ToolBoard: 2 wires fan, heater fault and how to extrude ?

-

R25 (kΩ): 500 ± 3%

β25/85 (K): 3800 ± 2%I find this for the thermistor.

M308 S1 P"121.temp0" Y"thermistor" T500000 B3800so I put this, the temp is 12°c when it must be ~19 I think. I have always the fault, do you now what I nead to change ?

-

I send M302 P1 to allow cold extrusion, and I test if the command went good:

"Cold extrusion is allowed (use M302 P0 to forbid it)"but I still can't use it:

-

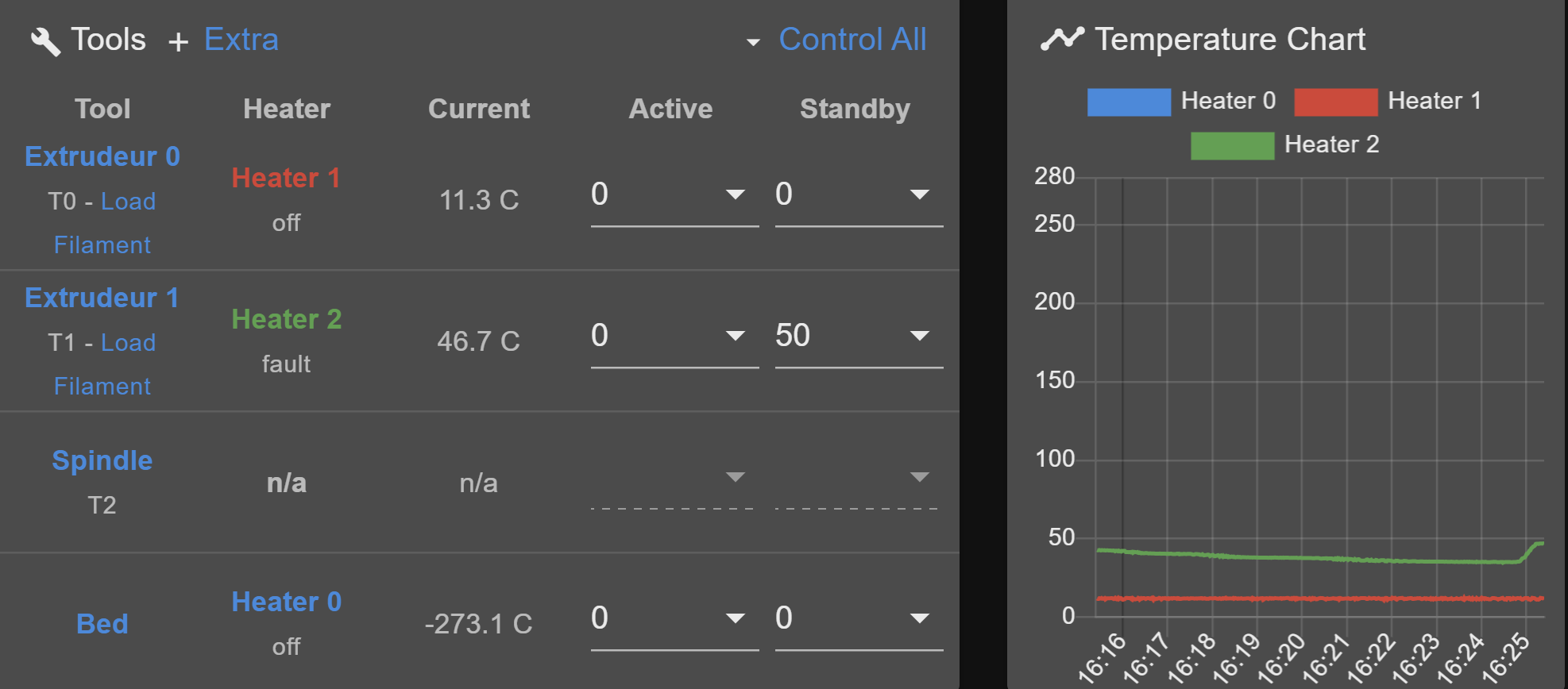

I test the "extrudeur 2" here, see it heat 5°c and then it stop. -

@Pseud3mys said in ToolBoard: 2 wires fan, heater fault and how to extrude ?:

R25 (kΩ): 500 ± 3%

β25/85 (K): 3800 ± 2%

I find this for the thermistor.in the online configurator

https://configtool.reprapfirmware.org/Heaters

click on the beta field and in the popup select slice high temperature. -

@Veti said in ToolBoard: 2 wires fan, heater fault and how to extrude ?:

@Pseud3mys said in ToolBoard: 2 wires fan, heater fault and how to extrude ?:

I connected the 2 wires fan on OUT2 (3 pins) and when I start it nothing happen (I have tested all wiring possible).

how did you configure it? post your config.g

; Fans M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"122.out2" Q500 ; create fan 1 on pin 122.out2 and set its frequency M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned offI put this, directly from RRF config tool.

-

did you verify that the fans are working? by connecting them to the always on port on the duet 3 mainboard?

-

@Veti yes, On Vin and GND it work

-

change the S0 to S1 for testing

-

@Veti with S0 or S1 It work just when It is at 100% now. But not for all other value it don't work

-

@Pseud3mys

some fans do not work with pwm. -

@Veti I just see that is a 24v fan, I power the board with 12v. But if I power with 24v did the output will go up 24v as well ?

-

@Pseud3mys said in ToolBoard: 2 wires fan, heater fault and how to extrude ?:

I power the board with 12v. But if I power with 24v did the output will go up 24v as well ?

no

see the wiring diagram.https://duet3d.dozuki.com/Wiki/Duet_3_Tool_Board

the out is 12v

-

ah yes, thank you

-

@Veti have you an idea for the heater fault or the cold extrusion ?

I send M302 P1 to allow cold extrusion, and I test if the command went good:

"Cold extrusion is allowed (use M302 P0 to forbid it)"but I still can't use it:

-

what is the error message in the console?

-

@Veti there are no error message. When I click on the "extrude" button nothing happen

-

@Pseud3mys

for the heating. how did you get the error?you still have not posted your config.g

-

@Veti for the heating a fault accure 2 or 3 sec after the start. But the temperature problem is good now.

here is my config..g:

config.g; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.9 on Wed Dec 02 2020 17:31:45 GMT+0100 (heure normale d’Europe centrale) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"MultiTool Cartesian" ; set printer name ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P1.0 S1 ; physical drive 1.0 goes forwards M569 P2.0 S1 ; physical drive 2.0 goes forwards M584 X0.0 Y0.1 Z0.2 E1.0:2.0 ; set drive mapping M350 X256 Y256 Z256 E256:256 I0 ; configure microstepping without interpolation M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X31800.00 Y31800.00 Z31800.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800 ; set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1000 Y1000 Z800 S0 ; set axis maxima ; Endstops ; WARNING: No endstops configured ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X20:980 Y20:980 S80 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"121.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"122.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 2 as thermistor on pin 122.temp0 M950 H2 C"122.out0" T2 ; create nozzle heater output on 122.out0 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S0 H1 T100 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"122.out2" Q500 ; create fan 1 on pin 122.out2 and set its frequency M106 P1 S0 H2 T100 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"Extrudeur 0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"Extrudeur 1" D1 H2 F1 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P2 S"Spindle" F-1 ; define tool 2 G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory -

@Pseud3mys said in ToolBoard: 2 wires fan, heater fault and how to extrude ?:

for the heating a fault accure 2 or 3 sec after the start.

what is the error message for that.

M350 X256 Y256 Z256 E256:256 I0

this will overload your cpu. switch back to x16 and interpolation.

M203 X31800.00 Y31800.00 Z31800.00 E1200.00:1200.00

are you sure thats the maximum speed you printer can achieve?

M906 X800 Y800 Z800 E800:800 ; set motor currents (mA)

these values are most likely wrong. you need to enter 75% of the rated current for each motor.

; Endstops

; WARNING: No endstops configured

you need to fix this

-

I allowed the cold extrusion. I can now extrude but when I do it nothing happen.

For the heating, the thermistor return the right temperature. But I still have "fault" few second after I turn ON the heater.