The long/short retraction challenge

-

TL;DR is a single printer/slicer configuration that can print well these two STLs?

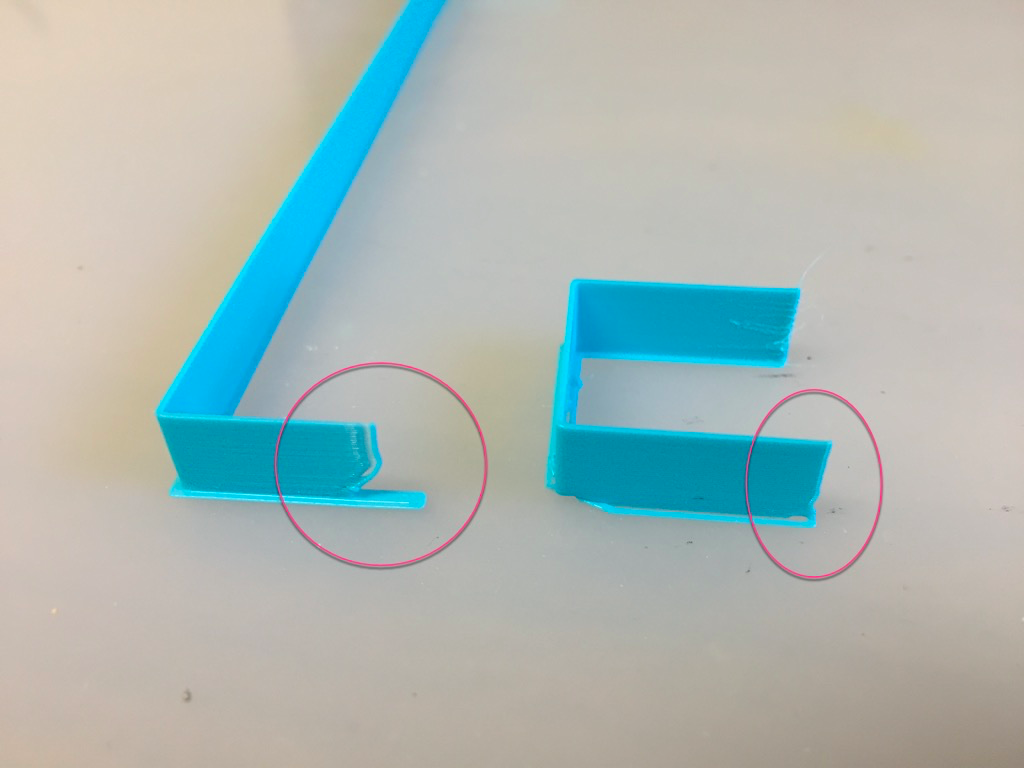

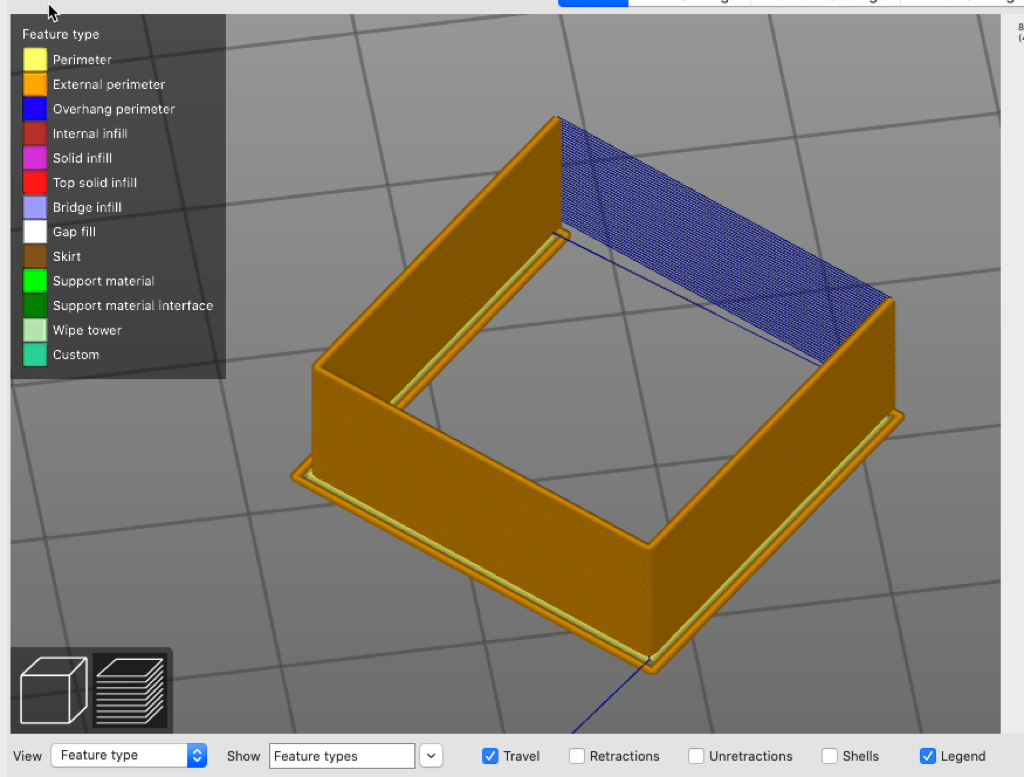

My printer creates a printing artifacts that I am able to reproduce with a simplified model. It looks like an under extrusion after a long retraction/move on a layer change. It happens after a long move (left) but not after a short move (right).

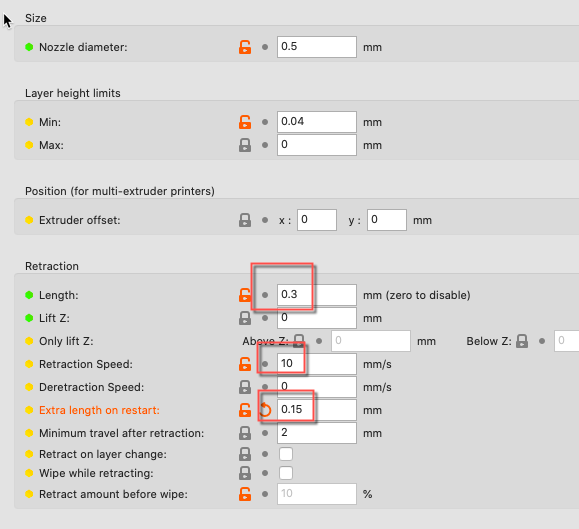

PA doesn't seem to affect it but if I set the slicer to 0.2mm extra extrusion after retraction it fixes the one of the left but add a bulge to the one of the right.

I think that a setting to add post retraction extra extrusion that is proportional to the time of the retraction would help but I don't see one in PrusaSlicer.

Here is more info that may help:

CoreXY HEvo 300mm printer. Direct drive BMG extruder, e3d hotend, 0.5mm nozzle. RRF 3.1.1. Config: https://github.com/zapta/misc/tree/master/hevo/duet3/sysModels:

test_case_long v13.stl

test_case_short v2.stl

-

I think cura has something similar to this. extra retraction relative to travel move length.

-

Retraction is a very weird thing when you think about it. When we unretract, we're usually doing so quite fast -- far above the extrusion rate of any extrusion path.

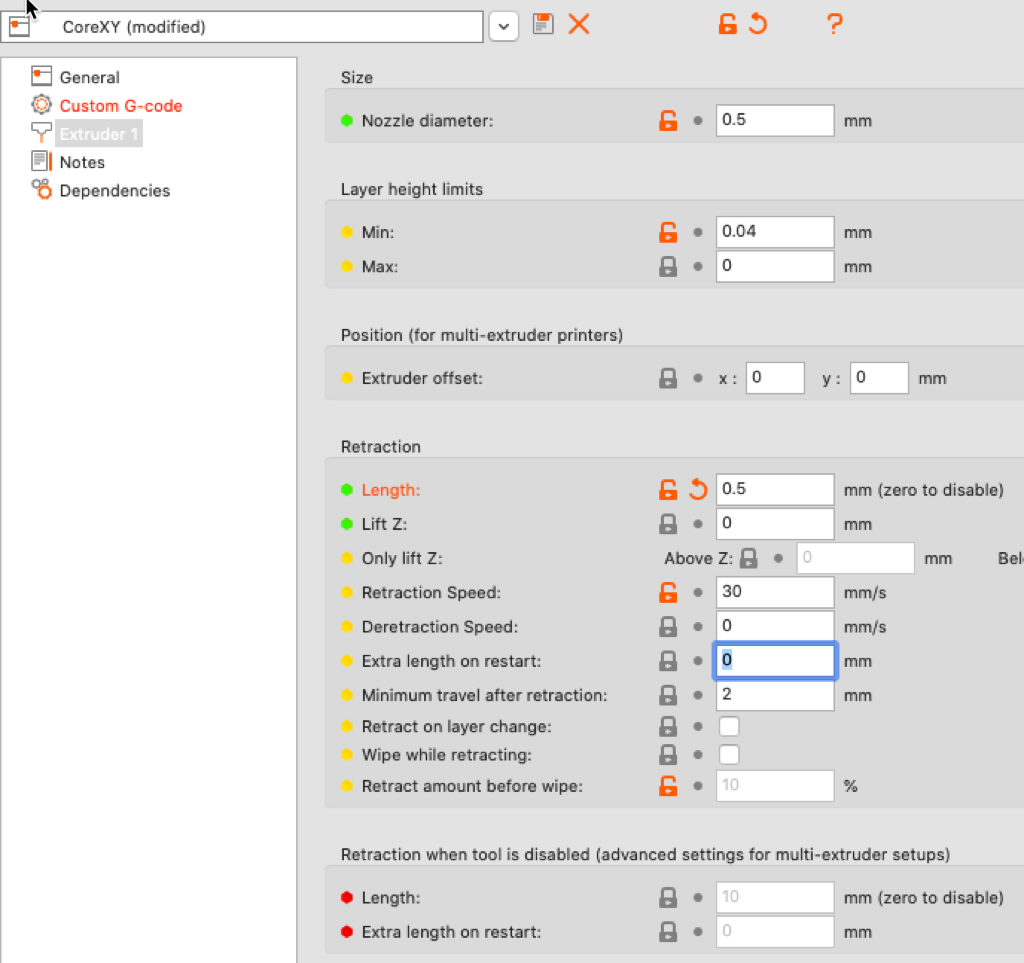

With 0.5 mm retract length, do you really need to do the retraction as quickly as 30 mm/s? Some of my best prints were done (on an old machine) with 0.4 mm retraction done at 5 mm/s. Yes, five.

5 mm/s is still much faster than most extrusion paths are printed at.

I think there is a better model, yet to be developed, that would work alongside pressure advance and replace fixed retractions. A retraction is really just a crude implementation of pressure advance

. Sort of.

. Sort of.Pressure advance is not quite at the point that we can disable retractions and let 'er rip -- but I think some small tweaks could bring it there.

-

@Phaedrux , that Cura feature is exactly what I need. I wish Cura would be as easy to use as PrusaSlicer (that's a subjective call of course)

@bot, do you suggest reducing the retraction/unretraction speeds? To what? Typically the recomendations are to use as fast as the extruder can handle.

BTW, I don't have stringing so this is not an issue of loosing melted material along the move.

-

@zapta said in The long/short retraction challenge:

Typically the recomendations are to use as fast as the extruder can handle.

At least for the retraction portion. The unretract should be tuned independently. Molten plastic being a non-newtonian fluid afterall.

-

If you don't have stringing, even more reason to lower the retraction speed. Heck, lower the amount too while you're at it. 0.4 mm can be noticeably different than 0.5 mm if you have a direct extruder. I have essentially the same setup: direct, bondtech drive gears, but I have a different filament path and extruder body so things might not be exactly translatable.

Try 10 mm/s speed.

-

Thanks for the suggestion. I ended up using the settings below and it gives me good enough results for print I need to do (a panel due case). It's not perfect and I may revisit it in the future.

I am having this problem since I switch to 'print outer perimeter first'. It gives me smoother surface but shows this this after-move under extrusion since it's external and visible.

-

@zapta said in The long/short retraction challenge:

'print outer perimeter first'.

That's a classic issue of printing the outside wall first. The nozzle isn't fully primed at the start of the print move. Each layer fails to start the move properly if the layer seam is stacked and it ends up as a gash. If the layer seam is randomized it ends up as little holes all over.

Inside walls before outside walls is the way to go IMO.

-

@Phaedrux said in The long/short retraction challenge:

Inside walls before outside walls is the way to go IMO.

I will give it a try. I think I am getting smoothers surfaces with outer-first but I will do a more objective comparison to see how significant it is.