Kind help on req Duet3d hardware based on specification

-

@Veti Big thanks, and I did read the SSR article you pointed to me already, I even have the SSR wiring diagram, so allow me to rephrase myself:

Having only a built-in thermistor and a properly applied SSR, is enough for Duet 3 to control on/of and specific celsius temperature, right ?

(So basically all not needed watts will be "burned" at SSR, simple is that if I understand well the concept behind)

-

a ssr will turn the power on or off as needed. like a switch. if the switch is off no power flows.

the thermistor reads the temperature.as long as the temperature is below the requests temperature the duet will let the power flow.

if its above the requested temperature , the power is turned off. -

@Veti SUPER CLEAR!!!!!!!!!!!!!!!!!!!!!!!!!!

I will add a fuse too, just as suggested in docwiki.

Big thank you !!!!!

(PS: i mark this for solved now, until i have new question. )

-

May I ask an other quick question:

I am planning to use 2pcs (since dual head) of Duet3D magnetic filament monitor.

Questions:

- Did I understood right, that this will work with ALL filament (even PVA or transparent) ?

- Did I understood right, that BOTh can be attached directly to Duet 3 6HC without the need of any daughterboard or other extension ?

- Do you truly recommend this? (I am asking this, as its very hard to buy, so would be great to know if this worth it or you recommend something else ?

Many many thanks for your time and help!!

-

i dont use filament runout sensors. i prefer to use my eyes.

someone else might be able to comment.

-

@ Veti

Truly ? I see. In my case it can happen e.g. overnight, so I would love to make sure, that he printing paused, while I refill the filament.

Hoping may others can respond, especially on the technical prospective, whether the 2 filament sensor can be attached directly to the Duet 3 6hc, right ? I am asking this, because after reviewing this 2 docwiki source, it still not fully clear:

https://duet3d.dozuki.com/Wiki/Connecting_and_configuring_filament-out_sensors

https://duet3d.dozuki.com/Wiki/Duet3dFilamentMonitor_RotatingMagnetVersion

-

@coolice2020 said in Kind help on req Duet3d hardware based on specification:

Truly ? I see. In my case it can happen e.g. overnight, so I would love to make sure, that he printing paused, while I refill the filament.

the slicer will generate the amount of filament required in grams.

you can then weight the spool to see if there is enough filament on the spool before the print. -

Yes you can attach several filament monitors to a 6HC. In RRF 3.2beta3, filament monitors attached to tool and expansion boards are supported too.

Please note, in all cases the filament monitor must be connected to the same board as the corresponding extruder drive motor. This is so that the firmware can correlate the commanded extrusion with the measured extrusion in real time.

-

Fair point, however, when you dont want to have many spools with a small bit of filament left, without a sensor, you are unable to use a complete spool 100%, at least in my experience.

-

i use the small leftovers, when i print smaller parts

-

Thank you for the confirmation!!

i have 5 axis stepper motors (x,y, z1, z2, z3) and 2 extruder ones (titan aqua), so in total 7 stepper motors.

I am sure about the 5 to connect with 6hc directly to use the onboard stepper motor drivers, but the additional 2 titan extruder may fit as well without any expansion ?

And in case I cant get the Duet3D magnetic filament monitor as it seems out of stock everywhere, can you recommend any other you trust and can be well connected to 6hc ?

Many many thanks for your time and help!

-

@dc42 Not to hurry you, just to be able to step forward, may I ask your kind help on the 2 questions above? So:

- if all 7 stepper motors (5 axis, 2 extruder) can be connected to 6HC directly ?

- can you recommend any other reliable filament sensor works with 6hc direct (because duet3d cant be purchased anywhere)

BIG BIG thanks in advance, and sorry to take your time.

-

@coolice2020 the 6HC only supports 6 drives directly. To add any more you will have to use either a 3HC or toolboard via CAN

-

Thanks, so to summarize, the best way to do this is:

- Buy and connect a 3HC expansion board with twisted pair (as I found based on search) cable to 6HC

- Connect 5 axis, 1 extruder stepper motors and its filament sensor to 6HC

- Connect 1 extruder stepper motor and its filament sensor to 3HC

So, at this way, I can fit all steppers, plus their filament sensors on the same board as dc42 indicated it above.

Correct ?

-

Yes. The cable between the 6HC and the 3HC would be a high speed ADSL cable with RJ11 connectors.

Your other option is a 6HC and 1 or more toolboards. This would reduce wiring to the extruder/hot end if you're running direct drives. It allows everything to be connected using 4 CAN cables (or possibly even 2) and 2 power cables. I think 2 tool boards and a distribution board is about the same as a 3HC.

https://www.duet3d.com/Duet3Toolboard1LC

https://www.duet3d.com/Duet3ToolDistribution -

@jay_s_uk

Awesome, thanks for the heads-up!!May I ask if by any chance you could recommend a reliable end switch for the axis ends which also connect to 6HC well ?

-

I mainly go with optical endstops on my machines but switches also work very well.

-

Can you recommend an optical endstop if thats more pro pls, which you have experience with and fit well with 6HC ? I will go that way too .

-

I use this type.

https://www.amazon.co.uk/dp/B07DK3J88S/ref=cm_sw_r_cp_apa_i_NdBPFbH6KK1K9

I have them fitted to my tool hanger and they are very repeatable. -

Awesome, thanks! Dummy question:

It is has to be mounted to ensure, that this part (the red X) where the moving part has to touch it ?

OR

A thin "flag" has to get into the U shape to block ?

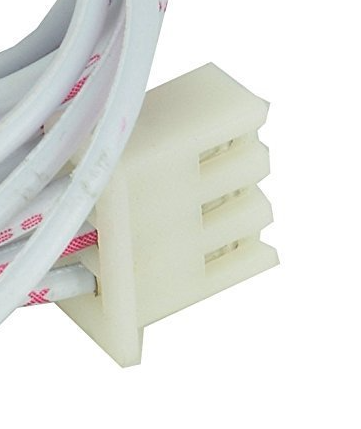

And this is the connector which is compatible with the 6HC or it is need to be replaced with ?