Problem by printing xyz Cube

-

That looks like some oozing on layer changes.

Try increasing the speed of your Z axis, it's quite slow atm.

Try

M566 Z60

M203 Z600

M201 Z300Also look into tuning pressure advance.

-

@Phaedrux thanks a lot

i want to set up pressure advance with the Marlin method but i dont see an option to select Bltouch ? if i insert only the z-offset it will print to high

-

@lui2004

check that there is a G28 in the beginning of the file. thats all that is required for the bltouch if it is set up correctlyalso to rule out a setting mistake, give another slicer a go like prusaslicer.

-

@Veti ok i will try once again to define pressure advance

i will try another slicer

-

i got my value now its 0.166

so i insert it in my config.g like this:

M572 D0 S0.166 ; Pressure Advance

how can i test this now? benchy ?

-

@lui2004 said in Problem by printing xyz Cube:

how can i test this now?

print the same thing as before

-

@Veti ok will reprint the xyz-cube

-

-

the corners are round.

grab the cold nozzle with your finger. see if you can displace it easily (we are talking about milimeters here)

-

@Veti i can Move it and its not to hard and not to easy

-

@lui2004

sorry forgot to add, while the motors are energized?check the eccentric nuts. the there should be no play, but also the wheels should move easily.

also the belt tension should be like a bass string when you pluck it. -

-

@Veti i have checked all belt tension x and y and the accentric nut has no play.

i print the cube again and post the results

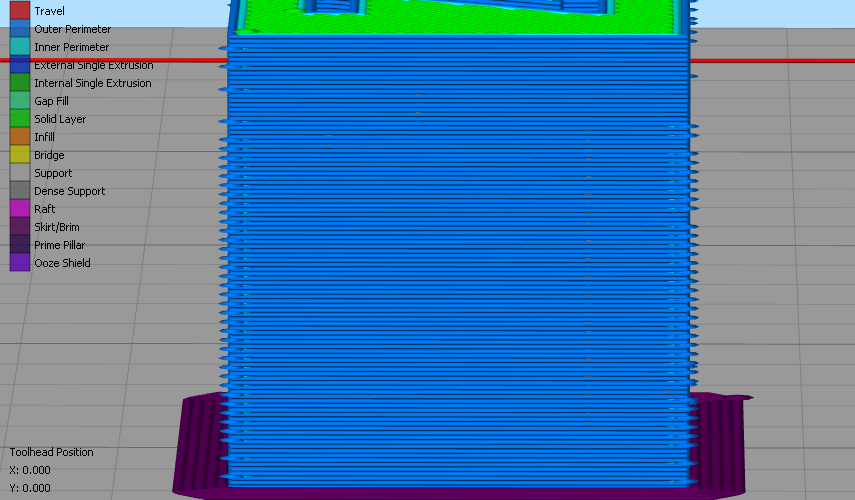

other strange is S3D show me the exact,what i am print

here a screenshot:

-

as i dont have s3d, why dont you give prusaslicer or cura a go?

lately i have switch from cura to prusaslicer, as its gotten really good. -

Those are the retractions, maybe trying increasing the length? Ender 5 is a bowden setup right?

-

yeah i think after i print the cube

i will try the alpha prusa slicer ,i heard its much better now -

@Rushmere3D i have install as DD

-

@lui2004 Oh OK, I'd suggest trying at least 0.8mm up to 1mm and maybe reduce the retraction speed to 45mm/s.

-

for tuning the seam it's usually best to force it to a single spot. But it really depends on the model you're printing. If the model has a lot of details and inner corners the slicer can hide the seam a lot easier. On cubes and cylinders it only has external faces to put them where they are obvious. Try printing a more complex model. Your cube looks good. Move on to a benchy or something.

-

I have order a new Nozzle ( Plated Wear Resistant All Metal MK8 ), now i am waiting for to test.

i will inform you here