I would like to have auto-scaling of temperatures graph - would make tracking lower temps easier.

Perhaps it would be also nice to have dual-scale - left scale for tools (usually higher range), right scale to heatbed/chamber (usualy lower range).

I would like to have auto-scaling of temperatures graph - would make tracking lower temps easier.

Perhaps it would be also nice to have dual-scale - left scale for tools (usually higher range), right scale to heatbed/chamber (usualy lower range).

@phaedrux I bought it from Hobbystore, around IX.2020

I have 2 of them, and can swap to check if this issue is still there.

In fact I have no idea why I did not do that already.

I will test 2 cases:

It would be nice to have recursive delete for non empty directories.

I think that viable solution would be to use NFC tags and a spool holder with reader. With new spool just put a nfc sticker (can be bought easily) and set a filament length when spool used for a first time.

Then each time spool in put on spoolholder read the tag, and update legth when print finished/tool change/ etc

Easy to implement - nfc readers are available with many intercaes, tags can be bought without problems.

If state.gpOut[3].pwm==0

M42 P3 S1

else state.gpOut[3].pwm==1

M42 P3 S0

condition in else is obsolete, and more "elegant" way is

If state.gpOut[3].pwm != 0

M42 P3 S0

else

M42 P3 S1

I am wondering how this "community repairs" idea is woking out.

Are there any stats how many community repairs been done so far?

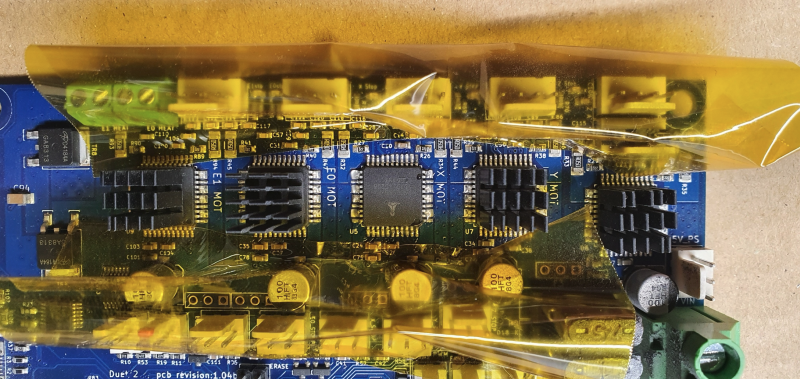

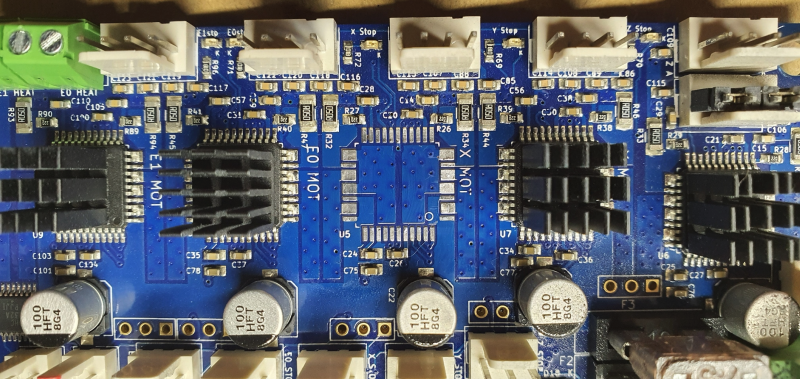

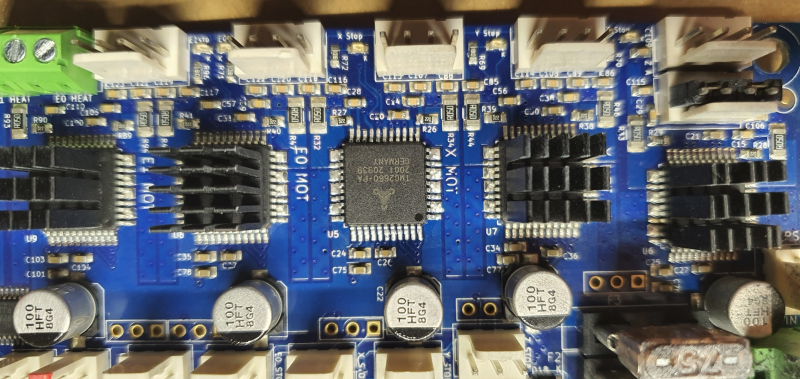

I recently replaced one of the stepper drivers in duet2.

Here are some pics from the process:

@dom I think latest paneldue will not work properly with 2.05.1 firmware. Update Duet firmware to 3.2.2

Probing twice the same point?

G30 P0 X26 Y226 Z-99999 ; probe near an adjusting screw

G30 P1 X26 Y226 Z-99999 ; probe near an adjusting screw

@wieman01 Y range is limited only from one side. Y=0 coordinates can be reached by bltouch - it just moves nozzle to position Y=36, and then proble is at Y=0.

But.. if nozzle can go only to Y=350, then probe can reach only points with Y <= 350-36.

So M557 would have Y range Y0:314, as any higher Y is out of reach of probe tip.

@chrishamm Duet 3 MB6HC,

And I have found part of uploaded file thas is corrupted... seems some issue with uploading? Looks like part of HTTP header found it's way to became part of file

;WIPE_START

G1 F8640.000

G1 X123.480 Y109.004 E-0.10336

G1 X123.276 Y108.556 E-0.11374

G1 X123.884 Y108.812 E-0.15251

;WIPE_END

G1 E-0.430.204

User-Agent: Mozilla/5.0 (Windows NT 10.0; Win64; x64; rv:92.0) Gecko/20100101 Firefox/92.0

Accept: */*

Accept-Language: pl,en-US;q=0.7,en;q=0.3

Accept-Encoding: gzip, deflate

Content-Type: application/json

X-Requested-With: XMLHttpRequest

Connection: keep-alive

Referer: http://192.168.0.204/

ؽþ 2 X121.725 Y107.215 I1.405 J-0.346 E-0.16829

;WIPE_END

G1 E-0.40387 F2100.000

G1 Z9.000 F10800.000

G1 X121.068 Y104.629

G1 Z8.600

G1 E0.80000 F2100.000

M204 S800

@droftarts OK. I did exactly like You, and... it works. No idea why could not get that working yesterday. Thanks.

Ahh.... forgot the basics.

Duet3 6HC standalone, RRF 3.4.6

No multiple probes - only one (super pinda).

My issue: After powering up printer, the bed/gantry is not parallel to the XY plane. Let's say maximum difference can be like 20mm. Homing is in the middle of the bed, but... when after homing executing bed.g probing points next to lead screws creates posibility of collision with the bed. Moving to probing points with G30 does not check if probe is triggered during that move. Soo... dive height has to be large enough to make head far enough from bed during G32.

However.... After bed leveling is done, dive height could be reduced to 0.5mm to make bed probing for mesh (G29) much faster. Not sure how I can do that, as just stating M558 with H paramter returns an error

M558 H0.5

Error: M558: Z probe 0 not found

Any suggestion how this can be done properly?

@fcwilt Wouldn't it be easier to just use start.g and stop.g files that are called automatically on print start and stop instead of creating separe ones and putting a call in slicer generated g-code?

@cbrunnem2

Ad. 2 - I have M558 just to change probing speed - first fast pass for less acurate, and second slower for better accuracy

Ad. 4 - The closer to leadscrews You probe the better the results will be (more accurate). This has nothing to do with area used for printing or mesh leveling. It is just to make sure bed.g will set left and right bed motors correctly too keep bed parallel to the gantry. G32 is not the same feature as mesh bed leveling. G32 makes sure the bed and gantry are parallel to eachother. Mesh leveling (G29) compensates for bed beeing not perfectly flat.

Ad. 5 - In general it should be fine doing it once, but nothing wrong with doing it more than once

Ad. 6. for homez.g put only homing z there.

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Wed Jul 21 2021 18:08:02 GMT-0400 (Eastern Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F3600 ; lift Z relative to current position

G90 ; absolute positioning

G1 X100 Y100 F3600 ; go to first probe point

G30 ; home Z by probing the bed

that is enough for it.

Then in slicer You have a startup g-code, where You should have:

homing - G28

bed leveling - G32 (this will execute bed.g with probing next to leadscrews, and re-home Z)

mesh compensation enabled G29 S1

Bed probing before each print depends on how stable geometry Your bed has.

@cbrunnem2 For reference my startup code in prusa slicer

G90 ; use absolute coordinates

M83 ; extruder relative mode

M144 S1

M140 S[first_layer_bed_temperature] ; set bed temp

G10 P0 R120 S[first_layer_temperature_0]

M116 H0

G28 ; home all without mesh bed level

G32 ; gantry leveling

G29 S1; mesh bed compensation

@cbrunnem2 I think You created a little bit of chaos in the files trying to solve the issue. Let's sort things out.

G91

G1 H2 Z5 F12000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X100 Y100 F12000

M558 F1200

G30 ; home Z by probing the bed

M558 F120

G30 ; home Z by probing the bed

G91 ; relative positioning

G1 H1 X5.0 Y5.0 F1200

G1 H1 X-260 Y-221.5 F3000

M98 P"homez.g"

G90

After that calling G28 should home all axes, and going to Z=0 position like G1 X100 Y100 Z0 results in nozzle just barely touching the bed.

Next step would be to set bed/gantry leveling using bed.g

BTW - make sure

M671 X200:200 Y-133:567 S15

is correct. This seems a little strange looking where Your bed.g probes for bed/gantry leveling.

G30 P0 X5 Y100 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X225 Y100 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

G28 Z

should be enough, use screws coordinates that are correct for Your printer.

After that calling G28 and G32 should result in homing all axes and pribing bed in 2 (or more) points and bed leveled and re-homing Z axis.

Soo... in Your startup gcode in slicer You should have

G28

G32

sequence

If Z trigger height is set correctly, that should give You correct-ish first layer without babystepping.

After that works, You can call G29 S0 to probe the bed and save heightmap and after G32 add G29 S1 to startup gcode

@cbrunnem2 Seems Your start g-code is a little messed up. Why not homing Z, but probing?

Seems this one will not execute home.z or home_all nor bed.g at all (might be wrong, but looks that way for me).

Probing and all other stuff is on purpose in printer files, so You can just execute G28 and G32.

@cbrunnem2 Can You upload gcode that You are trying to print? Are You sure, there is no offset set in slicer or something?

When You set Z trigger height, home XYZ, and the jog to Z=0. Nozzle should be just touching printbed.

(Home XY, Home Z with probe, then jog to position where Z=0)

@cbrunnem2 So You changed in config file

G31 P500 X27.6 Y18.7 Z2.31

as 2.31 was reported by G30 S-1 and You need to baby step even more?

If You manually dial to position where Z=0 (nozzle should be just barely touching bed) is that actually the case?

BTW - IMO Z should be homed and bed probed at printing temperature, as that might affect bed shape.

What kind of printer You have?