Formbot Troodon RRF 3.1.1 Update

-

Figured I'd bump this and see if anyone had any other idea before i dig into source myself.

-

@InsanityAutomation It appears newer machines are shipping with a slightly different board:

https://m.facebook.com/photo.php?fbid=2806644909555472&id=100006299702277&set=gm.949439705562814&source=57 -

I have exactely the same issue on my Troodon, but I'm using a different (self made) config.g file. So i'm back on 3.0 for now. And I do have a newer board which is black.

-

@Guzzi Does Troodon give any firmware guidance with regards to the custom board?

-

From what I can tell, the stock firmware for the Troodon isn't even available for download anywhere. The firmware for their other machines is provided via zip files hosted on a variety of file hosts (some on drop box, some on google drive, etc).

Also, Vivedino/Formbot appears to be a very small company. It looks like their entire lineup aside from the Troodon uses the same marlin motherboard.

All of this combined makes me think that perhaps a 3rd party designs boards for them. If that's the case then they may not even have someone who could provide help with firmware.

-

@Phaedrux no they only provide the firmware which the machine is shipped with. So 2.03RC3. I asked them if they already have a config for 3.0. They told me that if I wan't to upgrade I have to write my own. So that's what I did but unfortunately had the fault issue on 3.1.1.

-

@Guzzi Hi. Could you please share you configuration files for the 3.0?

-

Hi, here is my config file:

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Sun Aug 30 2020 21:21:23 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences M111 S0 ; debugging off G21 ; work in millimetres G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Troodon" ; set printer name M669 K1 ; select CoreXY mode M555 P2 ; set firmware compatibility to look like Marlin ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 D2 ; X M569 P1 S1 D2 ; Y M569 P3 S1 D2 ; E0 M584 X0 Y1 E3 Z6:5:8:7 ; set drive mapping // four Z motors, at 5, 6, 7, and 8 M671 X-100:-100:420:420 Y380:-115:-115:380 S20 ; Z belts at 4 corners ; Duex5 M569 P5 S1 D2 ; Z5 M569 P6 S0 D2 ; Z6 M569 P7 S1 D2 ; Z7 M569 P8 S0 D2 ; Z8 M569 P2 R-1 ; -1 = driver is always disabled and is not monitored M569 P4 R-1 ; -1 = driver is always disabled and is not monitored M569 P9 R-1 ; -1 = driver is always disabled and is not monitored ; Drive map ; _______ ; | 6 | 7 | ; | ----- | ; | 5 | 8 | ; ------- ; front M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E710.00 ; set steps per mm M566 X2000.00 Y2000.00 Z600.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z1500.00 E3600.00 ; set maximum speeds (mm/min) M201 X1500.00 Y1500.00 Z500.00 E600.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200 E430 I60 ; set motor currents (mA) and motor idle factor in per cent M84 S60 ; Set idle timeout ; Axis Limits M208 X5 Y0 Z0 S1 ; set axis minima to end of safe travel M208 X410 Y408 Z510 S0 ; set axis maxima to match endstop location ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop ;M574 Z1 S0 P"zstop" ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S7 C"!exp.heater7" ; create servo pin 7 for BLTouch M558 P9 C"^zprobe.in" H3.5 F300 T12000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y21 Z1.41 ; set Z probe trigger value, offset and trigger height M557 X10:410 Y21:400 S49 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B1 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S130 ; set temperature limit for heater 0 to 130C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp old settings:B4138 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 A517.3 C213.3 D11.1 S1.00 V24 B0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C M308 S2 P"e1_temp" Y"thermistor" T10000 B3950 A"Chamber" ; configure sensor 2 as thermistor on pin e1temp M308 S10 Y"mcu-temp" A"mcu-temp" ; create virtual temp sensor 10 M308 S11 Y"drivers" A"drivers" ; create virtual temp sensor 11 M308 S12 Y"drivers-duex" A"drivers-duex" ; create virtual temp sensor 12 ; Fans M950 F0 C"fan0" Q250 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 C"PART FAN" ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q250 ; create fan 1 on pin fan1 and set its frequency M106 P1 H1 T45 S1 C"EXTRUDER FAN" ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q250 ; create fan 2 on pin fan2 and set its frequency M106 P2 H10:11:12 T45:65 L0.4 X1.0 C"COMPARTMENT FAN" ; set fan 2 value. starts to turn on when the MCU temperature (virtual heater 10) reaches 45C and reaches full speed when the MCU temperature reaches 65C or if any TMC2660 drivers (virtual heaters 11 and 12) report that they are over-temperature M950 F8 C"duex.fan8" Q250 ; create pin 8 on pin fan8 and set its frequency M106 P8 H10:11:12 T40:65 L1.0 C"STEPPER FAN" ; set fan 8 value. Thermostatic control is turned on M950 F9 C"duex.fan7" Q250 ; create pin 9 on pin fan7 and set its frequency M106 P9 S0 H-1 C"AIR FILTRATION" ; set fan 9 value. Thermostatic control is turned off ; Free up Fan pin M950 F3 C"nil" ; disable fan 3 and free up the associated pin M950 F4 C"nil" ; disable fan 4 and free up the associated pin M950 F5 C"nil" ; disable fan 5 and free up the associated pin M950 F6 C"nil" ; disable fan 6 and free up the associated pin ; Tools M563 P0 S"E3D_Extruder_0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings ; Filament sensing M591 D0 P1 C"e0_stop" S1 ; Firmware retraction M207 P0 S0.3 R0 F3600 T3600 Z0 ; [ Snnn positive length to retract, in mm ] // std M207 S2.5 R0 F6500 T4500 Z0 ; [ Rnnn positive or negative additional length to un-retract, in mm ] ; [ Fnnn retraction feedrate, in mm/min ] ; [ Tnnn feedrate for un-retraction if different from retraction, mm/min ] ; [ Znnn additional zlift/hop ] ; Linear advance M572 D0 S0.13 ; Linear Advance ;M592 D0 A0.01 B0.0005 ; nonlinear extrusion ; RGB leds - White ;M950 P3 C"duex.fan3" Q250 ; create pin 3 on pin fan3 and set its frequency ;M106 P3 S255 ; not used for the moment M950 P4 C"duex.fan4" ; create pin 24 on pin fan4 and set its frequency M42 P4 S255 ; G- M950 P5 C"duex.fan5" ; create pin 25 on pin fan5 and set its frequency M42 P5 S255 ; R- M950 P6 C"duex.fan6" ; create pin 26 on pin fan6 and set its frequency M42 P6 S255 ; B- ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M911 S23 R24 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ;M581 ; Set Z-Probe Offset (Marlin Compatibility) M501 M500and I also got the wiring diagram for the vivedino custom board:

wiring diagram.pdf -

Hello,

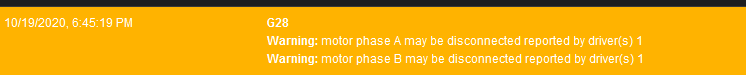

i have exactly the sam problem with RRF 3.1.1 and RFF 3.2 beta1 and RFF 3.2 beta 2.

Warning: motor phase A may be disconnected reported by driver(s) 0 1

Warning: motor phase B may be disconnected reported by driver(s) 0 1Only RRF 3.0 works wihtout error

Is there a solution to this problem now?

-

You can put me in the same basket whit the same problem.

Found this tread after 7 hours. Tried to go from 2,0 to 3,0 and whitout testing 3.0 to 3.11 hate myself for that

-

Hi - I have the same issue on 3.1.1 and came to confirm if the message is in fact drv 01 for y axis. I changed out the wires, soldered the clips and was about to change out a nice Vexta motor. Guess I should wait if others are having the same issue.

In the meantime, please confirm if the this is related to y Axis or not. I am on a Duet WiFI.

Cheers -

@wolf-3d4u said in Formbot Troodon RRF 3.1.1 Update:

Is there a solution to this problem now?

For the time being stay on 3.0.

-

This post is deleted! -

Add me as well in the group of people have the issue with 3.1.1 and 3.2b1/b2 on the Troodon.

Only 3.0 seems to work, unfortunately this version doesn't support the Meta gcode.I don't mind trying any alpha or beta if that might help

-

@EricN i think you have to directly talk to formbot. Normally new betas are only released for duet Boards. I know that the formbot is based on a duet but not completly the same.

And i do not know If they reached out to @T3P3Tony to solve the 3.1.1 or 3.2 Problem

-

@wolf-3d4u said in Formbot Troodon RRF 3.1.1 Update:

Hello,

i have exactly the sam problem with RRF 3.1.1 and RFF 3.2 beta1 and RFF 3.2 beta 2.

Warning: motor phase A may be disconnected reported by driver(s) 0 1

Warning: motor phase B may be disconnected reported by driver(s) 0 1Do the motors move despite the warnings, or not?

-

@dc42 no they don't. Could it be diff then expected sense resistors or more likely the added meta gcode is polling driver and picking up on the diff hardware ?

-

@dc42

My motors spin. I am on Duet2 WifiAlmost always throws the same error during home with G28 .

Printing has been mostly successful even with error thrown, but occasional print fails right after fault. Today I lost two prints after this error and a third 200 layer print had no issue (with a few of these errors).

The cable has been changed (shielded), connector crimps have been soldered and now debating a motor change until I saw these posts. Im waiting to change motor based on outcome of this thread.

-

@tommyb This thread is for people having problems with the Formbot Troodon custom RRF compatible board. Please start a new thread for your issue with the Duet Wifi.

-

@dc42 is their anything I should do to try and get you more info ? I honestly am just gonna change to a genuine duet 2 or 3 but am trying to find out if duet 3 will offer any benefit. Are their plans for any features that the 3 can support cause of increased cpu and sbc like input shaping etc that the duet 2 won't be able to do ?