Suggestions for hight precision CoreXY

-

@zapta said in Suggestions for hight precision CoreXY:

VZero

I'm very tempted indeed, shame its tricky to get 15mm alu locally

(edit: oh my, they have a sourcing guide with aliexpress links for most things, incl alu profile kits and belt/pulley kits. unfortunately hemera is on the way so it'll be a while for a voron)

-

@giostark Hi Sergio

Happy to have you as a customer. The Railcore kit is extremely stable. Only very few 3D printed parts are used so it is long term stable and extremely stiff. At the moment the only 3D printed parts are the feet, electronics enclosure corners, Endstops and BLtouch mount. The BLTouch mount will also soon be aluminum. In the near future there will also be a 135C chamber temperature version of the kit.Peter From HighTemp3D.com based in the EU

-

There is a Kinimatic bed mount system available for the Railcore produced by Mandela Rose Works:

Kinematic Mount -

@jballard86 Yes, thats the one I sell at my EU based shop: https://hightemp3d.com/collections/mandala-rose-work/products/kinematic-mounting-kit-from-mandala-rose-works

-

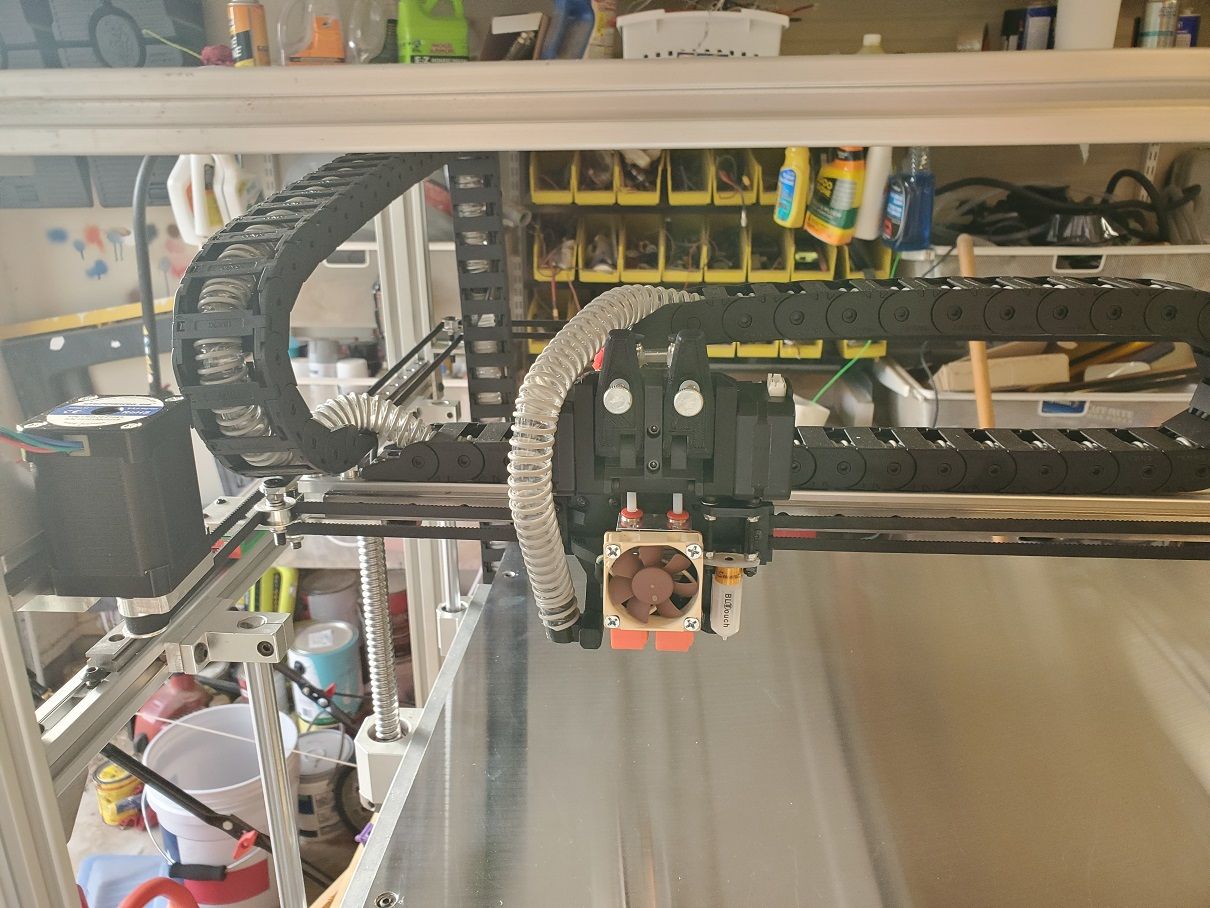

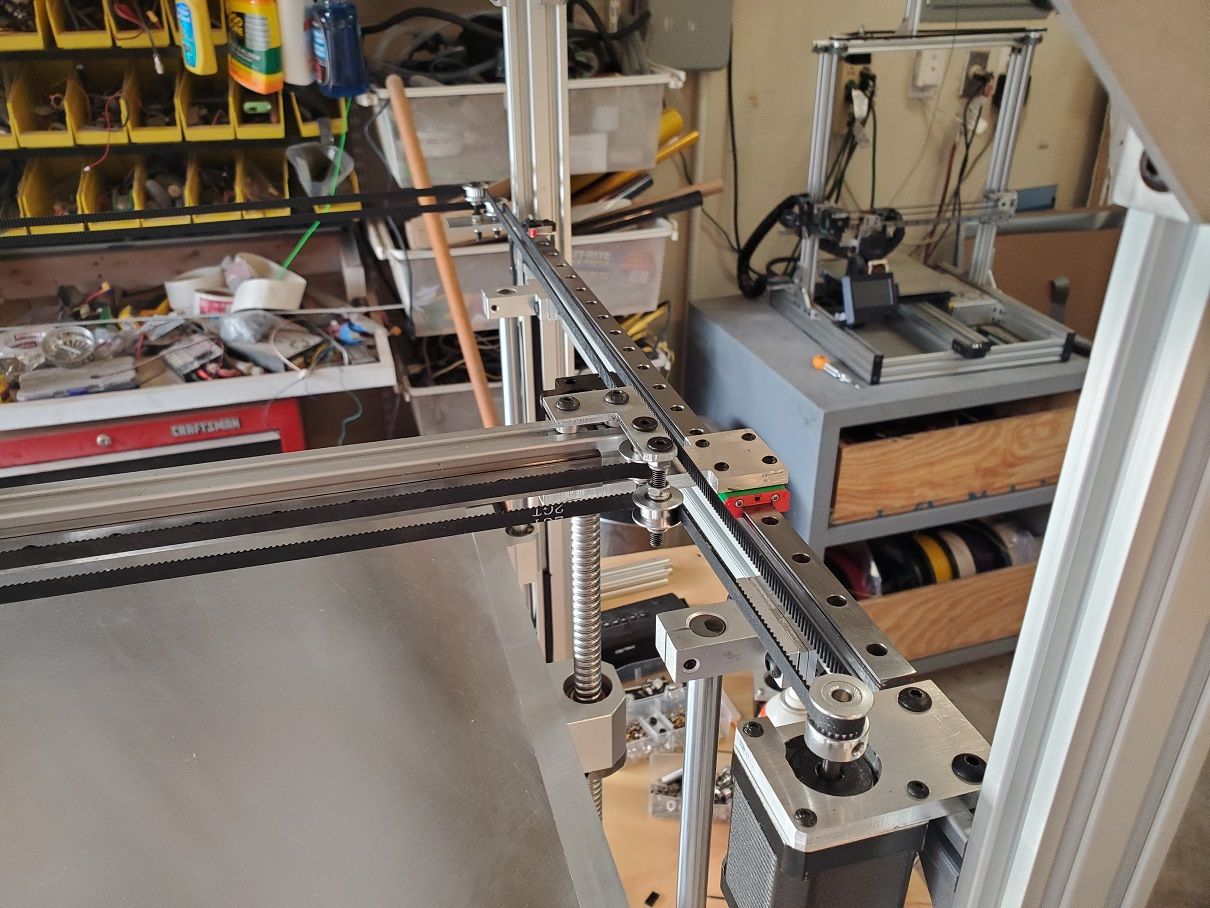

I just finished building a new CoreXY printer with the goal of no 3d printed structural parts at all. The only printed parts are the enclosures for the controller boards and the extruder mount (dual BMG extruders).

I've been 3d printing for several years on both cartesian and corexy. A more rigid printer usually produces better prints. The best improvements were around bed stiffness. I recently went to the 3 independent "true level" setup with a 1/4 thick MIC6 aluminum plate + 1/4 tempered glass. Each z axis motor is controlled by an external stepper and has a 3:1 gear reduction for both higher resolution and higher strength (HERE is a vid of my bed setup). Since this vid, I've added 12mm smooth rods to each ballscrew to improve linear motion.

Attached are a few pics of my printer:

!

!