Kind help on req Duet3d hardware based on specification

-

Thank you for the confirmation!!

i have 5 axis stepper motors (x,y, z1, z2, z3) and 2 extruder ones (titan aqua), so in total 7 stepper motors.

I am sure about the 5 to connect with 6hc directly to use the onboard stepper motor drivers, but the additional 2 titan extruder may fit as well without any expansion ?

And in case I cant get the Duet3D magnetic filament monitor as it seems out of stock everywhere, can you recommend any other you trust and can be well connected to 6hc ?

Many many thanks for your time and help!

-

@dc42 Not to hurry you, just to be able to step forward, may I ask your kind help on the 2 questions above? So:

- if all 7 stepper motors (5 axis, 2 extruder) can be connected to 6HC directly ?

- can you recommend any other reliable filament sensor works with 6hc direct (because duet3d cant be purchased anywhere)

BIG BIG thanks in advance, and sorry to take your time.

-

@coolice2020 the 6HC only supports 6 drives directly. To add any more you will have to use either a 3HC or toolboard via CAN

-

Thanks, so to summarize, the best way to do this is:

- Buy and connect a 3HC expansion board with twisted pair (as I found based on search) cable to 6HC

- Connect 5 axis, 1 extruder stepper motors and its filament sensor to 6HC

- Connect 1 extruder stepper motor and its filament sensor to 3HC

So, at this way, I can fit all steppers, plus their filament sensors on the same board as dc42 indicated it above.

Correct ?

-

Yes. The cable between the 6HC and the 3HC would be a high speed ADSL cable with RJ11 connectors.

Your other option is a 6HC and 1 or more toolboards. This would reduce wiring to the extruder/hot end if you're running direct drives. It allows everything to be connected using 4 CAN cables (or possibly even 2) and 2 power cables. I think 2 tool boards and a distribution board is about the same as a 3HC.

https://www.duet3d.com/Duet3Toolboard1LC

https://www.duet3d.com/Duet3ToolDistribution -

@jay_s_uk

Awesome, thanks for the heads-up!!May I ask if by any chance you could recommend a reliable end switch for the axis ends which also connect to 6HC well ?

-

I mainly go with optical endstops on my machines but switches also work very well.

-

Can you recommend an optical endstop if thats more pro pls, which you have experience with and fit well with 6HC ? I will go that way too .

-

I use this type.

https://www.amazon.co.uk/dp/B07DK3J88S/ref=cm_sw_r_cp_apa_i_NdBPFbH6KK1K9

I have them fitted to my tool hanger and they are very repeatable. -

Awesome, thanks! Dummy question:

It is has to be mounted to ensure, that this part (the red X) where the moving part has to touch it ?

OR

A thin "flag" has to get into the U shape to block ?

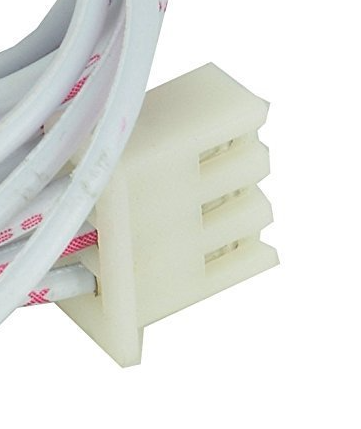

And this is the connector which is compatible with the 6HC or it is need to be replaced with ?

-

The moving part typically has a tab that goes into the gap where you've marked red. This then breaks the beam and indicated the endstop has been triggered.

That end you've shown is connected into the optical endstop and then the other end typically has bare wires for you to crimp with the appropriate connector for the board you are installing to. -

@jay_s_uk Thank you !!!! Have a lovely weekend!