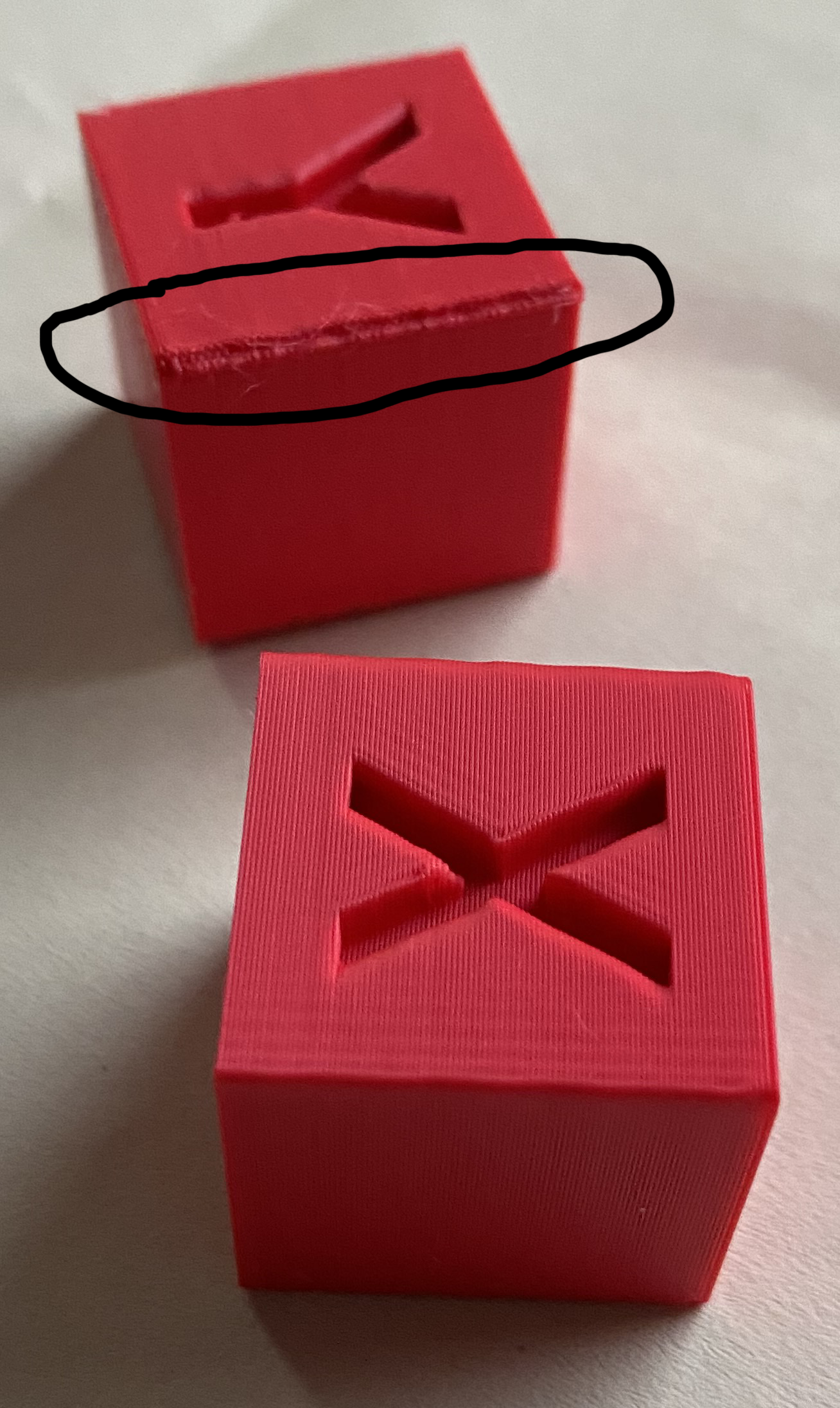

Help needed - print quality issue

-

Post your settings. config.g and your slicer settings.

It looks like some corner overshoot or blobbing.

The cube also looks a bit over heated. Try printing two cubes on either side of the bed.

-

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Aug 10 2020 22:00:49 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"duet3" ; set printer name M669 K1 ; select CoreXY mode ; Drives ; X:0.0, Y:0.1, E:0.2, Z_left_rear:0.3, Z_left_front:0.4, Z_right:0.5 M569 P0.0 S0 ; physical drive 0.0 goes forwards M569 P0.1 S0 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.5 S1 ; physical drive 0.5 goes forwards M584 X0.0 Y0.1 Z0.3:0.4:0.5 E0.2 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z800.00 E405.18 ; set steps per mm ;M566 X600.00 Y600.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M566 X600.00 Y600.00 Z24.00 E2000.00 ; set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z6000.00 E2000.00 ; set maximum speeds (mm/min) ;M201 X3000.00 Y3000.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M201 X3000.00 Y3000.00 Z100.00 E2000.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z1600 E1600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Three axis setup - leadscrew positions M671 X-43:-43:370 Y320:7:161 S10 ; Set up three Z-axis location ; Axis Limits M208 X-13 Y0 Z0 S1 ; set axis minima M208 X320 Y315 Z340 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io3.in" ; configure active-high endstop for low end on X via pin io3.in M574 Y1 S1 P"io4.in" ; configure active-high endstop for high end on Y via pin io4.in ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" R0.5 H5 F100 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X36.47 Y-4 Z1.153 ; set Z probe trigger value, offset and trigger height M557 X29:316 Y14:310 P5:5 ; define mesh grid ; Heaters M308 S0 P"temp1" Y"thermistor" T95000 B3950 ; configure sensor 0 as thermistor on pin temp1 M950 H0 C"out2" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"out3" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency M106 P0 S0 H-1 C"Bed" ;M950 F1 C"!out5+out5.tach" ;M106 P1 S1 H-1 I1 C"Hotend" ; set fan 0 value. Thermostatic control is turned off M950 F2 C"out8" Q500 ; create fan 2 on pin out6 and set its frequency M106 P2 S0.33 H-1 C"Board" ; set fan 2 value. Thermostatic control is turned off M950 F3 C"out7" Q500 ; create fan 3 on pin out7 and set its frequency M106 P3 S0.5 H-1 C"SBC" ; set fan 3 value. Thermostatic control is turned off ; Tools M563 P0 S"Hotend" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B115200 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory T0 ; select first tool M572 D0 S0.1 ; set pressure advance; G-Code generated by Simplify3D(R) Version 4.1.2 ; Oct 1, 2020 at 11:24:37 AM ; Settings Summary ; processName,Process1 ; applyToModels,xyzCalibration_cube ; profileName,Cube - PLA ; profileVersion,2020-09-30 15:35:27 ; baseProfile,Creality Ender 3 ; printMaterial,PLA ; printQuality,Medium ; printExtruders, ; extruderName,Primary Extruder ; extruderToolheadNumber,0 ; extruderDiameter,0.4 ; extruderAutoWidth,0 ; extruderWidth,0.4 ; extrusionMultiplier,0.96 ; extruderUseRetract,1 ; extruderRetractionDistance,0.75 ; extruderExtraRestartDistance,0.05 ; extruderRetractionZLift,0.2 ; extruderRetractionSpeed,3600 ; extruderUseCoasting,0 ; extruderCoastingDistance,0.1 ; extruderUseWipe,0 ; extruderWipeDistance,1 ; primaryExtruder,0 ; layerHeight,0.2 ; topSolidLayers,3 ; bottomSolidLayers,3 ; perimeterOutlines,3 ; printPerimetersInsideOut,1 ; startPointOption,3 ; startPointOriginX,0 ; startPointOriginY,500 ; sequentialIslands,0 ; spiralVaseMode,0 ; firstLayerHeightPercentage,120 ; firstLayerWidthPercentage,120 ; firstLayerUnderspeed,0.3 ; useRaft,0 ; raftExtruder,0 ; raftTopLayers,2 ; raftBaseLayers,2 ; raftOffset,4 ; raftSeparationDistance,0.14 ; raftTopInfill,100 ; aboveRaftSpeedMultiplier,0.5 ; useSkirt,1 ; skirtExtruder,0 ; skirtLayers,1 ; skirtOutlines,2 ; skirtOffset,4 ; usePrimePillar,0 ; primePillarExtruder,999 ; primePillarWidth,12 ; primePillarLocation,7 ; primePillarSpeedMultiplier,1 ; useOozeShield,0 ; oozeShieldExtruder,999 ; oozeShieldOffset,2 ; oozeShieldOutlines,1 ; oozeShieldSidewallShape,1 ; oozeShieldSidewallAngle,30 ; oozeShieldSpeedMultiplier,1 ; infillExtruder,0 ; internalInfillPattern,Rectilinear ; externalInfillPattern,Rectilinear ; infillPercentage,20 ; outlineOverlapPercentage,40 ; infillExtrusionWidthPercentage,100 ; minInfillLength,5 ; infillLayerInterval,1 ; internalInfillAngles,45,-45 ; overlapInternalInfillAngles,0 ; externalInfillAngles,45,-45 ; generateSupport,0 ; supportExtruder,0 ; supportInfillPercentage,25 ; supportExtraInflation,1 ; supportBaseLayers,0 ; denseSupportExtruder,0 ; denseSupportLayers,0 ; denseSupportInfillPercentage,15 ; supportLayerInterval,1 ; supportHorizontalPartOffset,1 ; supportUpperSeparationLayers,1 ; supportLowerSeparationLayers,1 ; supportType,0 ; supportGridSpacing,4 ; maxOverhangAngle,50 ; supportAngles,45,-45 ; temperatureName,Primary Extruder,Heated Bed ; temperatureNumber,0,0 ; temperatureSetpointCount,1,1 ; temperatureSetpointLayers,1,1 ; temperatureSetpointTemperatures,190,60 ; temperatureStabilizeAtStartup,1,1 ; temperatureHeatedBed,0,1 ; fanLayers,1,2 ; fanSpeeds,0,100 ; blipFanToFullPower,0 ; adjustSpeedForCooling,0 ; minSpeedLayerTime,15 ; minCoolingSpeedSlowdown,40 ; increaseFanForCooling,0 ; minFanLayerTime,45 ; maxCoolingFanSpeed,100 ; increaseFanForBridging,1 ; bridgingFanSpeed,100 ; use5D,1 ; relativeEdistances,0 ; allowEaxisZeroing,1 ; independentExtruderAxes,0 ; includeM10123,0 ; stickySupport,1 ; applyToolheadOffsets,0 ; gcodeXoffset,0 ; gcodeYoffset,0 ; gcodeZoffset,0 ; overrideMachineDefinition,1 ; machineTypeOverride,0 ; strokeXoverride,330 ; strokeYoverride,330 ; strokeZoverride,400 ; originOffsetXoverride,0 ; originOffsetYoverride,0 ; originOffsetZoverride,0 ; homeXdirOverride,-1 ; homeYdirOverride,-1 ; homeZdirOverride,-1 ; flipXoverride,1 ; flipYoverride,-1 ; flipZoverride,1 ; toolheadOffsets,0,0|0,0|0,0|0,0|0,0|0,0 ; overrideFirmwareConfiguration,1 ; firmwareTypeOverride,RepRap (Marlin/Repetier/Sprinter) ; GPXconfigOverride,r2 ; baudRateOverride,115200 ; overridePrinterModels,1 ; printerModelsOverride ; startingGcode,G21 ; metric values,G90 ; set absolute positioning,G28 ; home all,M561 ; Disable any current bed compensation,G1 X150 Y150 F6000,G90 G1 Z3 F400,M400,G92 Z4 ; Reset z to 8 to allow jogging up to touch bed to nozzle,M291 P"Jog the Z Axis until the bed and nozzle are touching and click OK" R"Setting Z=0" Z1 S3,M400,G92 Z0 ; Set z = 0,G90 G1 Z3 F400,M400,G1 Z5,M400,G30 S-1,M400,G1 Z5,M400,G30 S-1,M400,G1 Z5,M400,G30 S-1,M400,G1 Z5,M400,G30 S-1,M400,G1 Z5,M400,G30 S-3 ; measure probe height and set it.,M400,M500 P31 ; save trigger height to config-override.g,G1 Z5,M400,M557 X29:316 Y14:310 S20:20 ; mesh grid dummy,G29 ; mesh bed leveling,G29 S1 ; load bed mesh,M221 S90 ; set extrusion factor,G92 E0 F100 ; reset extruder,G1 X12 Y166 Z5 F6000 ; move to wipe,G1 E10 F300 ; extract 10mm filament to fill nozzle,G92 E0 ; reset extrusion distance,G1 X-8 Y166 Z3 F6000,G1 X-8 Y196 F6000,G1 X-8 Y166 F6000,G1 X-8 Y196 F6000,G1 X-8 Y166 F6000,G1 X-8 Y196 F6000,G1 X-8 Y166 F6000,G1 X-8 Y196 F6000,G1 X-8 Y166 F6000, ; layerChangeGcode, ; retractionGcode, ; toolChangeGcode, ; endingGcode,G90 ; absolute positioning,G1 X0 Y0 Z10 F3000 ; move z 10mm up,M106 S0 ; turn off cooling fan,M104 S0 ; turn off extruder,M140 S0 ; turn off bed,M84 ; disable motors, ; exportFileFormat,gcode ; celebration,0 ; celebrationSong,Funky Town ; postProcessing,/Library/Frameworks/Python.framework/Versions/3.7/bin/python3 /Users/martin.ziegler/tools/bin/meshgrid.py "[output_filepath]" ; defaultSpeed,3600 ; outlineUnderspeed,0.5 ; solidInfillUnderspeed,0.5 ; supportUnderspeed,1 ; rapidXYspeed,9000 ; rapidZspeed,1002 ; minBridgingArea,50 ; bridgingExtraInflation,5 ; bridgingExtrusionMultiplier,1.05 ; bridgingSpeedMultiplier,0.8 ; useFixedBridgingAngle,0 ; fixedBridgingAngle,0 ; applyBridgingToPerimeters,1 ; filamentDiameters,1.75|1.75|1.75|1.75|1.75|1.75 ; filamentPricesPerKg,30|46|46|46|46|46 ; filamentDensities,1.25|1.25|1.25|1.25|1.25|1.25 ; useMinPrintHeight,0 ; minPrintHeight,0 ; useMaxPrintHeight,0 ; maxPrintHeight,0 ; useDiaphragm,0 ; diaphragmLayerInterval,20 ; robustSlicing,1 ; mergeAllIntoSolid,0 ; onlyRetractWhenCrossingOutline,0 ; retractBetweenLayers,0 ; useRetractionMinTravel,1 ; retractionMinTravel,2 ; retractWhileWiping,1 ; onlyWipeOutlines,1 ; avoidCrossingOutline,1 ; maxMovementDetourFactor,3 ; toolChangeRetractionDistance,0 ; toolChangeExtraRestartDistance,0 ; toolChangeRetractionSpeed,600 ; externalThinWallType,0 ; internalThinWallType,2 ; thinWallAllowedOverlapPercentage,10 ; singleExtrusionMinLength,1 ; singleExtrusionMinPrintingWidthPercentage,50 ; singleExtrusionMaxPrintingWidthPercentage,200 ; singleExtrusionEndpointExtension,0.2 ; horizontalSizeCompensation,0 -

@MartinNYHC said in Help needed - print quality issue:

extruderExtraRestartDistance,0.05

Perhaps too much extra restart?

I think it's also a good idea to have at least 2 slicers configured and ready to go so you can compare results. That can really help narrow down if it's a machine issue or a slicing issue.

-

@Phaedrux said in Help needed - print quality issue:

@MartinNYHC said in Help needed - print quality issue:

extruderExtraRestartDistance,0.05

Perhaps too much extra restart?

I think it's also a good idea to have at least 2 slicers configured and ready to go so you can compare results. That can really help narrow down if it's a machine issue or a slicing issue.

Thanks.

I used this extruder and hotend for some months on another printer and 0.05 restart was perfect. But I'll doube check it and also try a different slicer.

Currently printing two cubes at the side of the bed.

-

@MartinNYHC said in Help needed - print quality issue:

extruderRetractionDistance,0.75

M572 D0 S0.1

Your pressure advance seems high for a retraction distance of 0.75

-

@Veti said in Help needed - print quality issue:

@MartinNYHC said in Help needed - print quality issue:

extruderRetractionDistance,0.75

M572 D0 S0.1

Your pressure advance seems high for a retraction distance of 0.75

I always used 1mm retraction and did a PA test. Result can be found here. I lowered the retraction this morning to check if that changes anything.

-

I just recognized that the "bad corner" is always the one where the layer starts.

-

As already mentioned it is always the corner where the layer starts that is "bad".

I'm totally lost. Any ideas please?

-

And another pressurte advance test...

-

Another Benchy...

-

what extruder do you have?

-

Bondtech, Mosquito Magnum with approx. 20mm PTFE tube between.

-

can you try to adjust to bondtech tension to a lot higher and try that?

-

@Veti said in Help needed - print quality issue:

can you try to adjust to bondtech tension to a lot higher and try that?

No difference. Still the corner where the layer starts

-

you did not yet say if the print with another slicer was better

-

@Veti said in Help needed - print quality issue:

you did not yet say if the print with another slicer was better

Oh sorry....no it's the same result.

-

and did you print one without pressure advance?

-

Yes, but in the meantine I changed some settings. Will do another print without PA.

I fear the worst that it is a mechanical issue. When I compare the prints the "bad corner" has the same pattern:

-

Without pressure advance it looks better but I still have the scars where the layer starts. I don't have an idea at all what to do next. Any more ideas from you experienced guys are very appreciated!

-

@MartinNYHC said in Help needed - print quality issue:

And another pressurte advance test...

What PA value did you land on?