Weird results using Kisslicer's preload wizard.

-

Hello everyone,

I'm in the process of tunig my machine, and I ran nto a wird issue while doing the preload test using Kisslicer.

Preload is an equivalent to linear advance/pressure advance.The wizard generates a gcode file of a rounded cube, and changes the preload value for each layer in order for the user to choose the best layer.

Problem is, as you can see on the following pictures, every single layer is more horrific than the next one.What puzzles me is that the printer acts weirdly. The outside perimeter isn't printed smoothly, the print head does some very jerky movements instead of moving at a regular speed. Idon't understand why the print head would vary its speed, isn't it supposed to change extruder's speed instead?

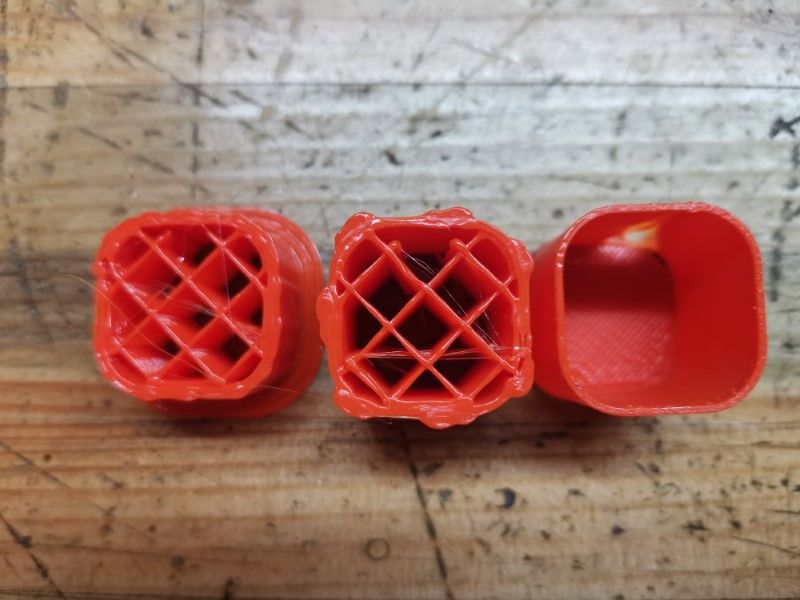

On the left, the horrible result I get while running the preload test, on the right what the print is supposed to look like

Left: preload values from 0 to 0.5, middle: from 0 to 2, right: what it's supposed to look like.

Does anyone has an idea of what's going on?

-

Aren't they calibration prints? You are suppose to check for which preload layer looks best and use this value for entire print?

If You have direct drive extruder I would expect pressure advance somewhere between 0.04 and 0.15

-

Post your config.g.

Do you have very low extruder jerk set?

-

@BoA said in Weird results using Kisslicer's preload wizard.:

Aren't they calibration prints? You are suppose to check for which preload layer looks best and use this value for entire print?

If You have direct drive extruder I would expect pressure advance somewhere between 0.04 and 0.15

Yes, but all layers are bad, even the first one when the preload is supposed to be zero in the test. I don't have a direct extruder, the printer has a very short bowden tube, total distance is about 190mm.

-

@Phaedrux said in Weird results using Kisslicer's preload wizard.:

Post your config.g.

Do you have very low extruder jerk set?

I can't right now since it is on my home computer and I'm at work right now (sorry), but I will do it this evening

Jerk setting was my first guess too, to I bumped it from 300 to 900 on X, Y and E, but it didn't change anything. -

I'm not really sure what kisslicer is doing here so I'd start there. I think they have a forum as well.

-

Here is the config file:

; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S0 ; physical drive 3 goes forwards M584 X0 Y1 Z2:4 E3; two Z motors connected to driver outputs Z and E1 M671 X-25:750 Y0:0 S50 ; leadscrews at left (connected to Z) and right(connected to E1) of X axis, S2 is maximum amount ofcorrection M208 X0:720 Y0:720 ; X carriage moves from -5 to 205, Y bed goes from 0 to 200 M350 X16 Y16 Z8 E16 I1 ; configure microstepping with interpolation M92 X100.00 Y100.00 Z1200.00 E86.20 ; set steps per mm M566 X600.00 Y600.00 Z2.00 E320.00 ; set maximum instantaneous speed changes (mm/min) M203 X10000.00 Y10000.00 Z800.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E500.00 ; set accelerations (mm/s^2) M906 X2200 Y2200 Z2400 E1200 I45 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X715 Y715 Z600 S0 ; set axis maxima ; Endstops M574 X2 Y2 Z2 S1 ; set active high endstops ; Z-Probe M307 H7 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch M558 P9 H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z3 ; set Z probe trigger value, offset and trigger height M557 X0:700 Y0:700 S350 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

I'd probably try increasing your extruder speeds a bit more.

M203 E6000

M201 E3000

M566 E3000Raising the limits there allows you to control extruder speed via retraction and pressure advance, or in the case of kisslicer, with it's preload commands.

Perhaps if you post the gcode that kisslicer creates we can see what it's actually trying to command the extruder to do.