[HELP] Ender 3 Pro + Duet WiFi 2

-

-

@Phaedrux Thanks!

-

Hi guys,

long time

I have a quick question if I may.

I became pretty familiar with 3d printing by now, all thanks to you!

I was wondering if there is a more efficient way for me to perform bed leveling instead of doing it manually?

is there a script that can move the motor to few places and then I just swipe the paper?

or is there a better way to do so?

and is it still necessary even though I'm using BLtouch? isn't it compensating the height differences already?Thanks!

didi -

The BLtouch and mesh compensation will adjust for any errors, but it's always best to start with as level a bed as possible,

This might be what you're looking for.

https://duet3d.dozuki.com/Wiki/Using_the_manual_bed_levelling_assistant

It will measure the points closest to the leveling screws and tell you how much to adjust them to bring them closer to your defined Z0 point (ideally set by probing the center of the bed).

But really for the ender 3 it's not too hard to level manually with some paper too.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

-

@Phaedrux Thanks!!

-

Hey guys,

Another quick question please

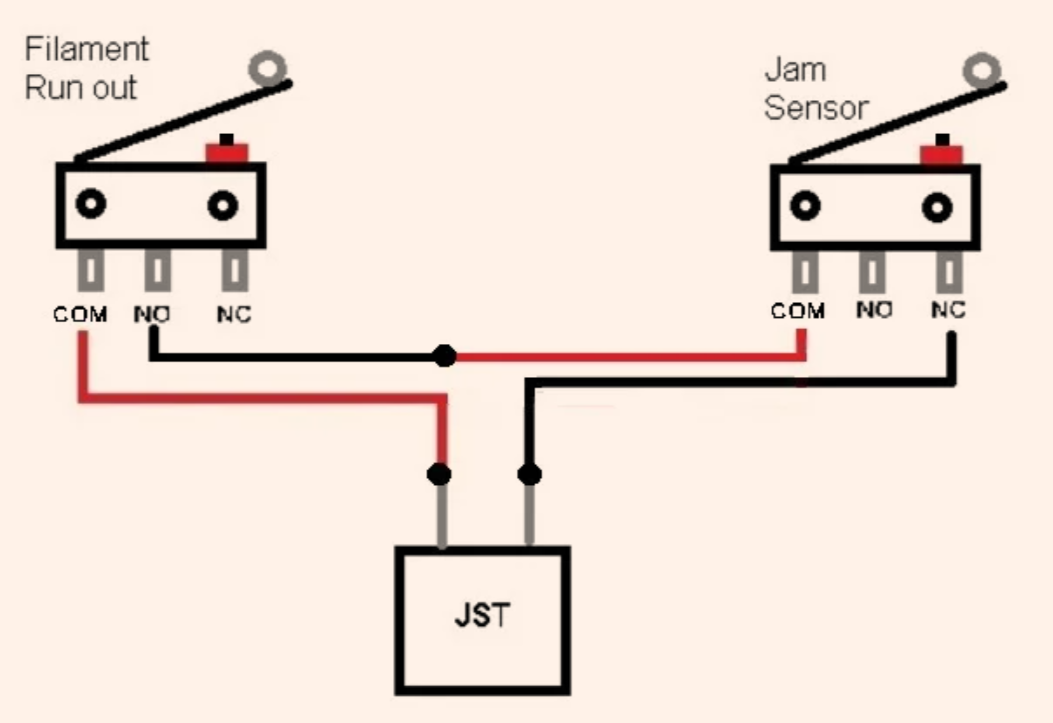

I have a filament sensor with two simple roller switches (one for the filament and the other for jam). I was looking for the documentation on how to connect it to the board but I'm a bit confused.

I only have two wires from the sensors, and in the documntation they mention an optical sensor which uses 3 (with the 3.3v which it my case I don't have).

so should I just connect it to the ground and signal? any additional configuration needed?

this is the wiring for the sensor (it's from a thingiverse project):

and this is the documentation I was refering to: https://duet3d.dozuki.com/Wiki/Duet3dFilamentMonitor_LaserVersion

Regards,

Didi -

Can you point to the project?

You can certainly connect two switches in series and sense two filament conditions like that given:

- Each switch is CLOSED when the filament is in a "Good" state.

- Either switch opening when the condition is "bad" will trigger the filament"out" sensing.

I can't tell fro your diagram what the state will be for each of your two switches when everything is good-to-go.

-

@alankilian Of course, it's this one:

https://www.thingiverse.com/thing:4672537

I think that's the best option I've printed, tried many other with optical sensor, the concept was nice but the actual thing wasn't

-

-

@alankilian "Use P2 in your M591 commands" didn't quite understand that part. so I'm assuming I need to edit the main config file, right?

to set the endstop as a sensor? (Would it display an error message while a jam or runout detected?) -

THIS thread will help you understand what you need to add to your config.g file to enable this sensor and some commands you can use to see if it's triggered or not.

When it's triggered, the extruder lifts up and waits for you to add more filament, and then you click the "Continue" button on the Duet Web Control to restart.

There are two macro files that get run so you can make it do different things depending on what you need it to do.

Basically, you will add:

- M591 D0 P2 S1 C<something>

to your config.g depending on where you plug the sensor in.

C3 if you plug in to E0_stop plug

-

@alankilian Thank you very much! I'll try it this weekend and update!

-

I'm reading this thread and I have flashbacks - I started the same way, as you didi767, with an Ender3 and a Duet.

The first tihing I did after getting Duet up and running, I added second Z motor and lead screw, to get rid of Ender's sagging X-gantry issues.

After all my modifications, my Ender looked more or less like a some sort of Franken-Prusa, basically the frame was from Creality, gantry was

a Prusa X gantry and I had Ender3 bed. In the end I decided to build a closed COREXY and I have a Duet3, the

Creality frame is not meant for heavy-duty printing I think. The wheels need adjusting and the frame is too narrow.