G29 failing height map has a substantial Z offset

-

@harlock328 said in G29 failing height map has a substantial Z offset:

I put changes in config.user.g config.g says Do NOT make changes here and to modify config.user

I think you will find that you are better off combining those two into just config.g.

And keep related things together.

Frederick

-

Well this may be part of the problem.

Error: Bad command: M208 S1 Z-5 :set minimum Z travel

You can delete that command from the config files. It gets overwritten a few lines down anyway, so it doesn't have the intended effect anyway.

Still no smoking gun on why there is an offset.

The only thing that might be causing issues is the split M558 commands with some values spread all over the place, but that bug was in RRF3 and not RRF2.

At this point I would suggest backing up your config files and then creating a fresh basic config using the web configurator and testing with that. If that works correctly then we know the error is somewhere in the added complexity of your current config.

If this is a config provided by the railcore users, you may want to try checking with their discord chat to see what they think.

-

@Phaedrux said in G29 failing height map has a substantial Z offset:

Well this may be part of the problem....

In my experience the Z offset message occurs when all the points of the height map have a Z value significantly different from the Z value as determined by G30.

In this case he has probed the corners but has not included a point at or very near the point used with G30.

Which is why I suggested using a 9 points (3 by 3) such that the 5th point is at the same location as the "G30" point.

Frederick

-

@fcwilt

This worked!!!

Used M557 X45:282 Y46:254 P3:3

Ran G29; no error and below is heatmap

I like to thank everyone that was helping me.

-

@harlock328 said in G29 failing height map has a substantial Z offset:

@fcwilt

This worked!!!

Used M557 X45:282 Y46:254 P3:3Glad to here the problem has been found.

JOOC why are you using those X and Y values as apposed to round numbers, something like X50:280 Y50:260?

Thanks.

In any case now you can up the P parameters to place the points closer together, perhaps P20:20.

Frederick

-

@fcwilt

Magnet bed; numbers I found for others using 713 mag bed to avoid the mags when probing for railcore II. -

@harlock328 said in G29 failing height map has a substantial Z offset:

@fcwilt

Magnet bed; numbers I found for others using 713 mag bed to avoid the mags when probing for railcore II.Understood. I use the BuildTak FlexPlate system and it wrecked havoc with my 12mm inductive sensor at certain points.

If you had problems because of the magnets you may find that when you change to using P20:20 or similar they will crop up again.

Let us know.

Thanks.

Frederick

-

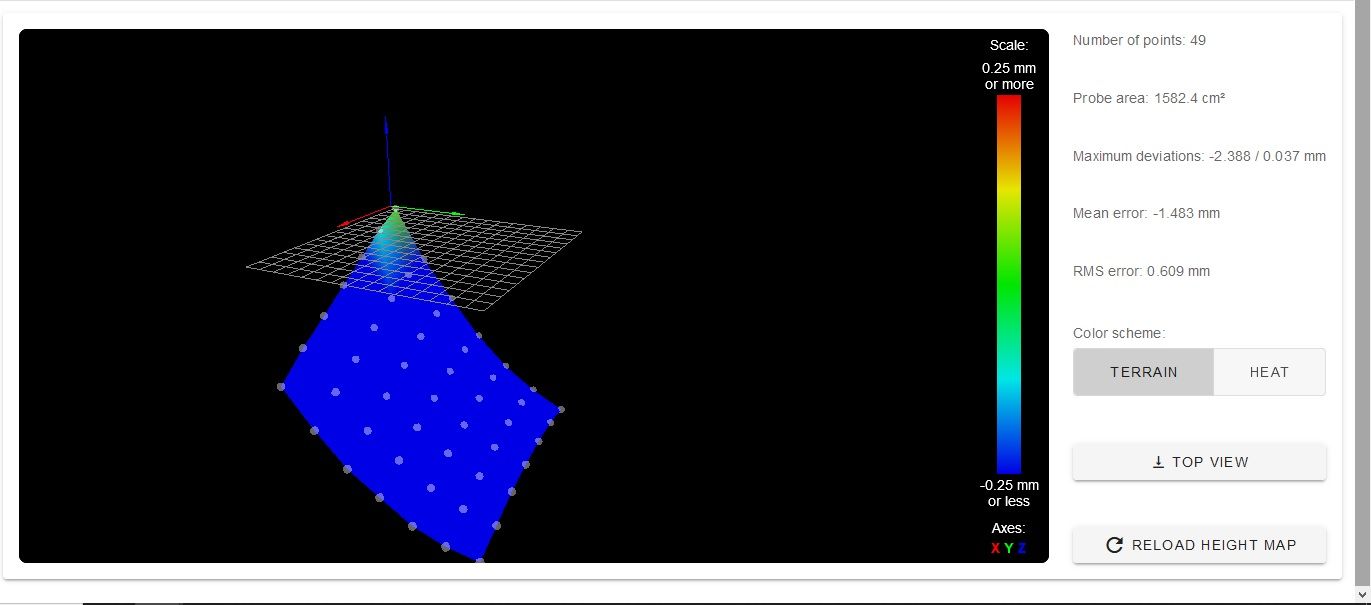

Hello everybody. I seem to have a similar problem with my z probe.I've run the G29 Mesh compensation, and the height map looks something like the pic bellow:

Now, the config.g is listed bellow:

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Oct 05 2020 11:50:08 GMT+0300 (Eastern European Summer Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Oscar" ; set printer name

M669 K1 ; select CoreXY mode; Network

M551 P"" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S0 ; disable Telnet; Drives

M584 X1 Y0 Z2 E3:4 ; set drive mapping; INIT:X=0; Y=1; Z2;E3:4

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes FORWARDS

M569 P3 S1 ; physical drive 3 goes FORWARDS

M569 P4 S0 ; physical drive 4 goes backwardsM350 X16 Y16 Z16:16 E16:16 I1 ; configure microstepping with interpolation ; INIT- M350 X16 Y16 Z16 E16:16 I1

M92 X160.00 Y160.00 Z3200.00 E881.10:881.10 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z360.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1400 Y1400 Z1200 E1200:1200 I80 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X600 Y600 Z525 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop -added "! to xstop"

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop - added"! to xstop"

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X10 Y10 Z3.5 ; set Z probe trigger value, offset and trigger height

M557 X15:470 Y15:470 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S250 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 S"Tool 1" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Tool 2" D1 H2 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

M912 P0 S-16.95 ; adjustment of the MCU temp read; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

Hi,

It looks like your probe is working but your bed needs to be leveled.

What kind of printer is it? How is the bed mounted? Does the bed have leveling adjustments?

Frederick

-

@fcwilt The bed is fixed. Is it possible to compensate via the firmware? I had a look over the "Mesh bed compensation" documentation, I have a height map which how can I use it to make the proper height compensations, and those compensations can be made with the G32 command if the Z motors are connected to the board in series( ZA;ZB)?

-

Hi,

G29 and G32 are different things.

G29 is use for mesh compensation. You used it to create the height map you posted.

If mesh compensation is active then during printing the Z position is tweaked as needed, according to the height map, to better follow the surface of the bed.

G32 is used to run the macro file bed.g. The contents of this file determine what it does.

It can do the following:

-

calibrate a delta style printer.

-

if you have manual leveling adjustments on your bed, it can probe the bed and tell you how to turn each adjustment to level your bed.

-

if you have multiple Z steppers supporting your bed in such a way that they can be used to level the bed, it can probe the bed and adjust the steppers to level the bed.

You really need 3 steppers to level a bed, 2 can only adjust the tilt in one axis, likely side-to-side.

BUT in either case you have to have steppers connected to their own drivers. The two Z connections on the Duet share a driver and cannot be used for leveling.

Now if you only had one extruder you could use the other extruder connection for one of the two Z motors.

You can still use mesh compensation during printing.

Assuming you have an existing height map you only need to do two things at the start of a print.

- use a G30 command to probe the bed at (or very near) the center of the bed, this sets the Z=0 datum.

- use a G29 S1 command to load the existing height map and thus activate mesh compensation.

Some folks create the height map at the start of every print. In that case you simply use G29 rather the G29 S1. Creating the height map also activates mesh compensation, at least for the duration of the print.

Hope that helps.

Frederick

-