Help needed - print quality issue

-

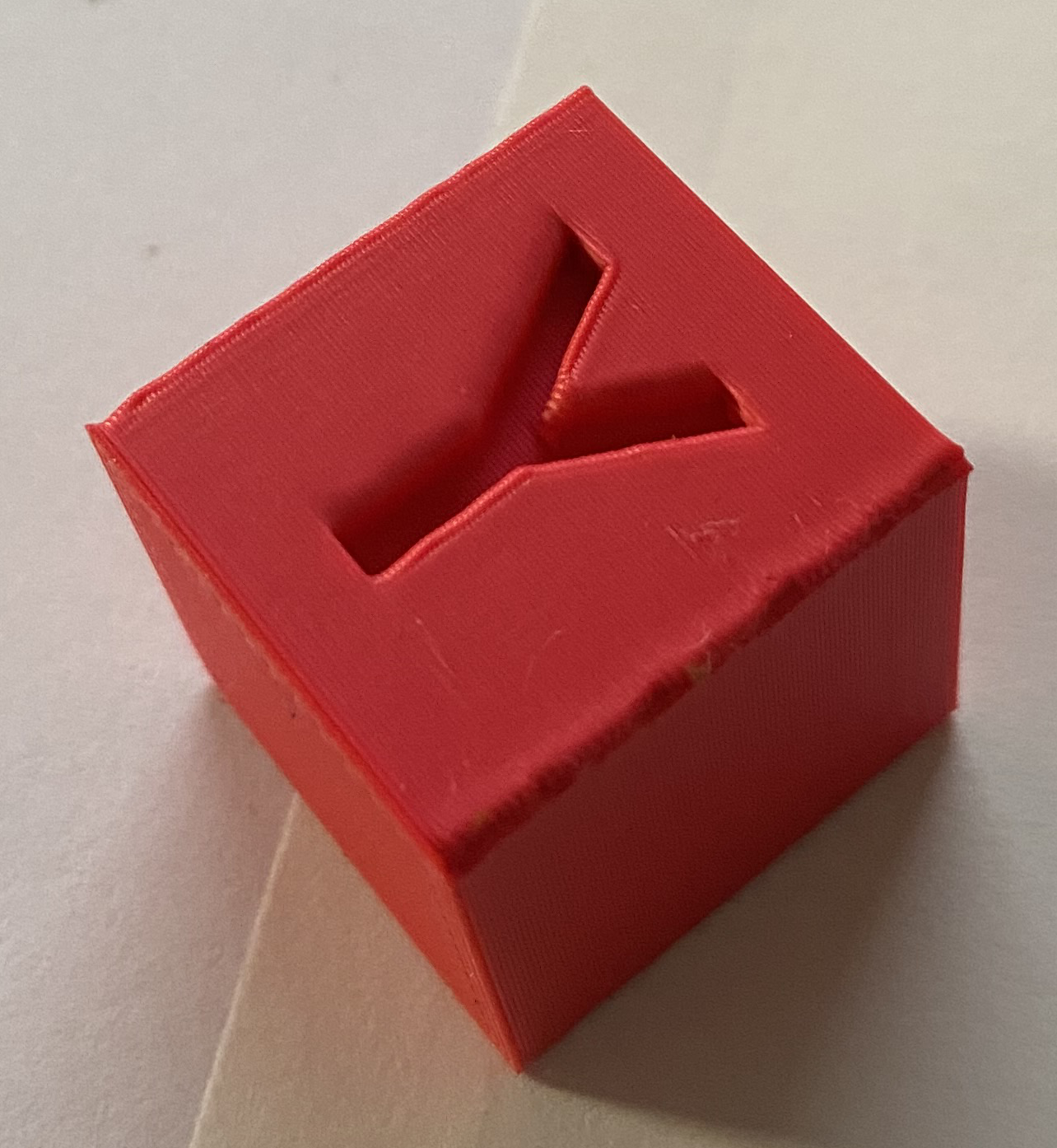

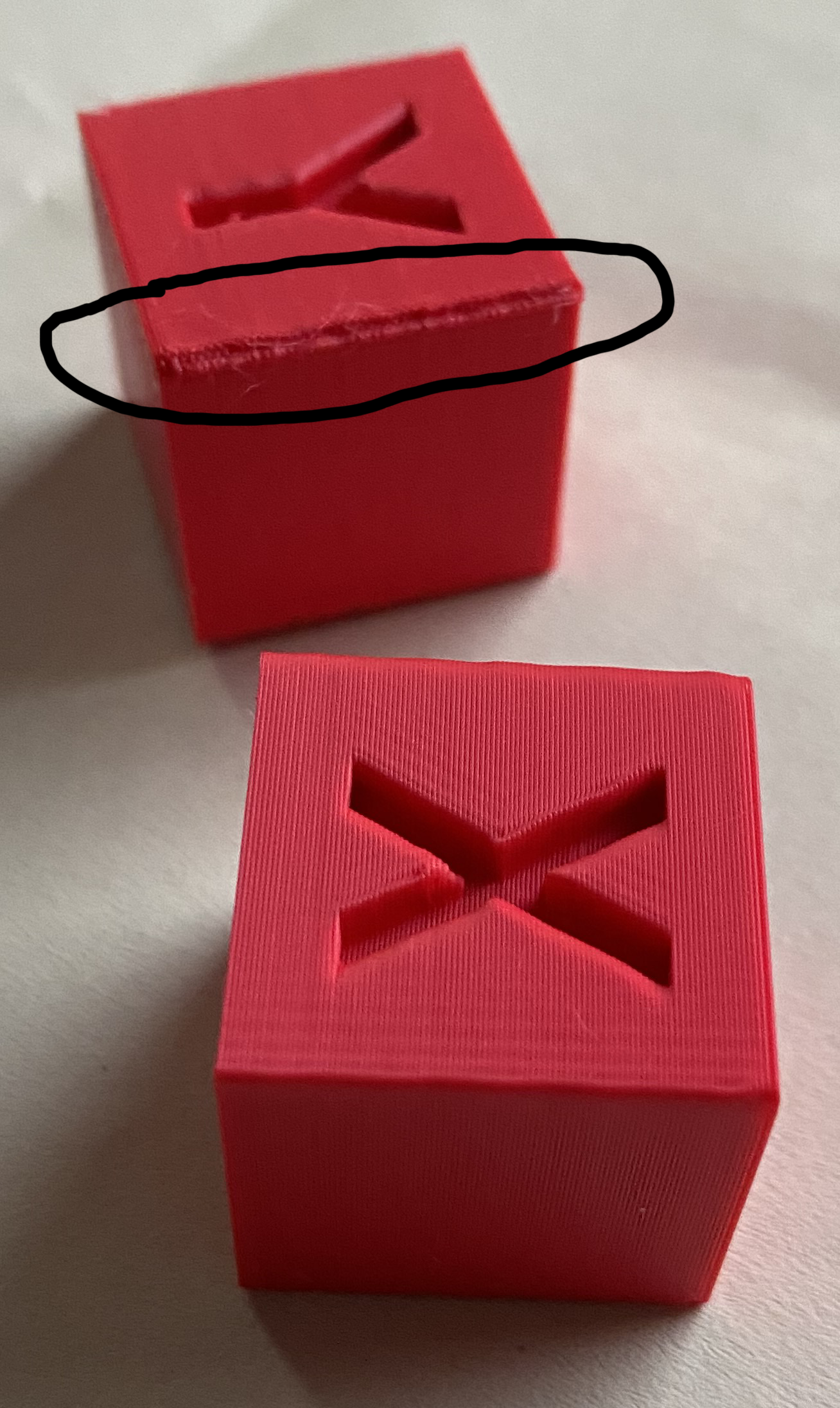

I finished my BLV mgn Cube build but unfortunately I still have some quality issues. Trying to fix that for days know but cannot figure out the cause. Any help from you experienced guys are appreciated!

Did all the tuning stuff (PID, steps, pressure advance, equal belt tension, etc.) but corners are still a mess. Any ideas what can cause this?

-

Post your settings. config.g and your slicer settings.

It looks like some corner overshoot or blobbing.

The cube also looks a bit over heated. Try printing two cubes on either side of the bed.

-

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Aug 10 2020 22:00:49 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"duet3" ; set printer name M669 K1 ; select CoreXY mode ; Drives ; X:0.0, Y:0.1, E:0.2, Z_left_rear:0.3, Z_left_front:0.4, Z_right:0.5 M569 P0.0 S0 ; physical drive 0.0 goes forwards M569 P0.1 S0 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.5 S1 ; physical drive 0.5 goes forwards M584 X0.0 Y0.1 Z0.3:0.4:0.5 E0.2 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z800.00 E405.18 ; set steps per mm ;M566 X600.00 Y600.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M566 X600.00 Y600.00 Z24.00 E2000.00 ; set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z6000.00 E2000.00 ; set maximum speeds (mm/min) ;M201 X3000.00 Y3000.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M201 X3000.00 Y3000.00 Z100.00 E2000.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z1600 E1600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Three axis setup - leadscrew positions M671 X-43:-43:370 Y320:7:161 S10 ; Set up three Z-axis location ; Axis Limits M208 X-13 Y0 Z0 S1 ; set axis minima M208 X320 Y315 Z340 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io3.in" ; configure active-high endstop for low end on X via pin io3.in M574 Y1 S1 P"io4.in" ; configure active-high endstop for high end on Y via pin io4.in ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" R0.5 H5 F100 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X36.47 Y-4 Z1.153 ; set Z probe trigger value, offset and trigger height M557 X29:316 Y14:310 P5:5 ; define mesh grid ; Heaters M308 S0 P"temp1" Y"thermistor" T95000 B3950 ; configure sensor 0 as thermistor on pin temp1 M950 H0 C"out2" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"out3" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency M106 P0 S0 H-1 C"Bed" ;M950 F1 C"!out5+out5.tach" ;M106 P1 S1 H-1 I1 C"Hotend" ; set fan 0 value. Thermostatic control is turned off M950 F2 C"out8" Q500 ; create fan 2 on pin out6 and set its frequency M106 P2 S0.33 H-1 C"Board" ; set fan 2 value. Thermostatic control is turned off M950 F3 C"out7" Q500 ; create fan 3 on pin out7 and set its frequency M106 P3 S0.5 H-1 C"SBC" ; set fan 3 value. Thermostatic control is turned off ; Tools M563 P0 S"Hotend" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B115200 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory T0 ; select first tool M572 D0 S0.1 ; set pressure advance; G-Code generated by Simplify3D(R) Version 4.1.2 ; Oct 1, 2020 at 11:24:37 AM ; Settings Summary ; processName,Process1 ; applyToModels,xyzCalibration_cube ; profileName,Cube - PLA ; profileVersion,2020-09-30 15:35:27 ; baseProfile,Creality Ender 3 ; printMaterial,PLA ; printQuality,Medium ; printExtruders, ; extruderName,Primary Extruder ; extruderToolheadNumber,0 ; extruderDiameter,0.4 ; extruderAutoWidth,0 ; extruderWidth,0.4 ; extrusionMultiplier,0.96 ; extruderUseRetract,1 ; extruderRetractionDistance,0.75 ; extruderExtraRestartDistance,0.05 ; extruderRetractionZLift,0.2 ; extruderRetractionSpeed,3600 ; extruderUseCoasting,0 ; extruderCoastingDistance,0.1 ; extruderUseWipe,0 ; extruderWipeDistance,1 ; primaryExtruder,0 ; layerHeight,0.2 ; topSolidLayers,3 ; bottomSolidLayers,3 ; perimeterOutlines,3 ; printPerimetersInsideOut,1 ; startPointOption,3 ; startPointOriginX,0 ; startPointOriginY,500 ; sequentialIslands,0 ; spiralVaseMode,0 ; firstLayerHeightPercentage,120 ; firstLayerWidthPercentage,120 ; firstLayerUnderspeed,0.3 ; useRaft,0 ; raftExtruder,0 ; raftTopLayers,2 ; raftBaseLayers,2 ; raftOffset,4 ; raftSeparationDistance,0.14 ; raftTopInfill,100 ; aboveRaftSpeedMultiplier,0.5 ; useSkirt,1 ; skirtExtruder,0 ; skirtLayers,1 ; skirtOutlines,2 ; skirtOffset,4 ; usePrimePillar,0 ; primePillarExtruder,999 ; primePillarWidth,12 ; primePillarLocation,7 ; primePillarSpeedMultiplier,1 ; useOozeShield,0 ; oozeShieldExtruder,999 ; oozeShieldOffset,2 ; oozeShieldOutlines,1 ; oozeShieldSidewallShape,1 ; oozeShieldSidewallAngle,30 ; oozeShieldSpeedMultiplier,1 ; infillExtruder,0 ; internalInfillPattern,Rectilinear ; externalInfillPattern,Rectilinear ; infillPercentage,20 ; outlineOverlapPercentage,40 ; infillExtrusionWidthPercentage,100 ; minInfillLength,5 ; infillLayerInterval,1 ; internalInfillAngles,45,-45 ; overlapInternalInfillAngles,0 ; externalInfillAngles,45,-45 ; generateSupport,0 ; supportExtruder,0 ; supportInfillPercentage,25 ; supportExtraInflation,1 ; supportBaseLayers,0 ; denseSupportExtruder,0 ; denseSupportLayers,0 ; denseSupportInfillPercentage,15 ; supportLayerInterval,1 ; supportHorizontalPartOffset,1 ; supportUpperSeparationLayers,1 ; supportLowerSeparationLayers,1 ; supportType,0 ; supportGridSpacing,4 ; maxOverhangAngle,50 ; supportAngles,45,-45 ; temperatureName,Primary Extruder,Heated Bed ; temperatureNumber,0,0 ; temperatureSetpointCount,1,1 ; temperatureSetpointLayers,1,1 ; temperatureSetpointTemperatures,190,60 ; temperatureStabilizeAtStartup,1,1 ; temperatureHeatedBed,0,1 ; fanLayers,1,2 ; fanSpeeds,0,100 ; blipFanToFullPower,0 ; adjustSpeedForCooling,0 ; minSpeedLayerTime,15 ; minCoolingSpeedSlowdown,40 ; increaseFanForCooling,0 ; minFanLayerTime,45 ; maxCoolingFanSpeed,100 ; increaseFanForBridging,1 ; bridgingFanSpeed,100 ; use5D,1 ; relativeEdistances,0 ; allowEaxisZeroing,1 ; independentExtruderAxes,0 ; includeM10123,0 ; stickySupport,1 ; applyToolheadOffsets,0 ; gcodeXoffset,0 ; gcodeYoffset,0 ; gcodeZoffset,0 ; overrideMachineDefinition,1 ; machineTypeOverride,0 ; strokeXoverride,330 ; strokeYoverride,330 ; strokeZoverride,400 ; originOffsetXoverride,0 ; originOffsetYoverride,0 ; originOffsetZoverride,0 ; homeXdirOverride,-1 ; homeYdirOverride,-1 ; homeZdirOverride,-1 ; flipXoverride,1 ; flipYoverride,-1 ; flipZoverride,1 ; toolheadOffsets,0,0|0,0|0,0|0,0|0,0|0,0 ; overrideFirmwareConfiguration,1 ; firmwareTypeOverride,RepRap (Marlin/Repetier/Sprinter) ; GPXconfigOverride,r2 ; baudRateOverride,115200 ; overridePrinterModels,1 ; printerModelsOverride ; startingGcode,G21 ; metric values,G90 ; set absolute positioning,G28 ; home all,M561 ; Disable any current bed compensation,G1 X150 Y150 F6000,G90 G1 Z3 F400,M400,G92 Z4 ; Reset z to 8 to allow jogging up to touch bed to nozzle,M291 P"Jog the Z Axis until the bed and nozzle are touching and click OK" R"Setting Z=0" Z1 S3,M400,G92 Z0 ; Set z = 0,G90 G1 Z3 F400,M400,G1 Z5,M400,G30 S-1,M400,G1 Z5,M400,G30 S-1,M400,G1 Z5,M400,G30 S-1,M400,G1 Z5,M400,G30 S-1,M400,G1 Z5,M400,G30 S-3 ; measure probe height and set it.,M400,M500 P31 ; save trigger height to config-override.g,G1 Z5,M400,M557 X29:316 Y14:310 S20:20 ; mesh grid dummy,G29 ; mesh bed leveling,G29 S1 ; load bed mesh,M221 S90 ; set extrusion factor,G92 E0 F100 ; reset extruder,G1 X12 Y166 Z5 F6000 ; move to wipe,G1 E10 F300 ; extract 10mm filament to fill nozzle,G92 E0 ; reset extrusion distance,G1 X-8 Y166 Z3 F6000,G1 X-8 Y196 F6000,G1 X-8 Y166 F6000,G1 X-8 Y196 F6000,G1 X-8 Y166 F6000,G1 X-8 Y196 F6000,G1 X-8 Y166 F6000,G1 X-8 Y196 F6000,G1 X-8 Y166 F6000, ; layerChangeGcode, ; retractionGcode, ; toolChangeGcode, ; endingGcode,G90 ; absolute positioning,G1 X0 Y0 Z10 F3000 ; move z 10mm up,M106 S0 ; turn off cooling fan,M104 S0 ; turn off extruder,M140 S0 ; turn off bed,M84 ; disable motors, ; exportFileFormat,gcode ; celebration,0 ; celebrationSong,Funky Town ; postProcessing,/Library/Frameworks/Python.framework/Versions/3.7/bin/python3 /Users/martin.ziegler/tools/bin/meshgrid.py "[output_filepath]" ; defaultSpeed,3600 ; outlineUnderspeed,0.5 ; solidInfillUnderspeed,0.5 ; supportUnderspeed,1 ; rapidXYspeed,9000 ; rapidZspeed,1002 ; minBridgingArea,50 ; bridgingExtraInflation,5 ; bridgingExtrusionMultiplier,1.05 ; bridgingSpeedMultiplier,0.8 ; useFixedBridgingAngle,0 ; fixedBridgingAngle,0 ; applyBridgingToPerimeters,1 ; filamentDiameters,1.75|1.75|1.75|1.75|1.75|1.75 ; filamentPricesPerKg,30|46|46|46|46|46 ; filamentDensities,1.25|1.25|1.25|1.25|1.25|1.25 ; useMinPrintHeight,0 ; minPrintHeight,0 ; useMaxPrintHeight,0 ; maxPrintHeight,0 ; useDiaphragm,0 ; diaphragmLayerInterval,20 ; robustSlicing,1 ; mergeAllIntoSolid,0 ; onlyRetractWhenCrossingOutline,0 ; retractBetweenLayers,0 ; useRetractionMinTravel,1 ; retractionMinTravel,2 ; retractWhileWiping,1 ; onlyWipeOutlines,1 ; avoidCrossingOutline,1 ; maxMovementDetourFactor,3 ; toolChangeRetractionDistance,0 ; toolChangeExtraRestartDistance,0 ; toolChangeRetractionSpeed,600 ; externalThinWallType,0 ; internalThinWallType,2 ; thinWallAllowedOverlapPercentage,10 ; singleExtrusionMinLength,1 ; singleExtrusionMinPrintingWidthPercentage,50 ; singleExtrusionMaxPrintingWidthPercentage,200 ; singleExtrusionEndpointExtension,0.2 ; horizontalSizeCompensation,0 -

@MartinNYHC said in Help needed - print quality issue:

extruderExtraRestartDistance,0.05

Perhaps too much extra restart?

I think it's also a good idea to have at least 2 slicers configured and ready to go so you can compare results. That can really help narrow down if it's a machine issue or a slicing issue.

-

@Phaedrux said in Help needed - print quality issue:

@MartinNYHC said in Help needed - print quality issue:

extruderExtraRestartDistance,0.05

Perhaps too much extra restart?

I think it's also a good idea to have at least 2 slicers configured and ready to go so you can compare results. That can really help narrow down if it's a machine issue or a slicing issue.

Thanks.

I used this extruder and hotend for some months on another printer and 0.05 restart was perfect. But I'll doube check it and also try a different slicer.

Currently printing two cubes at the side of the bed.

-

@MartinNYHC said in Help needed - print quality issue:

extruderRetractionDistance,0.75

M572 D0 S0.1

Your pressure advance seems high for a retraction distance of 0.75

-

@Veti said in Help needed - print quality issue:

@MartinNYHC said in Help needed - print quality issue:

extruderRetractionDistance,0.75

M572 D0 S0.1

Your pressure advance seems high for a retraction distance of 0.75

I always used 1mm retraction and did a PA test. Result can be found here. I lowered the retraction this morning to check if that changes anything.

-

I just recognized that the "bad corner" is always the one where the layer starts.

-

As already mentioned it is always the corner where the layer starts that is "bad".

I'm totally lost. Any ideas please?

-

And another pressurte advance test...

-

Another Benchy...

-

what extruder do you have?

-

Bondtech, Mosquito Magnum with approx. 20mm PTFE tube between.

-

can you try to adjust to bondtech tension to a lot higher and try that?

-

@Veti said in Help needed - print quality issue:

can you try to adjust to bondtech tension to a lot higher and try that?

No difference. Still the corner where the layer starts

-

you did not yet say if the print with another slicer was better

-

@Veti said in Help needed - print quality issue:

you did not yet say if the print with another slicer was better

Oh sorry....no it's the same result.

-

and did you print one without pressure advance?

-

Yes, but in the meantine I changed some settings. Will do another print without PA.

I fear the worst that it is a mechanical issue. When I compare the prints the "bad corner" has the same pattern:

-

Without pressure advance it looks better but I still have the scars where the layer starts. I don't have an idea at all what to do next. Any more ideas from you experienced guys are very appreciated!