Duet 2 wifi CR10 end stops not working

-

Duet 2 wifi CR10 end stops not working X & Y. Motors keep going. Tried NO,NC,LOW and HIGH no change.

-

@Smedley please provide firmware version, config.g and homeall.g to check the configuration. A few images of the XY endstops and the wiring is helpful, but more important for a first check are the files and firmware version.

-

2.05 1 (2020-02-09b1

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Jul 27 2020 18:06:23 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"CR-10" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E95.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z300.00 E1500.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S300 ; Set idle timeout; Axis Limits

M208 X5.5 Y7.4 Z0 S1 ; set axis minima

M208 X310 Y310 Z260 S0 ; set axis maxima; Endstops

M574 X1 Y1 S1 ; set active high endstops

M574 Z1 S2 ; set endstops controlled by probe; Z-Probe

M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

M558 P9 H2.5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X-31 Y0 Z0.6 ; set Z probe trigger value, offset and trigger height

M557 X20:215 Y20:215 S64 ; define mesh grid; Heaters

M305 P0 T98801 B4185 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T98801 B4185 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S270 ; set temperature limit for heater 1 to 270C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H0:1 T45 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings

;M591 D0 C3 P1 E1 S1 ; Turn on functionality for a filament run-out switch; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power losshomeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Jul 27 2020 18:06:24 GMT-0400 (Eastern Daylight Time)

G91 ; relative positioning

G1 H2 Z2.5 F6000 ; lift Z relative to current position

G1 H1 X-309.5 Y-307.6 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-309.5 Y-307.6 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X51 Y20 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z2.5 F100 ; lift Z relative to current position

;G90 ; absolute positioning -

Can you test the endstops as described here: https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+3:+Commissioning/39#s145

If you click the endstops does the LED on the board change?

How have you wired the endstops?

-

Yes They change the LED on the board.

As for the TEST

X triggers YES

Y. triggers. YES

Z. triggers NO on the test and all the time. The LED on the board tigers with the switch.They are wired to the OUTSIDE 2 pins.

-

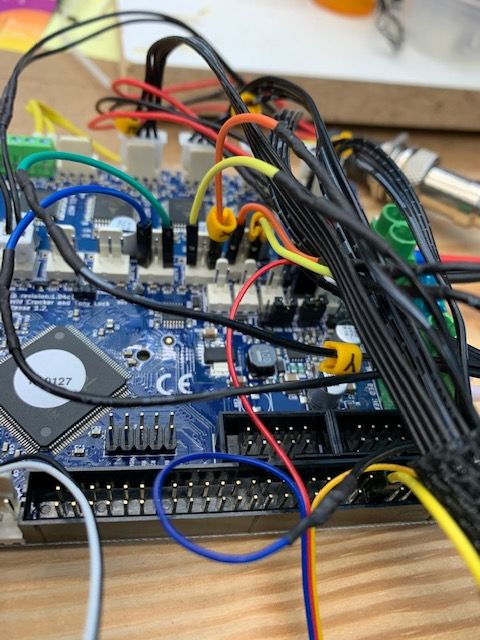

Photo of the endstop?

-

This post is deleted! -

-

@Smedley you have not configured to use a Z endstop, but to use the probe (the bltouch) as endstop.

-

Before the test you asked for I don't have the Z switch hooked up. Are you saying the BLTouch gets weird to the Z end stop pins.

Why are the X and Y not working.Thank You, Dave

-

@Smedley said in Duet 2 wifi CR10 end stops not working:

As for the TEST

X triggers YES

Y. triggers. YESIt's a bit confusing: are your endstops X and Y working or not??

Triggers Yes would mean they are working. If they trigger as LEDs, do they also are marked triggered in PanelDue/Duet Web Control DWC?I didn't ask to change anything. But please check the endstops: is it a normal open - close endstop and is it of type NO or NC? NO means normal open, i.e. if not triggered it is open, no current flows. NC means normal closed, if not triggered current flows (no resistance). From the type of endstops it depends how the configuration must be made.

-

If the LEDs on the board are changing when you click the switch that at least proves an electrical connection.

Though it's odd that the motors continue to move even though they hit the endstops. If the endstop status indicates triggered yes already before being depressed they should not move at all because the endstop is already triggered.

The only thing to change with the endstop config is the S parameter.

You have:

M574 X1 Y1 S1 ; set active high endstops

Please try:M574 X1 Y1 S0 ; set active LOW endstops -

I was referring to the test above I was asked to run from the MODERATOR.

That is why the wires were plugged in for the Z stop.I am sorry for the confusion. Did not realize I was working with two different people trying to help me.

x and y are not working. The test proved that they are wired correctly and tripping the board.

-

@Smedley do you have some electronic instrument to verify that the endstops are working? Or please post a photo, maybe we know the type and see what could be wrong.

(after the tests of Phaedrux)No problem about the confusion. Better two people help you than noone

-

Now X and Y move a couple of inches and stop. They do not go to the end stop switch. Each time I run home all they stop in a different place each time. I do a EMERGENCY STOP so Z does not hit the bed. If I run home all they will move a couple of inches from were they stopped for the last time I ran home all.

The Z comes down all the way to the bed. I under stand the Z is not set yet.

-

@Phaedrux said in Duet 2 wifi CR10 end stops not working:

M574 X1 Y1 S1

Ok then M574 X1 Y1 S1 was correct.

Are you using homeall or the individual homing files?

Can you confirm that your motor directions are correct?

-X should move to the left, +x to the right

-y moves the nozzle to the front of the bed, +Y moves it to the back.Where are the endstops physically located?

-

X+10 will move to the right each time all the way to the end.

X-10 will move to the left only to the middle of the bed.

Y+10 will move the past the back

Y-10 will move half way to the front of the bed. -

@Phaedrux said in Duet 2 wifi CR10 end stops not working:

Where are the endstops physically located?

-

It doesn't make it all the way to the end because it doesn't know where it actually is yet.

-

@Phaedrux

The switch for X is on the left side and if you home x it goes to the right a couple of inches and stops. It will not move to the switch.The Y switch is in the back. if I home Y the bed goes forward.

Before we changed HIGH to LOW they move to the switch and did not stop. Now they go away from the switch a couple of inches. And will not let me move them all the way to the switch with the Machine Movement on the screen.