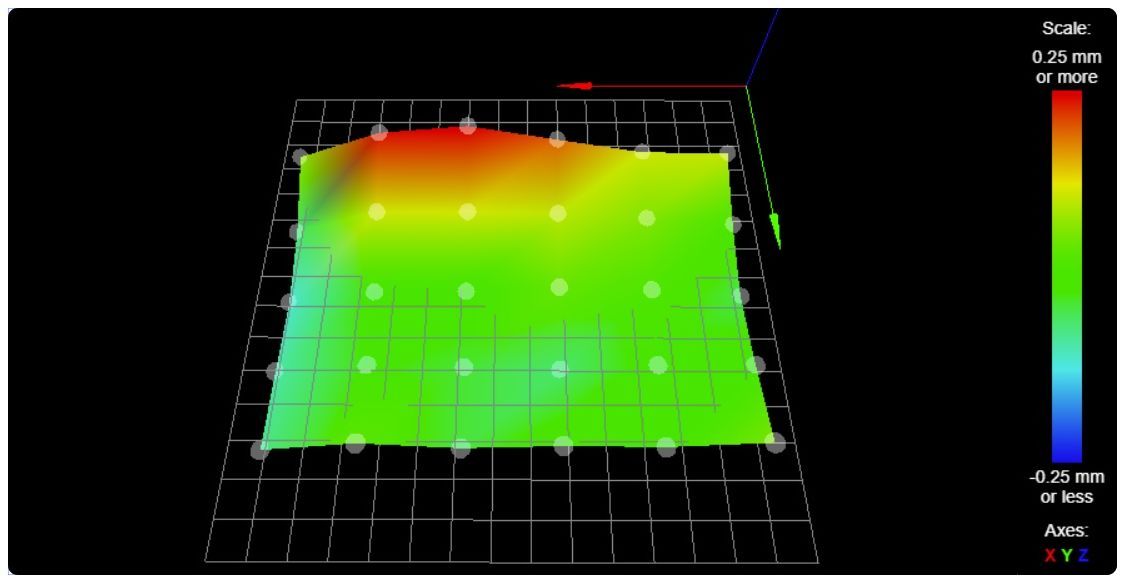

And my mesh isn't very pretty

xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum

15.00,295.00,15.00,252.00,-1.00,56.00,47.40,6,6

0.103, 0.110, 0.197, 0.286, 0.240, 0.068

0.014, 0.063, 0.101, 0.112, 0.111, -0.057

-0.041, 0.018, 0.041, -0.002, -0.011, -0.112

-0.003, -0.007, -0.061, -0.036, -0.018, -0.091

0.058, -0.010, 0.002, -0.037, 0.031, -0.074

0, 0, 0, 0, 0, 0 -

I tried this revised start code

G90 ; absolute positioning

M83 ; set extruder to relative mode - enable relative extruder distances in the slicer

T0 ; select tool

M107 ; part fan off

M220 S100 ; reset speed multiplier

M221 S100 ; reset extrusion multiplier

M109 S195 ; wait for hotend temp

M190 S60 ; wait for bed temp

G28 ; home all axes

G1 X130.0 Y5 Z0.3 F2000 ; move tool

G1 X40.0 E10 F1000 ; prime nozzleWith the same results as before. The printer halts, stalls at the second G1 line.

-

@luckyflyer If it still doesn't work, it might be best to start fresh and create a post below with the current state. The thread has grown quite a bit and it's pretty hard to follow.

- Use the CODE formatting button </> above and post both the working and non-working config.g.

- Also post your latest homeall.g.

- Be sure to add a good description letting us know what works and what doesn't work, what breaks it, what you notice happens, etc.

-

I inadvertently left the

G29 S1 ; load bed mesh

command in the start script so I took it out and tried again,

And HOTDAMN it now works. Mwolter you are a genius. If I could I would buy you your favorite beverage!!! -

@luckyflyer Great, glad it works!